Patents

Literature

33results about How to "Good sputtering performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

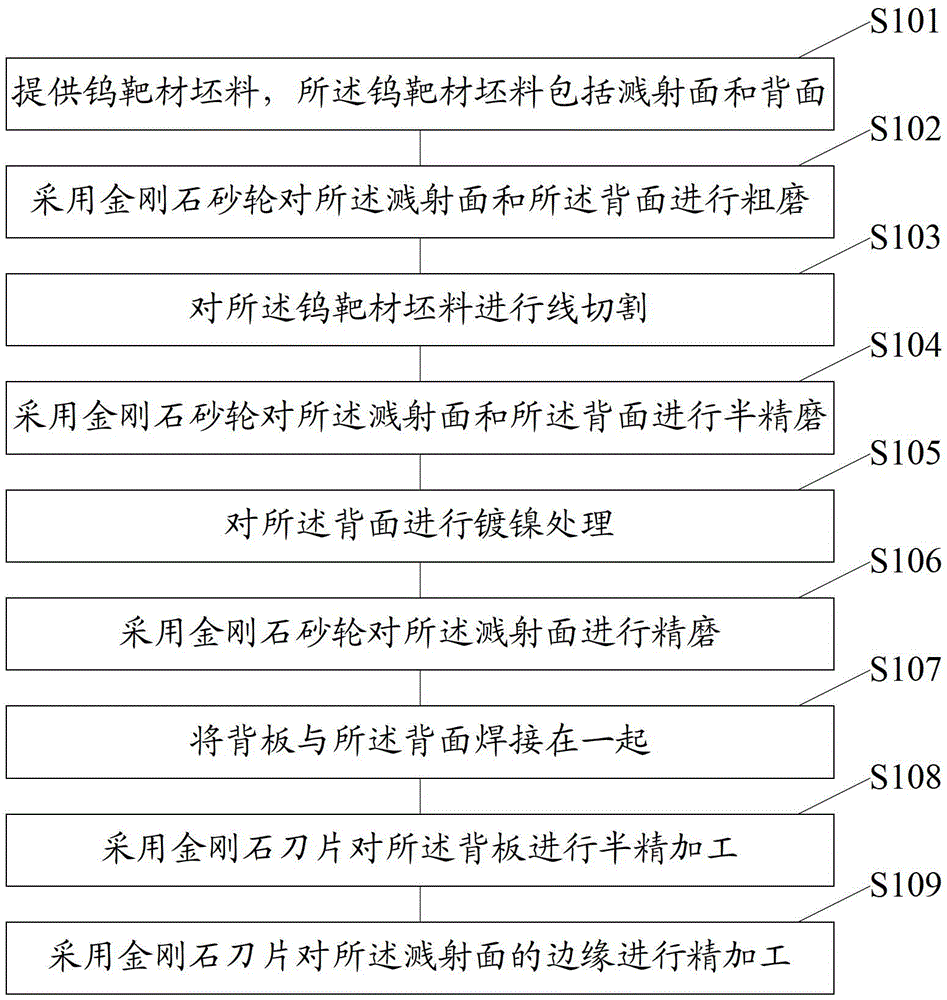

Manufacturing method of tungsten target

ActiveCN104416325AQuick Correction of ThicknessImprove production efficiencyVacuum evaporation coatingSputtering coatingSurface roughnessMachining process

Disclosed is a manufacturing method of a tungsten target. The manufacturing method of the tungsten target comprises providing a tungsten target blank, wherein the tungsten target blank comprises a sputtering surface and a back surface; rough-grinding the sputtering surface and the back surface through a diamond grinding wheel; performing accurate semi-grinding on the sputtering surface and the back surface through the diamond grinding wheel; performing accurate grinding on the sputtering surface through the diamond grinding wheel. The manufacturing method of the tungsten target can reduce or avoid edge failure of the tungsten target blank during the machining process to obtain the tungsten target high in dimensional precision, low in surface roughness and capable of meeting the sputtering performance, and meanwhile, can reduce losses of tools during the machining process of the tungsten target blank and further reduce the machining cost of the tungsten target.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

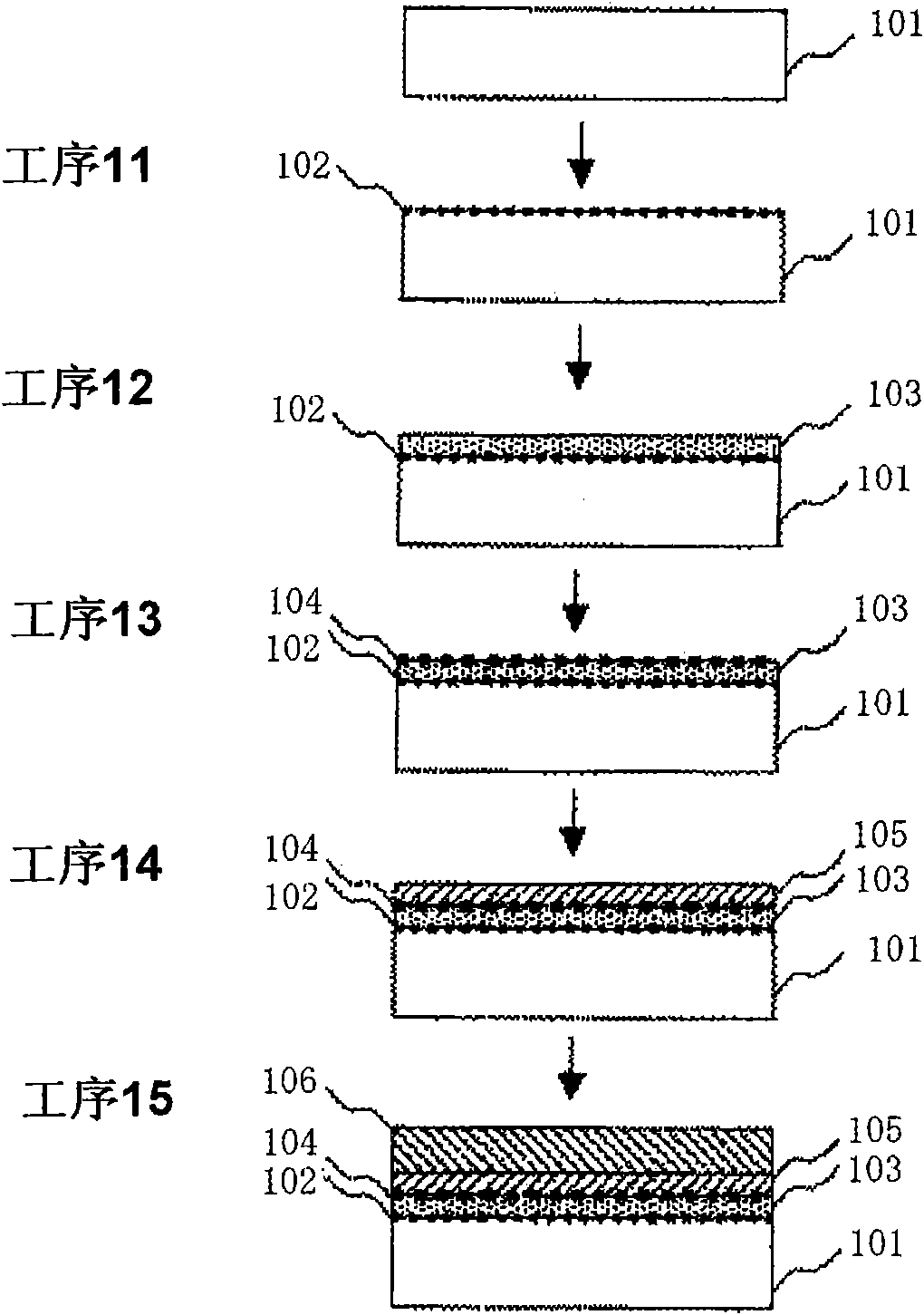

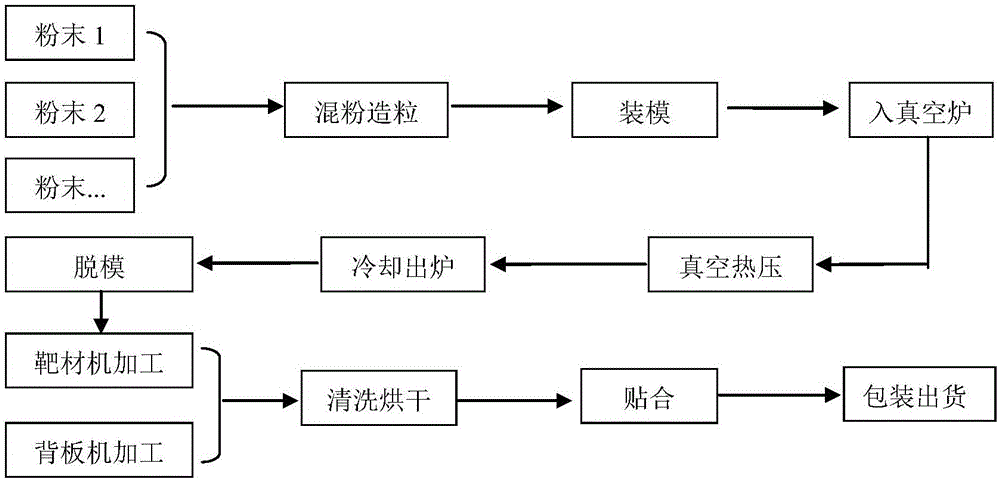

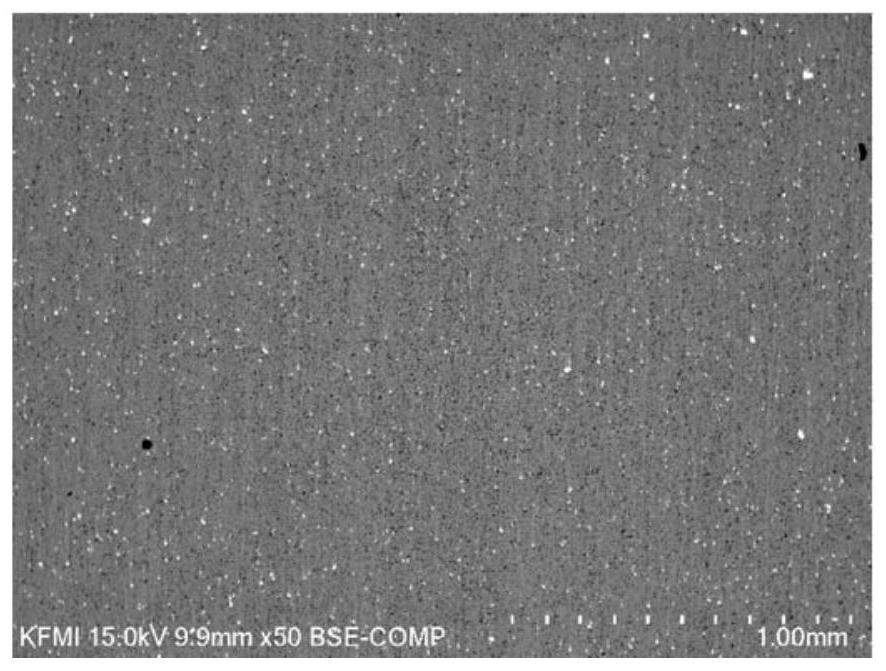

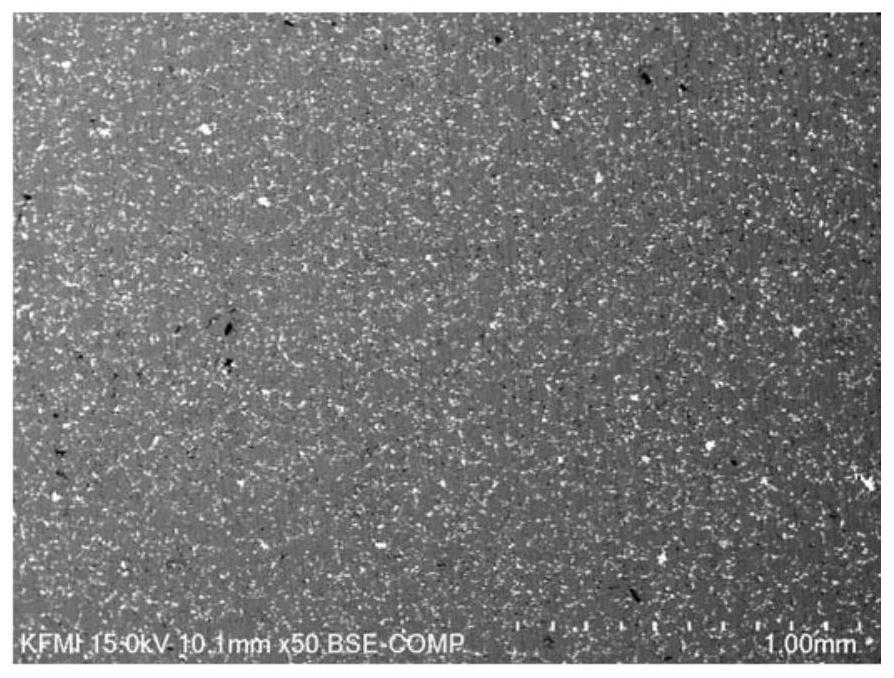

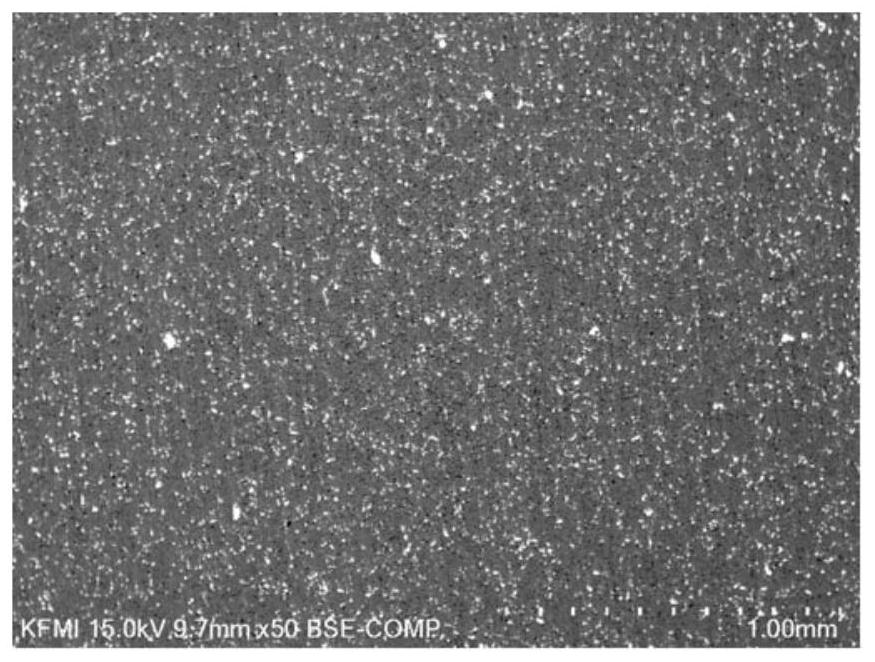

Manufacturing method of tungsten-titanium target material and manufacturing method of tungsten-titanium target material combination

ActiveCN103691953AUniform microstructureGood sputtering performanceVacuum evaporation coatingSputtering coatingTitanium powderTungsten

The invention discloses a manufacturing method of a tungsten-titanium target material and a manufacturing method of a tungsten-titanium combination. The manufacturing method of the tungsten-titanium target material comprises the following steps: filling mixed powder of tungsten powders and titanium powder into a mold; performing cold press molding on the mixed powder to form a tungsten-titanium target material blank; performing vacuum hot pressing sintering on the tungsten-titanium target material blank to form a tungsten-titanium target material. According to the manufacturing method of the tungsten-titanium target material disclosed by the invention, cold press molding treatment and vacuum hot pressing sintering are performed and relevant process parameters are set, so that the density of the prepared tungsten-titanium target material is more than or equal to 99 percent, and the obtained tungsten-titanium target material has a uniform microstructure and superior splashing usability. Meanwhile, the manufacturing methods disclosed by the invention have the advantages of less process steps and high production speed.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

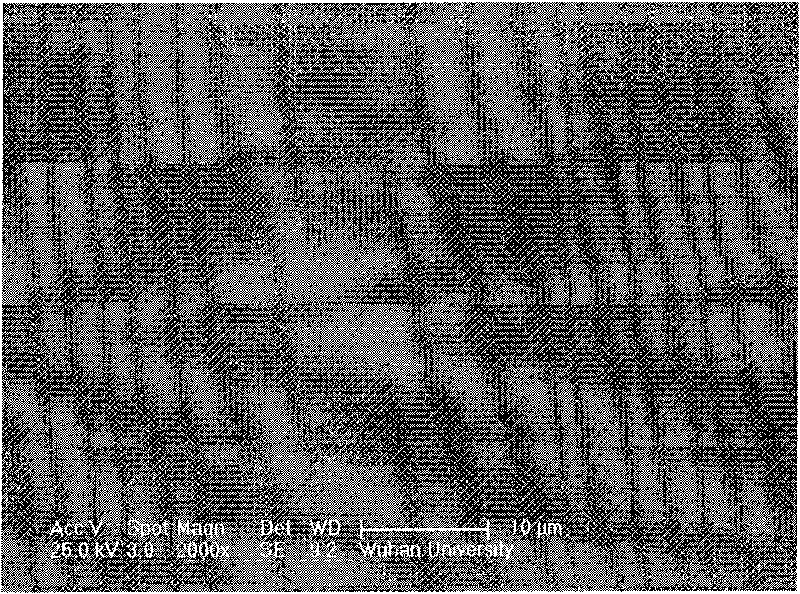

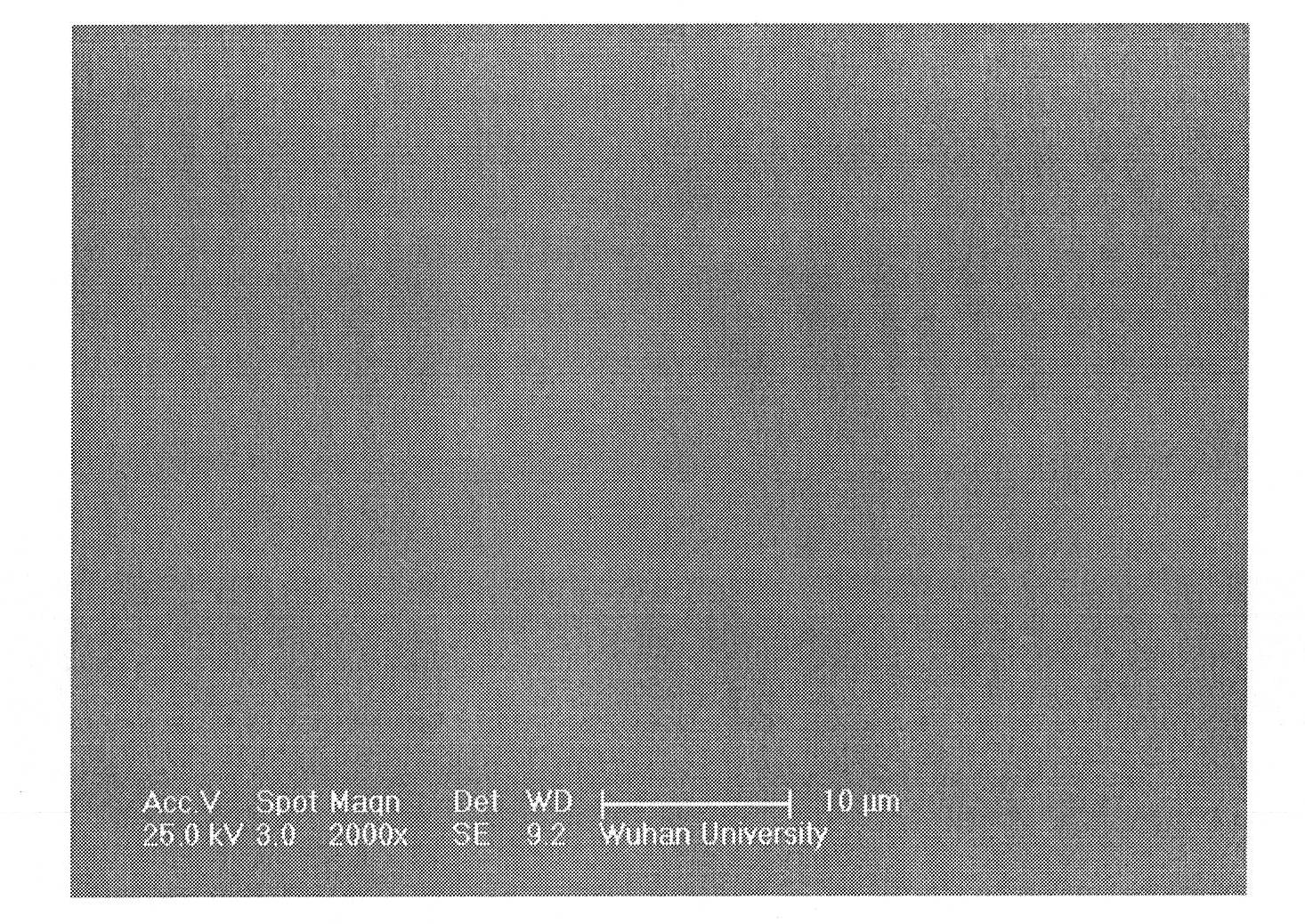

Method for preparing compound diamond-like carbon coating by using medium-frequency magnetic-control glow discharge method

InactiveCN101701332AHigh hardnessImprove the lubrication effectVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention relates to a method for preparing a nano compound diamond-like carbon coating, which is realized in a way that: glow discharge is produced by using a medium-frequency magnetic-control sputtering target; argon and excessive hydrocarbon gases are introduced, so that the metal on the target surface reacts with the hydrocarbon gases to produce metallic carbides; when the argon ions bombard the target surface, the target surface sputters the metallic carbides; strong plasma produced by the glow discharge of the target surface ionize the hydrocarbon gases, so that the hydrocarbon gases produce highly-ionized carbon ions; and the carbides sputtered from the target surface and the highly-ionized carbon ions produced from the hydrocarbon gases form a high-hardness carbide-doped nano compound diamond-like carbon coating on a workpiece surface. The coating prepared by the invention has the characteristics of high hardness, strong adhesive force, high growth speed, high production efficiency, low depositing temperature, low production cost, simple equipment structure and the like; and diamond-like carbon coatings with different thicknesses can be prepared on hard alloy, high-speed steel and various other workpieces.

