Hot-pressing technology for preparing boride sputtering target material

A technology of sputtering targets and hot-pressing technology, which is applied in the field of preparing boride sputtering targets by hot-pressing technology, can solve the problems of high raw material cost of boride powder, unstable target performance, difficult sintering and densification, etc., and achieves Good sputtering performance, simple preparation method, high relative density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

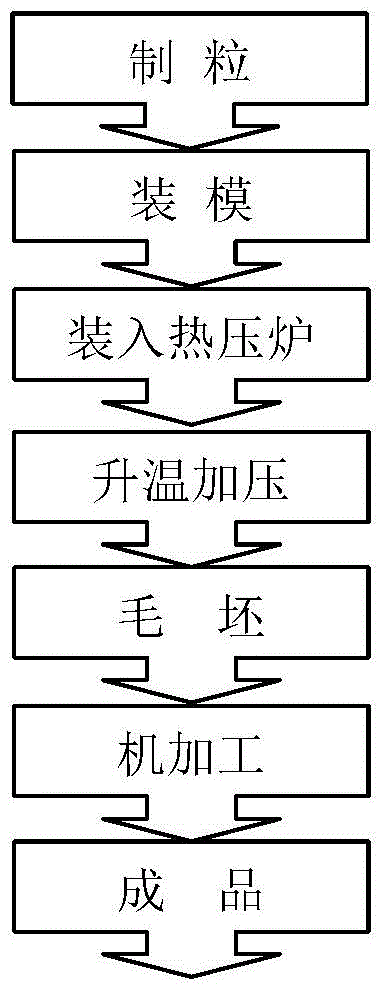

[0021] The process steps of the preparation method of the boride sputtering target material prepared by the hot pressing process in the present invention are as follows: granulation, mold loading, loading into a hot pressing furnace, heating and pressing, blank, machining, and finished product; specifically, the following steps are included:

[0022] ⑦ Granulation: After the boride powder with purity ≥ 99.9% and particle size ≤ 5 μm has passed the quality inspection, use granulation equipment to make the powder into boride particles with a diameter of 1-3 mm;

[0023] ⑧Mould loading: install the high temperature resistant graphite mold on the mechanical equipment, fill the boride particles into the graphite mold, and use the mechanical device to vibrate;

[0024] ⑨ Furnace loading: Remove the graphite mold filled with boride particles and vibrated from the mechanical equipment and put it into a vacuum hot-press furnace;

[0025] ⑩Heating and pressurization: heat up and pressur...

Embodiment 1

[0029] Embodiment 1: as attached figure 1 As shown, TiB with a purity of 99.95% and a particle size of 4 μm 2 powder, after passing the quality inspection, use granulation equipment to granulate TiB 2 Powder made of TiB with a diameter of 2mm 2 Particles; the high temperature resistant graphite mold is installed on the mechanical equipment, and the TiB 2 Fill the particles into the graphite mold, the size of the graphite mold is 106×96×220mm, the size of the mold pressure head is 104×94×220mm, and use mechanical device to vibrate; the TiB will be filled 2 The particle and vibrated graphite mold is removed from the mechanical equipment and put into the vacuum hot-press furnace; the vacuum hot-press furnace is heated and pressurized, and the maximum temperature is set to 2000°C. When the temperature is 0-1500°C, the heating rate 5°C / min, when the temperature is 1500°C-2000°C, the heating rate is 2°C / min, and the pressure is 50MPa; after 5 hours of heat preservation, the cooli...

Embodiment 2

[0030]Embodiment 2: the purity is 99.9%, the ZrB particle size is 3 μm 2 After passing the quality inspection of the powder, the granulation equipment is used to make particles with a diameter of 3mm; the high temperature resistant graphite mold is installed on the mechanical equipment, and the ZrB 2 The particles are filled into the graphite mold and vibrated using a mechanical device; the ZrB 2 The particle and vibrated graphite mold is removed from the mechanical equipment and put into the vacuum hot-press furnace; the vacuum hot-press furnace is heated and pressurized, and the maximum temperature is set to 1800°C. When the temperature is 0-1500°C, the heating rate 6°C / min, when the temperature is 1500°C-1800°C, the heating rate is 1°C / min, and the pressure is 60MPa; after 6 hours of heat preservation, the cooling rate is 1°C / min for another 15 hours, and when it drops to 200°C, the The graphite mold was taken out from the vacuum hot-press furnace, allowed to stand and coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com