Preparation method and application of tungsten sputtering target blank

A sputtering target and blank technology, applied in the field of sputtering targets, can solve the problems of low chip yield, unstable sputtering rate, high film resistivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the tungsten sputtering target blank of the present embodiment comprises:

[0035] Atmospheric pressure chemical vapor deposition process: WF with electronic grade 99.9995% purity 6 As raw material, 99.9995% pure H 2 As the raw material, red copper is used as the substrate, the deposition temperature is 580°C, and the deposition rate is 0.4mm / h, to obtain a tungsten slab with a length of 380mm, a width of 190mm, and a thickness of 35mm, with a purity of 8N and a density of 19.18g / cm 3 ;

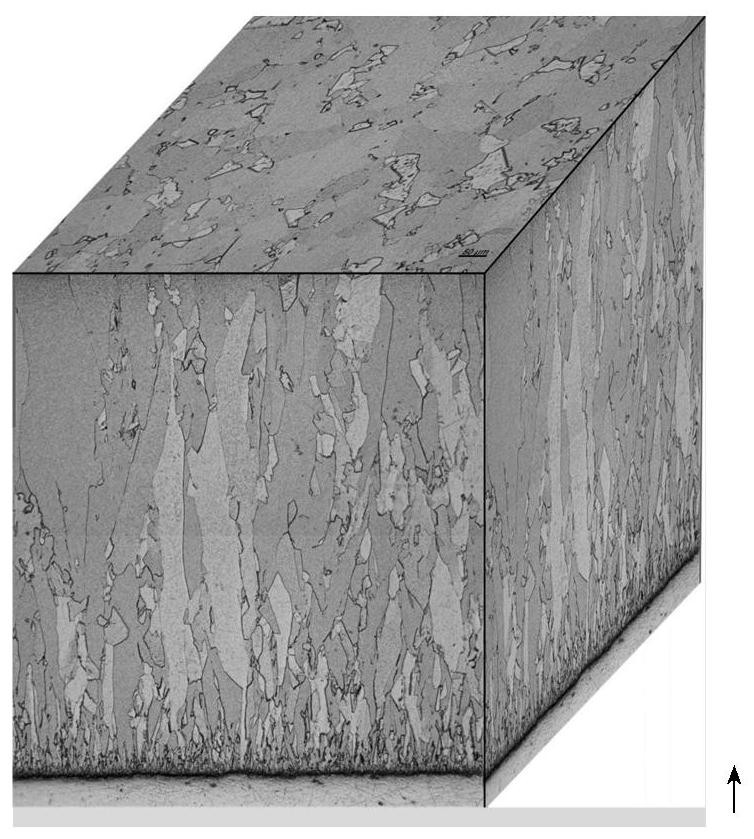

[0036] Heat preservation and cross rolling process: hydrogen furnace heat preservation at 1600°C for 40 minutes, enter the rolling mill along the length direction, first pass, reduction 30%, heat preservation at 1570°C for 30 minutes, second pass, reduction 30%, heat preservation at 1570°C 20 minutes, the rolling direction is turned 90°, the third pass, the reduction is 30%, and the temperature is kept at 1570°C for 10 minutes, the fourth pass, the reduction...

Embodiment 2

[0040] The preparation method of the tungsten sputtering target blank of the present embodiment comprises:

