A kind of preparation method of vanadium-tungsten alloy target blank

A technology of alloy target and vanadium tungsten, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of complex preparation process and poor density, and achieve the goal of avoiding abnormal discharge and excellent sputtering performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

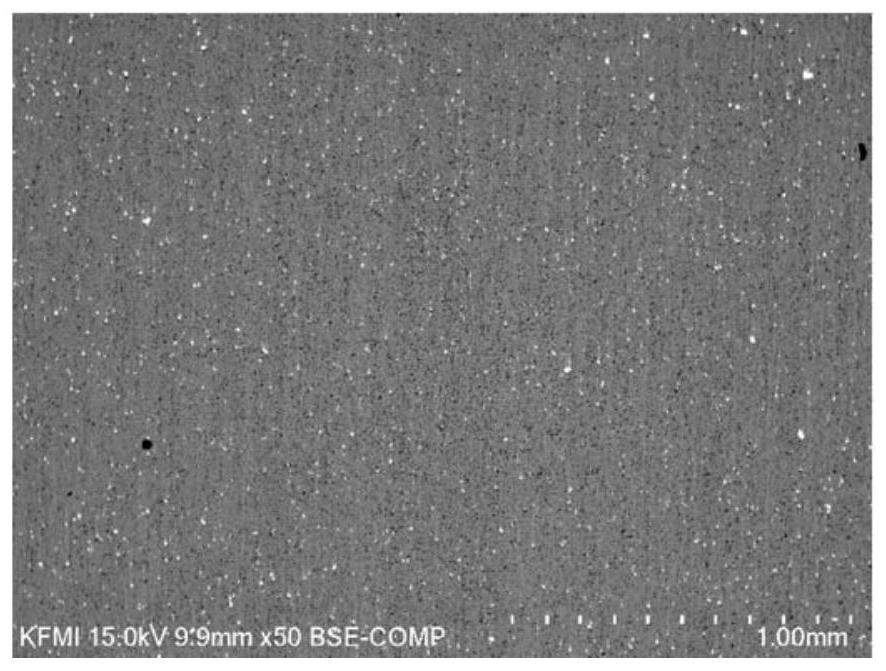

Embodiment 1

[0040] The invention provides a method for preparing a vanadium-tungsten alloy target blank, wherein the vanadium-tungsten alloy target blank includes: 11% W, and the balance is vanadium;

[0041] Described preparation method comprises the steps:

[0042] (1) Mix vanadium powder and tungsten powder according to the formula, and then put them into the mold;

[0043] (2) putting it into a furnace and vacuuming it, and then performing hot pressing and sintering to obtain the vanadium-tungsten alloy target blank.

[0044] The mixing method in step (1) is dry mixing, and the mass ratio of zirconia balls and powder in the mixing is 1:10; the mixing time is 24h; the particle size of the vanadium powder is <74 μm; the The particle size of the tungsten powder is 2-2.5 μm;

[0045] The end point of the vacuum described in step (2) is evacuated to an absolute vacuum of 40Pa; the hot press sintering includes heating up to a constant temperature at 12°C / min and keeping it warm, and then ...