Owner:WUHAN UNIV

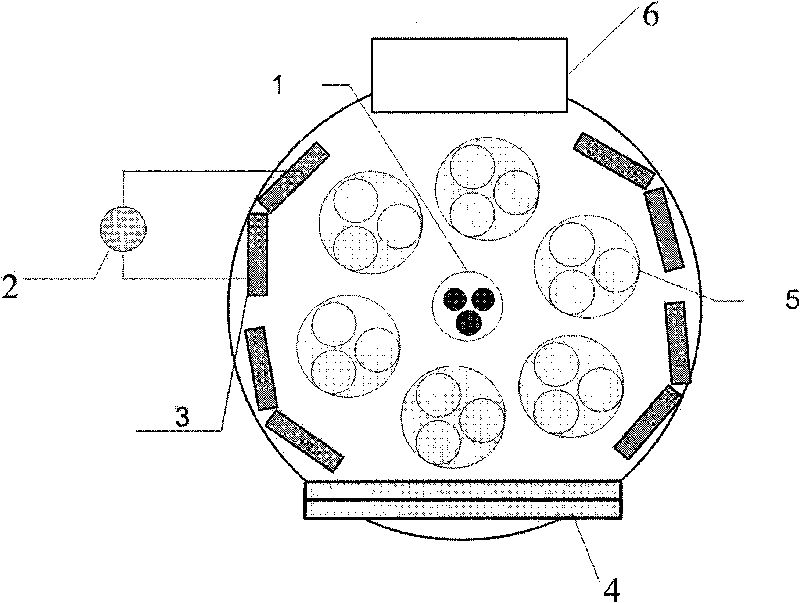

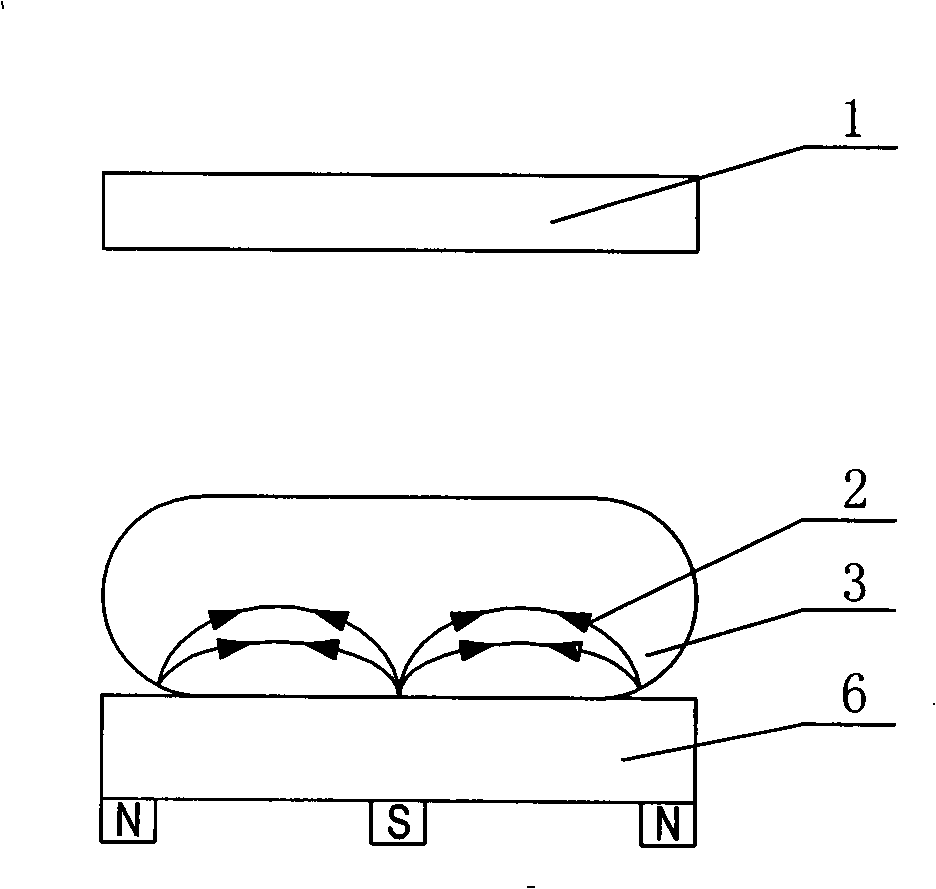

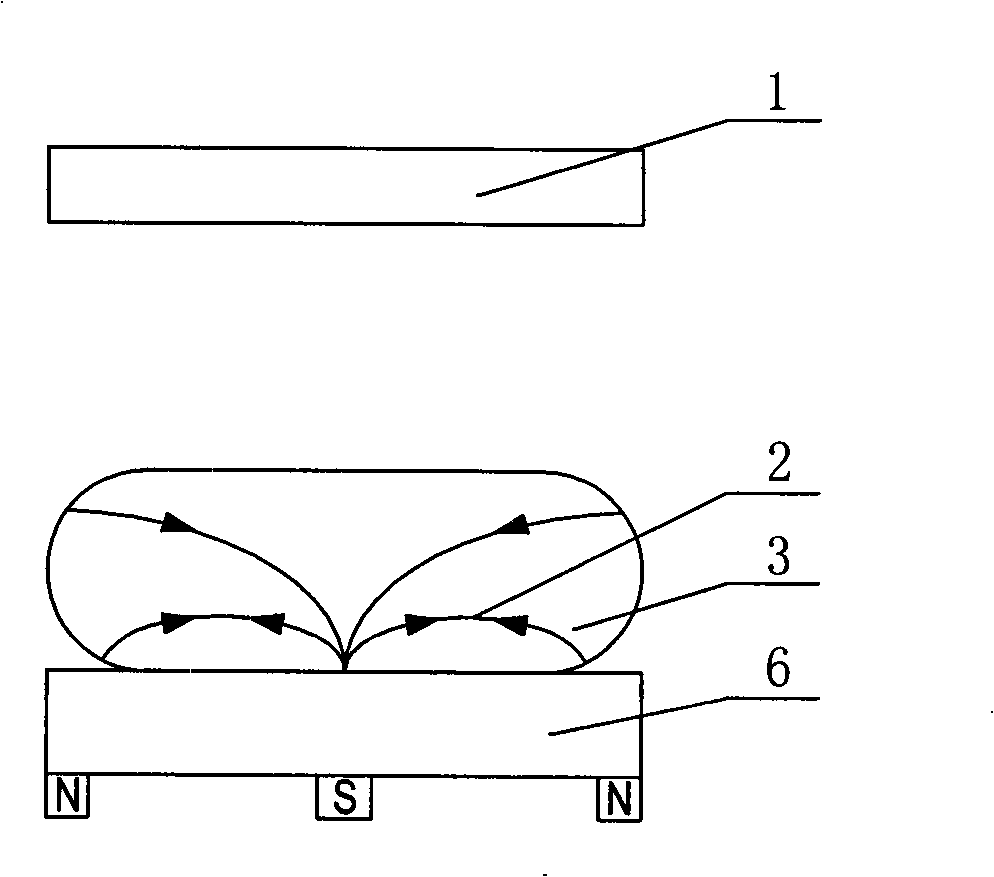

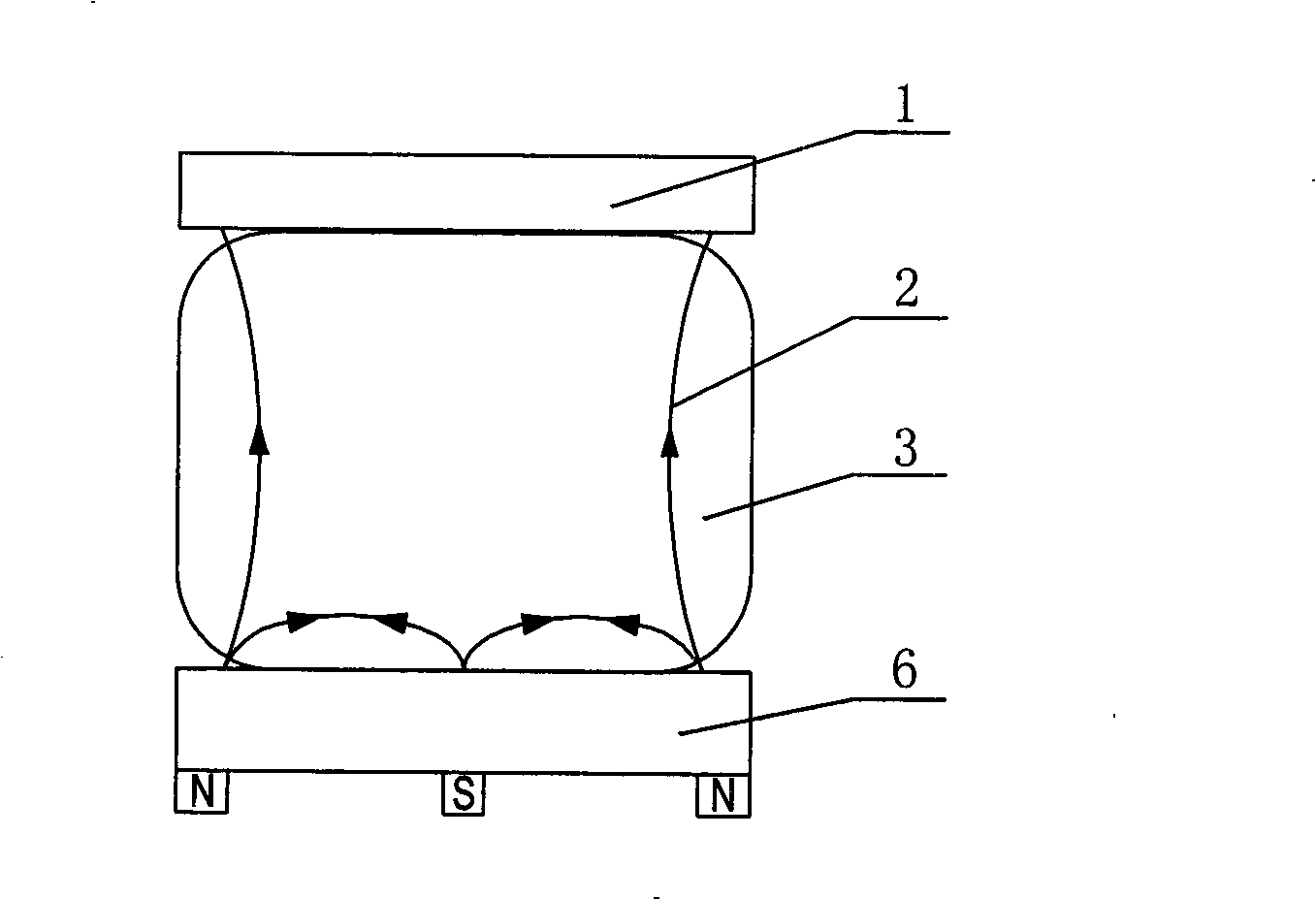

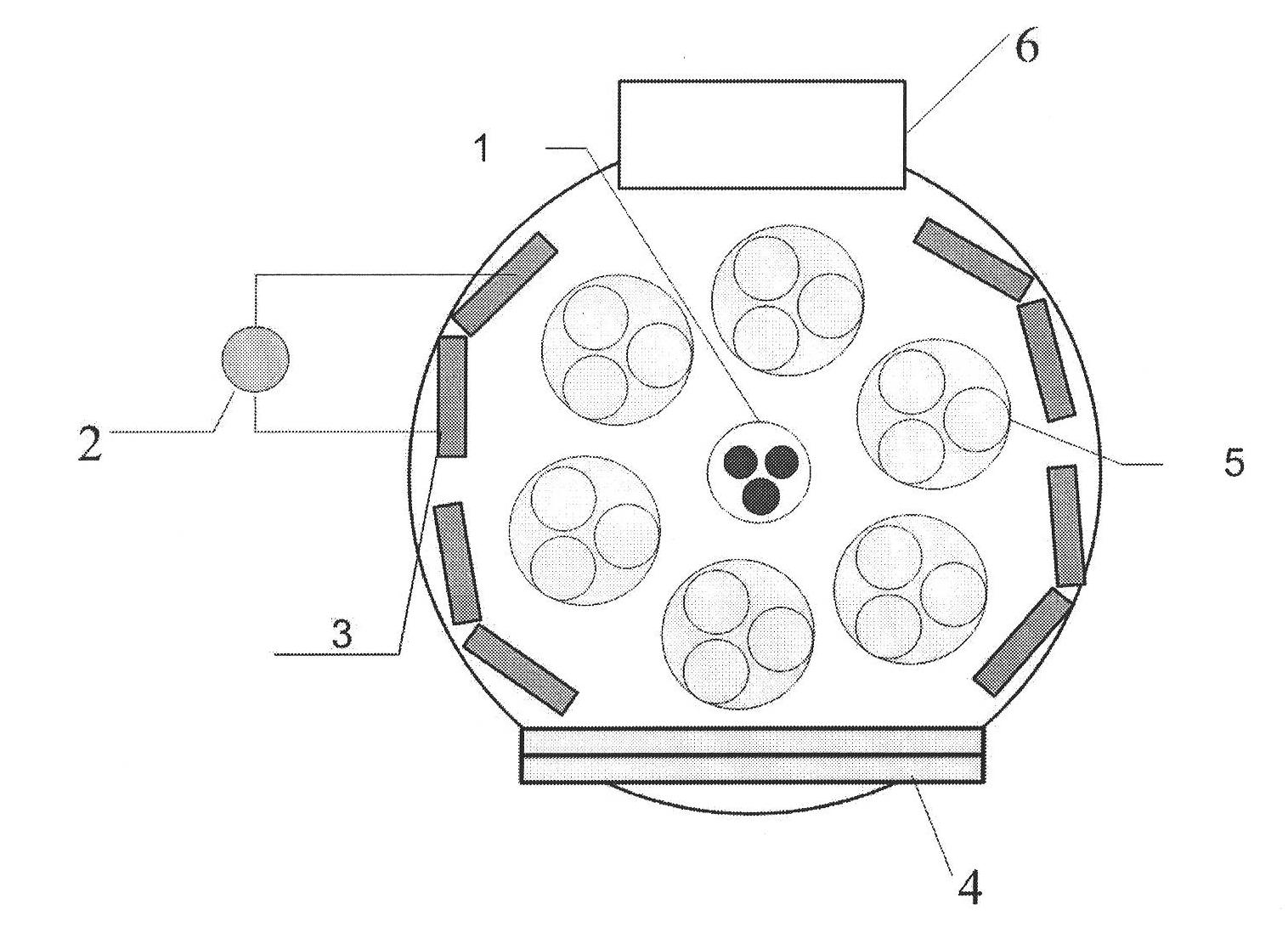

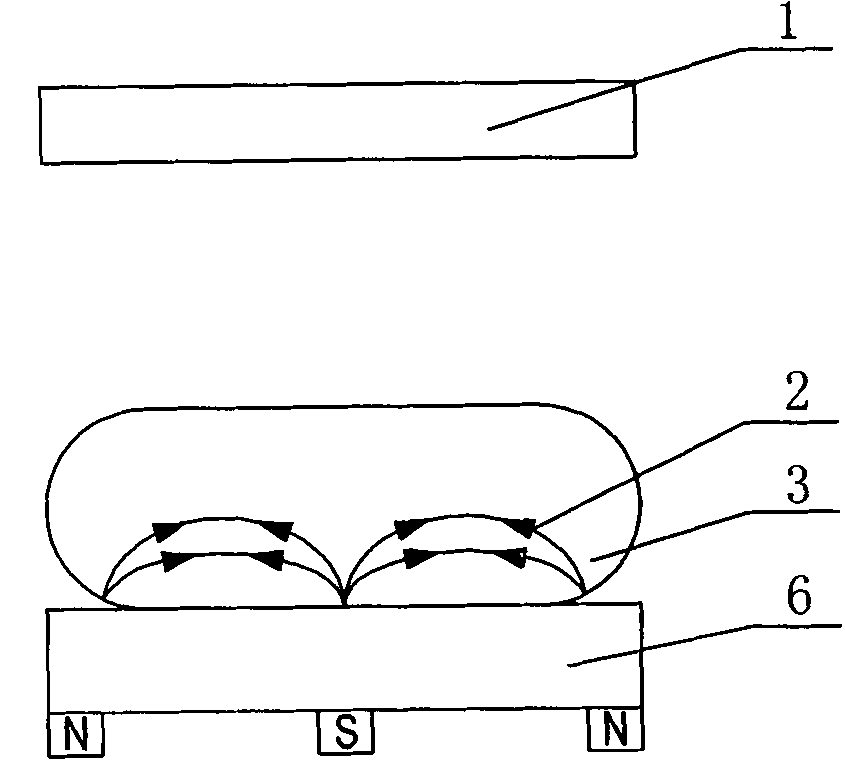

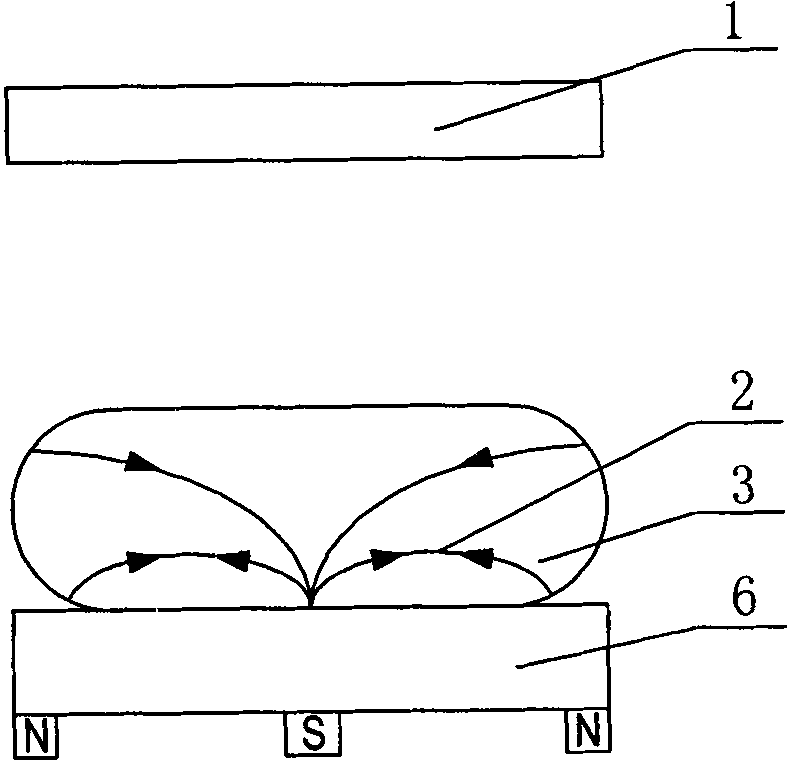

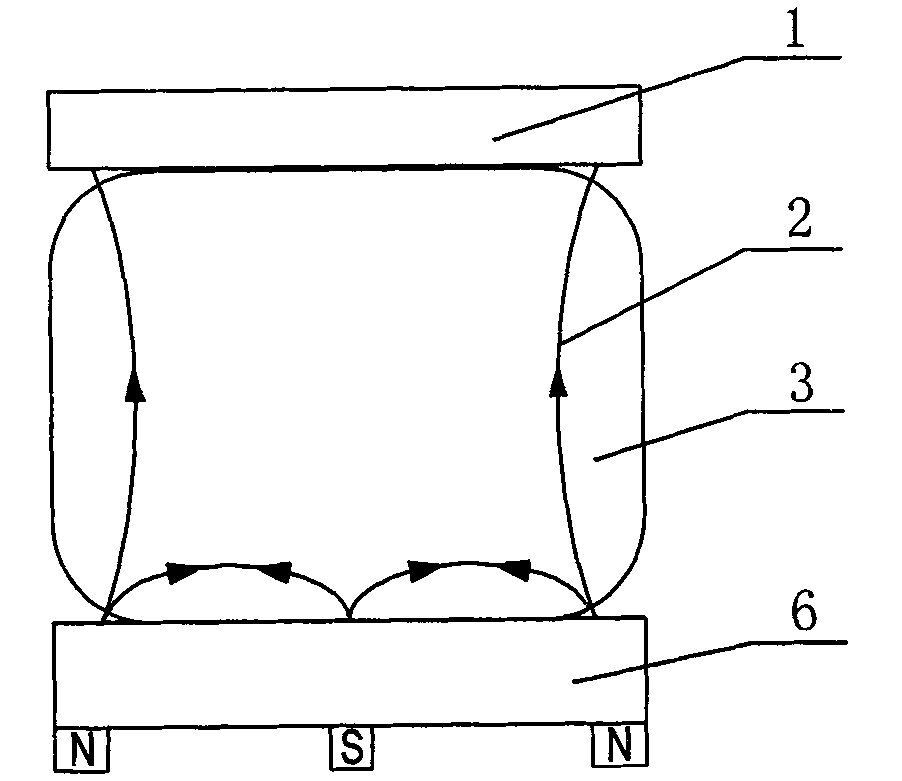

Magnetic confinement magnetron sputtering method and magnetron sputtering apparatus manufactured by the method

InactiveCN101348897AMake a leapReduce internal stressVacuum evaporation coatingSputtering coatingTarget surfaceMagnetic poles

The invention relates to a magnetic confinement magnetron sputtering method and a magnetron sputtering device prepared by use of the same. As the prior art adopts a balanced magnetron sputtering mode and an unbalanced magnetron sputtering mode, the target material utilization rate can only be raised to be between 20 and 35 percent even if permanent magnet movement or the transformation of a plurality of electromagnetic coil sets is adopted, and the prior art has the problems of complex structure and high processing cost. The magnetic confinement magnetron sputtering method forms a magnetic confinement magnetic field with the overall direction parallel to a target surface above the surface of a sputtering target. The magnetron sputtering device manufactured by use of the method comprises a magnet, a magnetic conductor, a substrate and the sputtering target, wherein contrary magnetic poles of the magnet are oppositely fixed on the sides of the sputtering target; the magnetic confinement magnetic field generated by the magnet is positioned between the substrate and the sputtering target, and a connecting line of the two magnetic poles is parallel to the target surface. The magnetron sputtering device can effectively overcome the problem that the prior art is low in target material utilization rate and deposition rate.

