Sputtering target capable of enhancing wear resistance and corrosion resistance of coated glass and manufacturing method

A technology of coated glass and sputtering target material, which is applied in the direction of chemical instruments and methods, sputtering coating, glass/slag layered products, etc., can solve the problems of lack of reference and enlightenment, and achieve uniform composition, stable arc light, and good Effect of Sputtering Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

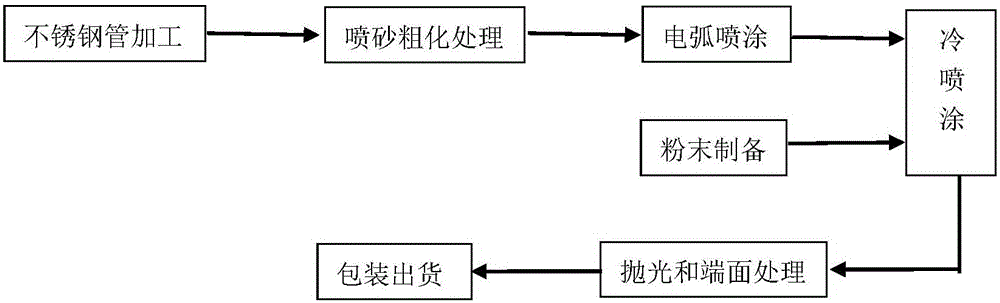

[0030] Embodiment 1: Prepare rotating target by cold spraying, as attached figure 1 As shown, the end face of the stainless steel pipe with an inner diameter (50-130) mm and an outer diameter (60-140) mm is processed into a spiral groove, a straight groove, a thread shape or a welded flange shape according to the drawing, and the middle part of the steel pipe is sprayed. Sand is used for surface roughening treatment, followed by an electric arc for a bonding layer, and then loaded into cold spray equipment; use granulated and agglomerated wear-resistant and weather-resistant powder, and the powder particle size is (1-80) um. The powder is fed into the cold spray gun by the powder feeder and sprayed on the surface of the stainless steel pipe. The spraying of the target can be completed by two methods: spray gun movement or workpiece movement. It can be made into a dog-bone rotating target with adjustable length and thickness at both ends. After the spraying is finished, the su...

Embodiment 2

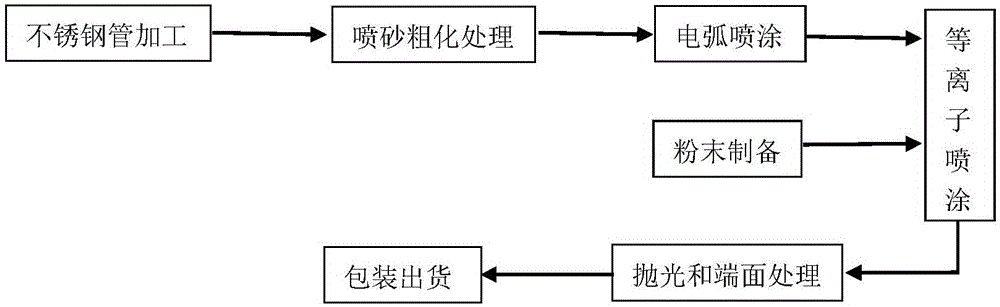

[0032] Embodiment 2: plasma spraying prepares rotating target material, as attached figure 2 As shown, the end face of the stainless steel pipe with an inner diameter (50-130) mm and an outer diameter (60-140) mm is processed into a spiral groove, a straight groove, a thread shape or a welded flange shape according to the drawing, and the middle part of the steel pipe is sandblasted. The surface is roughened, and then a layer of bonding layer is arced, and then loaded into the auxiliary plasma spraying equipment, using granulated and agglomerated wear-resistant and weather-resistant powder, the powder particle size is (1-80) um. The powder is fed into the plasma spray gun through the powder feeder to spray on the surface of the stainless steel pipe. The spraying of the target can be completed by two methods: spray gun movement or workpiece movement. It can be made into a dog-bone rotating target with adjustable length and thickness at both ends. After the spraying is finishe...

Embodiment 3

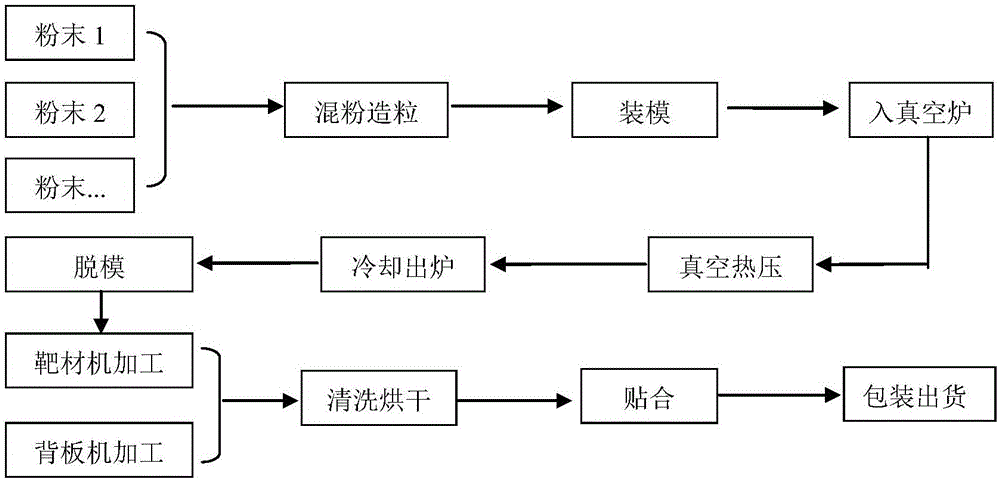

[0034] Embodiment 3: Powder metallurgy method prepares planar target material, as attached image 3 As shown, the powder composition is detected by ICP, and the purity is above 99.5%; the particle size and particle size distribution of the powder are detected by a Coulter particle size analyzer. After the test is passed, the powder is weighed, sieved, weighed and mixed with powder, and granulated. Then put the mixed powder into the mold. Put them together into a vacuum hot-press furnace, vacuumize, heat, and press at a high temperature under a pressure of (10-100) MPa to form a block. Hot pressing temperature (1400-1600) ℃, holding time (20-30) h. After the vacuum hot pressing is completed, lower the temperature to below 100°C, open the hot pressing furnace, take out the mold and target block, lower it to below 50°C, take out the target block from the mold, cut, grind, clean, and dry to make the required target size. If the size of the prepared target block does not meet th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com