Patents

Literature

46 results about "Plasma impedance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

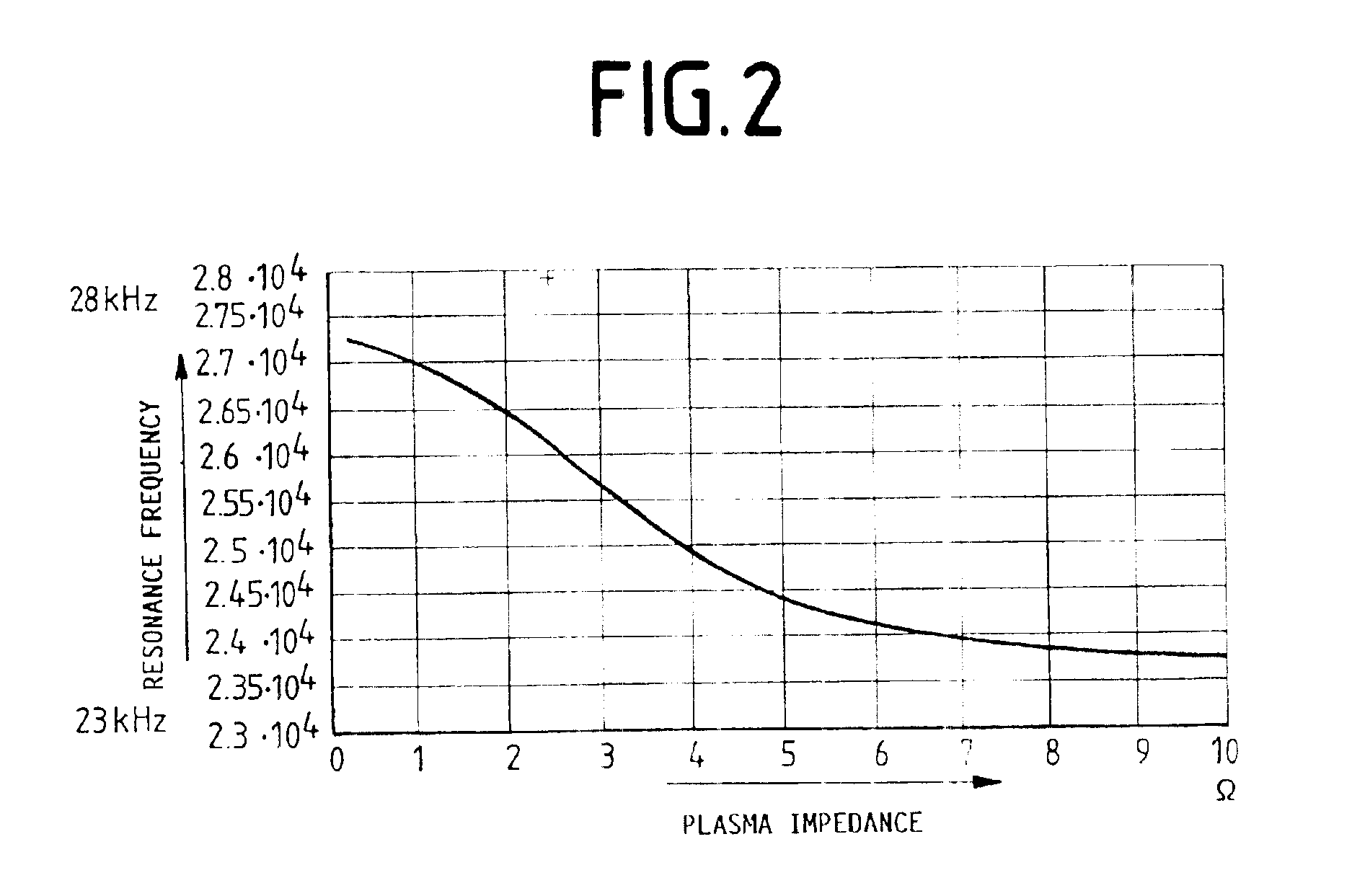

During reactive sputtering, the plasma impedance changes on addition of the reactive gas to the plasma. At constant current, this change in plasma impedance is manifested by a discharge voltage change. Depending on the target material, the discharge voltage decreases or increases when the target becomes fully positioned.

Method and apparatus for preventing instabilities in radio-frequency plasma processing

ActiveUS7304438B2Guaranteed uptimeEasy to controlElectric discharge tubesElectric arc lampsElectricityPlasma impedance