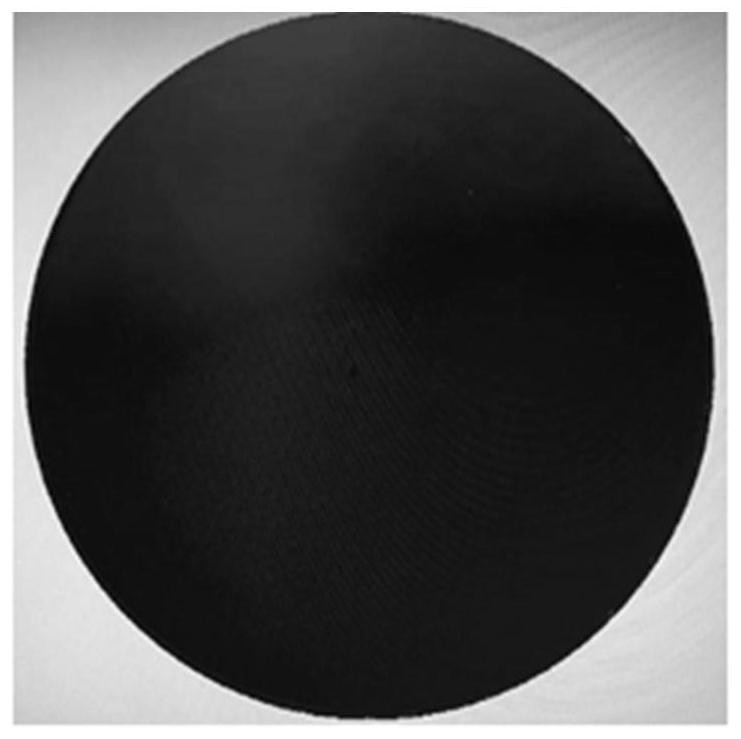

[0041] Atmospheric pressure chemical vapor deposition process: WF with electronic grade 99.9995% purity 6 As raw material, 99.9995% pure H 2 As the raw material, red copper is used as the substrate, the deposition temperature is 550°C, and the deposition rate is 0.3mm / h. A tungsten slab with a length and width of 240mm and a thickness of 35mm is obtained, with a purity of 8N and a density of 19.21g / cm 3 ;

[0042]Heat preservation and cross rolling process: hydrogen furnace heat preservation at 1580°C for 40 minutes, enter the rolling mill along the length direction, first pass, reduction 30%, heat preservation at 1580°C for 30 minutes, second pass, reduction 30%, heat preservation at 1580°C 20 minutes, the rolling direction is turned 90°, the third pass, the reduction is 30%, and the temperature is kept at 1580°C for 10 minutes, the fourth pass, the reduction is 30%,...

Embodiment 3

[0046] The difference between the preparation method of the tungsten sputtering target blank of this embodiment and that of Embodiment 1 is that the rolling process is different. Specifically, the rolling process of this embodiment includes: a hydrogen furnace at 1600 ° C for 40 minutes, entering the rolling mill along the length direction, The first pass, the reduction is 30%, 1570°C for 30min, the second pass, the reduction is 20%, 1570°C for 20min, the third pass, the reduction is 10%, 1570°C for 10min, the 4th pass Pass times, the reduction amount is 10%.

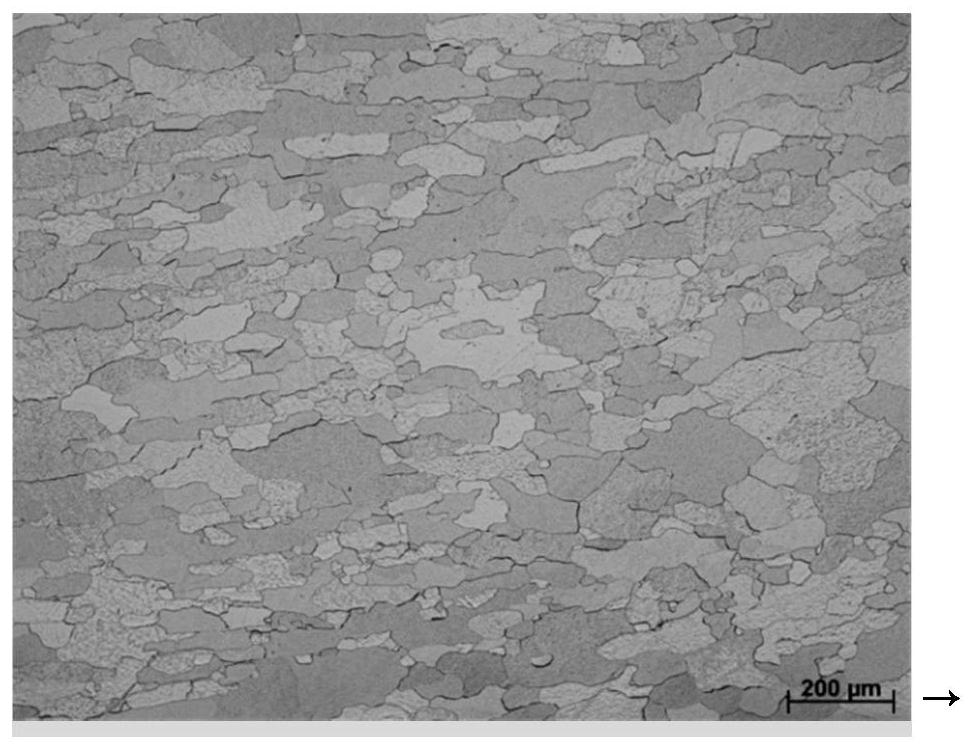

[0047] see figure 2 and Figure 5 ,and Figure 6 , compared with Example 1, the microstructure uniformity of the tungsten sputtering target blank prepared in this example is significantly poorer, and the mechanical properties are also significantly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com