A kind of indium tin alloy target and preparation method thereof

An indium tin alloy and target technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve problems such as adverse effects on film properties, and achieve high target blank purity, good sputtering effect, and uniform composition. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An indium tin alloy target, the specification of which is 1600mm×200mm×10mm, and the preparation method is as follows:

[0035] (1) According to the mass ratio of indium ingot:tin ingot=4:1, put indium ingot and tin ingot with a purity of 4N into a stainless steel crucible with a ratio of opening diameter to height of 0.5, heat and melt at 185°C, and use electromagnetic Stir for more than 5 minutes until the melt composition is uniform;

[0036] (2) Heat the square mold made of stainless steel at 80°C (80-85°C is acceptable), then spray boron nitride release agent on the inner wall of the square mold uniformly, and inject the melt obtained in step (1) into the square mold , demoulding after cooling and forming to obtain an ingot of indium tin alloy with a thickness of 42 mm;

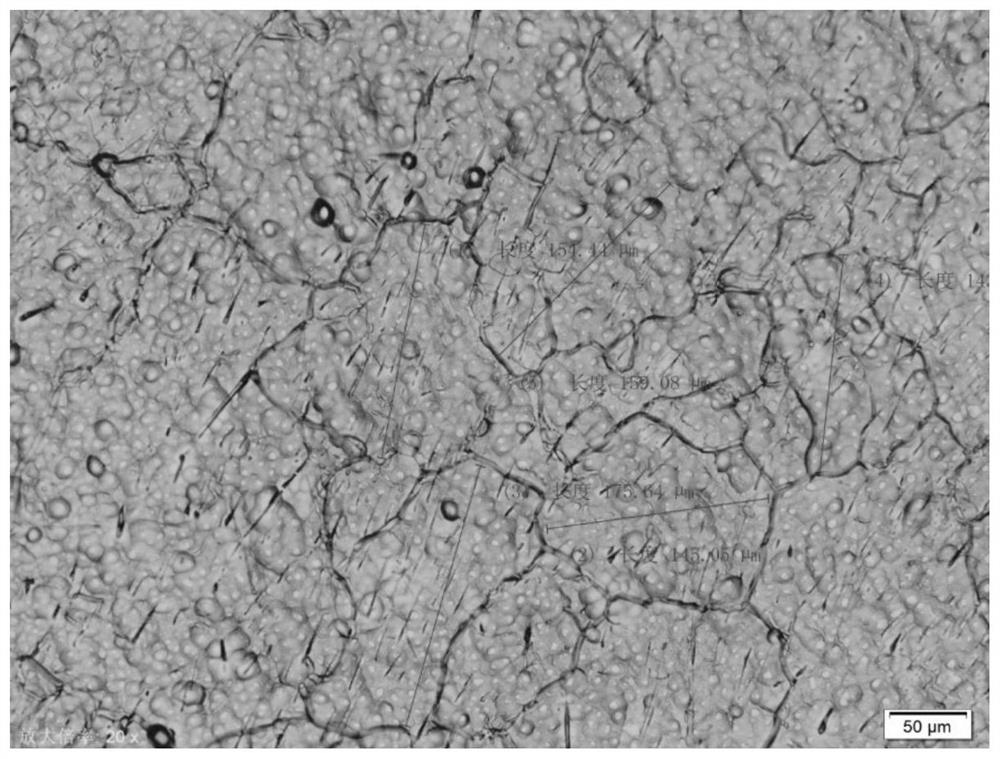

[0037] (3) rolling the indium tin alloy ingot obtained in step (2) with a 150-ton cold and hot reversing rolling mill to a thickness deformation of 20% to obtain an indium tin alloy billet;

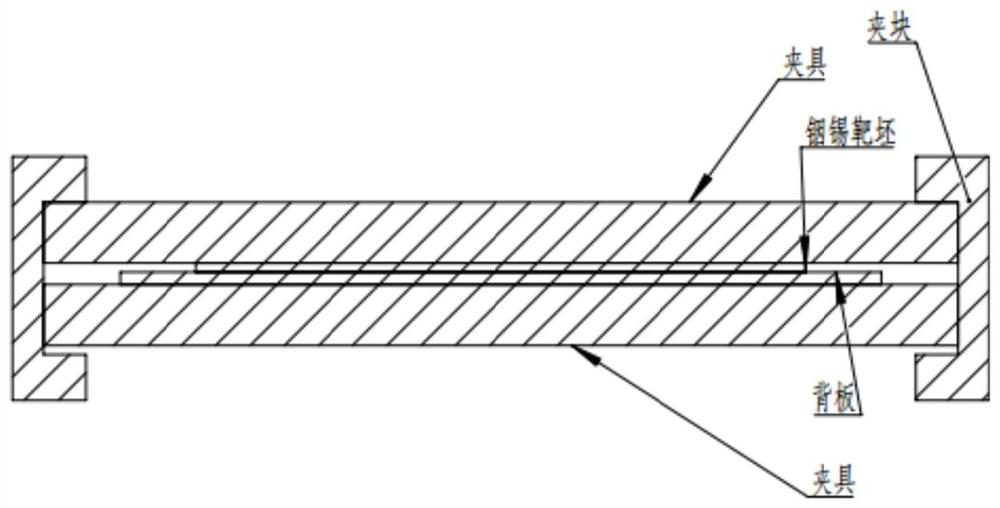

[0...