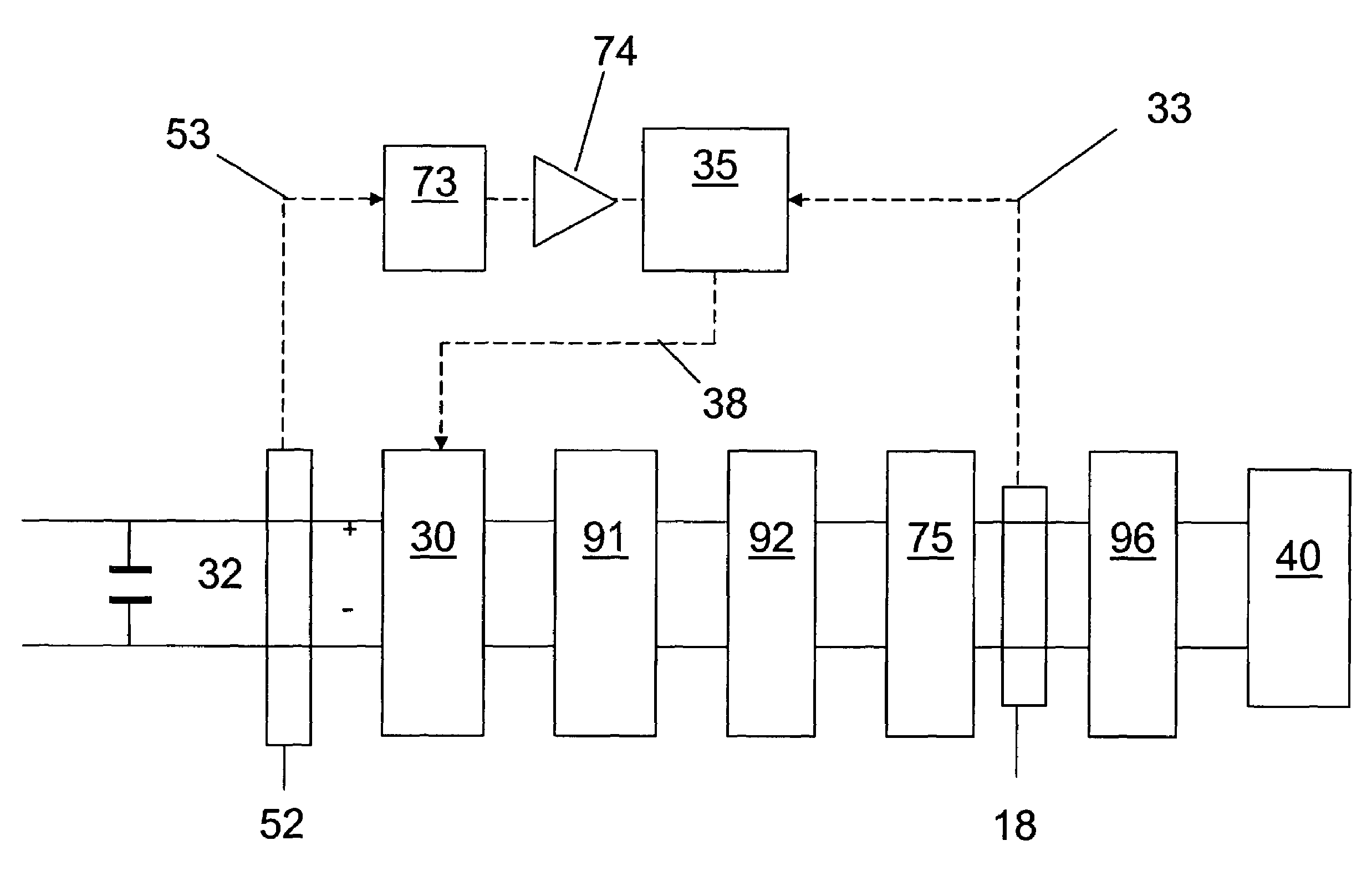

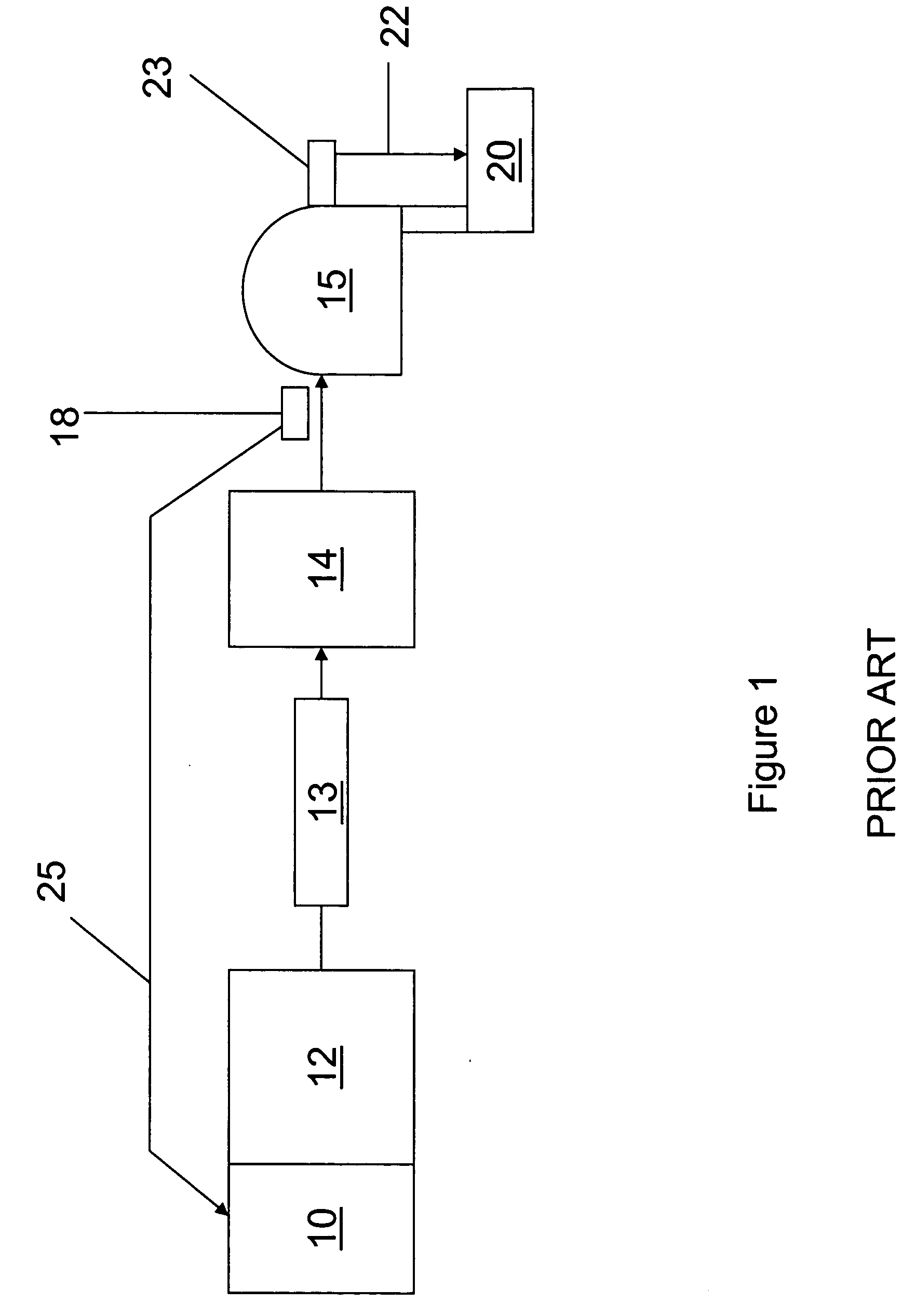

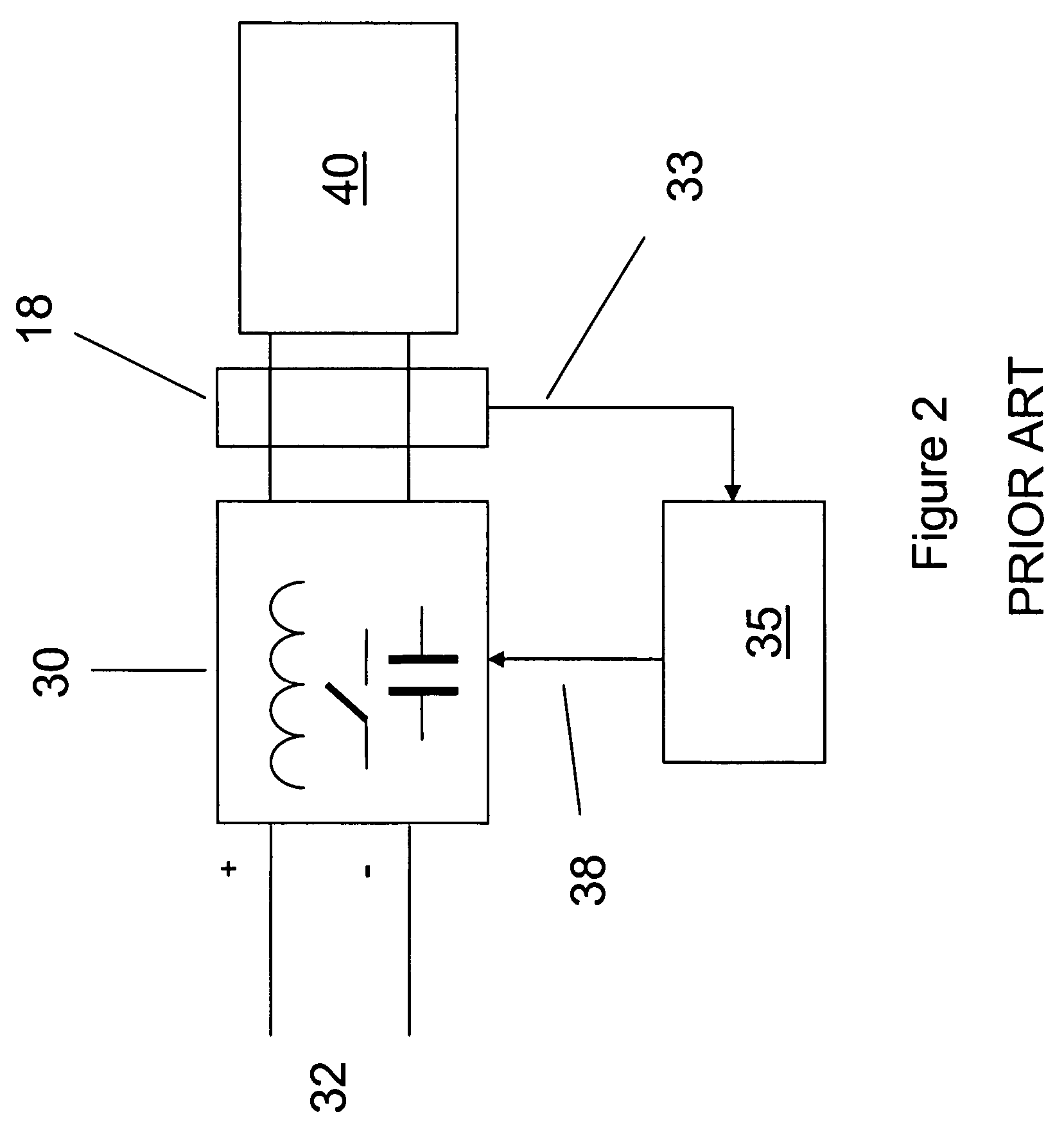

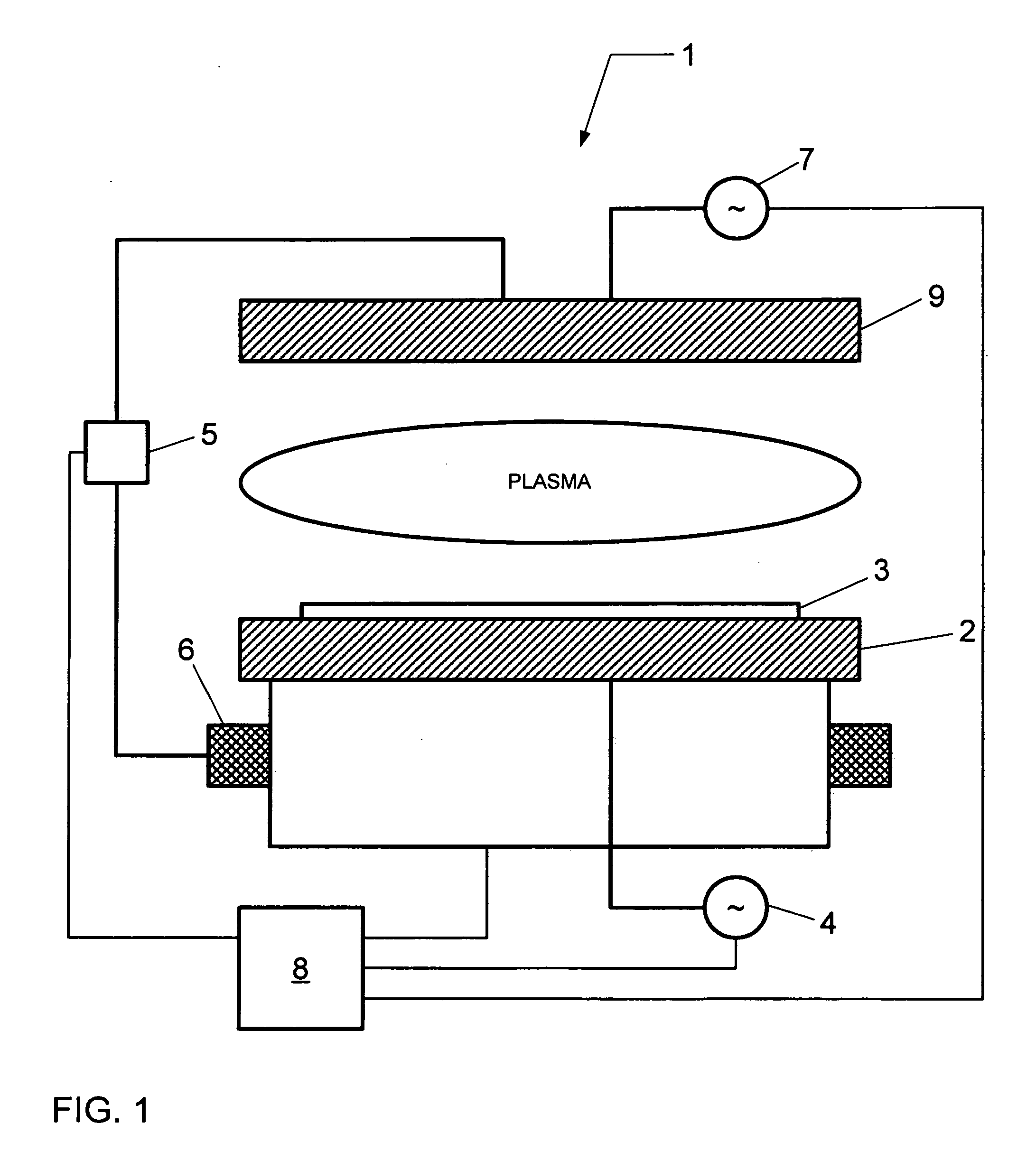

A method and apparatus for controlling a power supply to prevent instabilities due to dynamic loads in RF plasma processing systems, operating at frequencies of from 1 MHz and up, uses a feedforward type of control loop to tightly regulate the power supplied to the dynamic electrical load, such as loads caused by variable and inconsistent plasma impedance. A feedback control loop can also be used in combination with the feedforward loop, but at a slower rate, to help regulate the amount of power provided to the load.

