Preparation method for alloy target material and alloy target material prepared by preparation method

A technology of alloy target and target material, applied in the field of target material, can solve the problems of poor ratio precision and uneven mixing of alloy target material, and achieve the effects of improving precision, improving production efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

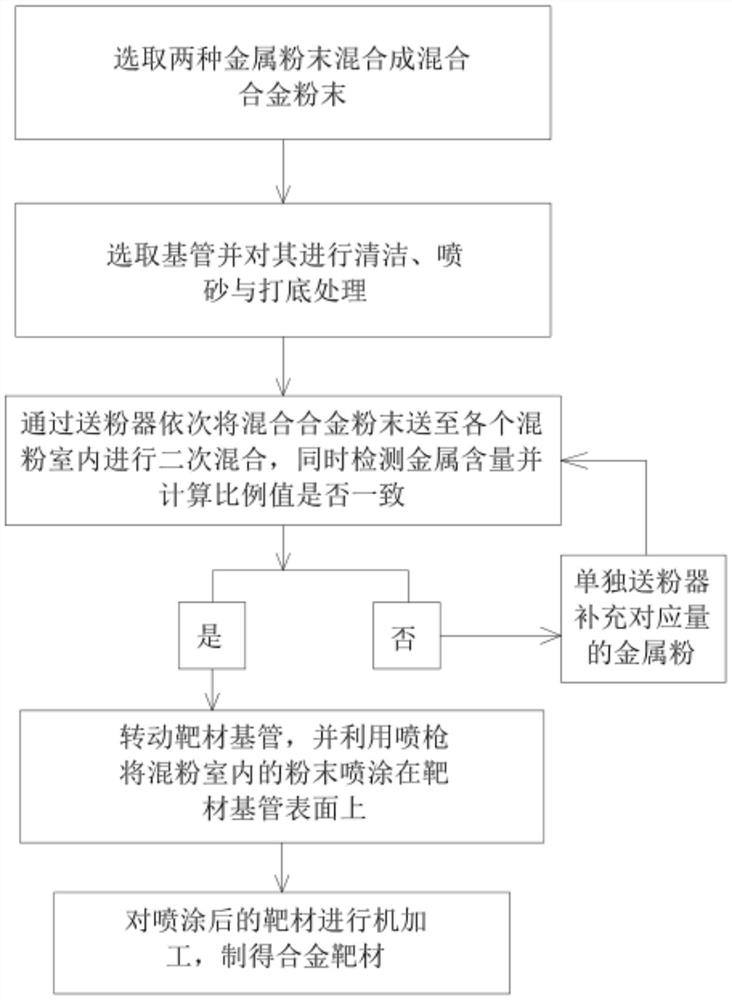

[0030] Example 1: A method for preparing an alloy target, such as figure 1 shown, including the following steps:

[0031] S1. Preparation of alloy powder: choose not less than two kinds of metal powders and mix them into mixed alloy powders according to the required ratio and put them in the powder mixing box; in this embodiment, two metal powders of titanium and molybdenum are used for mixing, and the powders are required to be mixed. Strength of D50 is 15μm ~ 45μm, purity ≥ 99.5%;

[0032] S2. Prepare the base tube: select a non-magnetic stainless steel tube of suitable size as the base tube of the target material, and perform machining, and clean, sandblast, and prime the surface of the steel tube base; the sandblasting process uses cast steel grit ;

[0033] S3. Send the powder mixing box to the spraying gun through the powder feeder, and carry out secondary mixing and stirring in the spraying gun, so that the ratio of the alloy powder in the spraying gun is consistent w...

Embodiment 2

[0040] Embodiment 2: This embodiment is to provide an alloy target, which is prepared by the preparation method in Embodiment 1, including the first metal and the second metal, and the content of the first metal is 70%-90% atomic percentage, and the remaining The amount is the second metal and unavoidable impurities. The oxygen content of the target impurity is less than 100ppm, and the relative density is greater than 99%. The first metal is silicon, and the second metal is aluminum. The ratio of the first metal to the second metal is 70: 30. Therefore, after being prepared according to the preparation method of Example 1, the ratio error of the first metal and the second metal in the alloy target is small, the uniformity is good, the stability is improved, and the sputtering effect is good.

Embodiment 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the first metal is selected from silicon, and the second metal is selected from aluminum, wherein the ratio of the first metal to the second metal is 90:10, so that according to the preparation method of Embodiment 1 After being obtained, the proportion error of the first metal and the second metal in the alloy target is small, the uniformity is good, the stability is improved, and the sputtering effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com