Manufacturing method of tungsten-titanium target material and manufacturing method of tungsten-titanium target material combination

A technology of tungsten-titanium target material and manufacturing method, which is applied in the field of sputtering target material, can solve the problems of tungsten-titanium target material being unreachable, high hardness value of tungsten-titanium target material, and prone to cracks, etc., and achieve fast production speed and excellent Effects of sputtering performance and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

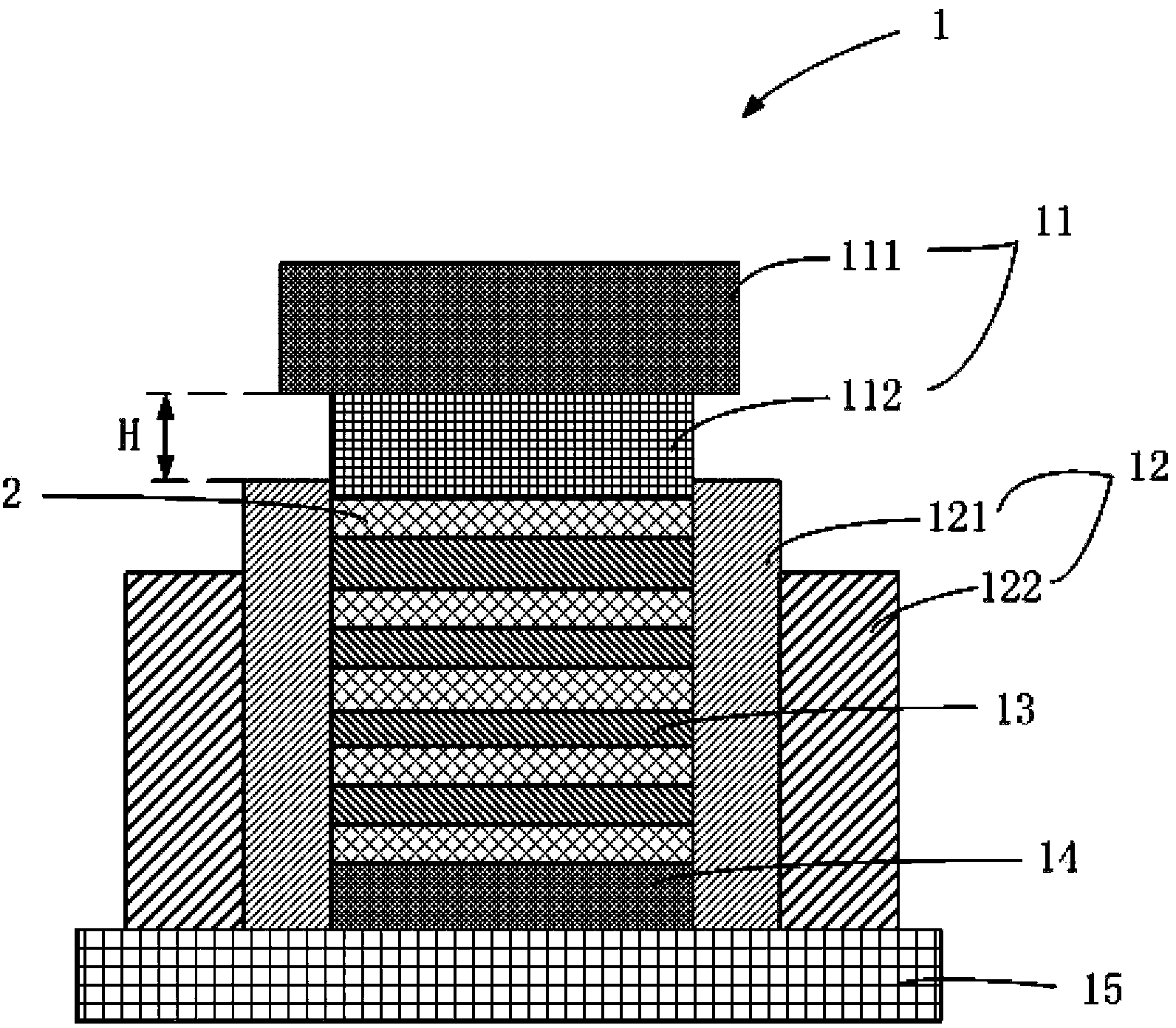

Image

Examples

Embodiment Construction

[0029] The invention discloses a method for manufacturing a tungsten-titanium target material. A mixed powder of tungsten powder and titanium powder is loaded into a mold, and then the mixed powder is subjected to cold-press forming treatment to form a tungsten-titanium target material blank, and then The tungsten-titanium target blank is vacuum hot-pressed and sintered to form a tungsten-titanium target. Wherein, the vacuum hot-press sintering treatment includes: evacuating the vacuum hot-press furnace to an absolute pressure below 100 Pa, raising the temperature to 900-1100°C at a heating rate of 5°C / min-10°C / min, and holding the temperature for 60-90min. Then fill in an inert gas until the relative pressure of the vacuum hot pressing furnace is -0.08MPa~-0.06MPa. Finally, pressurize to the maximum pressure at a pressurization rate of 0.1MPa / min~0.4MPa / min, and raise the temperature to the highest temperature at a heating rate of 5°C / min~10°C / min, and the maximum temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com