Owner:XIAN TECHNOLOGICAL UNIV

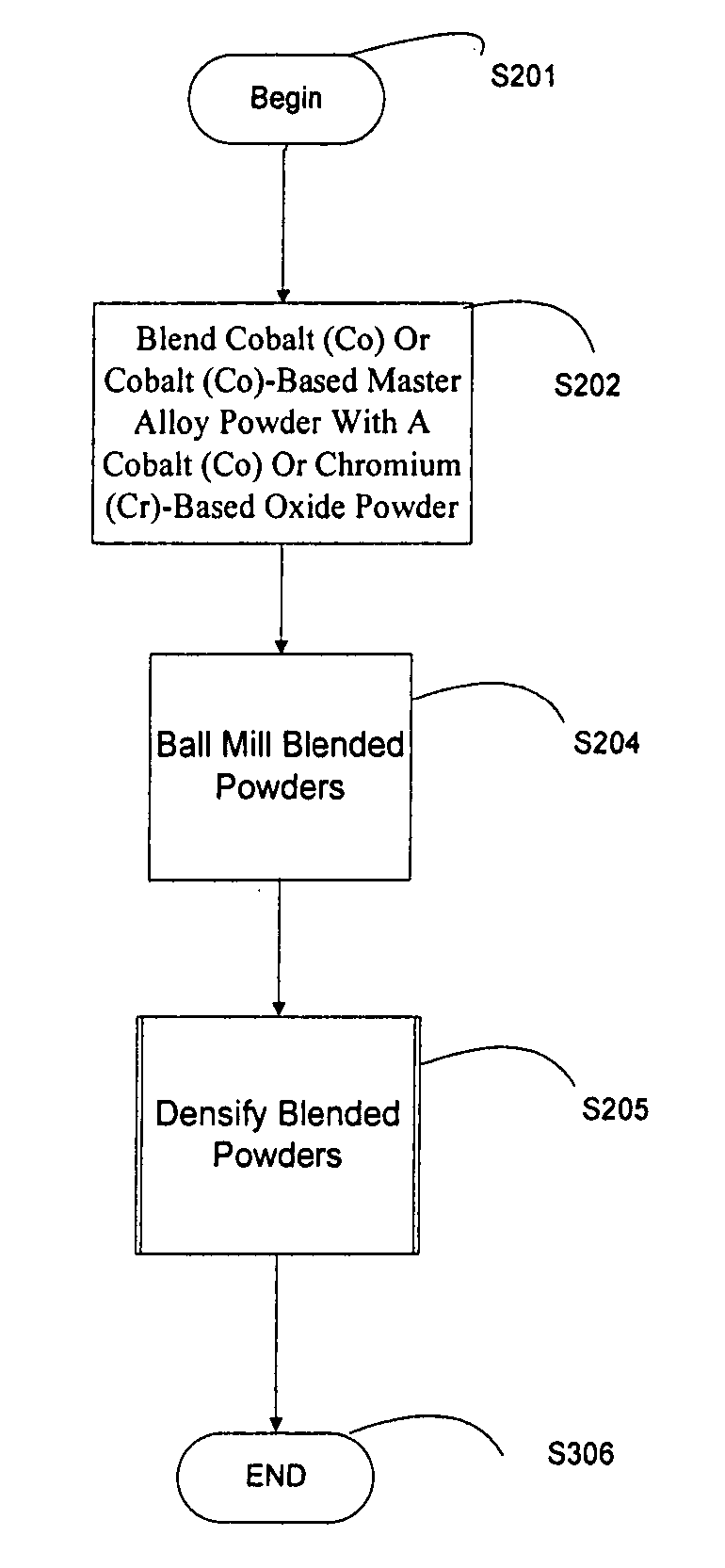

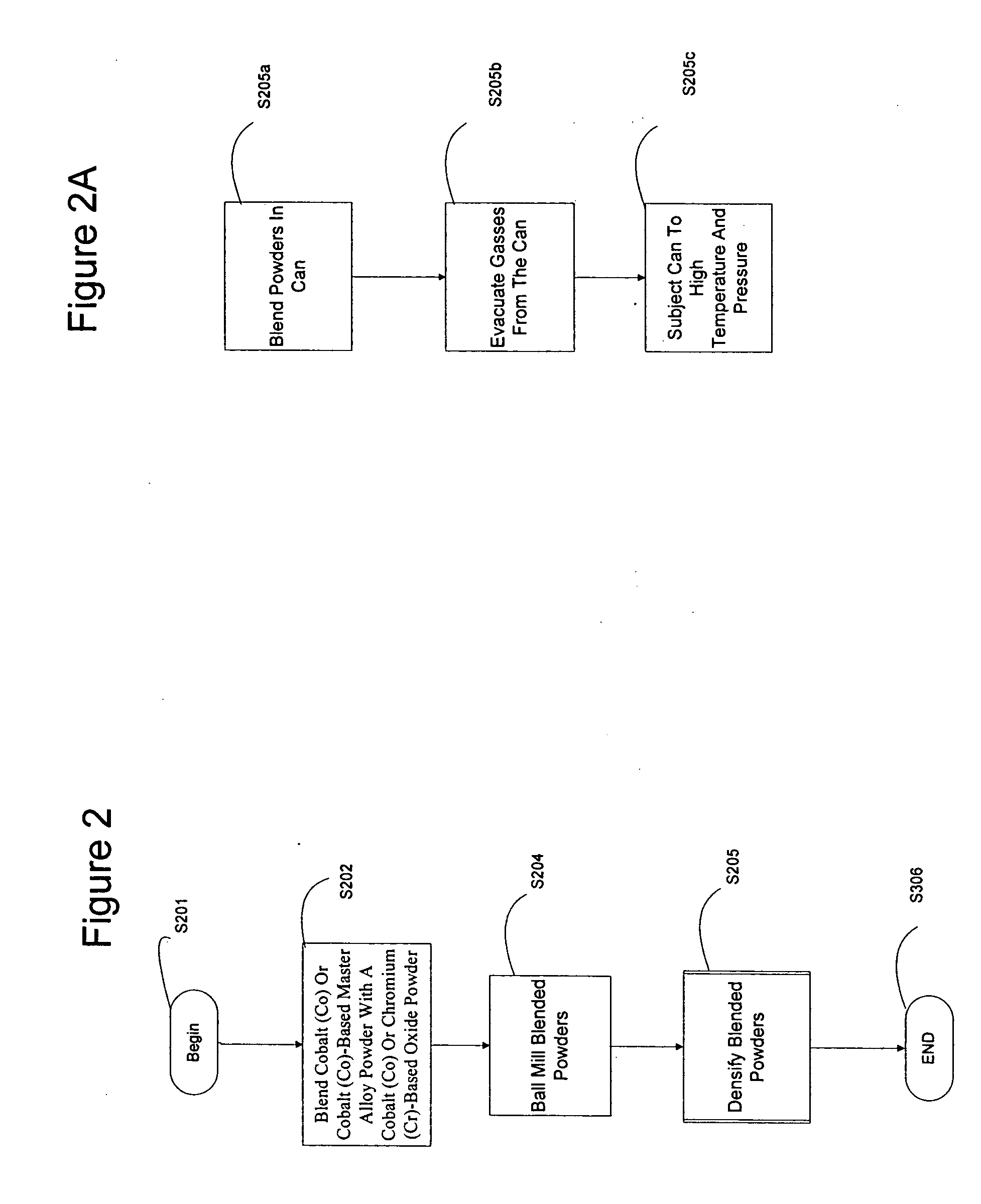

Enhanced formulation of cobalt alloy matrix compositions

InactiveUS20060233658A1Good sputtering performanceOptimize allocationCellsMagnetic materials for record carriersIndiumHafnium

A method for manufacturing a single-element matrix cobalt-based granular media alloy composition formulated as Cof<sub2>1< / sub2>-(MuOv)f<sub2>2< / sub2>, M representing a base metal selected from the group consisting of magnesium (Mg), titanium (Ti), vanadium (V), chromium (Cr), manganese (Mn), iron (Fe), nickel (Ni), copper (Cu), zinc (Zn), aluminum (Al), silicon (Si), yttrium (Y), zirconium (Zr), niobium (Nb), molybdenum (Mo), ruthenium (Ru), indium (In), lanthanum (La), hafnium (Hf), tantalum (Ta), and tungsten (W), u and v representing the number of atoms of base metal M and oxygen (O) per oxide formula, respectively, and f1 and f2 being mole fractions represented by the equation f1+(u+v)f2=1. The method includes the steps of blending a Co-M master alloy powder and a Cou′Ov′ powder into a corresponding (CoaM1−a)f<sub2>1< / sub2>′-(Cou′Ov′)f<sub2>2< / sub2>′ formula, and densifying the blended powders.

Owner:HERAEUS INC

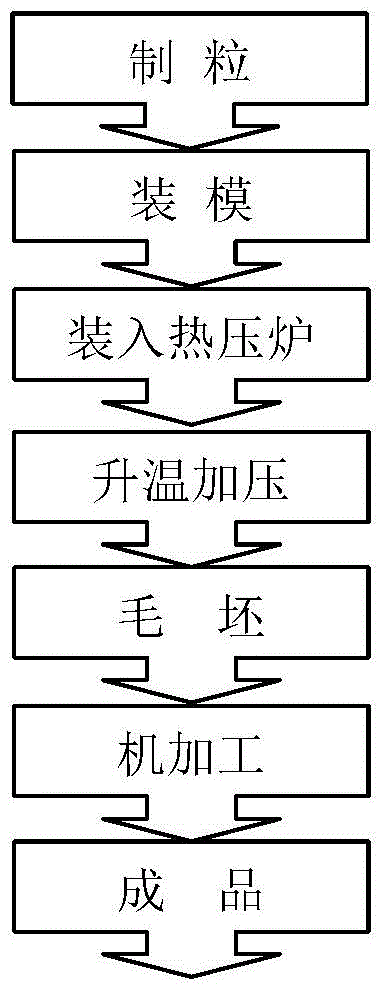

Hot-pressing technology for preparing boride sputtering target material

ActiveCN105693252AGood sputtering performanceMeet the needs of useVacuum evaporation coatingSputtering coatingBorideHigh pressure

The invention relates to a hot-pressing technology for preparing a boride sputtering target material. A preparation method sequentially comprises the following process steps of pulverizing boride with the purity being larger than or equal to 99.9 percent and the particle size being less than or equal to 5mum to be boride particles with the diameter being 1 to 3mm; filling in a graphite jig; loading in a hot-pressing furnace; warming and pressurizing; after keeping warm for 5 to 10h, cooling to form a workblank; obtaining a finished product through machining, wherein the relative density is 85 percent to 90 percent, and the electrical resistivity is 1.0 to 3.5 ohm.cm; the boride powder forms compact blocks at high temperature and high pressure, so that the compact blocks are high in relative density, low in electrical resistivity, good in uniformity, high in stability and favorable in sputtering performance, and meets the usage requirements of the target material. The preparation method is simple and easy to implement, the complicated mold design required by adopting a traditional powder metallurgy pressing method is avoided, the molding efficiency is greatly improved, and the obtained target material is excellent in sputtering performance, less in impurities, and suitable for sputtering coatings.

Owner:GEMCH MATERIAL TECH SUZHOU

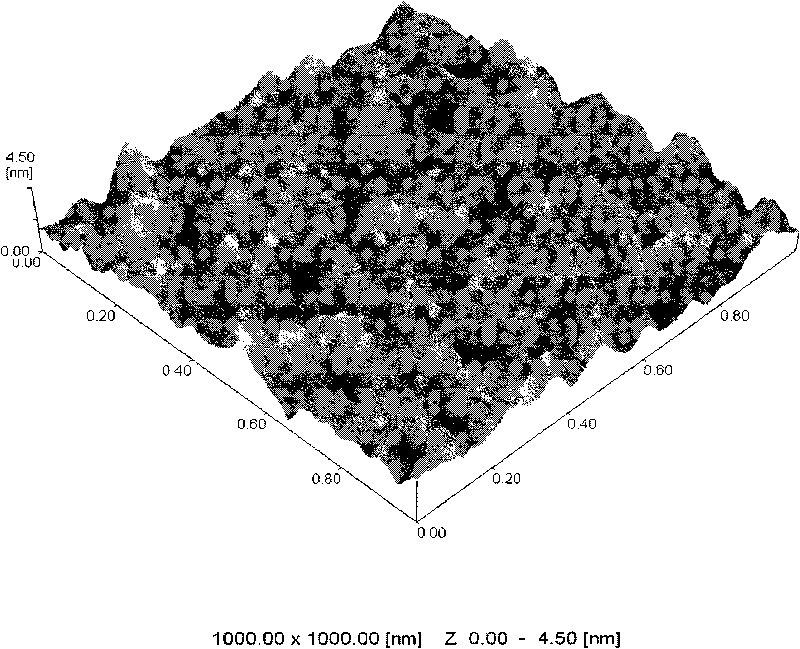

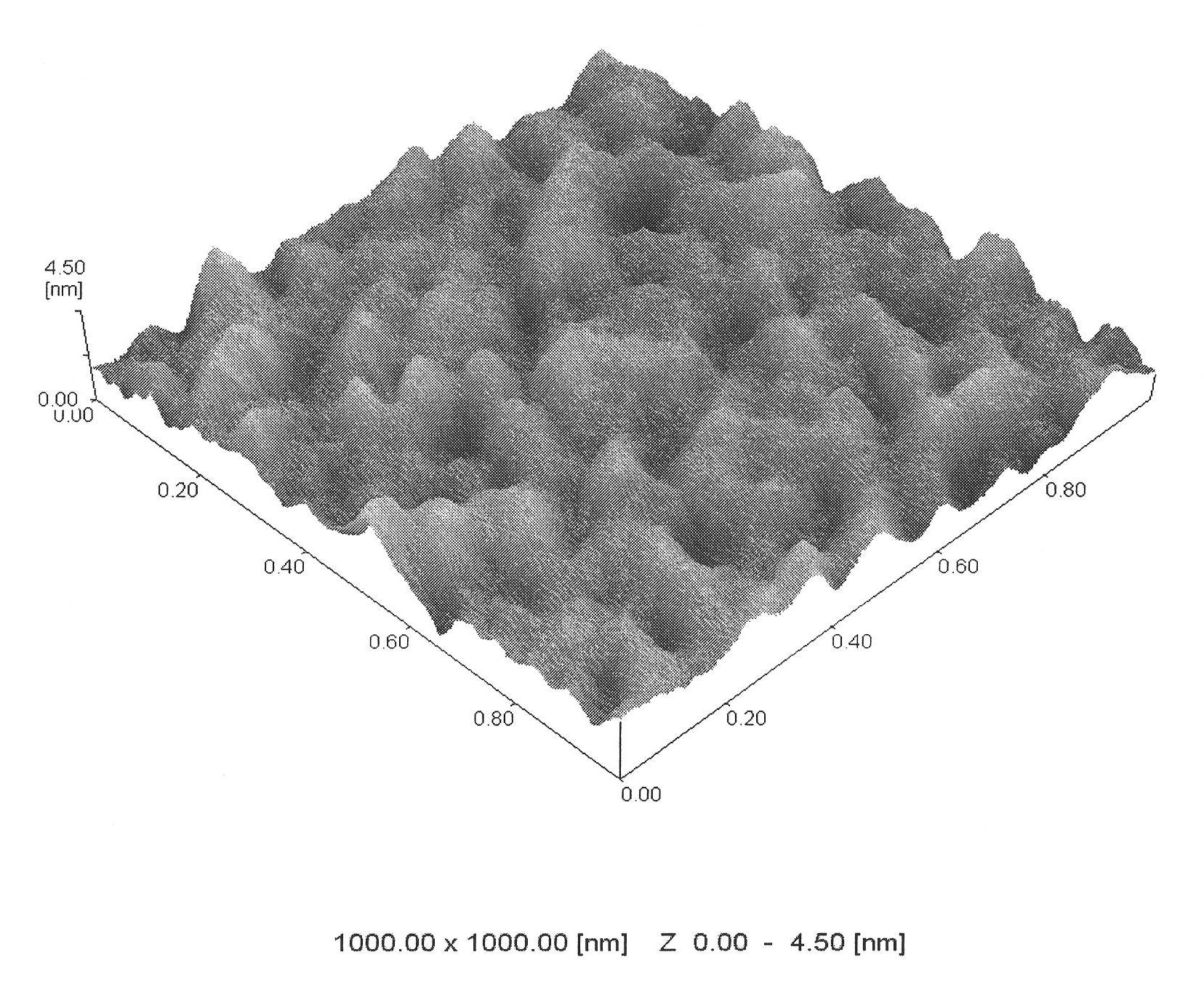

Polyimide film, method for production thereof, polyimide-metal laminated product, and circuit board

InactiveCN101550240AExcellent adhesionSufficient peel strengthCircuit susbtrate materialsMetal layered productsAlkoxy groupChelation

The present invention provides a polyimide film having excellent adhesive properties, sputtering property, metal vapor deposition property and metal plating property, and excellent surface smoothness, while maintaining the excellent properties of a polyimide film. Another objective of the present invention is to provide a polyimide film produced by heating a self-supporting film of a polyimide precursor solution onto which a solution containing aluminum chelate compound and, optionally, a nonionic surfactant and / or an aluminum alcoholate compound having at least one alkoxy group is applied to effect imidization.