Owner:MKS INSTR INC

Method and apparatus for preventing instabilities in radio-frequency plasma processing

ActiveUS20050093459A1Guaranteed uptimeEasy to controlElectric discharge tubesElectric arc lampsPlasma impedanceInstability

A method and apparatus for controlling a power supply to prevent instabilities due to dynamic loads in RF plasma processing systems, operating at frequencies of from 1 MHz and up, uses a feedforward type of control loop to tightly regulate the power supplied to the dynamic electrical load, such as loads caused by variable and inconsistent plasma impedance. A feedback control loop can also be used in combination with the feedforward loop, but at a slower rate, to help regulate the amount of power provided to the load.

Owner:MKS INSTR INC

Stabilizing plasma and generator interactions

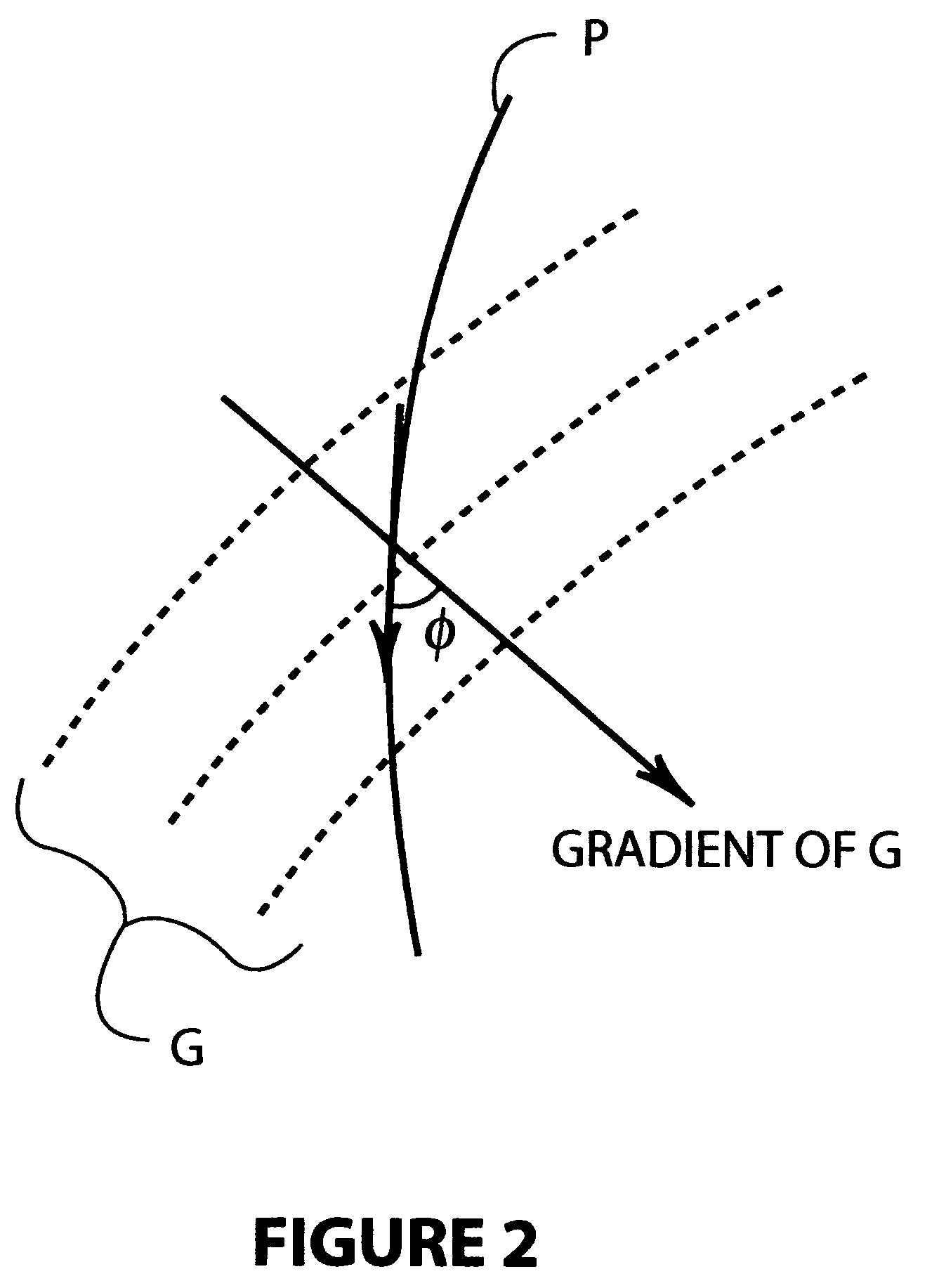

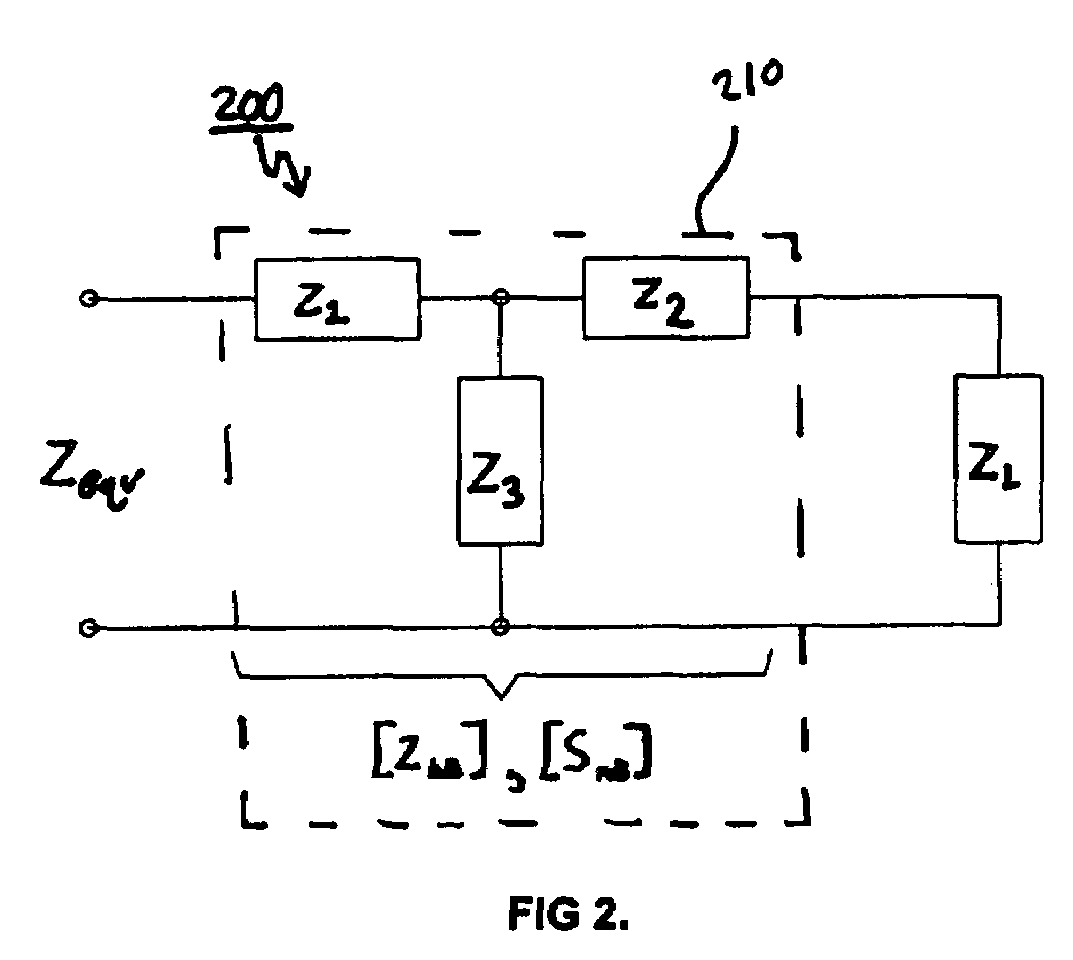

ActiveUS20050134186A1Strong interactionIncreased fluctuationElectric discharge tubesElectric arc lampsPlasma impedanceConstant power