Embodiment 2

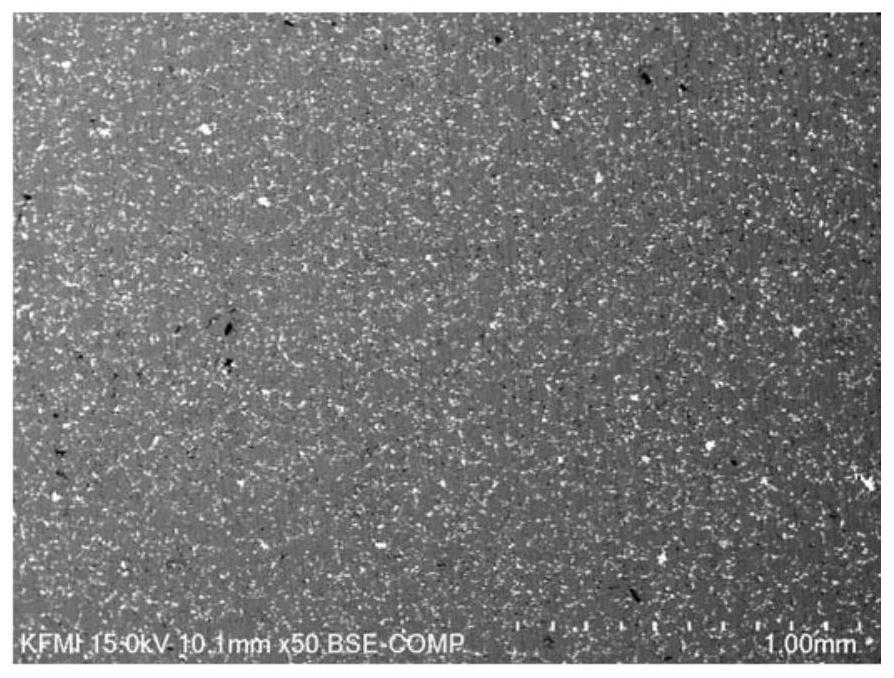

[0048] The invention provides a method for preparing a vanadium-tungsten alloy target blank, wherein the vanadium-tungsten alloy target blank includes: 19% W, and the balance is vanadium;

[0049] Described preparation method comprises the steps:

[0050] (1) Mix vanadium powder and tungsten powder according to the formula, and then put them into the mold;

[0051] (2) putting it into a furnace and vacuuming it, and then performing hot pressing and sintering to obtain the vanadium-tungsten alloy target blank.

[0052] The mixing method in step (1) is dry mixing, the mass ratio of zirconia balls and powder in the mixing is 2:10; the mixing time is 25h; the particle size of the vanadium powder is <55 μm; the The particle size of the tungsten powder is 2.7-3 μm;

[0053] The end point of the vacuum described in step (2) is evacuated to an absolute vacuum of 20Pa; the hot pressing sintering includes heating to a constant temperature at 10°C / min and keeping it warm, and then heat...

Embodiment 3

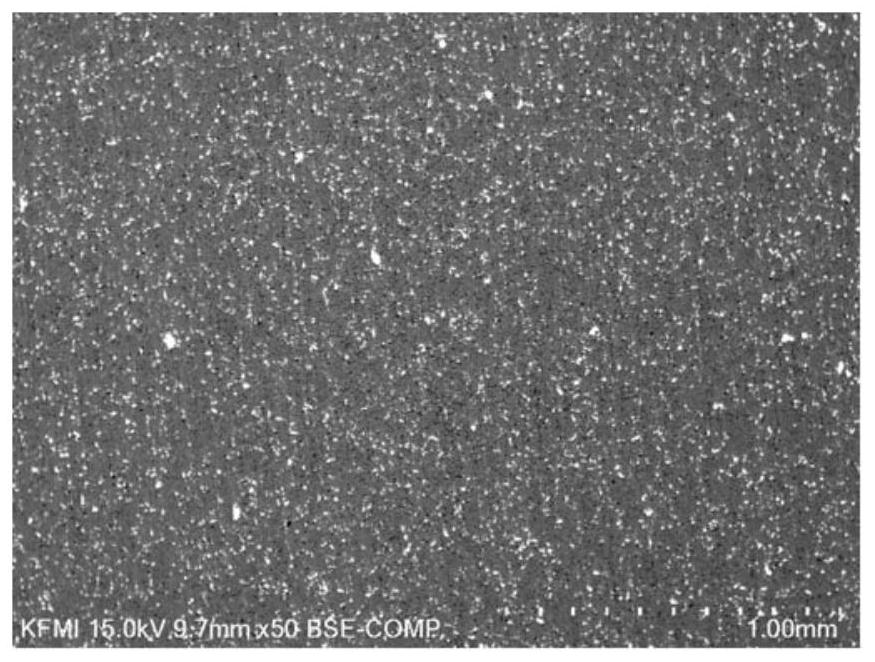

[0056] The invention provides a method for preparing a vanadium-tungsten alloy target blank, wherein the vanadium-tungsten alloy target blank includes: 15% W, and the balance is vanadium;

[0057] Described preparation method comprises the steps:

[0058] (1) Mix vanadium powder and tungsten powder according to the formula, and then put them into the mold;

[0059] (2) putting it into a furnace and vacuuming it, and then performing hot pressing and sintering to obtain the vanadium-tungsten alloy target blank.

[0060] The mixing method in step (1) is dry mixing, and the mass ratio of zirconia balls and powder in the mixing is 1.2:10; the mixing time is 26h; the particle size of the vanadium powder is <35 μm; the The particle size of the tungsten powder is 2.5-3 μm;

[0061] The end point of the vacuum described in step (2) is evacuated to an absolute vacuum of 10 Pa; the hot press sintering includes heating up to a constant temperature at 15°C / min and keeping it warm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com