Owner:UBE IND LTD

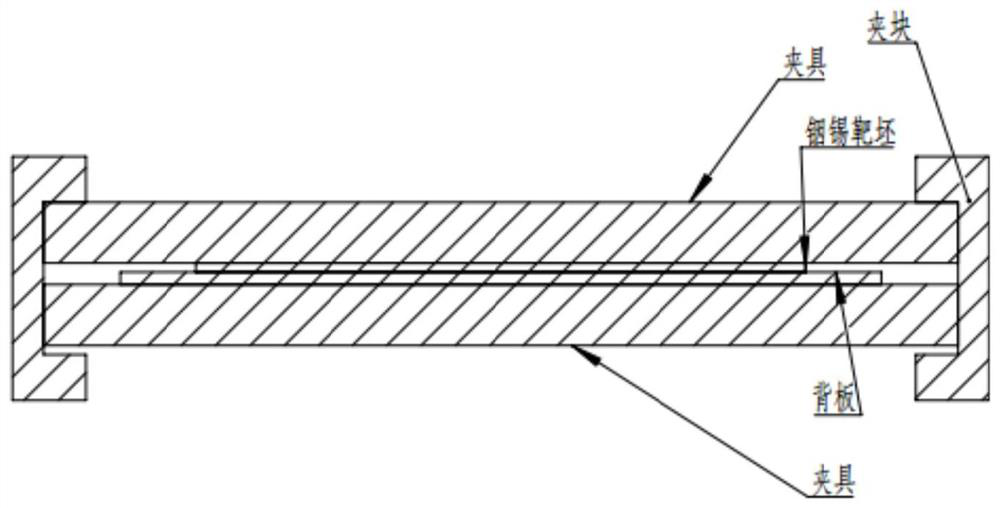

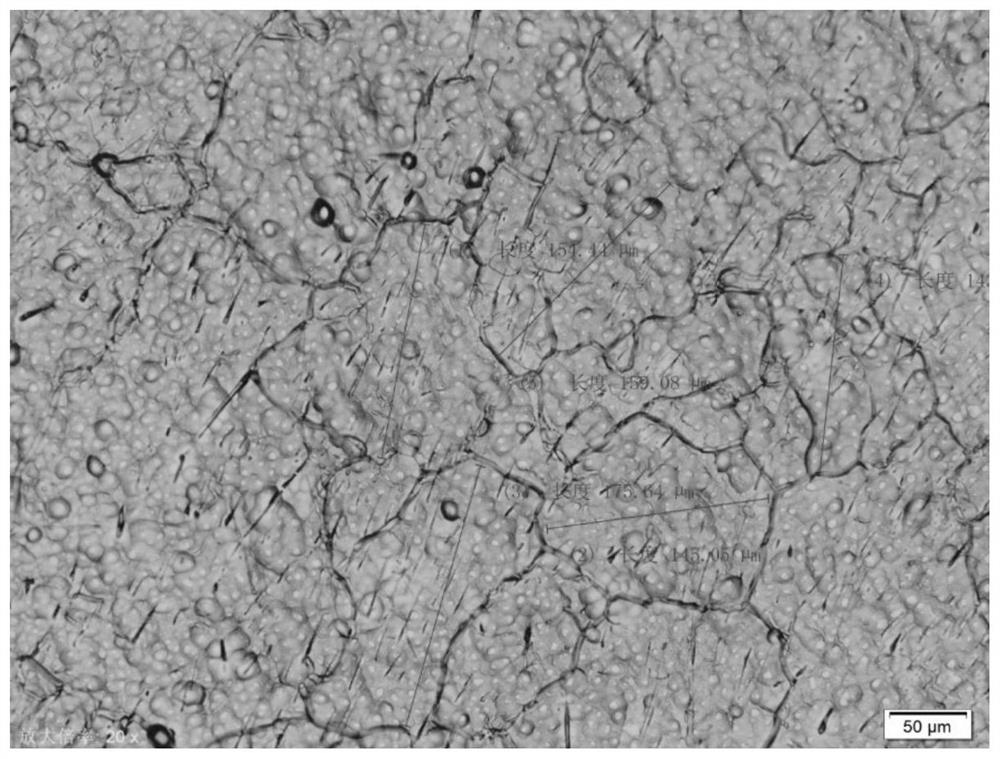

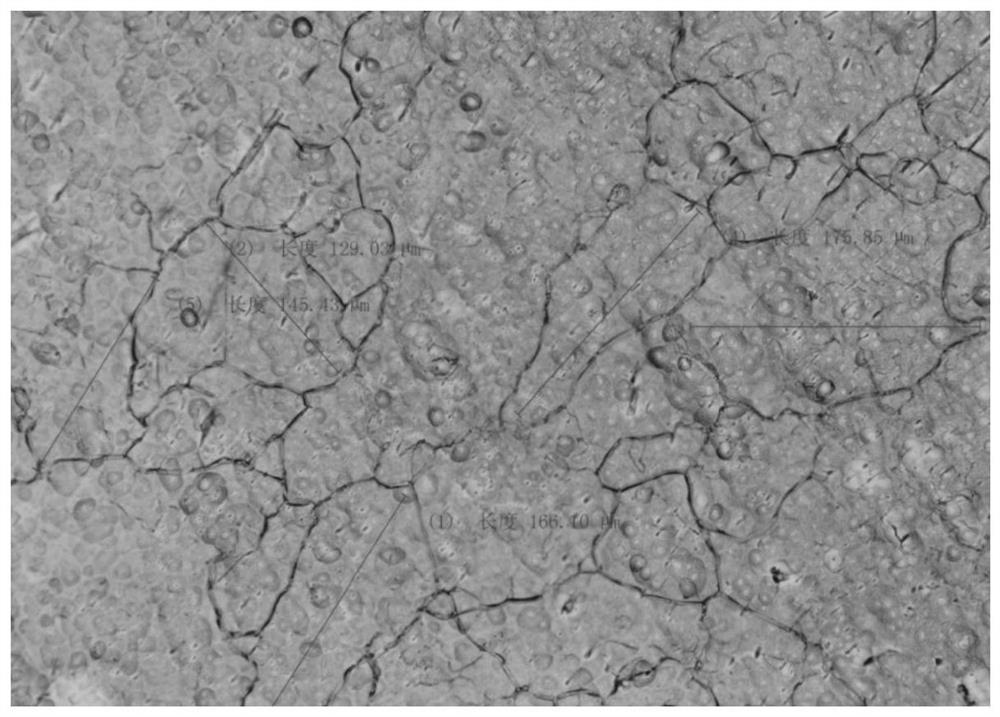

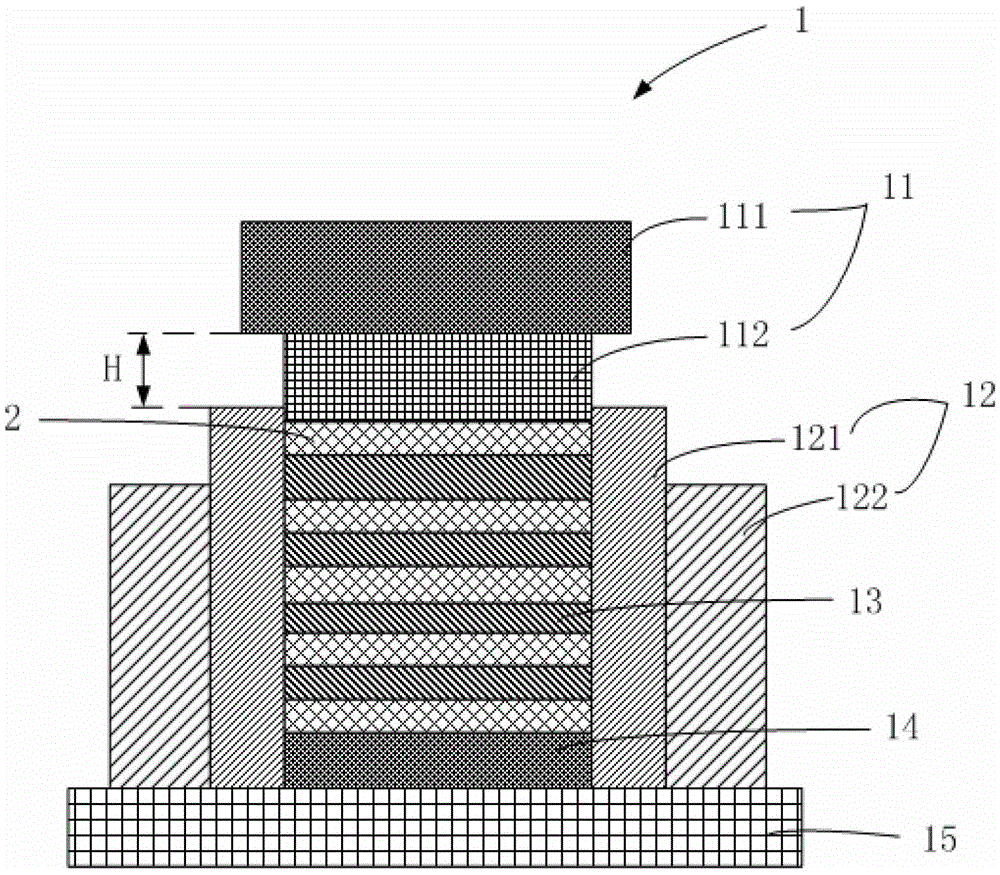

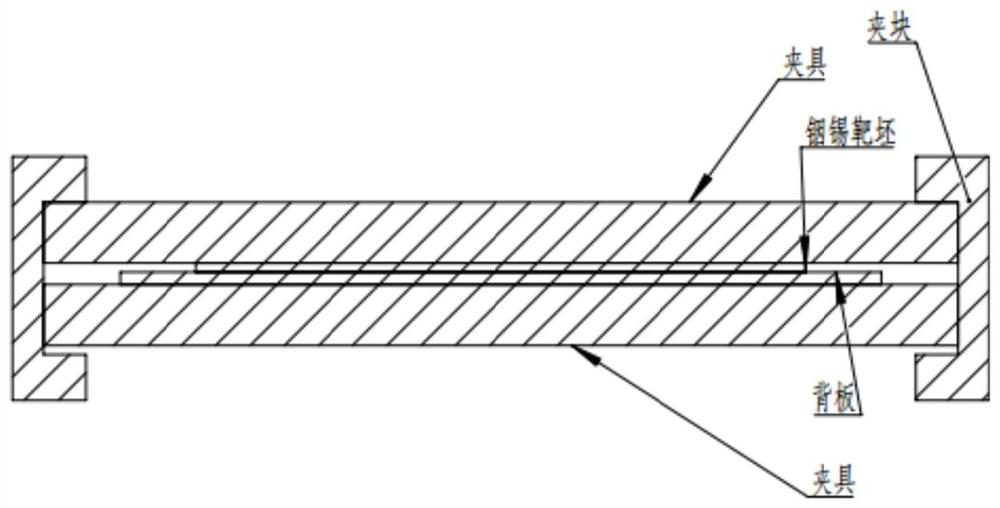

Indium-tin alloy target material and preparation method thereof

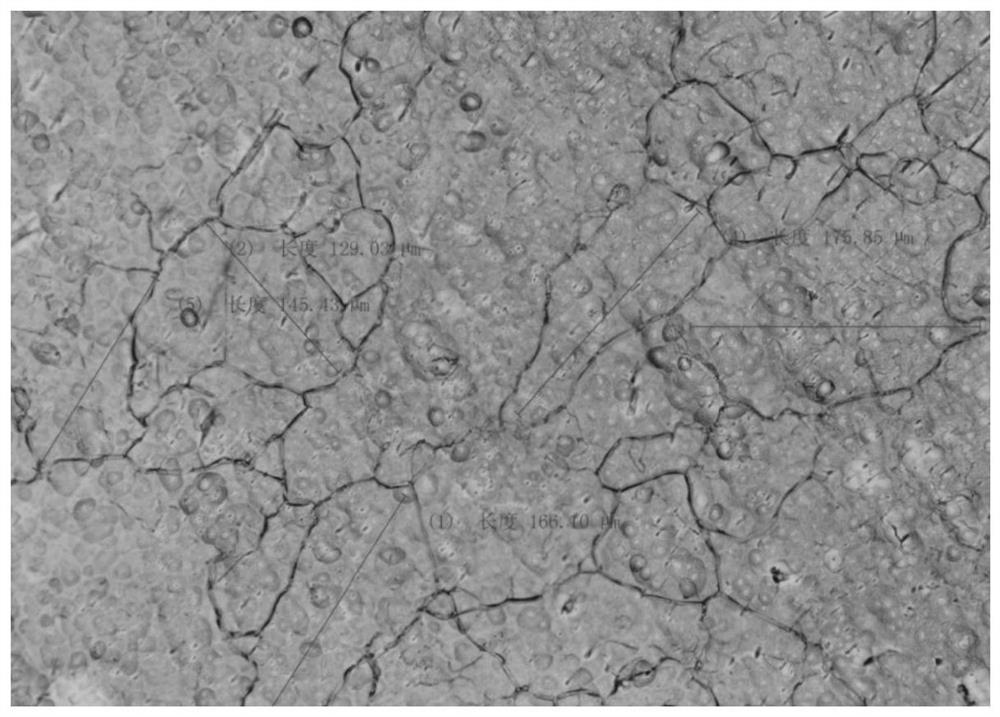

ActiveCN111809152AHigh puritySmall granularityVacuum evaporation coatingFoundry mouldsIndiumCrucible

The invention discloses a preparation method of an indium-tin alloy target material. The preparation method specifically comprises the following steps that metal indium and metal tin are put into a crucible, heated to be melted, and stirred until the melt components are uniform; the melt is subjected to casting and molding to obtain an indium-tin alloy cast ingot; the indium-tin alloy ingot is rolled to obtain an indium-tin alloy blank; the indium tin alloy blank is machined into a rough target blank with the thickness larger than the target size, and the binding face of the rough target blankis machined to be smooth; and a matched back plate and the rough target blank are heated and subjected to heat preservation at the temperature lower than the critical melting point of the rough target blank, then the back plate and the rough target blank are attached and clamped and gradually cooled to the room temperature, and after binding is qualified, the rough target blank is machined to thetarget size. By means of the method, the indium-tin target materials can be rapidly produced in batches, no melting medium exists between the target blank and the back plate, the target blank is highin purity, uniform in grain size and small in granularity, the average granularity ranges from 100 micrometers to 150 micrometers, the component uniformity is good, the indium-tin component deviationis smaller than + / -0.5%, and the sputtering effect is good.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

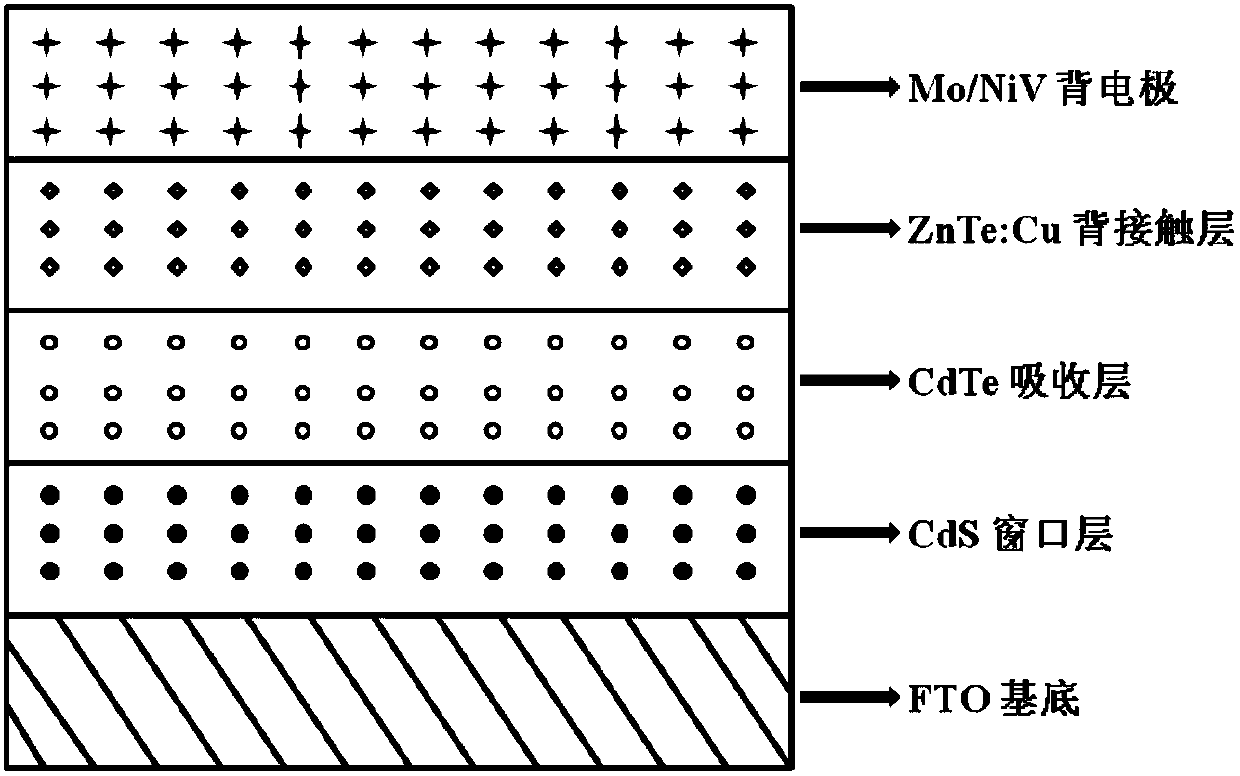

Cadmium telluride thin film battery with composite back electrode and preparation method of battery

InactiveCN107768453AReduce interface lossImprove collection and delivery capabilitiesFinal product manufacturePhotovoltaic energy generationNickelCopper

The invention discloses a cadmium telluride thin film solar battery with a composite back electrode and a preparation method of the battery. The solar battery comprises a substrate layer, a window layer, an absorption layer, a back contact layer and a composite back electrode layer in sequence; the window layer adopts the material of cadmium sulfide; the adsorption layer adopts the material of cadmium telluride; the back contact layer adopts the material of copper-doped zinc telluride; and the composite back electrode layer is formed by a molybdenum layer and a nickel vanadium layer. The battery adopts the molybdenum and nickel vanadium composite back electrode structure, so that combination of the thin film interface in the battery can be improved, the interface loss can be lowered, and the collection and transfer capability of the interface current can be improved, thereby further improving photoelectric performance of the battery.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