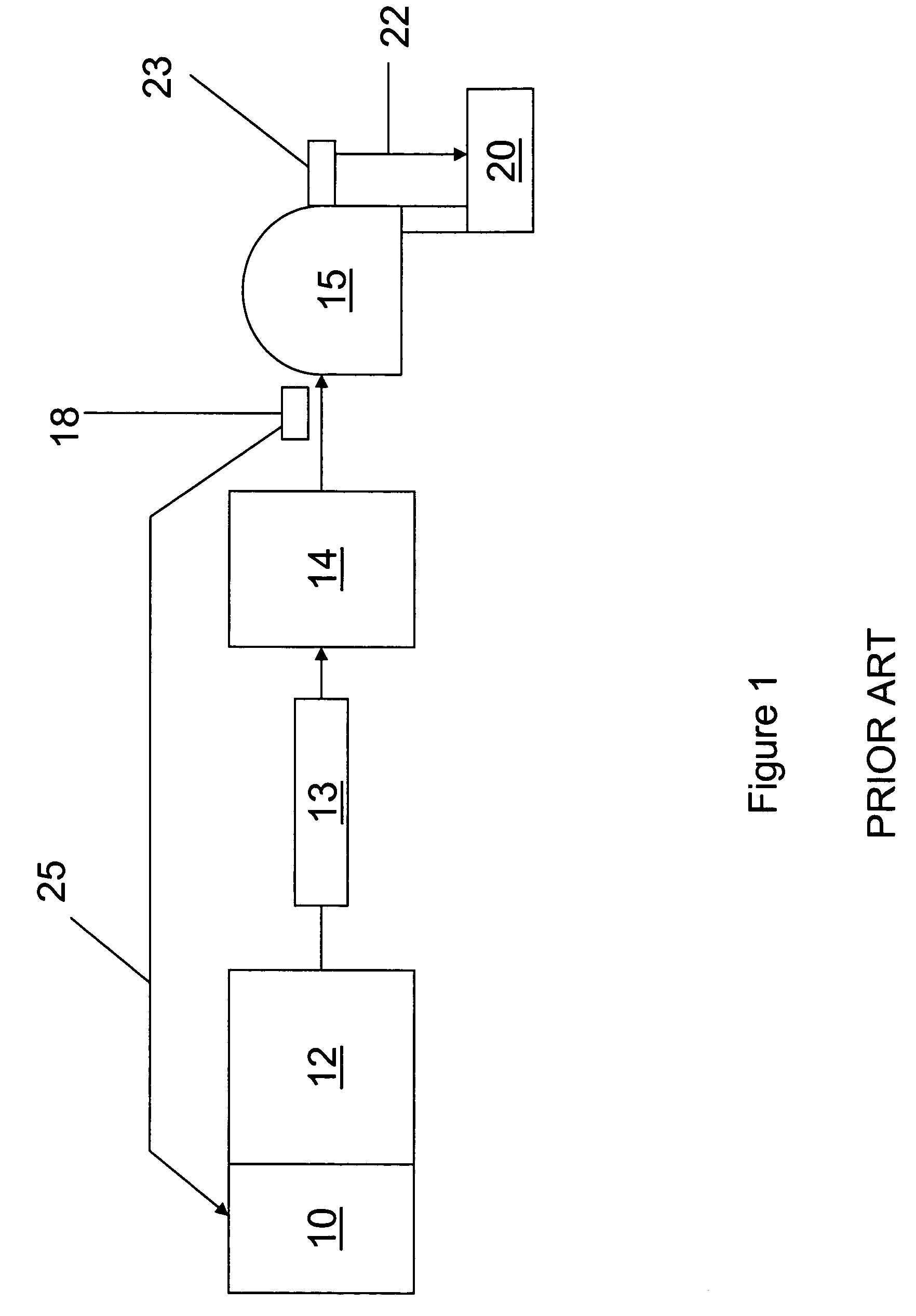

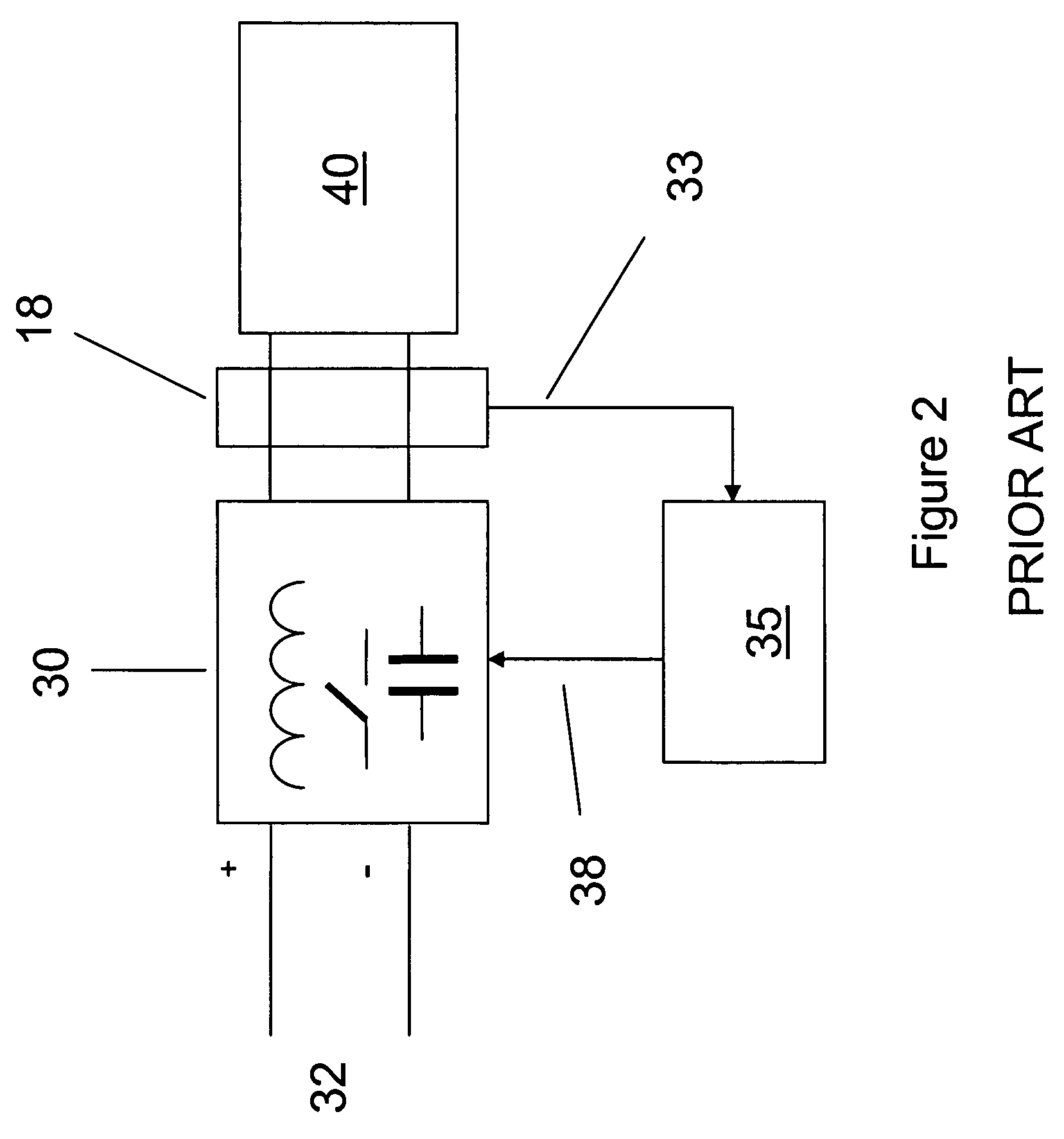

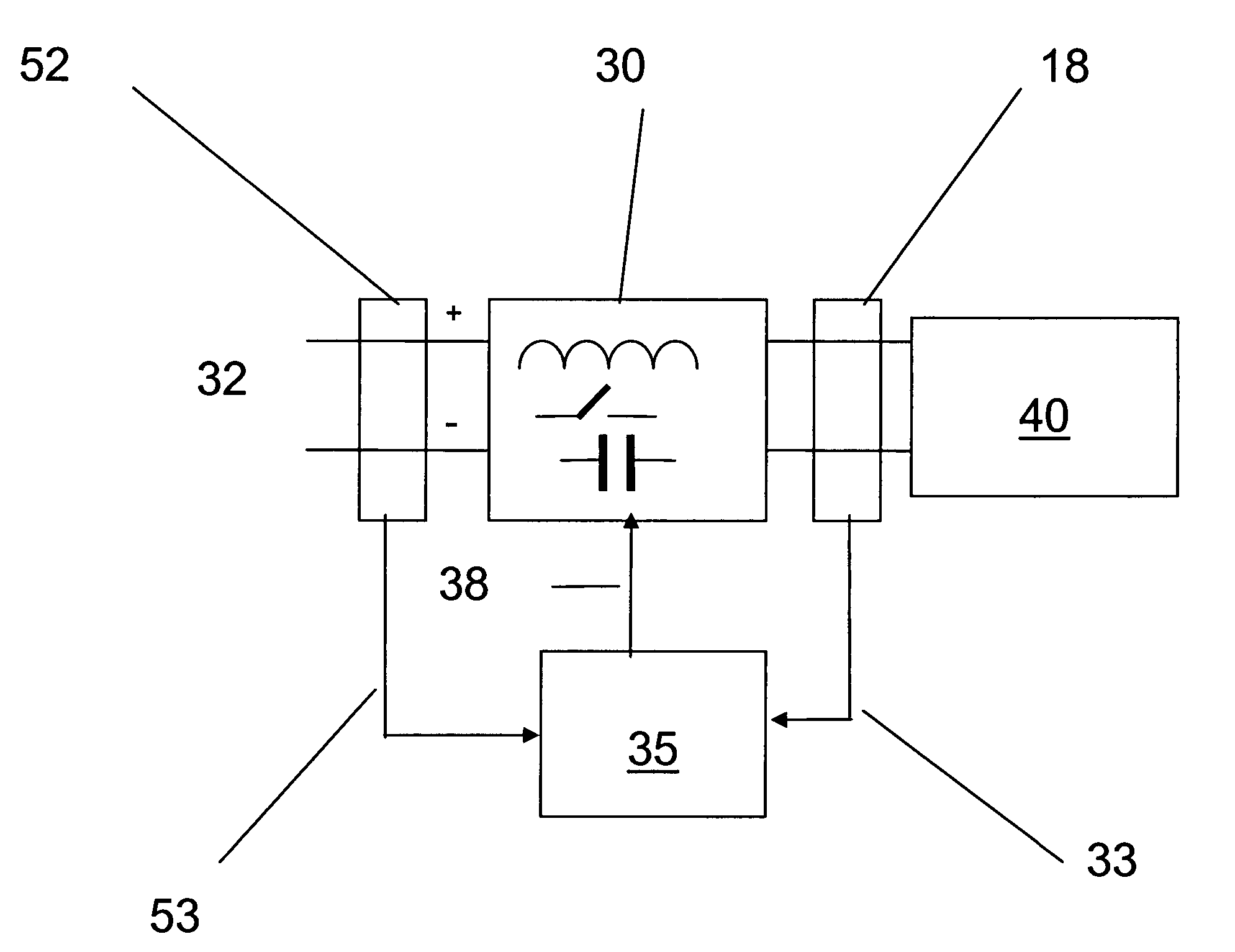

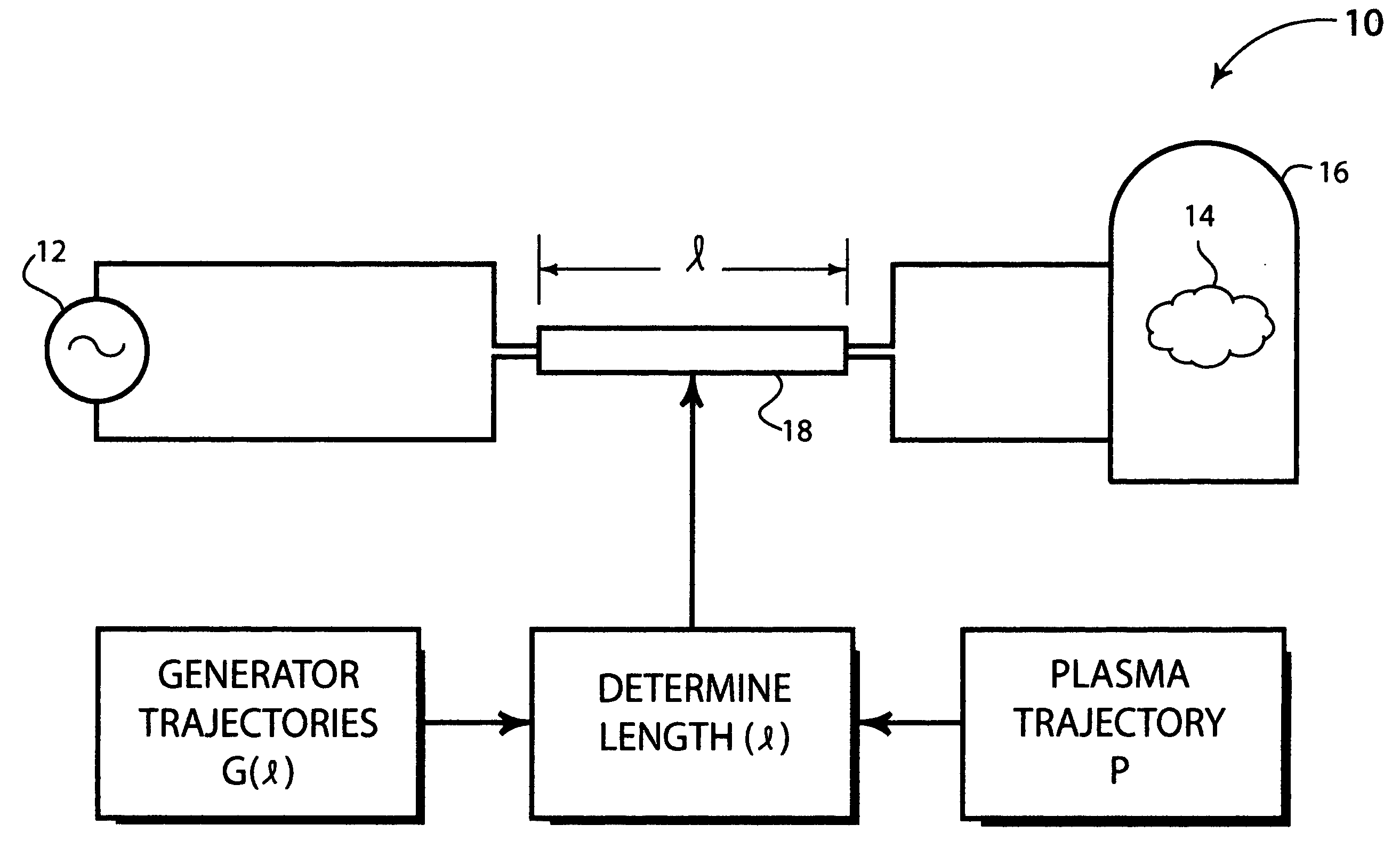

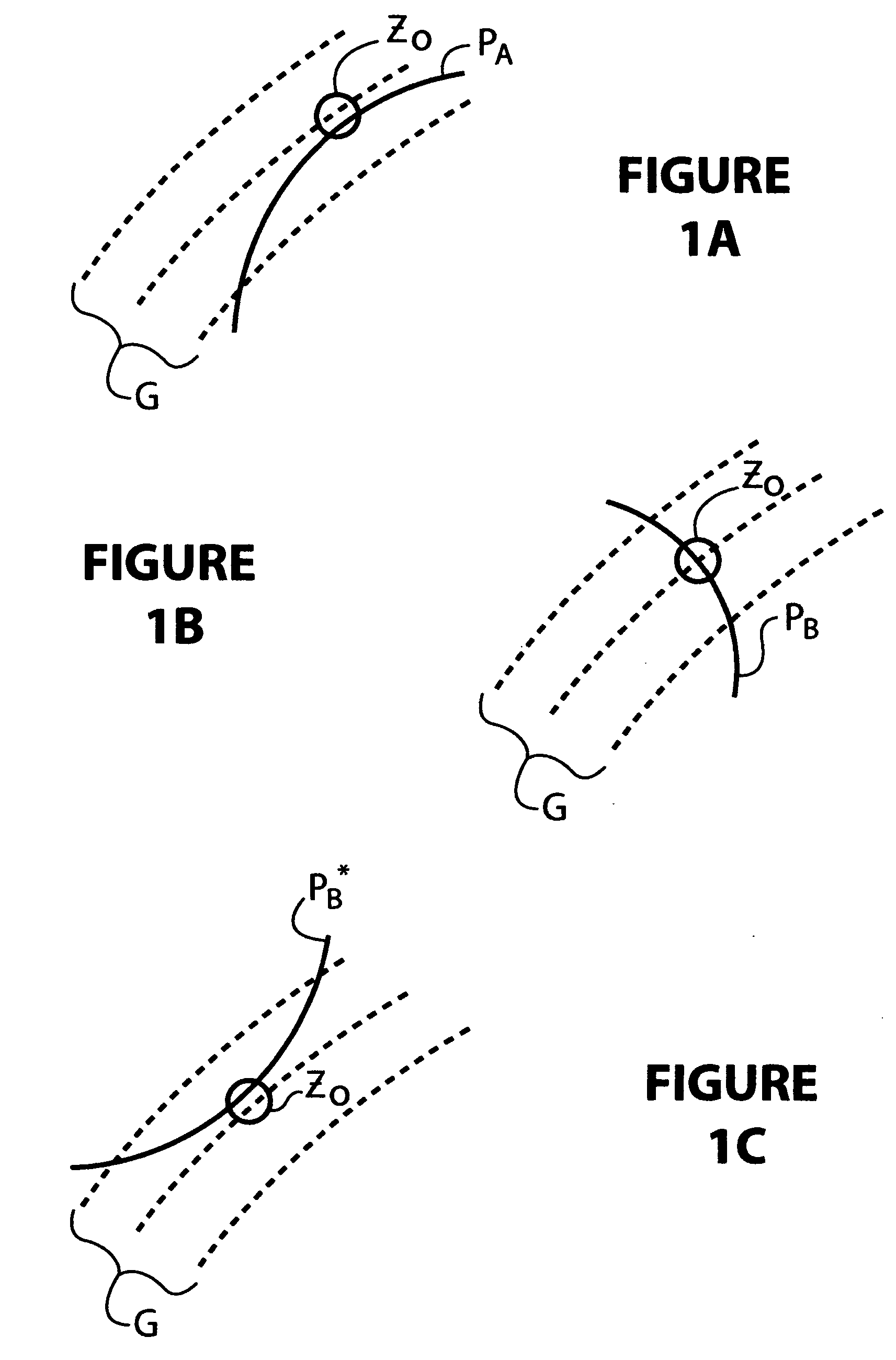

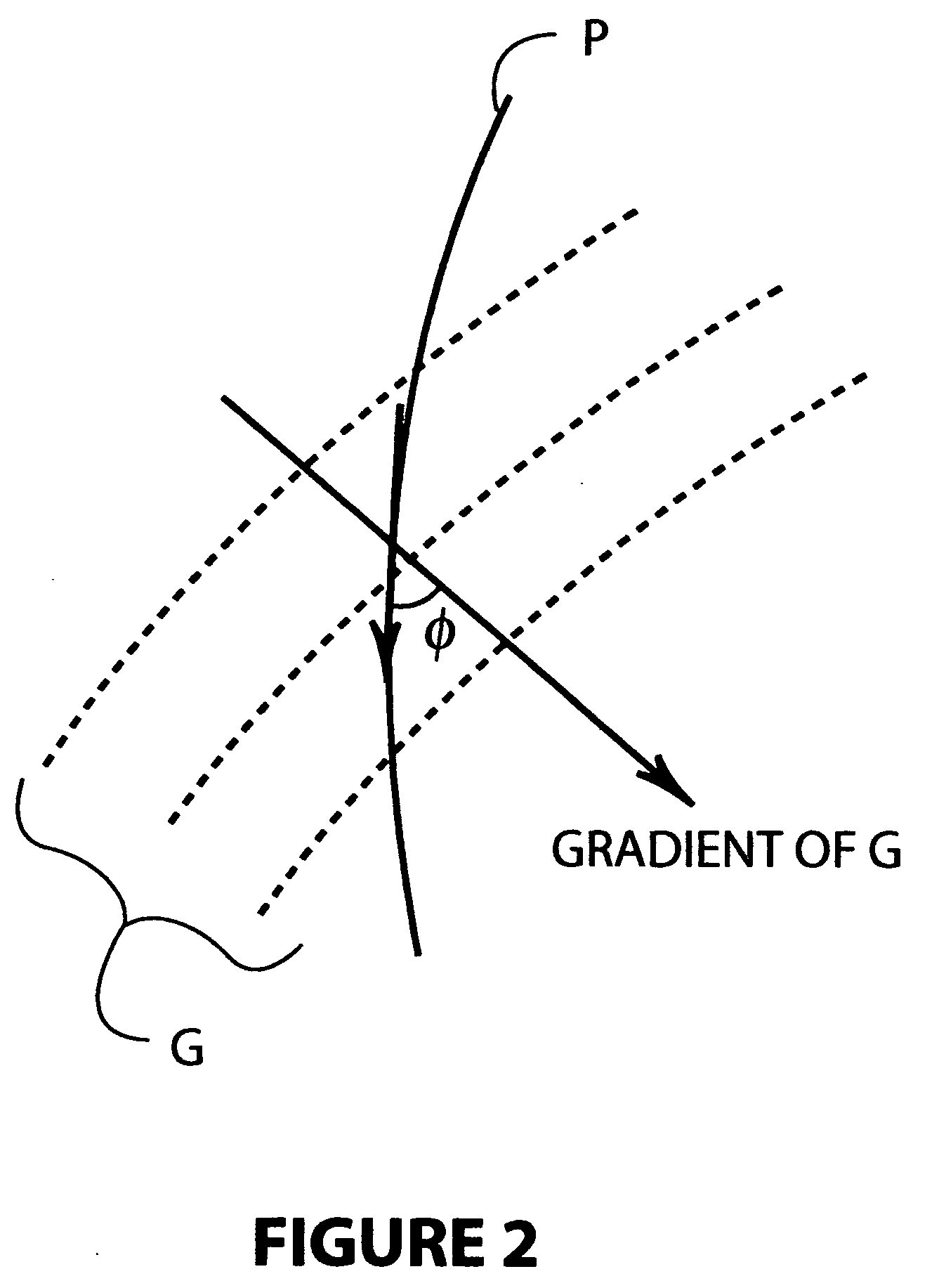

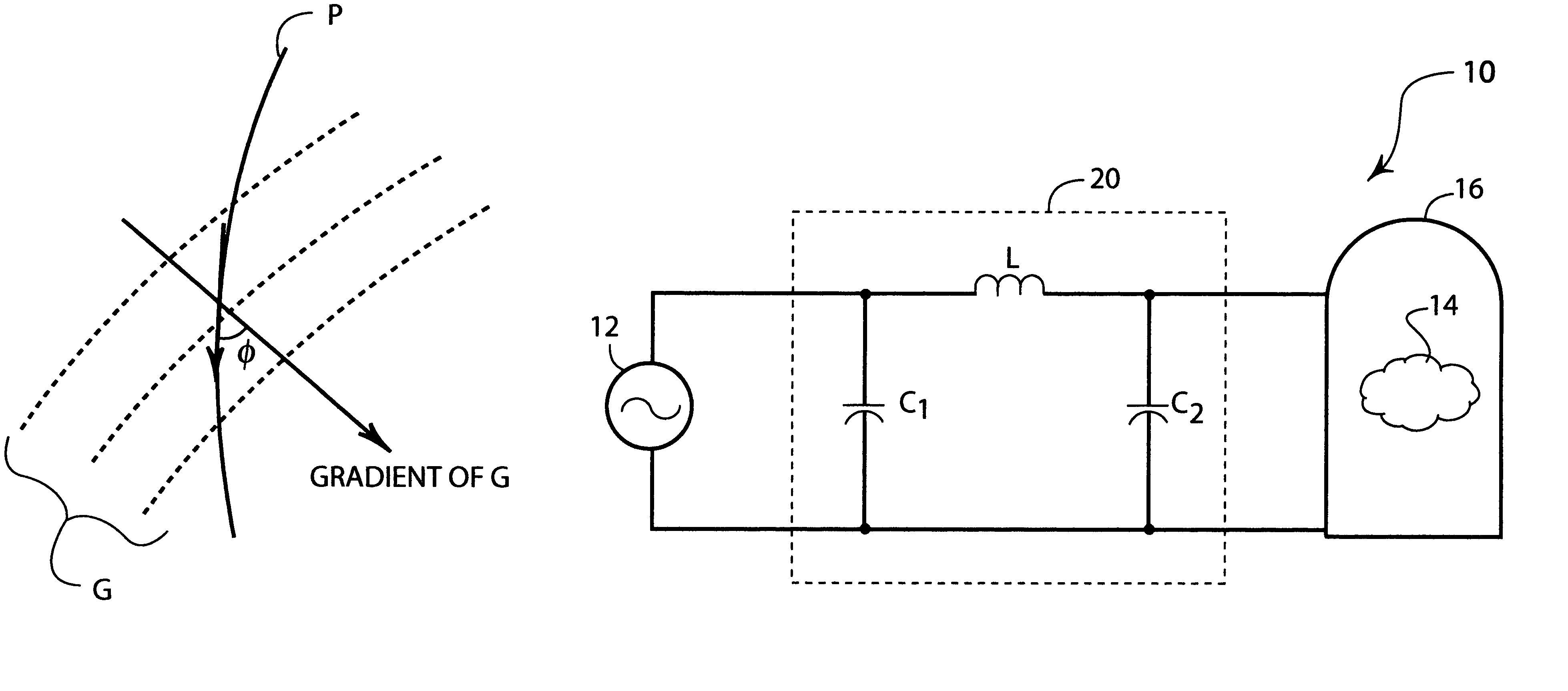

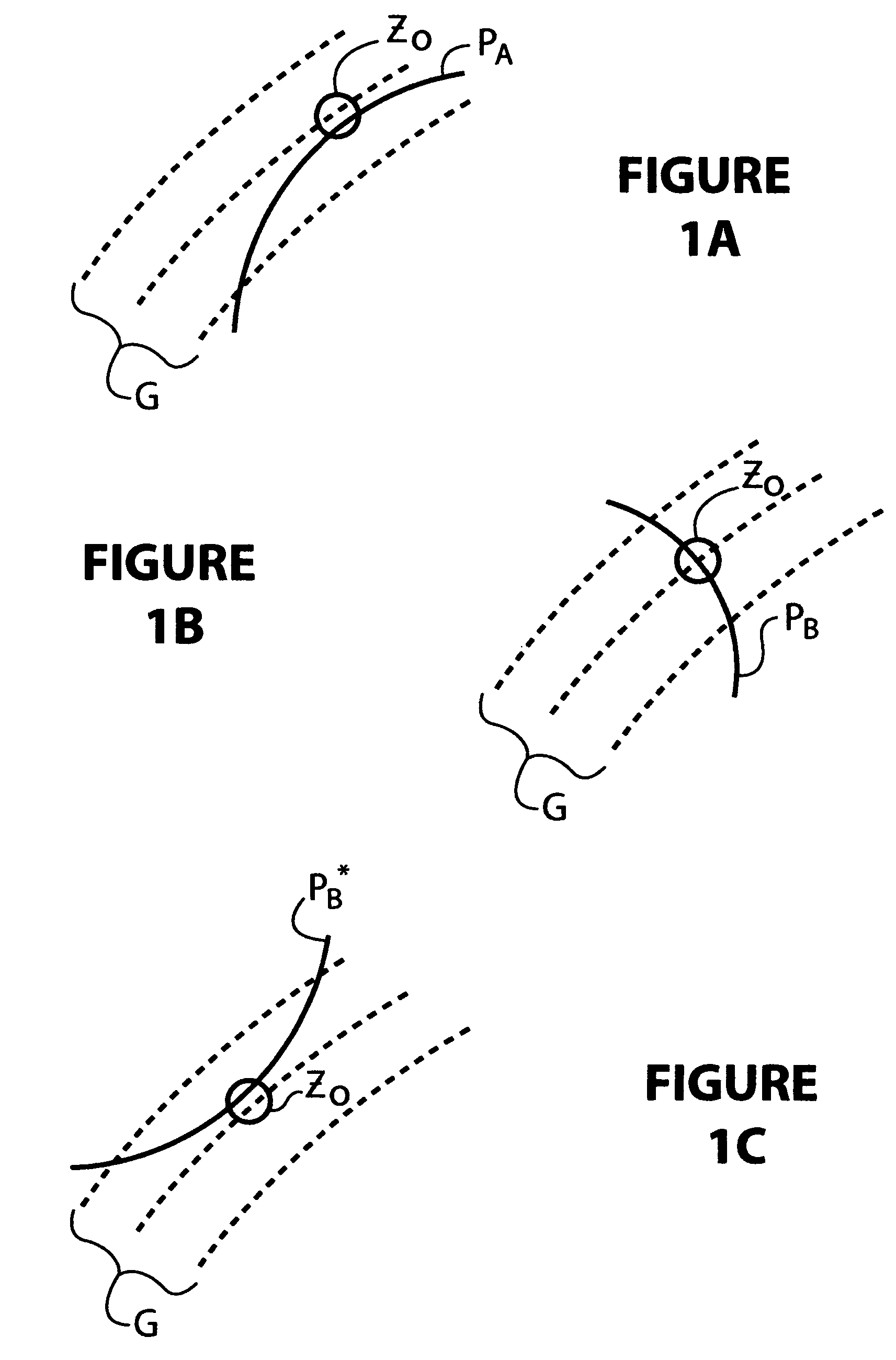

