A back tube for casting a rotating target and its manufacturing method

A technology of rotating target and back tube, which is used in the improvement of process efficiency, metal material coating process, solid-state diffusion coating, etc., can solve the problem that the content of nickel and aluminum in the target exceeds the standard, the bonding strength is high, and the surface wetting time is long. and other problems, to achieve the effect of less target impurities, small shielding effect and high sputtering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

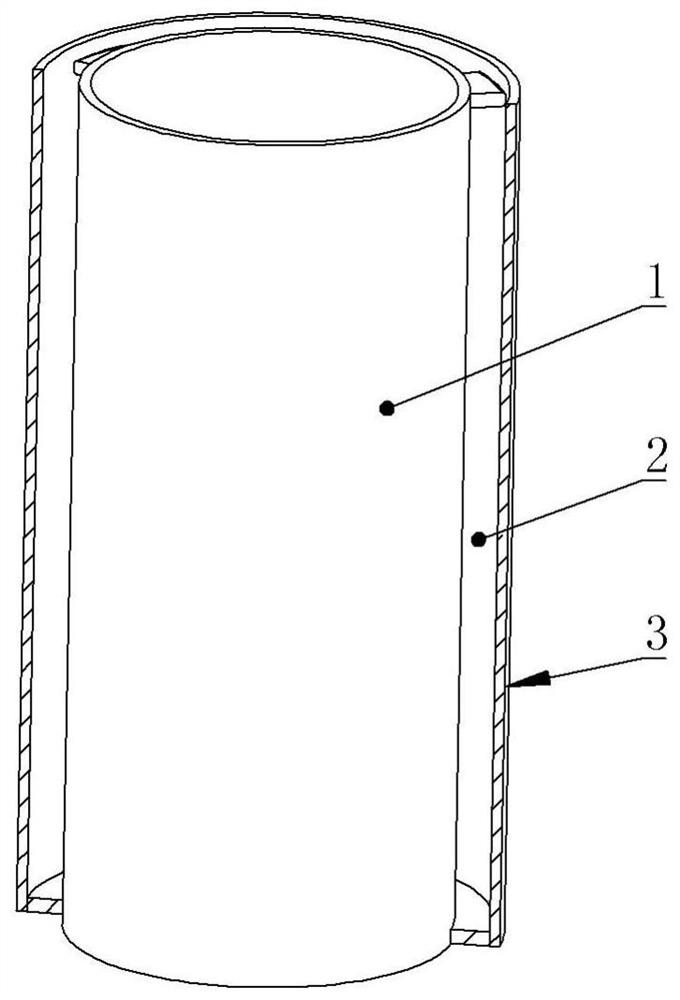

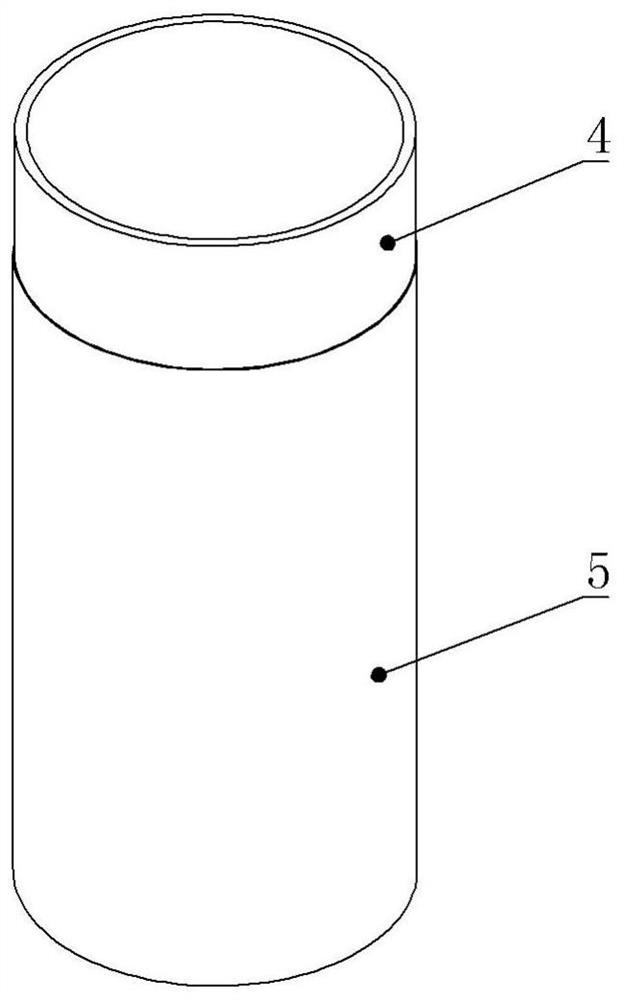

[0027] A back tube for casting a rotating target, comprising a stainless steel tube 4, the stainless steel tube 4 is plated with a nickel layer 5 outside, the thickness of the nickel layer 5 is 0.005 mm, and the surface roughness of the nickel layer 5 is Ra3.2~Ra6.3, the surface of the nickel layer 5 has a tin infiltration layer. The grade of the stainless steel pipe is 304, 304L, 316 or 316L.

[0028] The production method of the back tube for casting a rotating target, the steps of which are:

[0029] a. Clean the outer surface of the stainless steel tube to remove dust and oil, and then polish the outer surface with P120 abrasive belt to make the outer surface roughness Ra3.2~Ra6.3. In order to improve the grinding efficiency, a sander equipped with a P120 annular abrasive belt can be used for grinding.

[0030] b. Put the stainless steel tube obtained in step a into an electroplating tank for nickel electroplating, so that the outer surface of the stainless steel tube is...

Embodiment 2

[0039] This example is basically the same as Example 1, except that in step f of the production method, the tin infiltration solution is applied to the outer surface of the stainless steel tube obtained in step e and the holding time is 80 minutes. At this time, the tin infiltration time is longer, and the area occupied by the tin layer on the surface of the nickel layer becomes larger, reaching more than 40%, and some parts are even connected into pieces, and the thickness of the tin layer is less than 0.002 mm.

[0040] When the back tube of this embodiment is used for target production, the total amount of nickel and tin infiltrated into the target material accounts for less than 0.009% by weight of the target material. However, due to the large proportion of the tin layer, the wetting time is more than 70% shorter than that of the tin-free layer.

Embodiment 3

[0042] A back tube for casting a rotating target material, comprising a stainless steel tube 4, the outside of the stainless steel tube 4 is electroplated with a nickel layer 5, the thickness of the nickel layer 5 is 0.02 mm, and the surface roughness of the nickel layer 5 is Ra3.2~Ra6.3, the surface of the nickel layer 5 has a tin infiltration layer. The grade of the stainless steel pipe is 304, 304L, 316 or 316L.

[0043] The production method and steps of the back tube used for casting the rotating target in this embodiment are the same as those in Embodiment 1.

[0044] Using the back tube of this embodiment to produce the target, under other conditions being the same, has a higher purity than the back tube of the prior art. In addition, since the thickness of the nickel layer is 0.02 mm, it is still very thin compared with the 0.5 mm nickel-aluminum layer by arc spraying in the prior art, the shielding effect on the magnetic field is small, and the sputtering effect is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com