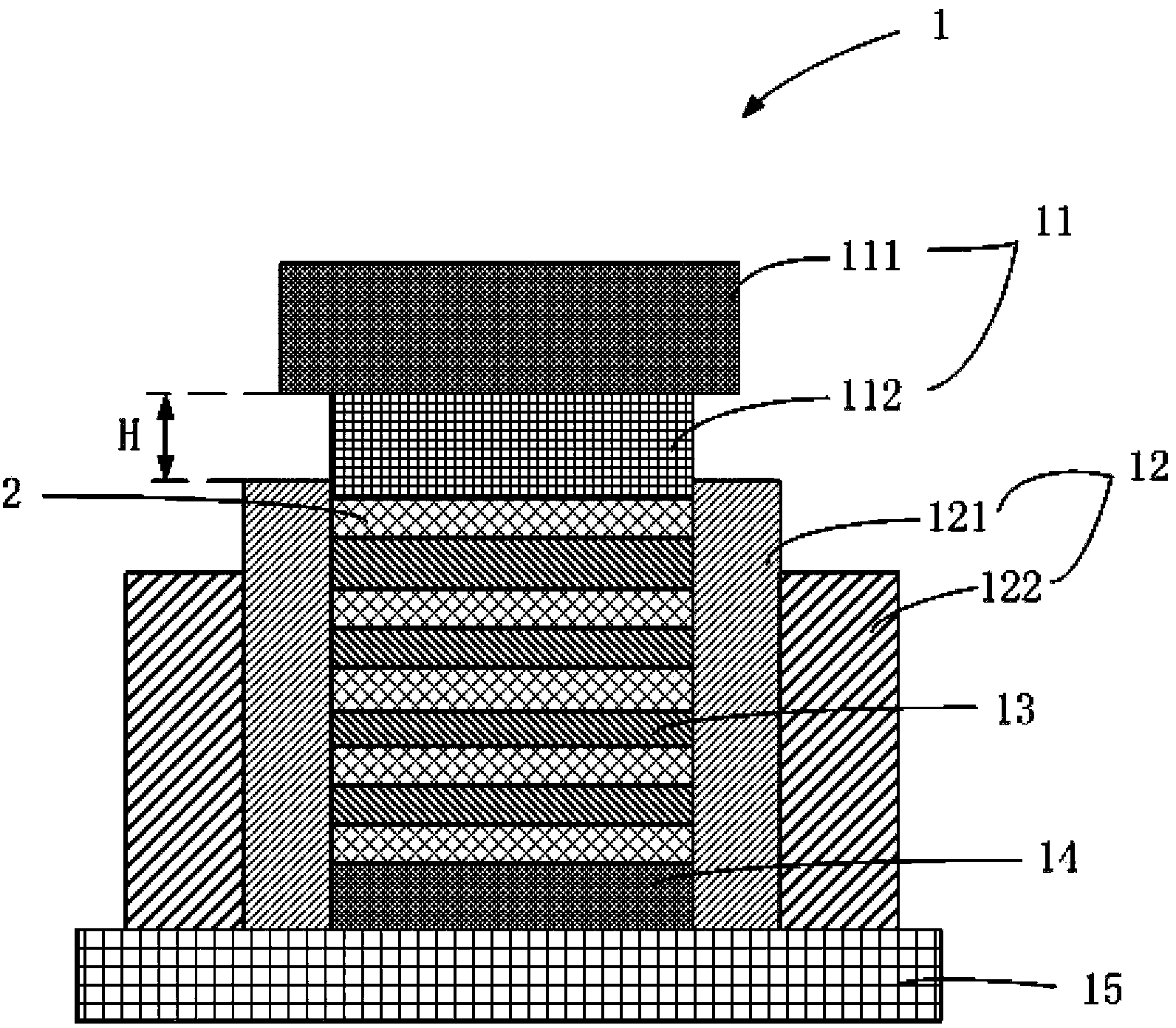

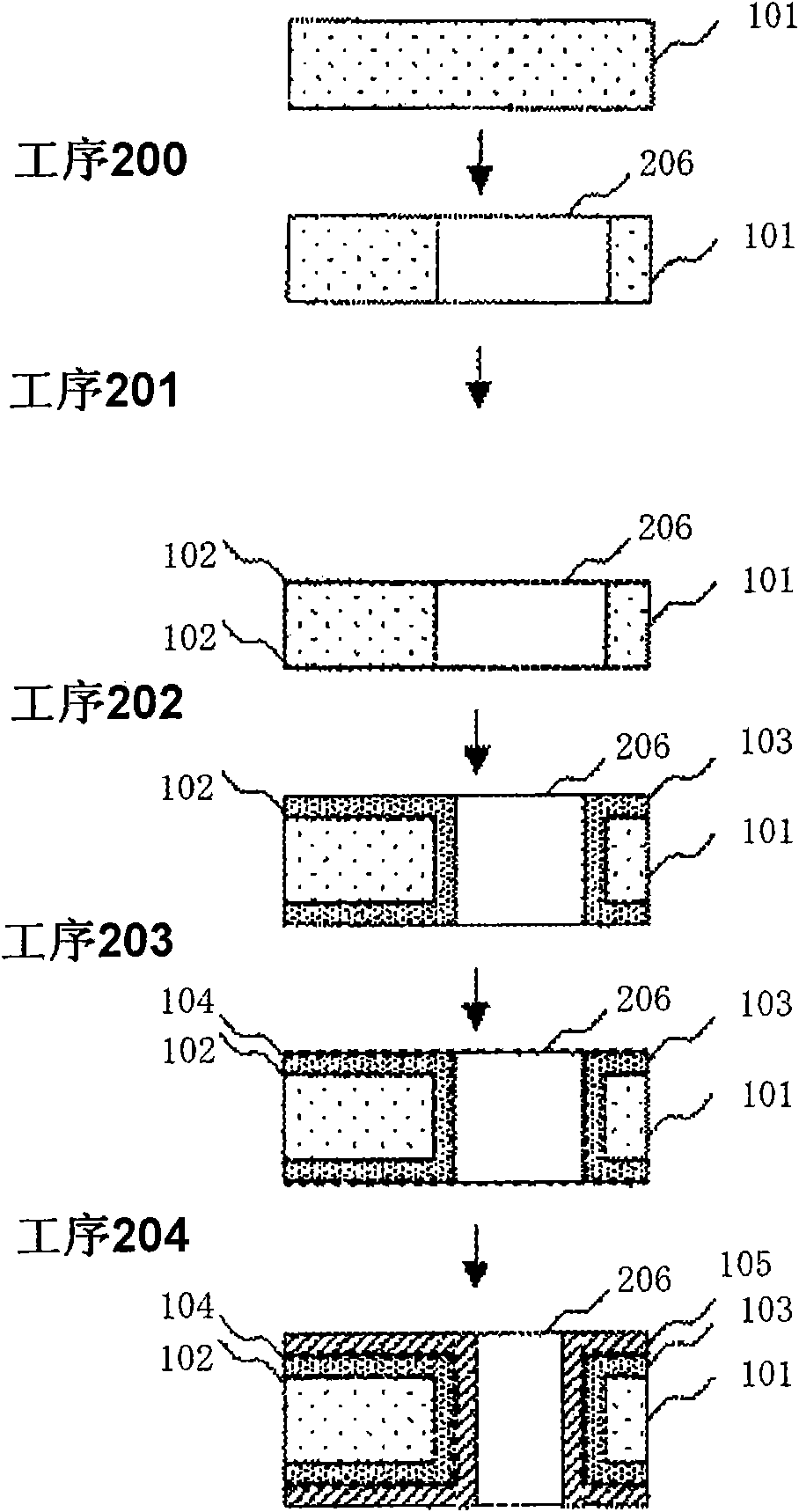

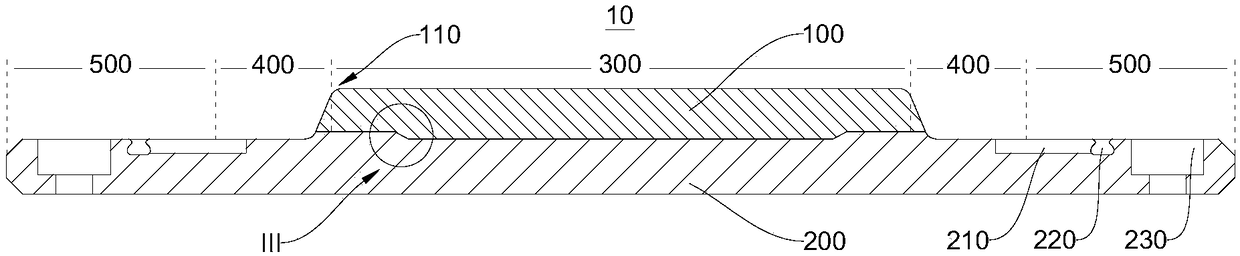

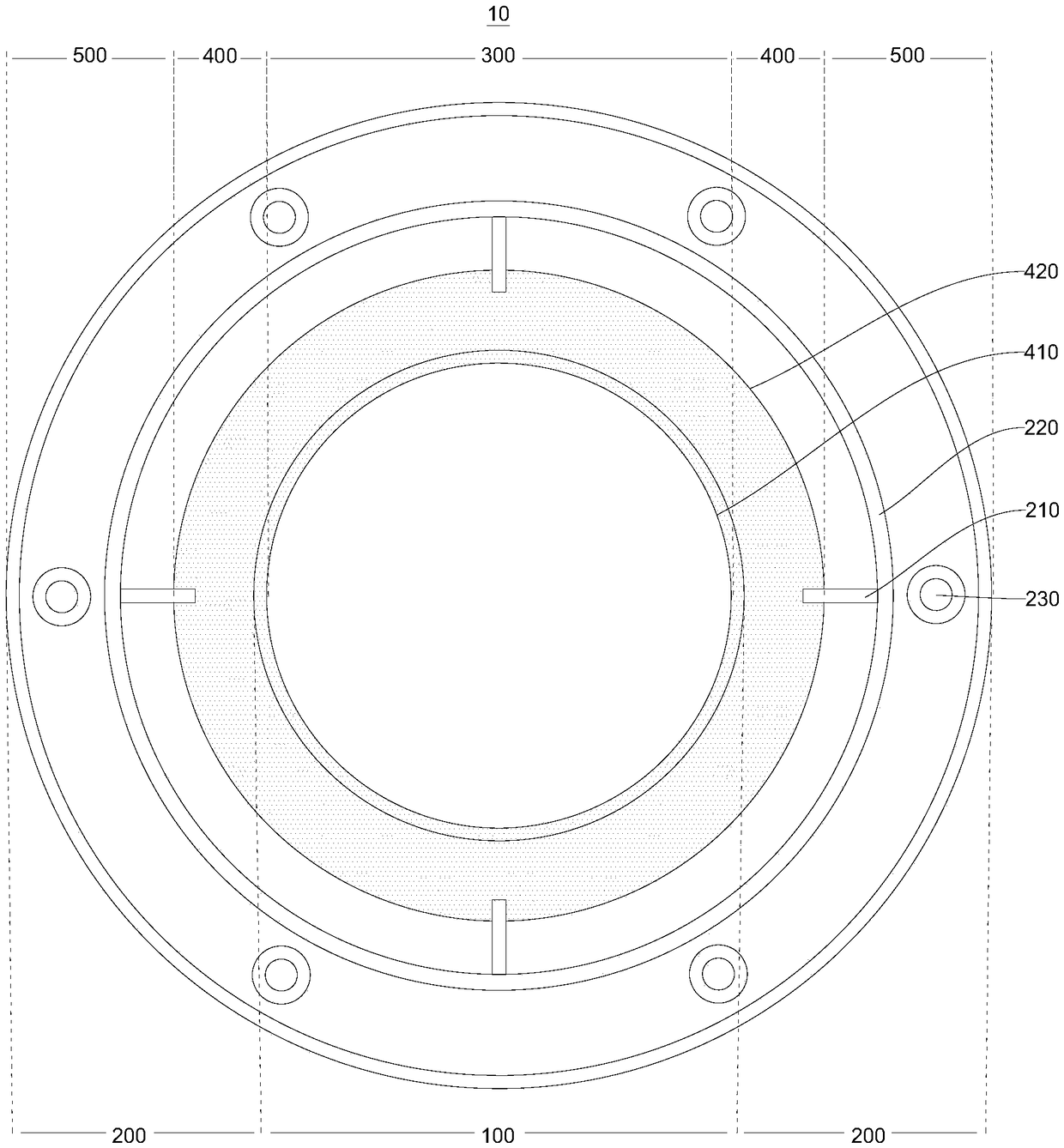

Target module and machining method

ActiveCN108581169AGood sputtering performanceQuality improvementNon-electric welding apparatusMachining processWeld line

The invention relates to the technical field of machining, and provides a target module and a machining method. The target module comprises a target and a back plate for bearing the target. The surface of the target comprises a front surface and a back surface; the front surface of the target is a sputtering surface of the target; the back surface of the target is opposite to the front surface ofthe target; a first step is projected on the back surface of the target; and the side surface of the first step is an inclined surface. A first groove matched with the first step is formed in the front surface of the back plate; the back surface of the target and the front surface of the back plate are connected through dispersion welding; and the first step is embedded in the first groove. In thedispersion welding process, the back surface of the target is tightly bonded with the front surface of the back plate; and a finally molded target module generates no welding line in the joint position of the two, so that the sputtering performance of the target can be improved, meanwhile, the problem related to the welding line cannot occur in subsequent machining process of the target module, and the quality of the produced target module is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

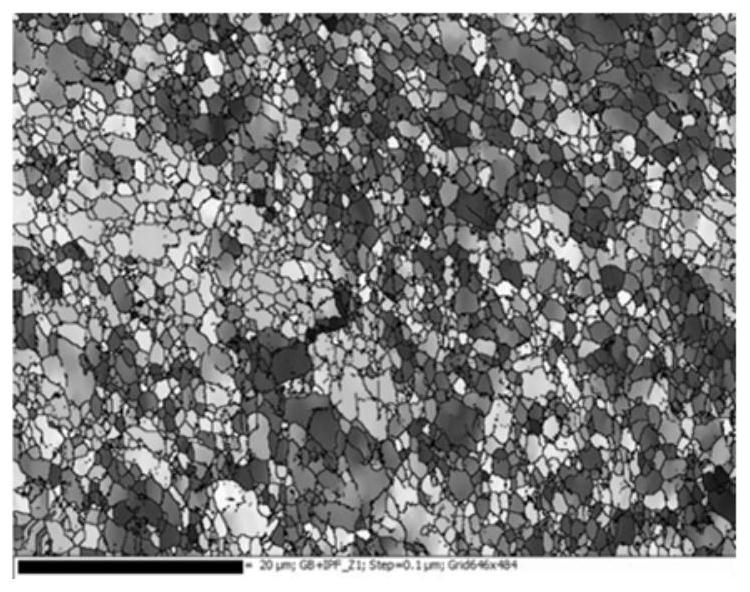

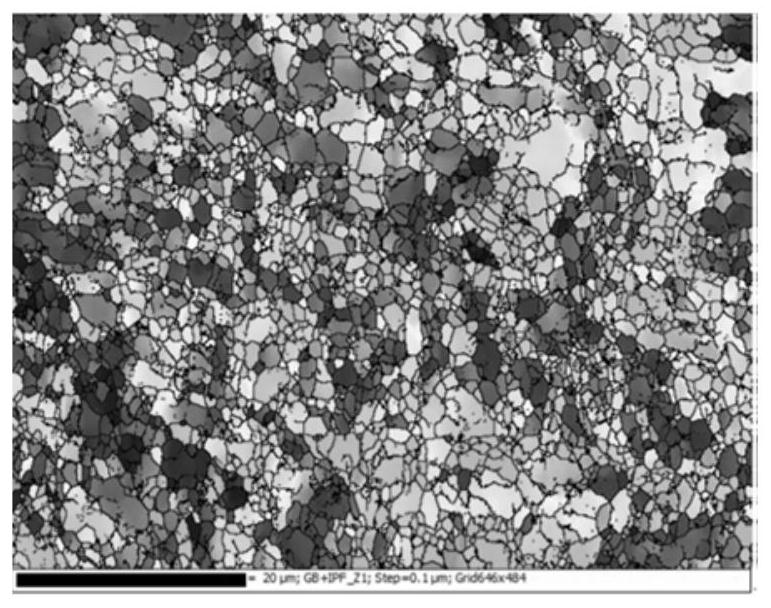

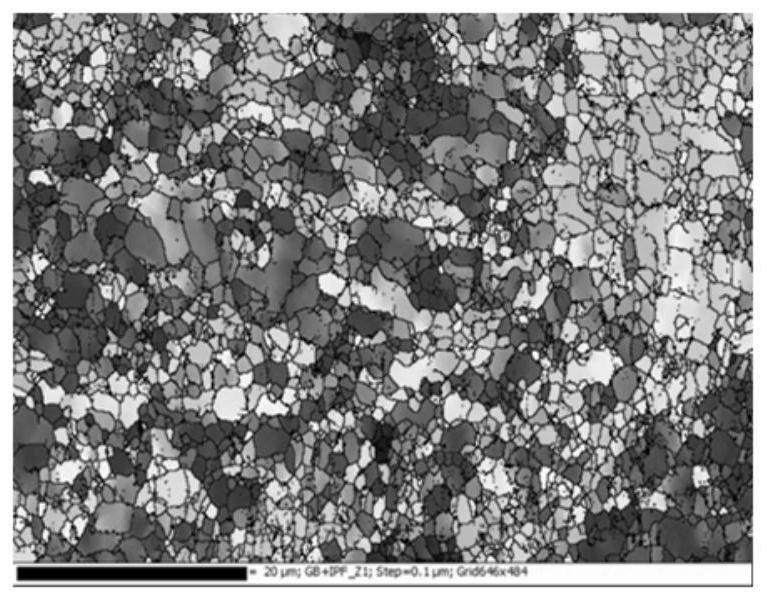

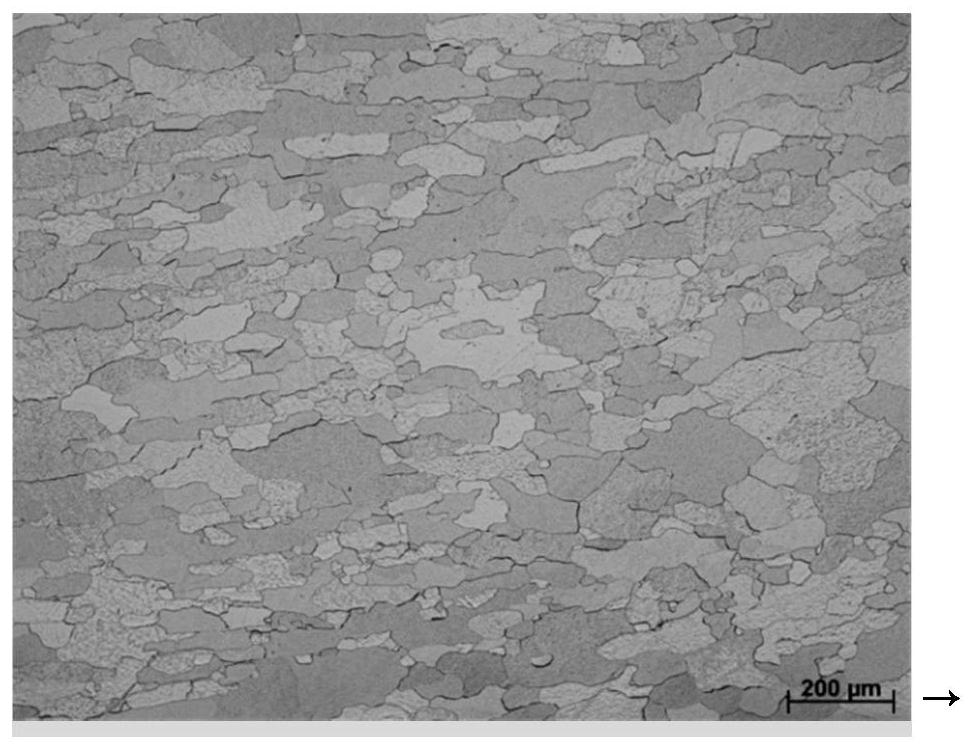

Method for refining crystal grains in ultra-pure copper or copper alloy

ActiveCN112453088AGood sputtering performanceIncrease deposition rateExtrusion diesExtrusion control devicesPlasma impedanceThin membrane

The invention relates to a method for refining crystal grains in ultra-pure copper or copper alloy. The refining method comprises the steps of: heating an ultra-pure copper or copper alloy blank; andthen sequentially carrying out first equal channel angular pressing and second equal channel angular pressing. According to the method provided by the invention, by adopting the specific equal channelangular pressing process, crystal grains are refined to the specification of below 5mum so as to ensure that a target material has good sputtering performance when being sputtered by adopting the refined ultra-pure copper or copper alloy; and furthermore, by the refining method, when in use, the target material is low in plasma impedance, high in thin film deposition rate and good in thin film thickness uniformity.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Preparing method for titanium-aluminum alloy target material

InactiveCN107815653AHigh densityGood sputtering performanceVacuum evaporation coatingSputtering coatingBriquetteTitanium powder

The invention discloses a preparing method for a titanium-aluminum alloy target material. The preparing method includes the following steps that after titanium powder and aluminum powder are evenly mixed, an isostatic press is used for pressing the mixed powder into a briquette; the briquette is subjected to pressurizing sintering in the vacuum environment, and a prefabricated billet is obtained;and the billet is subjected to annealing treatment, and the titanium-aluminum alloy target material is obtained. By means of the preparing method for the titanium-aluminum alloy target material, the problems that existing titanium-aluminum alloy target material preparing is poor in effect and complex in technology are solved; according to the titanium-aluminum alloy target material, the titanium powder and the aluminum powder which are small in particle size and high in purity are selected firstly to be mixed for isostatic pressing treatment, the briquette high in compactness is obtained, andafter the briquette is subjected to vacuum pressurizing sintering and ultrasonic cleaning, the titanium-aluminum alloy target material is obtained through preparing; and the preparing technology is simple, and the prepared titanium-aluminum alloy target material is high in compactness and good in sputtering effect.

Owner:陕西爱骨医疗股份有限公司

Sputtering target capable of enhancing wear resistance and corrosion resistance of coated glass and manufacturing method

InactiveCN105058923ACompact structureUniform compositionVacuum evaporation coatingSputtering coatingVolumetric Mass DensityBinding force

The invention discloses a sputtering target capable of enhancing wear resistance and corrosion resistance of coated glass and a preparation method of the sputtering target . The sputtering target mainly comprises a zirconium based material; the shape and specification of the target are not limited, and a rotating target and a plane target can be manufactured; the rotating target is prepared through the equivalent cold spraying and plasma spraying technology; the plane target is prepared through the following steps: target blocks are prepared through the powder metallurgy technology, and then the target blocks are spliced and bound to form a large-size target; the structure of the target is compact, the components of the target are uniform, and the electrical conductivity of the target is excellent; the density is (5.3-5.9) g / cm3, and the relative density is greater than 90%. The target has excellent sputtering performance, stable arc light, and a sputtering coating rate of (0.5-1.0) nm*m / min. A plated zirconium based film is used as a protective film and has excellent binding force with adjacent films and excellent abrasive resistance and weather fastness; after film coating, glass requires no film protection, can be stored for a long time, facilitates deep processing in different places, effectively prevents coated glass from scratching and scrapping during the follow-up deep-processing process, and requires no film removal of a side before lamination.

Owner:GEMCH MATERIAL TECH SUZHOU

Welding rod contg. titanium dioxide series flux for CO2 gas arc welding

InactiveCN1334173AGood sputtering performanceImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsTitaniumTitanium oxide

Provided is a flux cored wire containing titanium oxides for CO2 gas shielded arc welding. The flux cored wire containing titanium oxides for CO2 gas shielded arc welding comprises C 0.03-0.07%, Mn 1.6-2.0%, Si 0.35-0.7%, Mg 0.5-1.1%, B 0.005-0.02%, Al 0.08-0.3%, Ni 0.7-2.0%, F 0.15-0.35%, titanium oxides 5.5-7.5%, 0.25% or less of at least two non-titanates selected from SiO2, Al2O3 and ZrO2, a balance of Fe and other inevitable impurities. The total content of titanate and non-titanate is controlled below 8.0%, based on the total weight of the flux cored wire. The provided flux cored wire containing titanium oxides for CO2 gas shielded arc welding has superior impact toughness at low thermal temperature and excellent all position welding.