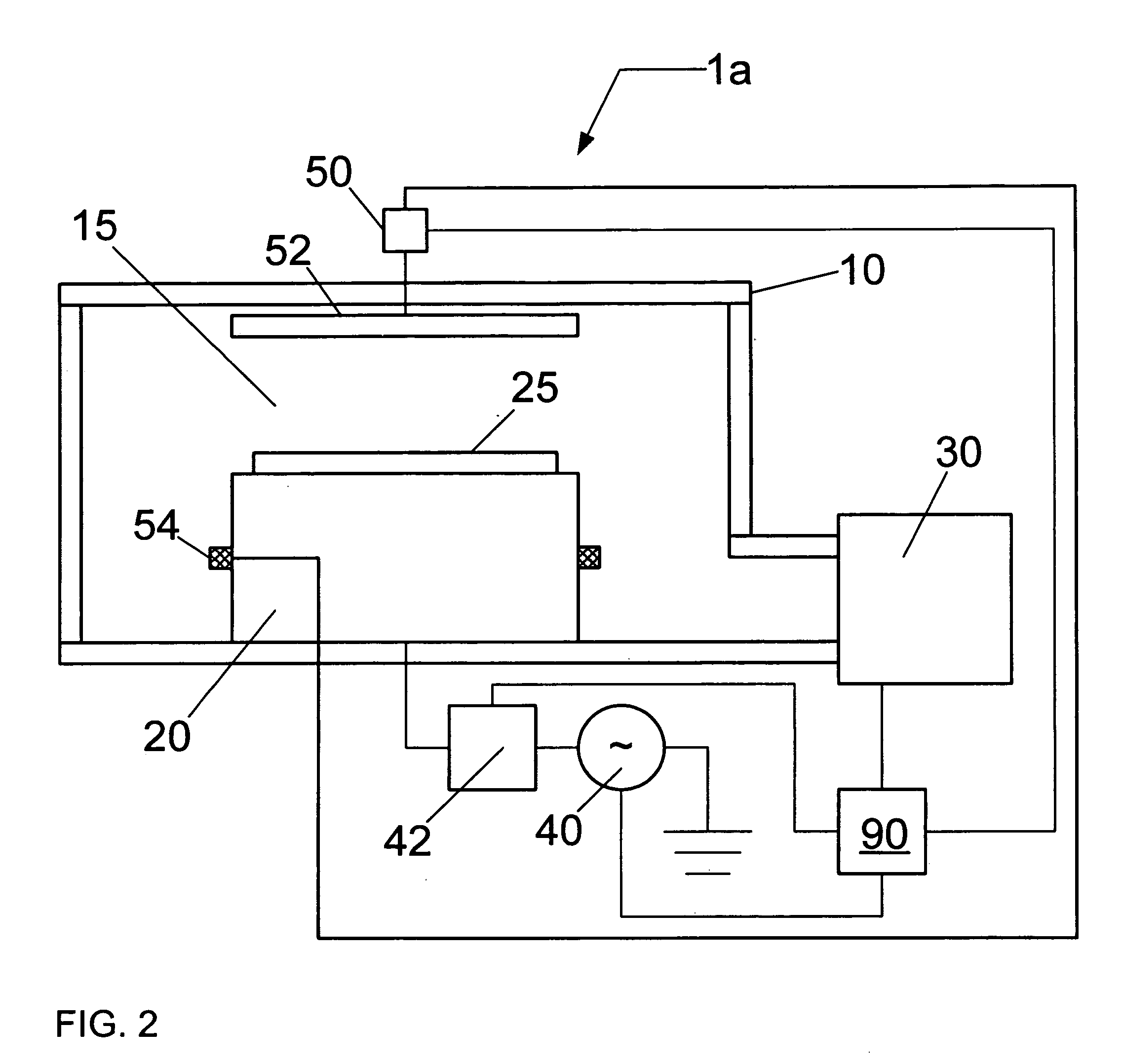

An approach for stabilizing the interactions between a plasma and the generator powering the plasma is provided. Reactive elements disposed between the power generator and plasma operate to modify the apparent impedance characteristics of the plasma such that the trajectory of the plasma load