Embodiment 2

[0041]An indium tin alloy target material, its specification is 1600mm×200mm×10mm, and its preparation method is as follows:

[0042] (1) According to the mass ratio of indium ingot:tin ingot=4:1, put indium ingot and tin ingot with a purity of 4N into a stainless steel crucible with a ratio of opening diameter to height of 0.5, heat and melt at 150°C, and use electromagnetic Stir for more than 5 minutes until the melt composition is uniform;

[0043] (2) heating a square mold made of stainless steel at 80°C, then uniformly spraying boron nitride mold release agent on the inner wall of the square mold, injecting the melt obtained in step (1) into the square mold, cooling and forming, and releasing the mold to obtain Ingot of indium-tin alloy with a thickness of 42mm;

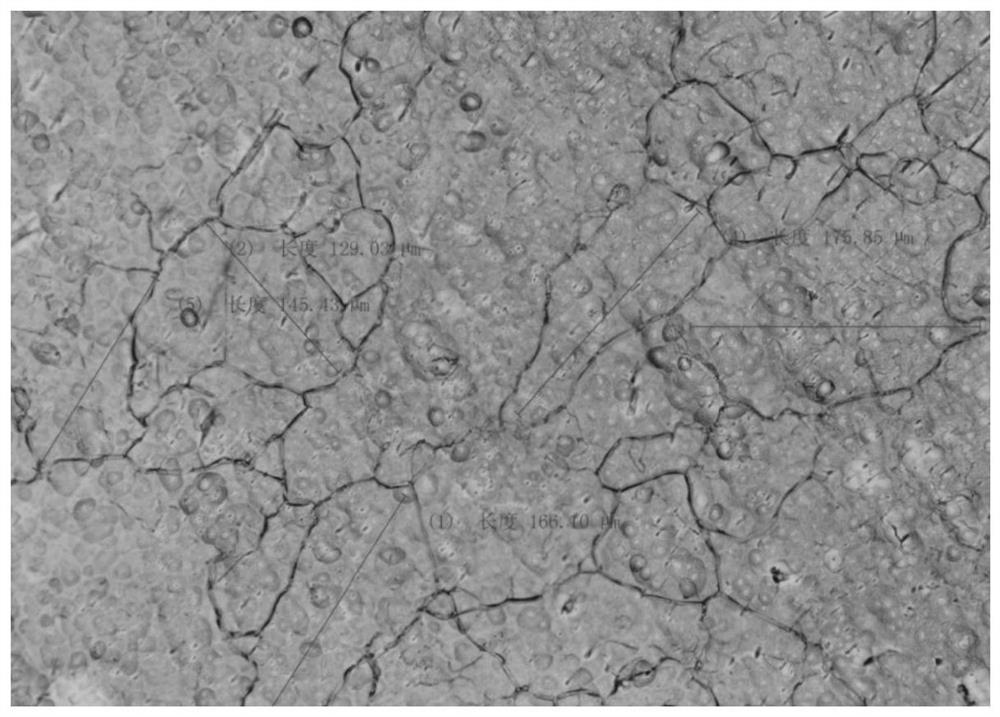

[0044] (3) rolling the indium tin alloy ingot obtained in step (2) with a 150-ton hot and cold reversing rolling mill to a thickness deformation of 20% to obtain an indium tin alloy billet;

[0045] (4) Machin...

Embodiment 3

[0048] An indium tin alloy target material, its specification is 1600mm×200mm×10mm, and its preparation method is as follows:

[0049] (1) According to the mass ratio of indium ingot:tin ingot=4:1, put indium ingot and tin ingot with a purity of 4N into a stainless steel crucible with a ratio of opening diameter to height of 0.5, heat and melt at 250°C, and use electromagnetic Stir for more than 5 minutes until the melt composition is uniform;

[0050] (2) heating a square mold made of stainless steel at 80°C, then uniformly spraying boron nitride mold release agent on the inner wall of the square mold, injecting the melt obtained in step (1) into the square mold, cooling and forming, and releasing the mold to obtain Ingot of indium-tin alloy with a thickness of 42mm;

[0051] (3) rolling the indium tin alloy ingot obtained in step (2) with a 150-ton hot and cold reversing rolling mill to a thickness deformation of 20% to obtain an indium tin alloy billet;

[0052] (4) Machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com