Owner:HYUNDAI WELDING

Titanium target grain refining method and titanium target

PendingCN113481475AFully warmed upGood sputtering performanceVacuum evaporation coatingMetal-working apparatusTitaniumMachining

The invention provides a titanium target grain refining method and a titanium target. The method comprises the following steps that (1) the titanium target is preheated at the temperature of 400-500 DEG C; (2) three-way forging is conducted on the titanium target obtained in the step (1); and (3) the titanium target obtained in the step (2) is cooled, and the titanium target with the grain size being 10-20 microns is obtained. The provided method is specially used for grain refinement of the titanium target, the sputtering performance and the sputtering environment of the titanium target are improved, the coating quality is improved, meanwhile, the technological process is simplified, and the machining cost is reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

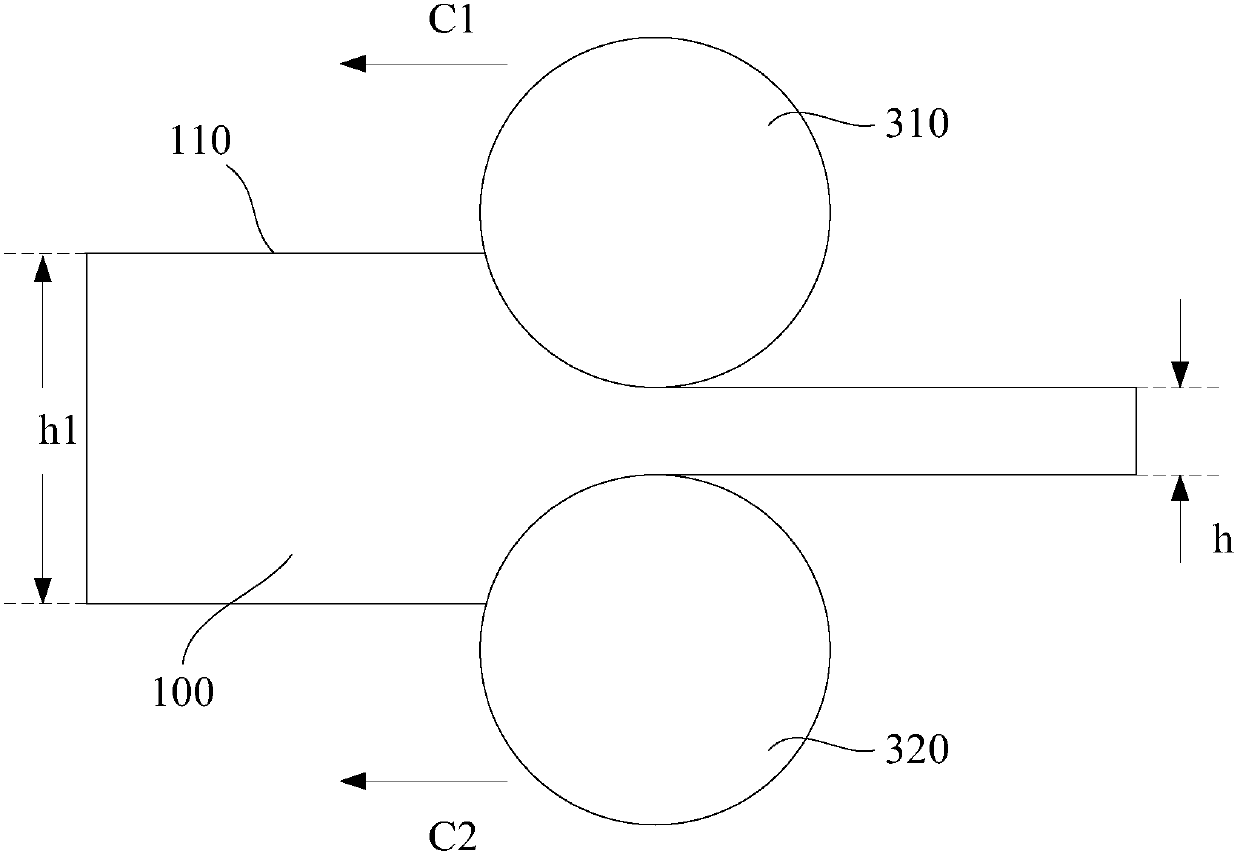

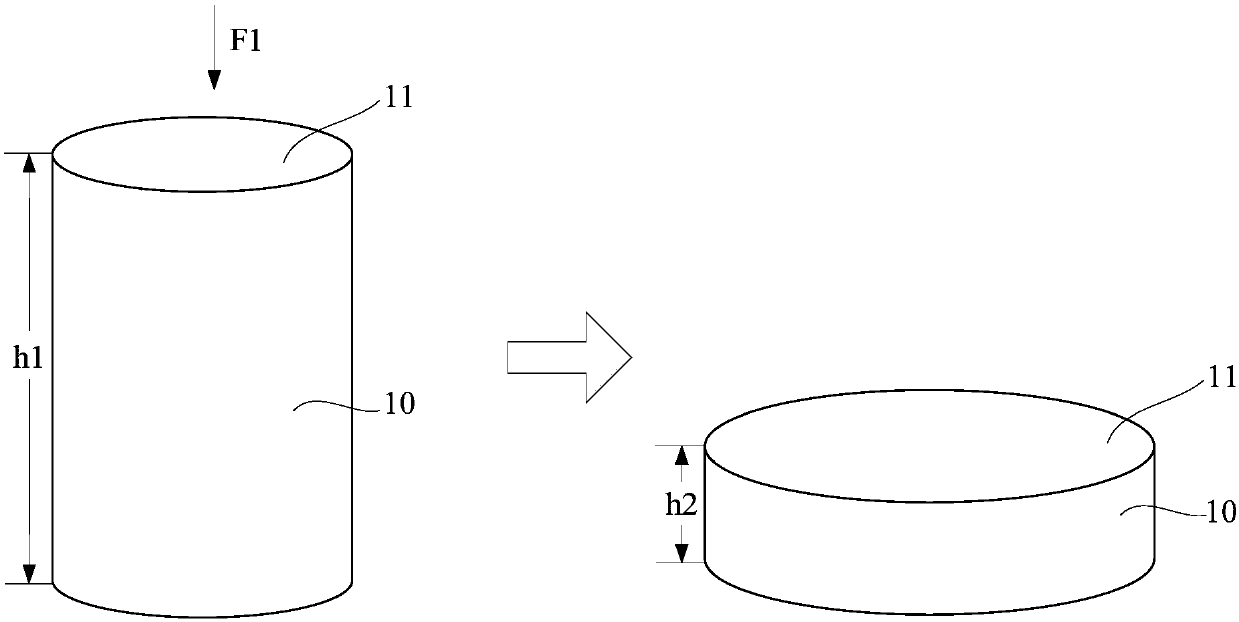

Target rolling method

InactiveCN110000211AImprove rolling qualityGood sputtering performanceWork heating devicesMetal rolling arrangementsMaterials science

The invention relates to a target rolling method. The target rolling method comprises the steps that a target blank is provided; the target blank is heated to a first temperature; after the target blank is heated to the first temperature, the target blank is calendered; during the calendering process, when the temperature of the target blank decreases to a second temperature, the target blank is heated, and the target blank is heated to the first temperature and then is calendered; and the heating treatment and the calendering treatment are carried out alternately until the target blank is manufactured into a target. According to the target rolling method, the target blank can be prevented from cracking during the calendering process, the rolling quality of the target can be improved, andthe sputtering performance of the target is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

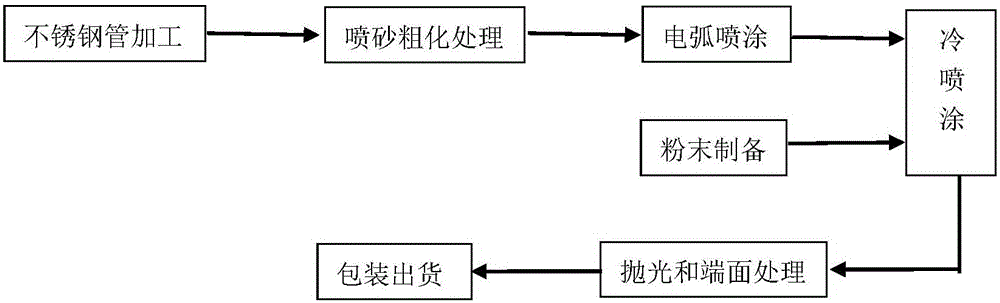

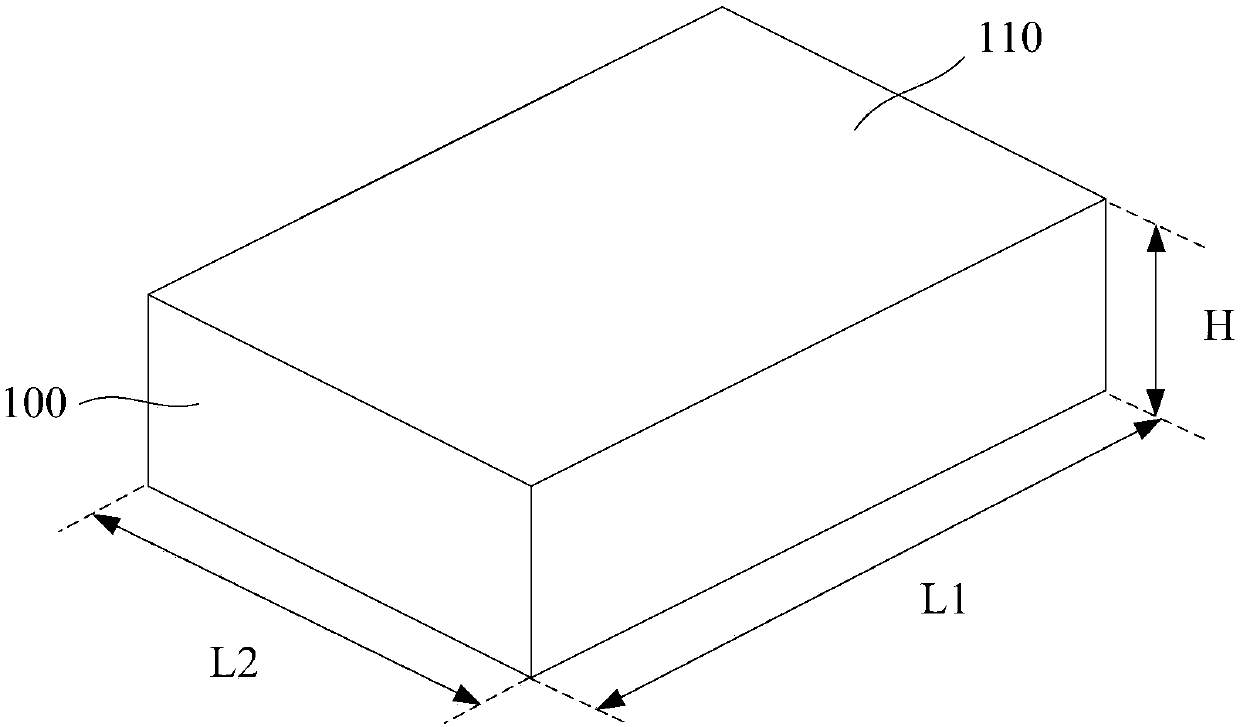

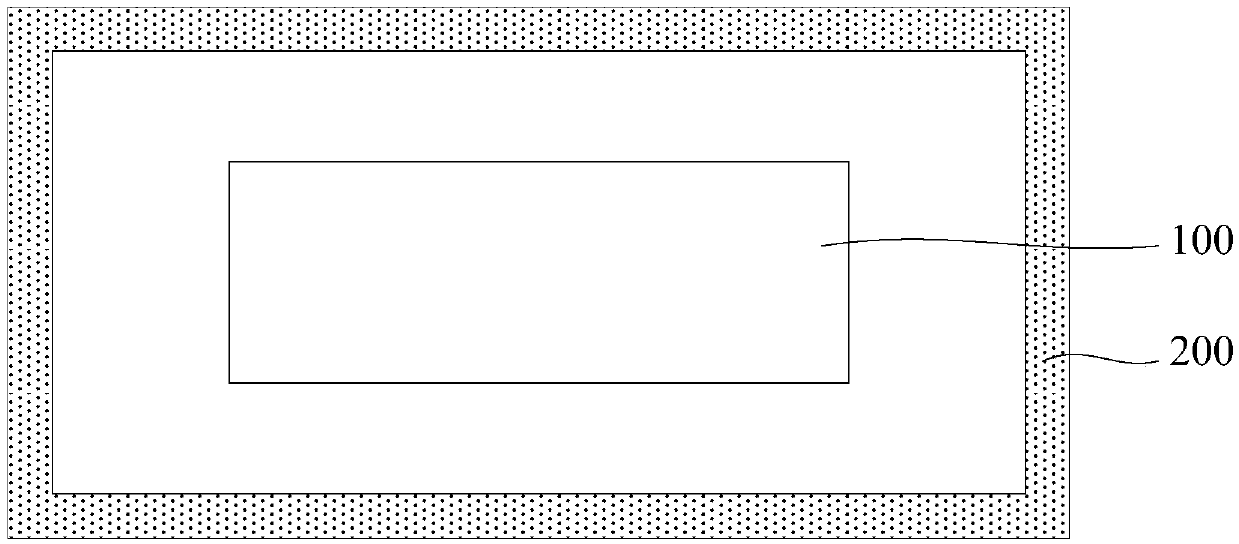

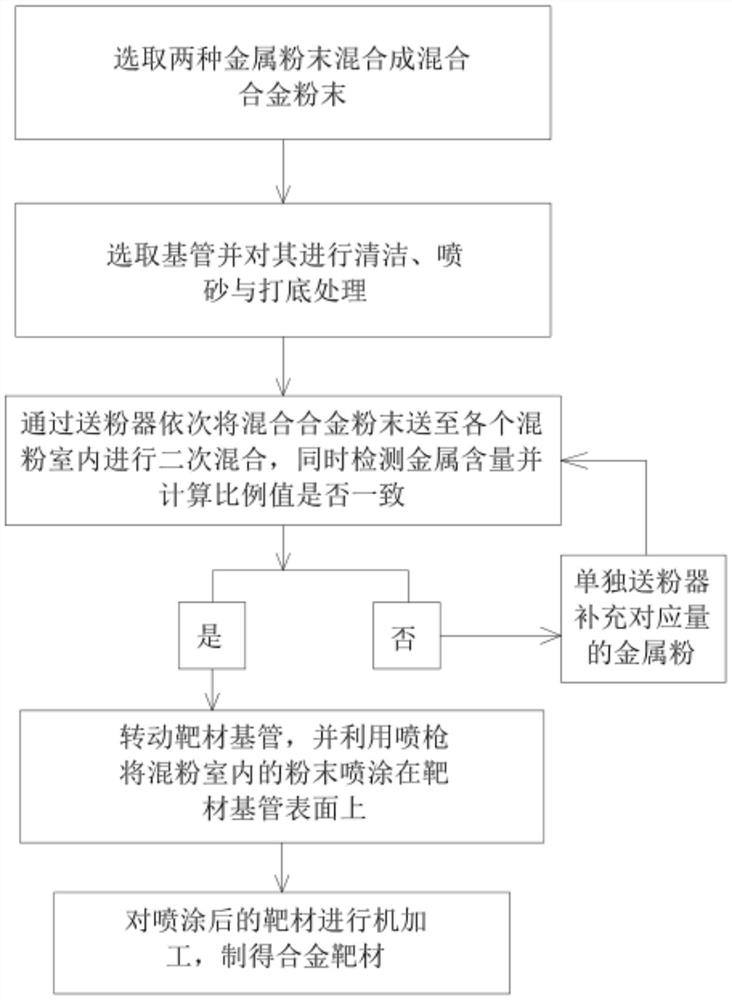

Preparation method for alloy target material and alloy target material prepared by preparation method

ActiveCN111826625AGuaranteed uniformityHigh precisionVacuum evaporation coatingSputtering coatingSteel tubePowder