impedance as a function of power is substantially aligned locally with the contours of constant power output in impedance space. In this way, instabilities in the generator and plasma system are avoided because reinforcement or amplification of fluctuations in plasma impedance due to interactions between the generator and the plasma are reduced or eliminated. The reactive elements may be variable in order to align plasma trajectories and generator power contours under a range of process conditions.

Owner:AES GLOBAL HLDG PTE LTD

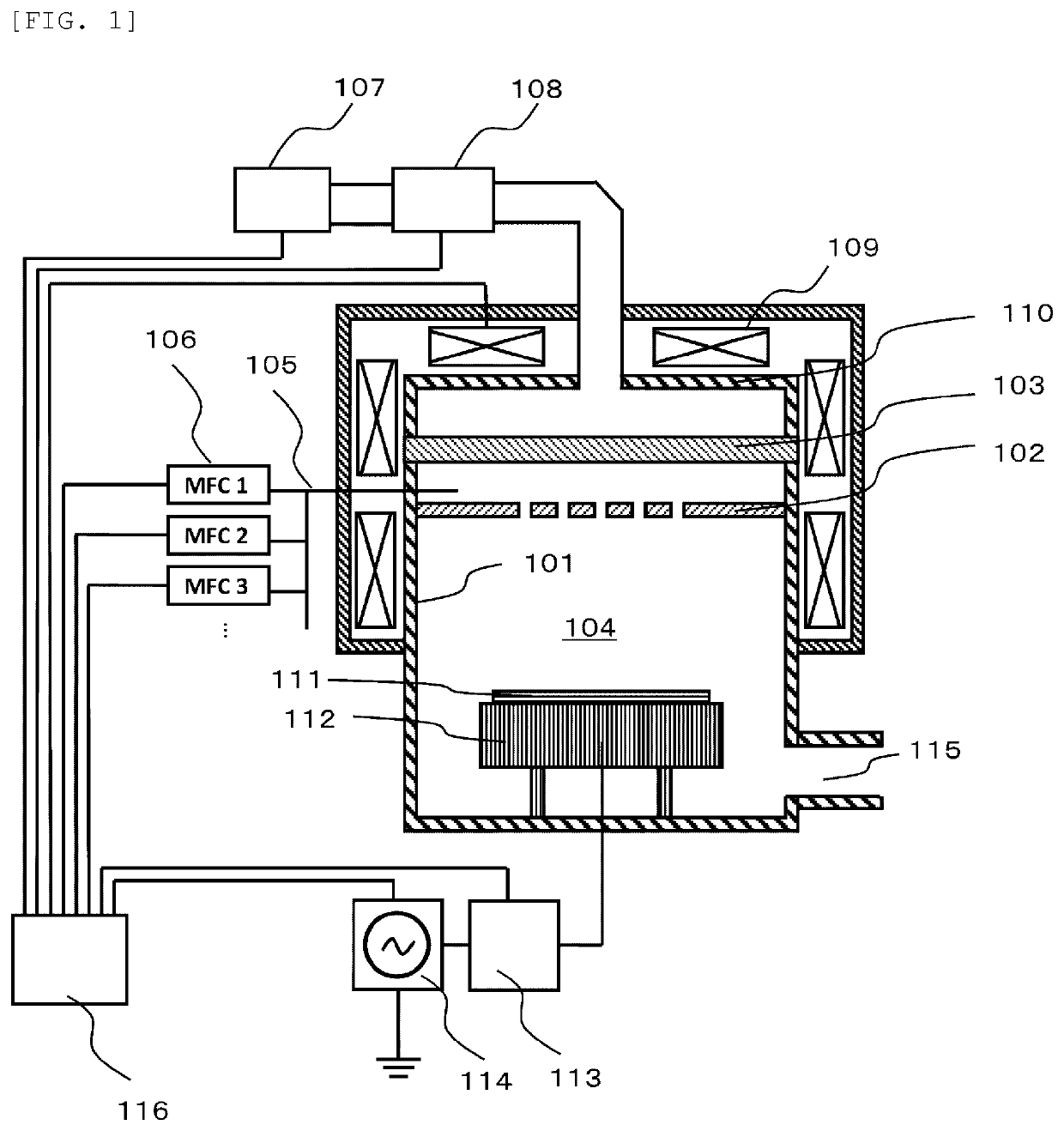

Plasma processing apparatus, plasma processing method, and computer readable storage medium