Owner:厦门佰事兴新材料科技有限公司

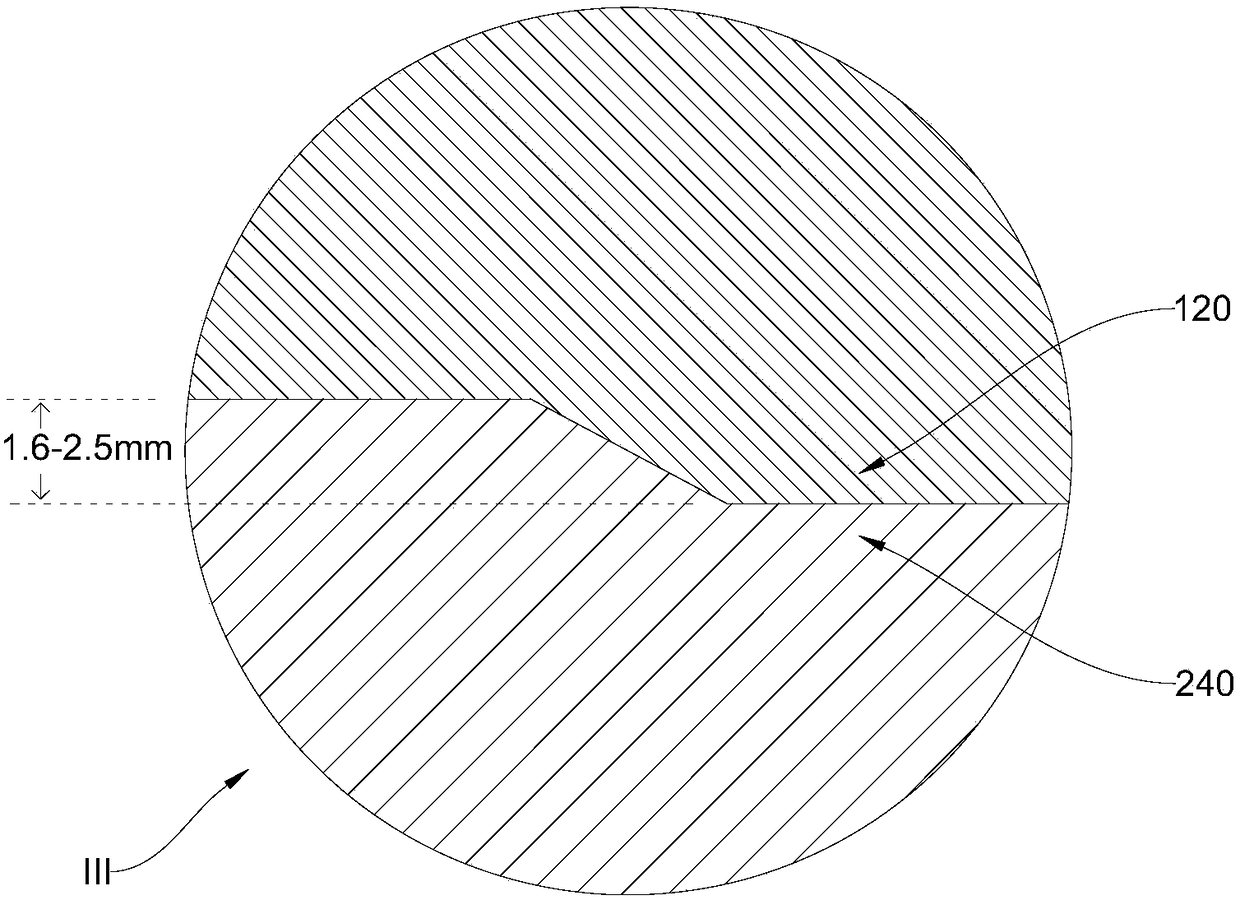

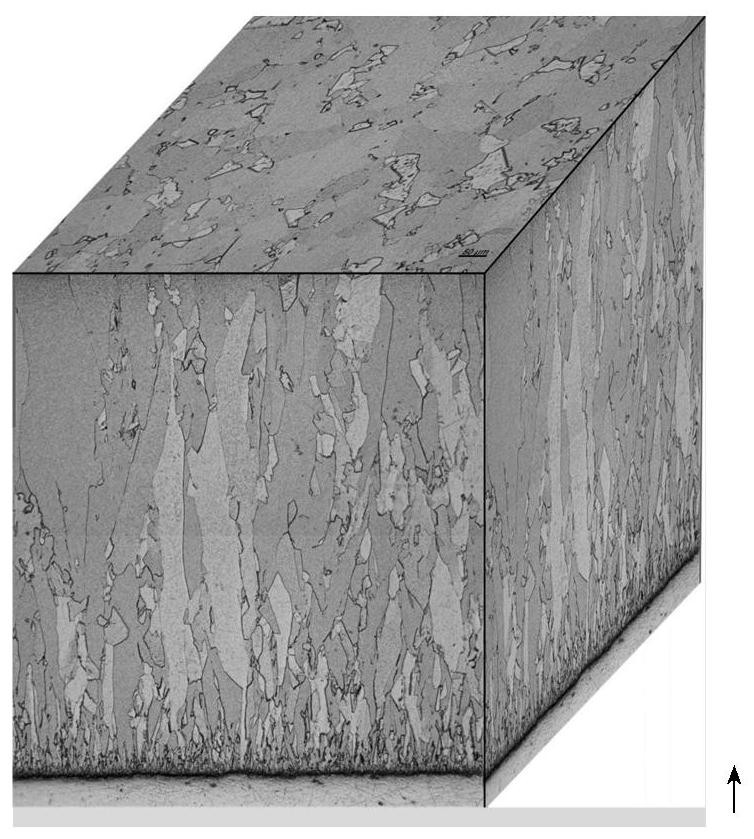

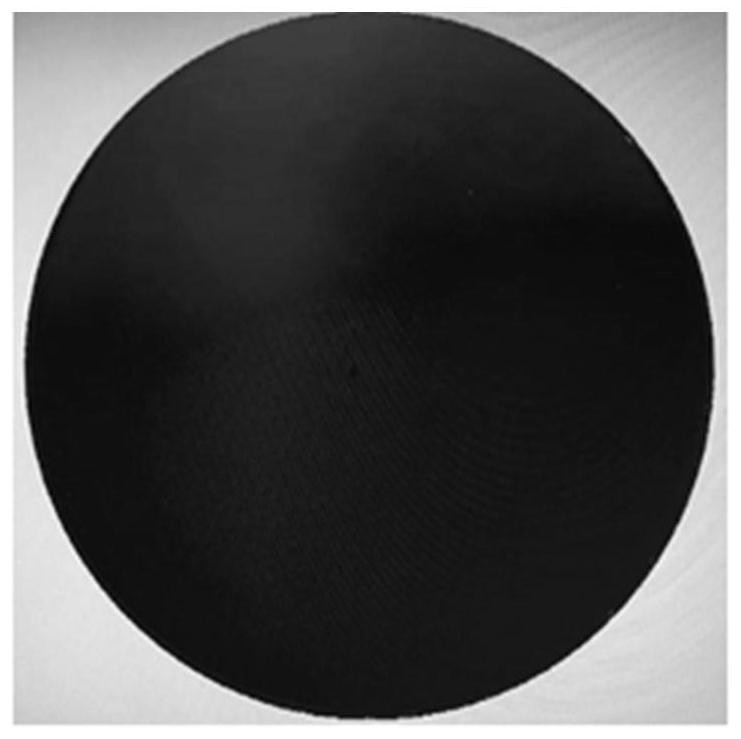

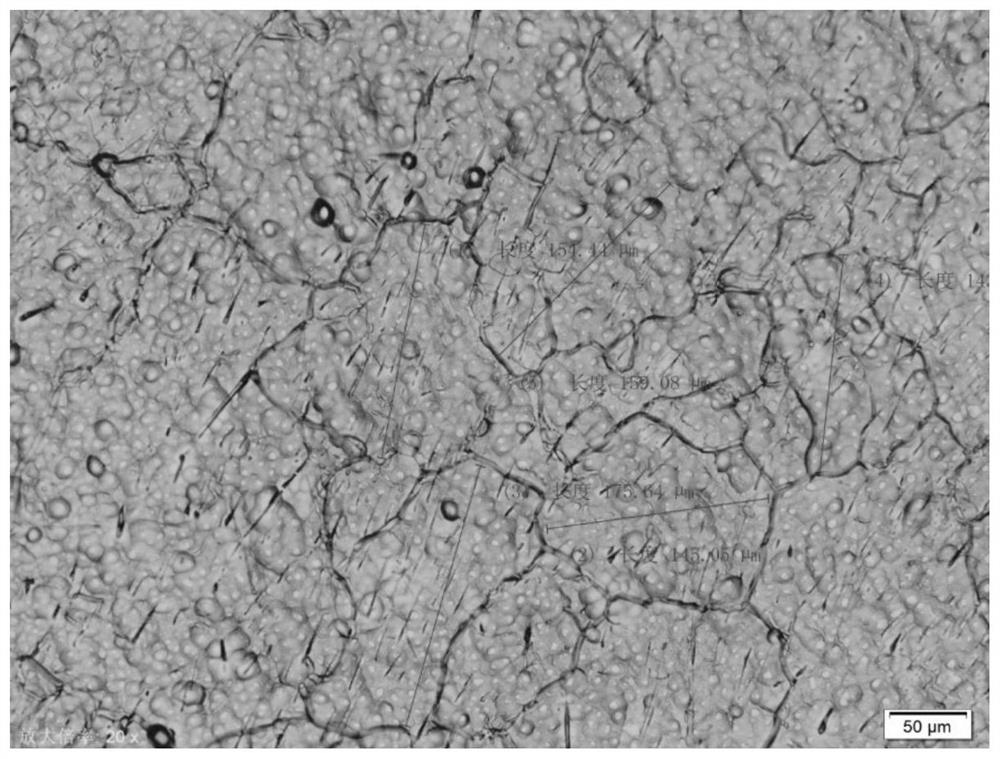

Preparation method and application of tungsten sputtering target blank

ActiveCN113073295AImprove uniformityImprove yieldVacuum evaporation coatingSputtering coatingFilm resistanceSputtering

The invention provides a preparation method and application of a tungsten sputtering target blank. The method comprises the following steps: performing cross rolling on a tungsten plate blank to crush columnar crystals, and then performing recrystallization annealing to enable the crystal grains to be equiaxial, wherein the tungsten plate blank is prepared by a chemical vapor deposition method, and the purity of the tungsten plate blank is greater than or equal to 6N. The tungsten sputtering target blank prepared by the method provided by the invention has ideal performance indexes such as purity and density; when the tungsten sputtering target blank is used as a raw material for manufacturing an integrated circuit for vacuum sputtering film formation, the sputtering rate is stable, the film is uniform and consistent, the resistivity of the film is reduced, and the yield of finished products is improved; and meanwhile, the method is high in operability and has a wide application prospect.

Owner:海朴精密材料(苏州)有限责任公司

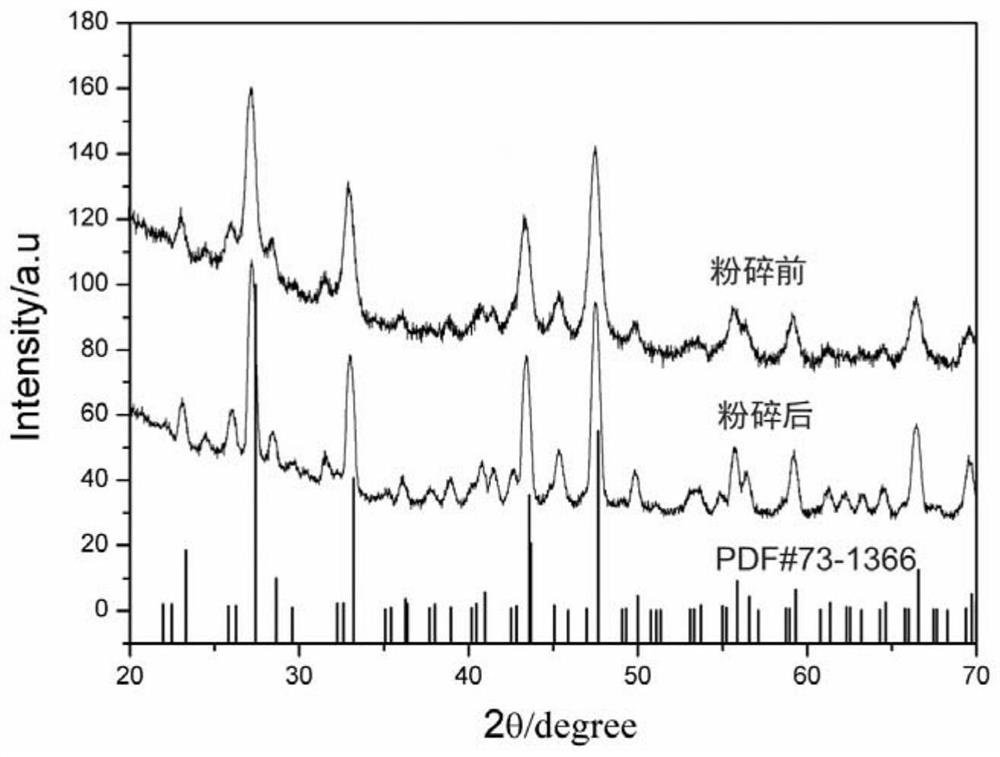

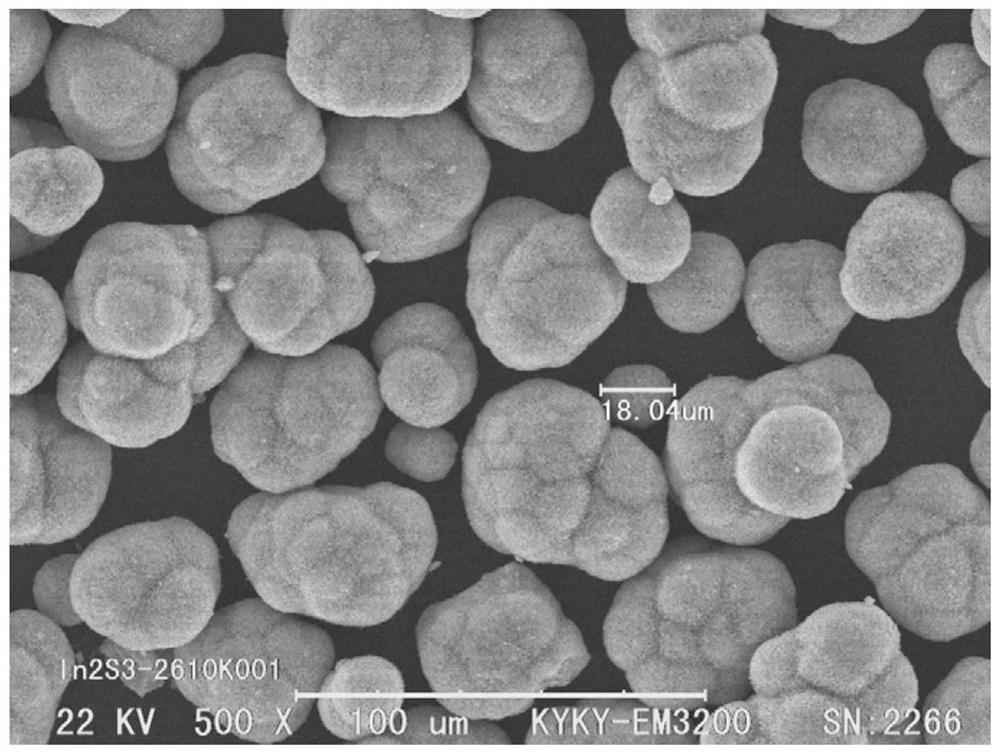

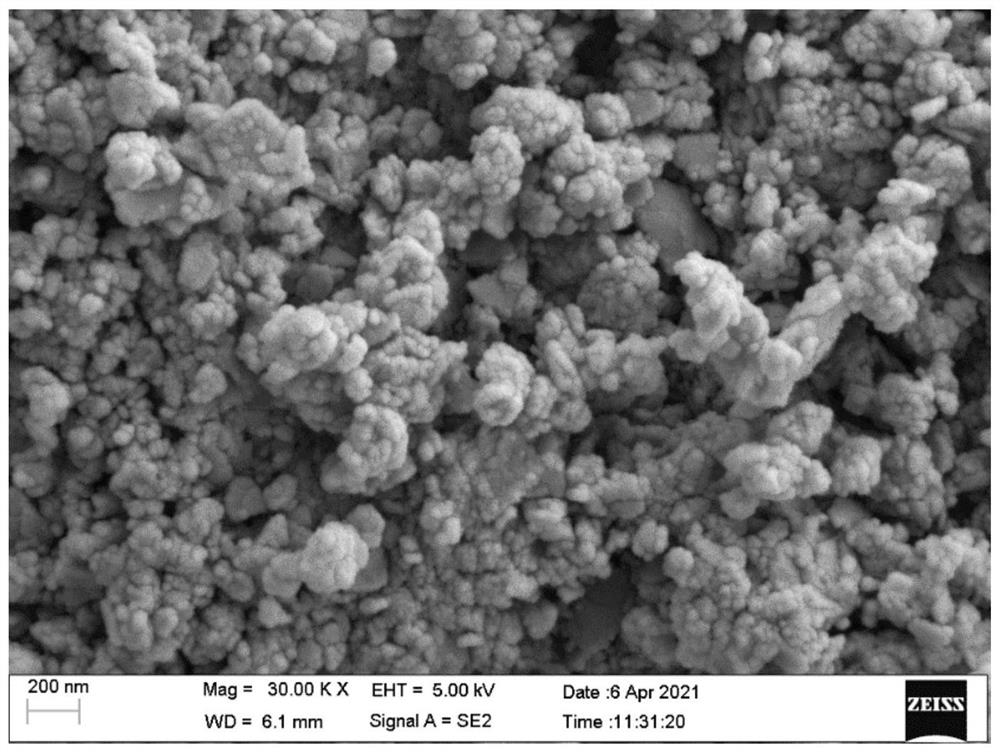

Preparation method of fine indium sulfide powder and target material

ActiveCN113213938AUniform resistivityUniform thickness distributionGallium/indium/thallium compoundsVacuum evaporation coatingPhysical chemistrySulfidation

The invention discloses a preparation method of fine indium sulfide powder and a target material, and the preparation method of the fine indium sulfide powder comprises the following steps: introducing H2S gas into an In2 (SO4) 3 solution, reacting under stirring to synthesize indium sulfide, and after the reaction is finished, rinsing, filtering, calcining, ball-milling and sieving the synthesized product to obtain indium sulfide powder with the particle size D90 of 20-40 [mu] m; and allowing the indium sulfide powder to be subjected to airflow crushing, wherein the feeding pressure and crushing pressure of airflow crushing are 8-12 kg, the feeding speed is 3-5 kg / h, and continuing ventilation for 3-5 min after feeding is finished to obtain the fine indium sulfide powder with D90 smaller than 5 micrometers. The prepared indium sulfide powder is beta-In2S3 of a tetragonal structure, the particle size D90 is smaller than 5 microns, the indium sulfide powder is used for preparing the target material, the quality of the target material is improved, the average grain size of the target material is smaller than 5 microns, the resistivity is smaller than 0.5 K omega / cm, the relative density is larger than or equal to 97%, the impurity content is low, and a film formed through sputtering is good in stability, uniform in thickness distribution and consistent in grain size.

Owner:先导薄膜材料(安徽)有限公司

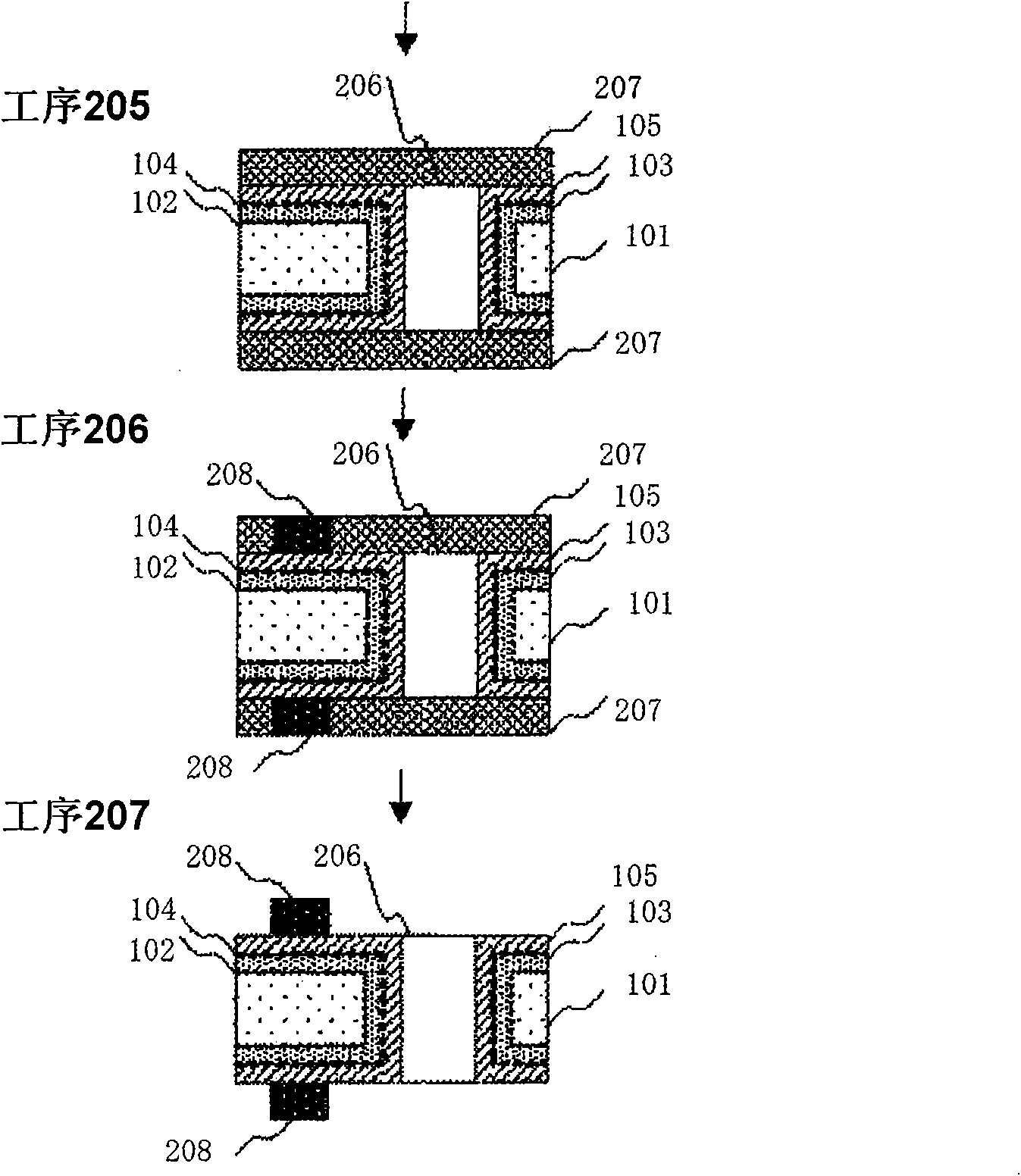

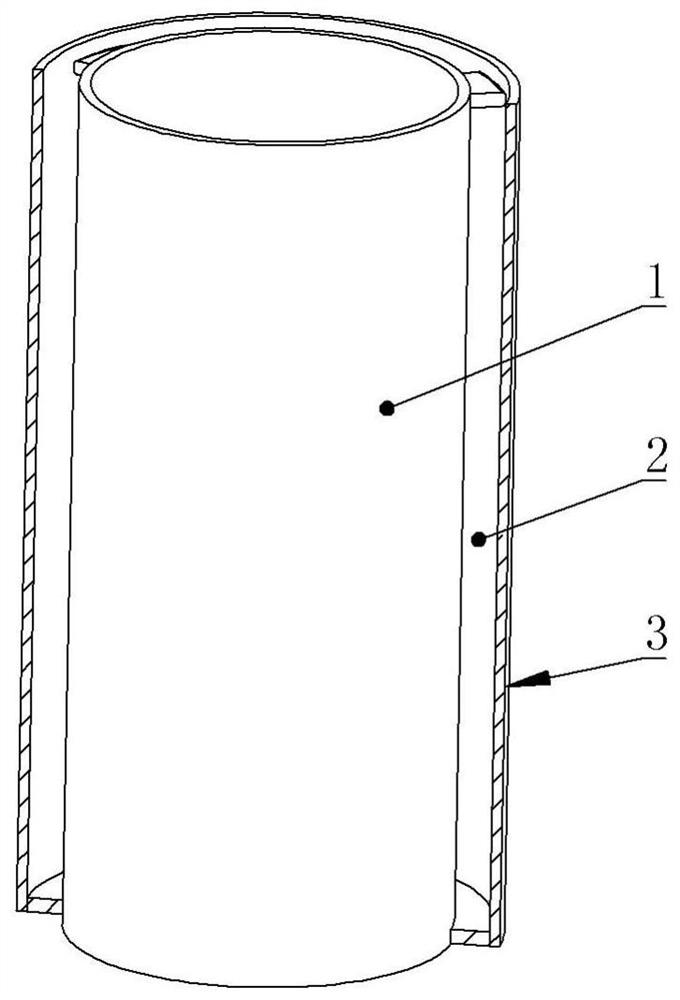

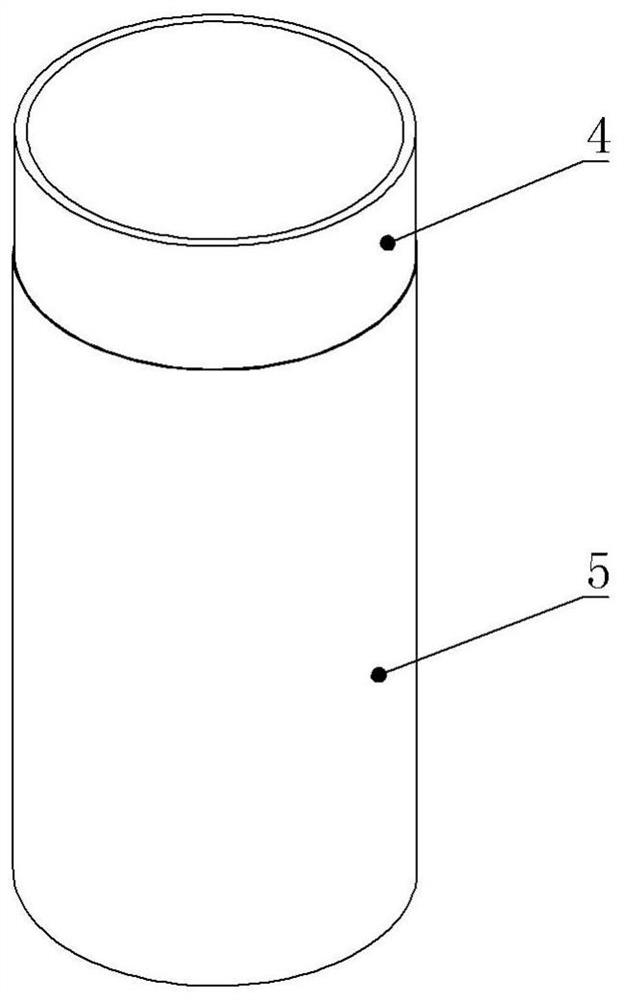

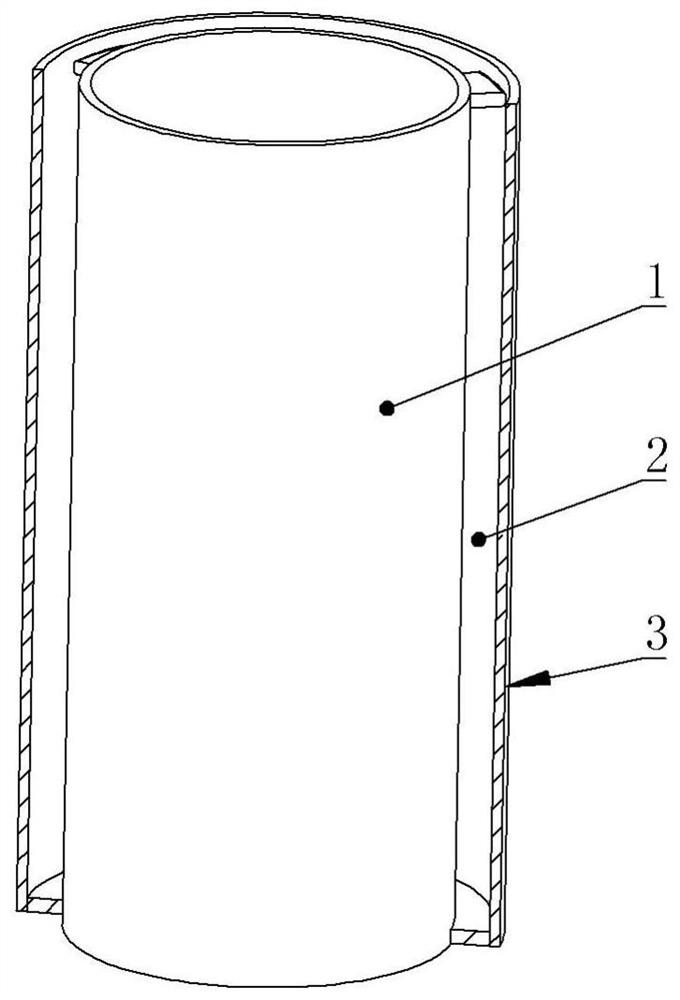

Back pipe for casting rotary target material and manufacturing method thereof

ActiveCN112522754ALess impuritiesReduced shieldingVacuum evaporation coatingSputtering coatingSurface roughnessSS - Stainless steel

The invention relates to the technical field of rotary target material manufacturing, in particular to a back pipe for casting a rotary target material. The back pipe comprises a stainless steel pipe,wherein a nickel layer is electroplated outside the stainless steel pipe, the thickness of the nickel layer ranges from 0.005 mm to 0.1 mm, the surface roughness of the nickel layer ranges from Ra3.2to Ra6.3, and a tin impregnation layer is arranged on the surface of the nickel layer. The manufacturing method comprises the following steps of, cleaning the surface of the stainless steel pipe, polishing the stainless steel pipe, electroplating the nickel layer on the surface of the stainless steel pipe, carrying out annealing, treating the outer surface by using an acidic solution, treating the outer surface by using a tin impregnation solution, cleaning and airing to obtain the back pipe for casting the rotary target material. The rotary target material produced by the back tube has few impurities, has a small shielding effect on a magnetic field, and has a good sputtering effect.

Owner:JIANGYIN ENTRET COATING TECH

Welding rod contg. titanium dioxide series flux for CO2 gas arc welding

InactiveCN1191914CGood sputtering performanceImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsTitaniumTitanium oxide

Provided is a flux cored wire containing titanium oxides for CO2 gas shielded arc welding. The flux cored wire containing titanium oxides for CO2 gas shielded arc welding comprises C 0.03-0.07%, Mn 1.6-2.0%, Si 0.35-0.7%, Mg 0.5-1.1%, B 0.005-0.02%, Al 0.08-0.3%, Ni 0.7-2.0%, F 0.15-0.35%, titanium oxides 5.5-7.5%, 0.25% or less of at least two non-titanates selected from SiO2, Al2O3 and ZrO2, a balance of Fe and other inevitable impurities. The total content of titanate and non-titanate is controlled below 8.0%, based on the total weight of the flux cored wire. The provided flux cored wire containing titanium oxides for CO2 gas shielded arc welding has superior impact toughness at low thermal temperature and excellent all position welding.

Owner:HYUNDAI WELDING

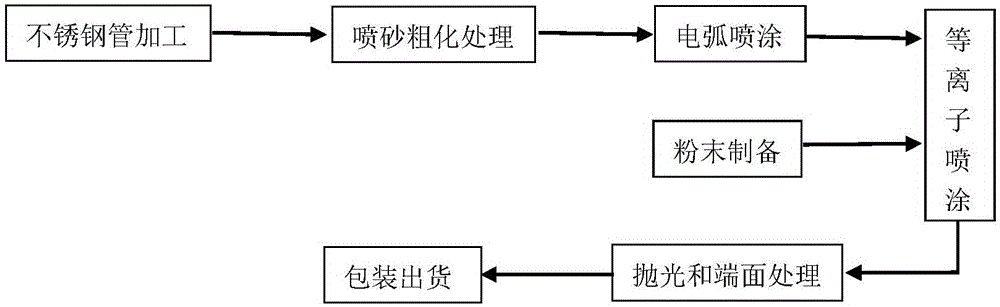

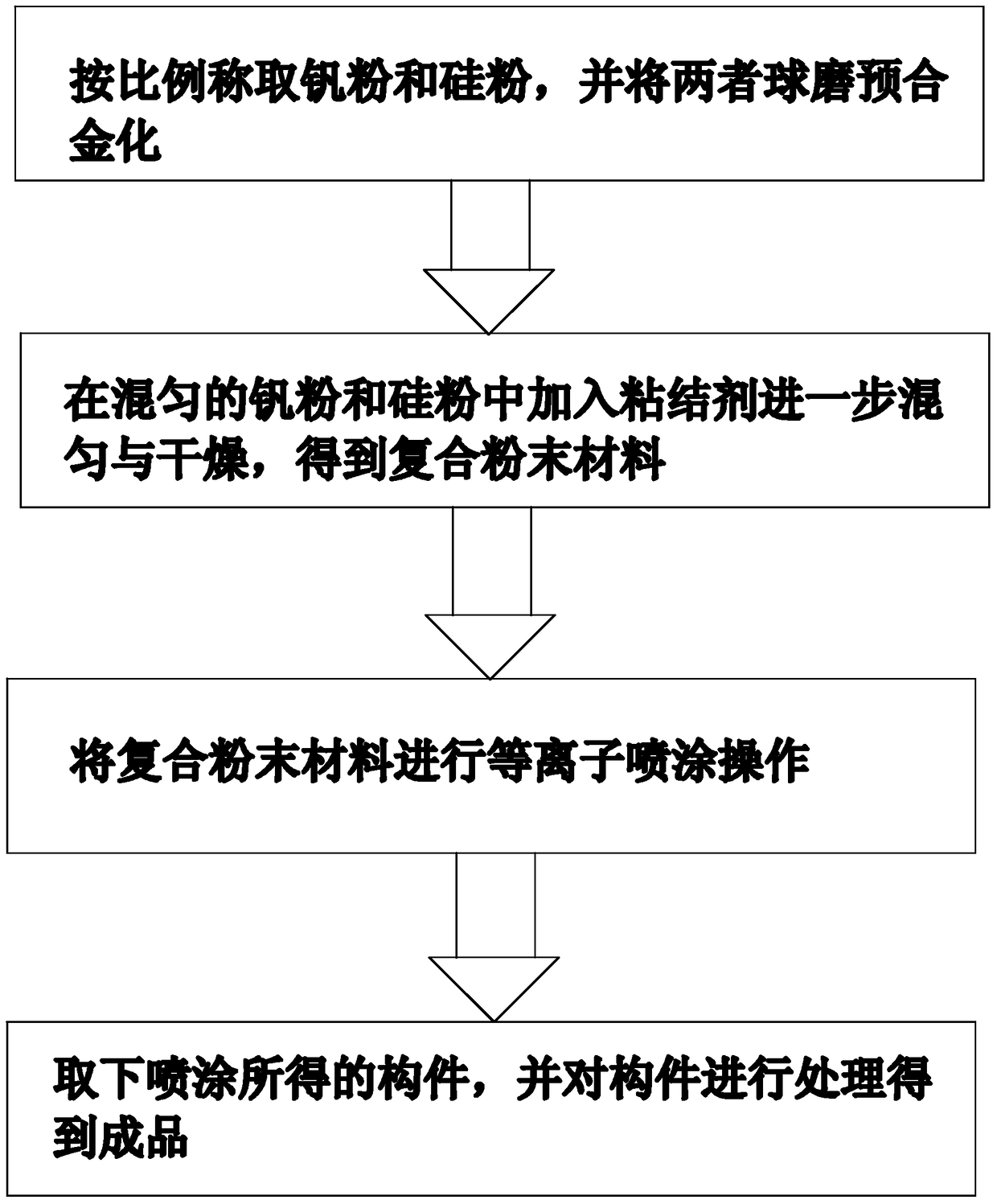

A kind of vanadium-silicon alloy target material and preparation method thereof

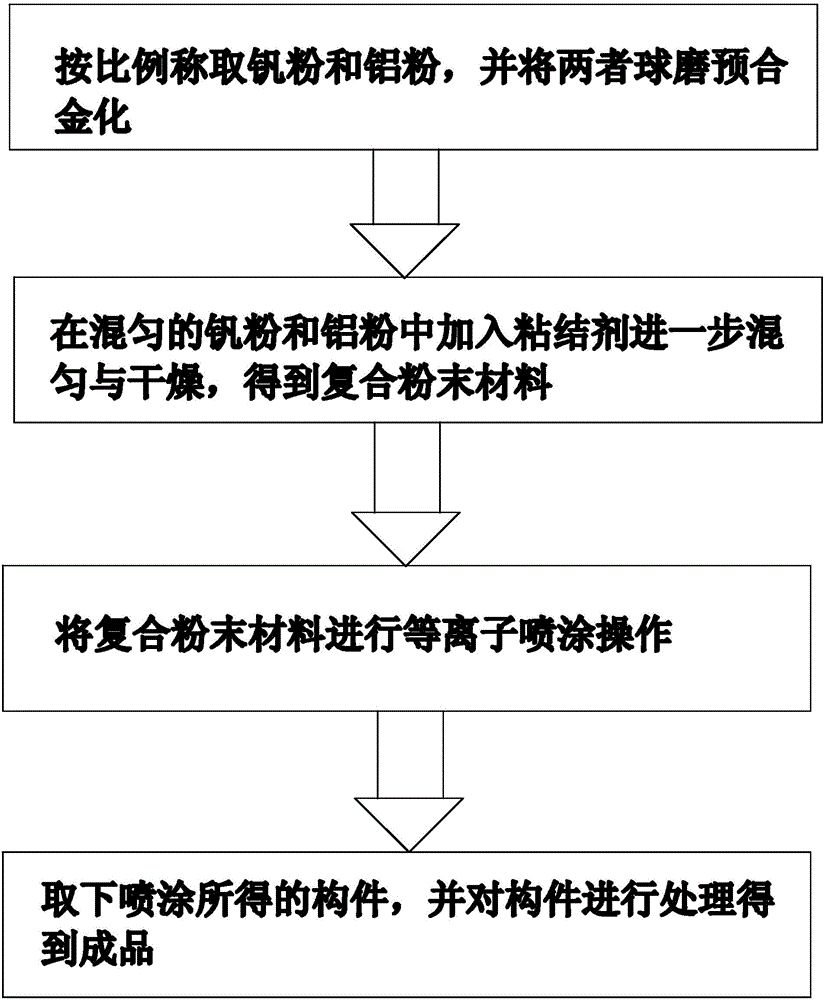

The invention provides a vanadium-silicon alloy target and a preparation method thereof. The target is made of vanadium powder, silicon powder and a binder, wherein the mass ratio of vanadium powder to silicon powder is 19:1-3:2 , the purity of the vanadium powder and silicon powder is greater than 99.5%. The preparation method comprises the following steps: weighing vanadium powder and silicon powder in proportion, and fully mixing the two; adding the mixed vanadium powder and silicon powder to a binder for further mixing, and processing to obtain dry vanadium silicon powder Composite powder material with binder; performing plasma spraying operation on the composite powder material in step (2); removing the sprayed component, and processing the component to obtain a finished product. The vanadium-silicon alloy target material of the invention has good uniformity and high stability. The preparation method of the invention adopts the plasma spraying method, which is simple and easy, does not need mold design and expensive pressing equipment, is convenient to operate, and the prepared target material has excellent sputtering performance and less impurities, and is suitable for optical coating.

Owner:深圳市威勒科技股份有限公司

Method for preparing compound diamond-like carbon coating by using medium-frequency magnetic-control glow discharge method

InactiveCN101701332BHigh hardnessImprove the lubrication effectVacuum evaporation coatingSputtering coatingDiamond-like carbonAlloy

The invention relates to a method for preparing a nano compound diamond-like carbon coating, which is realized in a way that: glow discharge is produced by using a medium-frequency magnetic-control sputtering target; argon and excessive hydrocarbon gases are introduced, so that the metal on the target surface reacts with the hydrocarbon gases to produce metallic carbides; when the argon ions bombard the target surface, the target surface sputters the metallic carbides; strong plasma produced by the glow discharge of the target surface ionize the hydrocarbon gases, so that the hydrocarbon gases produce highly-ionized carbon ions; and the carbides sputtered from the target surface and the highly-ionized carbon ions produced from the hydrocarbon gases form a high-hardness carbide-doped nano compound diamond-like carbon coating on a workpiece surface. The coating prepared by the invention has the characteristics of high hardness, strong adhesive force, high growth speed, high production efficiency, low depositing temperature, low production cost, simple equipment structure and the like; and diamond-like carbon coatings with different thicknesses can be prepared on hard alloy, high-speed steel and various other workpieces.

Owner:WUHAN UNIV

Magnetron sputtering apparatus manufactured by magnetic confinement magnetron sputtering method

InactiveCN101348897BMake a leapReduce internal stressVacuum evaporation coatingSputtering coatingTarget surfaceMagnetic poles

The invention relates to a magnetic confinement magnetron sputtering method and a magnetron sputtering device prepared by use of the same. As the prior art adopts a balanced magnetron sputtering mode and an unbalanced magnetron sputtering mode, the target material utilization rate can only be raised to be between 20 and 35 percent even if permanent magnet movement or the transformation of a plurality of electromagnetic coil sets is adopted, and the prior art has the problems of complex structure and high processing cost. The magnetic confinement magnetron sputtering method forms a magnetic confinement magnetic field with the overall direction parallel to a target surface above the surface of a sputtering target. The magnetron sputtering device manufactured by use of the method comprises amagnet, a magnetic conductor, a substrate and the sputtering target, wherein contrary magnetic poles of the magnet are oppositely fixed on the sides of the sputtering target; the magnetic confinementmagnetic field generated by the magnet is positioned between the substrate and the sputtering target, and a connecting line of the two magnetic poles is parallel to the target surface. The magnetron sputtering device can effectively overcome the problem that the prior art is low in target material utilization rate and deposition rate.

Owner:XIAN TECH UNIV

A back tube for casting a rotating target and its manufacturing method

ActiveCN112522754BLess impuritiesReduced shieldingVacuum evaporation coatingSputtering coatingSurface roughnessSS - Stainless steel

The invention relates to the technical field of the manufacture of rotating targets, in particular to a back pipe used for casting rotating targets. It includes a stainless steel tube, the outer part of the stainless steel tube is electroplated with a nickel layer, the thickness of the nickel layer is 0.005-0.1 mm, the surface roughness of the nickel layer is Ra3.2-Ra6.3, and the surface of the nickel layer has Tin layer. The production method is as follows: first, the surface of the stainless steel tube is cleaned, then polished, and then electroplated with a nickel layer on its surface, then annealed, then treated with an acid solution, and then treated with a tin infiltration solution. It is cleaned and dried to obtain the back tube for casting the rotating target. The rotating target produced by the back tube of the present invention has less impurities, less shielding effect on the magnetic field, and better sputtering effect.

Owner:JIANGYIN ENTRET COATING TECH

Vanadium-aluminum alloy target and preparation method thereof

InactiveCN104947051AImprove uniformityImprove stabilityMolten spray coatingVacuum evaporation coatingAlumPlasma sprayed

The invention provides a vanadium-aluminum alloy target and a preparation method thereof. The target consists of vanadium powder, aluminum powder and a binding agent, wherein the mass ratio of the vanadium powder to the aluminum powder is 19: 1-3: 2; and the purities of the vanadium powder and the aluminum powder are higher than 99.5%. The preparation method comprises the following steps: the vanadium powder and the aluminum powder are weighed out according to a certain proportion, and are fully and uniformly mixed; the binding agent is added in the vanadium powder and the aluminum powder for further uniform mixing to obtain a dry composite powder material of the vanadium and aluminum powders and the binding agent; the plasma spraying operation is performed for the composite powder material in the step (2); and a component obtained by spraying is taken down, and is treated to obtain a finished product. The vanadium-aluminum alloy target is excellent in uniformity and high in stability. The preparation method adopts the plasma spraying mode, is simple and feasible, needs no mold design or expensive pressing equipment, and is convenient to operate; and the prepared target is excellent in sputtering performance, few in impurities and suitable for optical film coating.

Owner:深圳市威勒科技股份有限公司

Target material manufacturing method

InactiveCN109666907AReduce stress buildupUpsetting thickness deformation rate is moderateVacuum evaporation coatingRoll mill control devicesForge

The invention relates to a target material manufacturing method which comprises the steps of providing a forge piece target material, wherein the forge piece target material comprises a sputtering surface; and adopting a calendaring process for calendaring the forge piece target material, enabling the calendaring thickness deformation rate of the forge piece target material in the direction perpendicular to the sputtering surface to be 40 percent to 60 percent, and forming a finished product target material, wherein the calendaring thickness deformation rate is a ratio between the thickness variation amount before and after calendaring and the thickness before calendaring. If the calendaring thickness deformation rate is small, the stress accumulation, along the direction perpendicular tothe sputtering surface, in the forge piece target material is small, so that (111) texture aggregation cannot be easily produced in the forge piece target material, the number of the (111) textures can be reduced, the sputtering rate of the formed finished product target material is improved, and the sputtering performance of the finished product target material is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Manufacturing method of tungsten-titanium target and manufacturing method of tungsten-titanium target combination

ActiveCN103691953BUniform microstructureGood sputtering performanceVacuum evaporation coatingSputtering coatingVolumetric Mass DensityTitanium powder

The invention discloses a manufacturing method of a tungsten-titanium target material and a manufacturing method of a tungsten-titanium combination. The manufacturing method of the tungsten-titanium target material comprises the following steps: filling mixed powder of tungsten powders and titanium powder into a mold; performing cold press molding on the mixed powder to form a tungsten-titanium target material blank; performing vacuum hot pressing sintering on the tungsten-titanium target material blank to form a tungsten-titanium target material. According to the manufacturing method of the tungsten-titanium target material disclosed by the invention, cold press molding treatment and vacuum hot pressing sintering are performed and relevant process parameters are set, so that the density of the prepared tungsten-titanium target material is more than or equal to 99 percent, and the obtained tungsten-titanium target material has a uniform microstructure and superior splashing usability. Meanwhile, the manufacturing methods disclosed by the invention have the advantages of less process steps and high production speed.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

A kind of indium tin alloy target and preparation method thereof

ActiveCN111809152BHigh puritySmall granularityVacuum evaporation coatingFoundry mouldsIndiumCrucible

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

A kind of preparation method of vanadium-tungsten alloy target blank

ActiveCN112760538BGood sputtering performanceAvoid phenomena such as abnormal dischargeVacuum evaporation coatingSputtering coatingVanadium atomAbnormal discharge

The invention relates to a method for preparing a vanadium-tungsten alloy target blank. The vanadium-tungsten alloy target blank includes: 11-19% W in terms of mass percentage, and the balance is vanadium; the preparation method includes the following steps: (1 ) mixing vanadium powder and tungsten powder according to the formula, and then putting them into a mould; (2) putting them into a furnace and evacuating, and then performing hot-press sintering to obtain the vanadium-tungsten alloy target blank. The preparation method provided by the present invention realizes the preparation of a vanadium-tungsten alloy target blank with a density ≥ 98.79% by redesigning the proportion of vanadium and tungsten in the target blank and using a specific sintering process. The target material prepared by using the target blank When sputtering, it has excellent sputtering performance, and abnormal discharge can be avoided during the sputtering process.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com