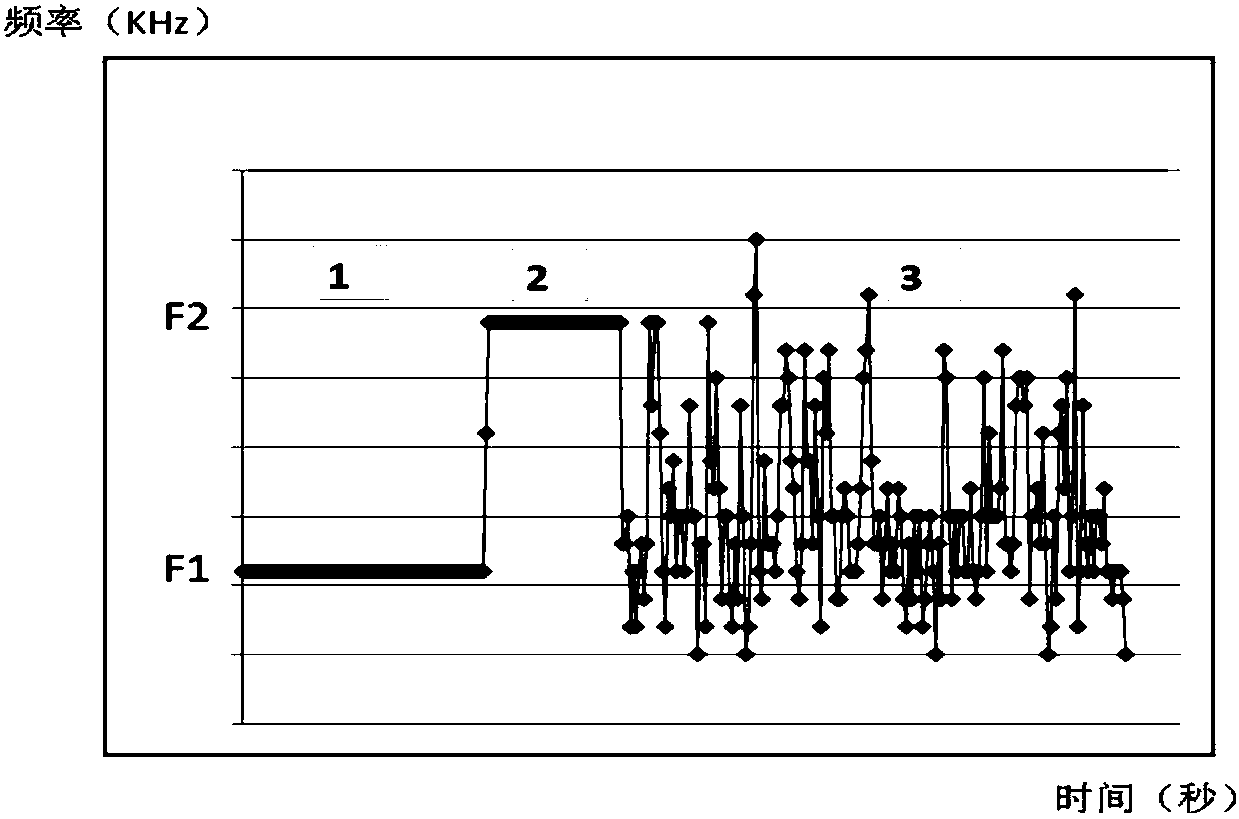

ActiveCN101552187AReduce impedance variationGuaranteed security protectionElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma impedanceHigh frequency power

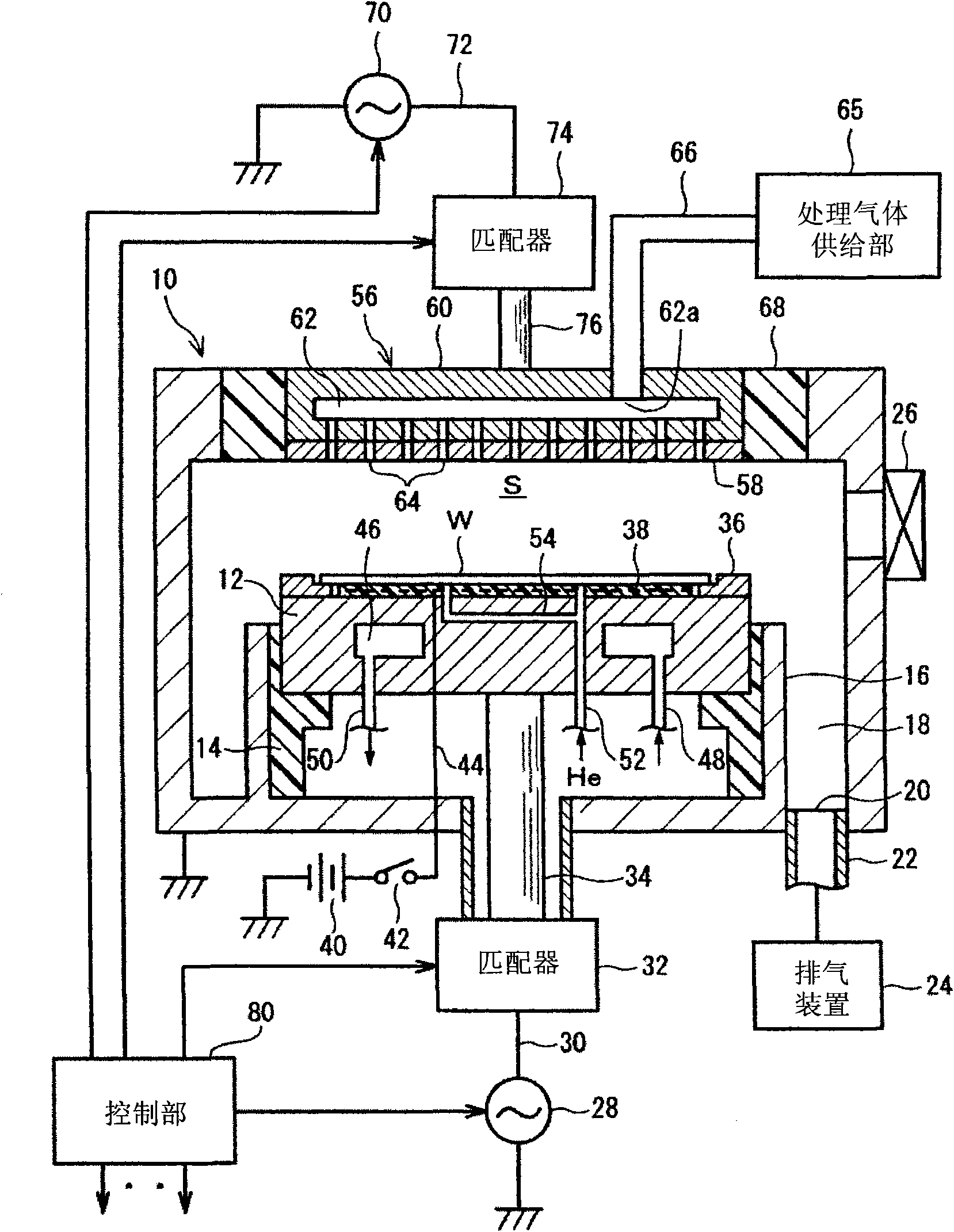

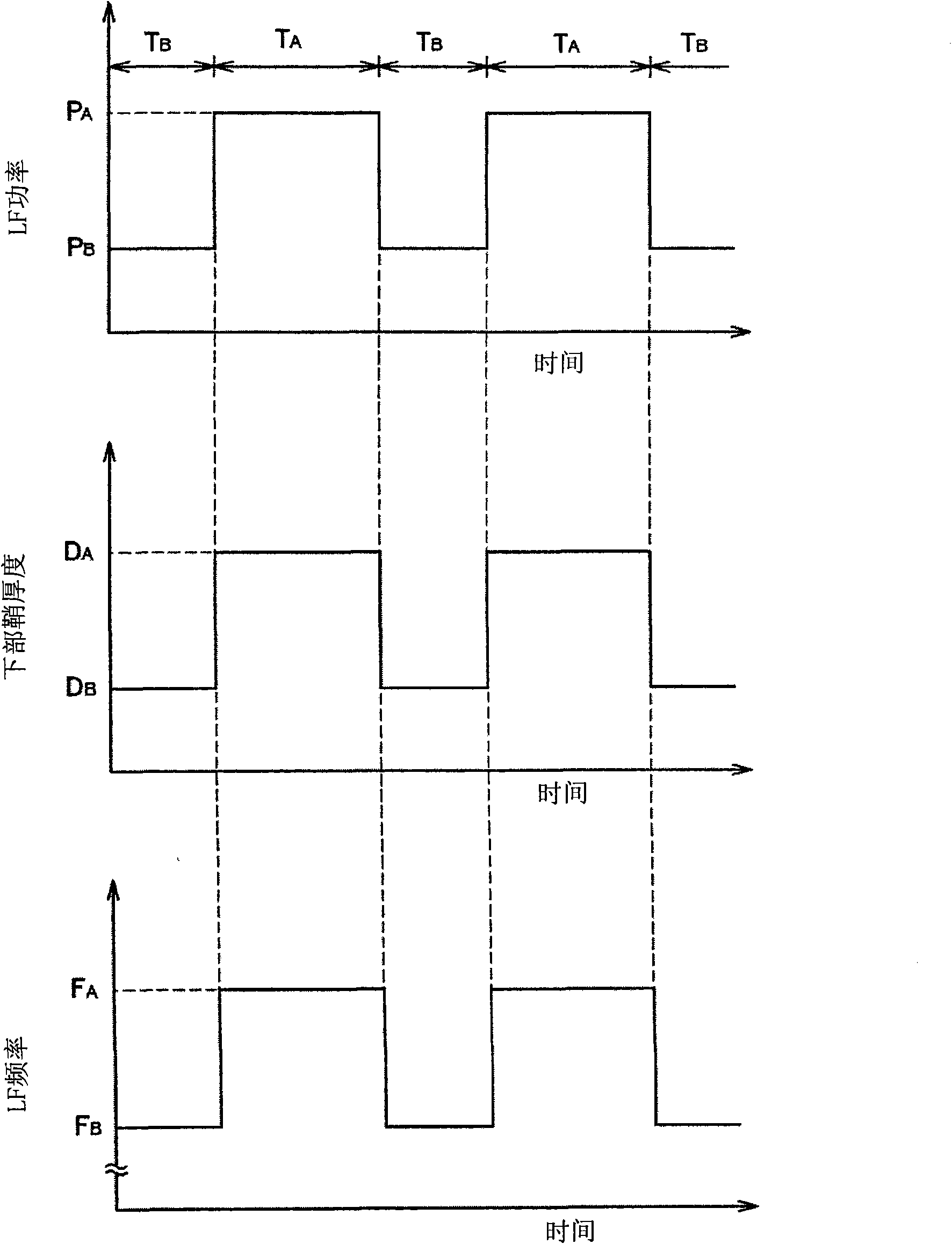

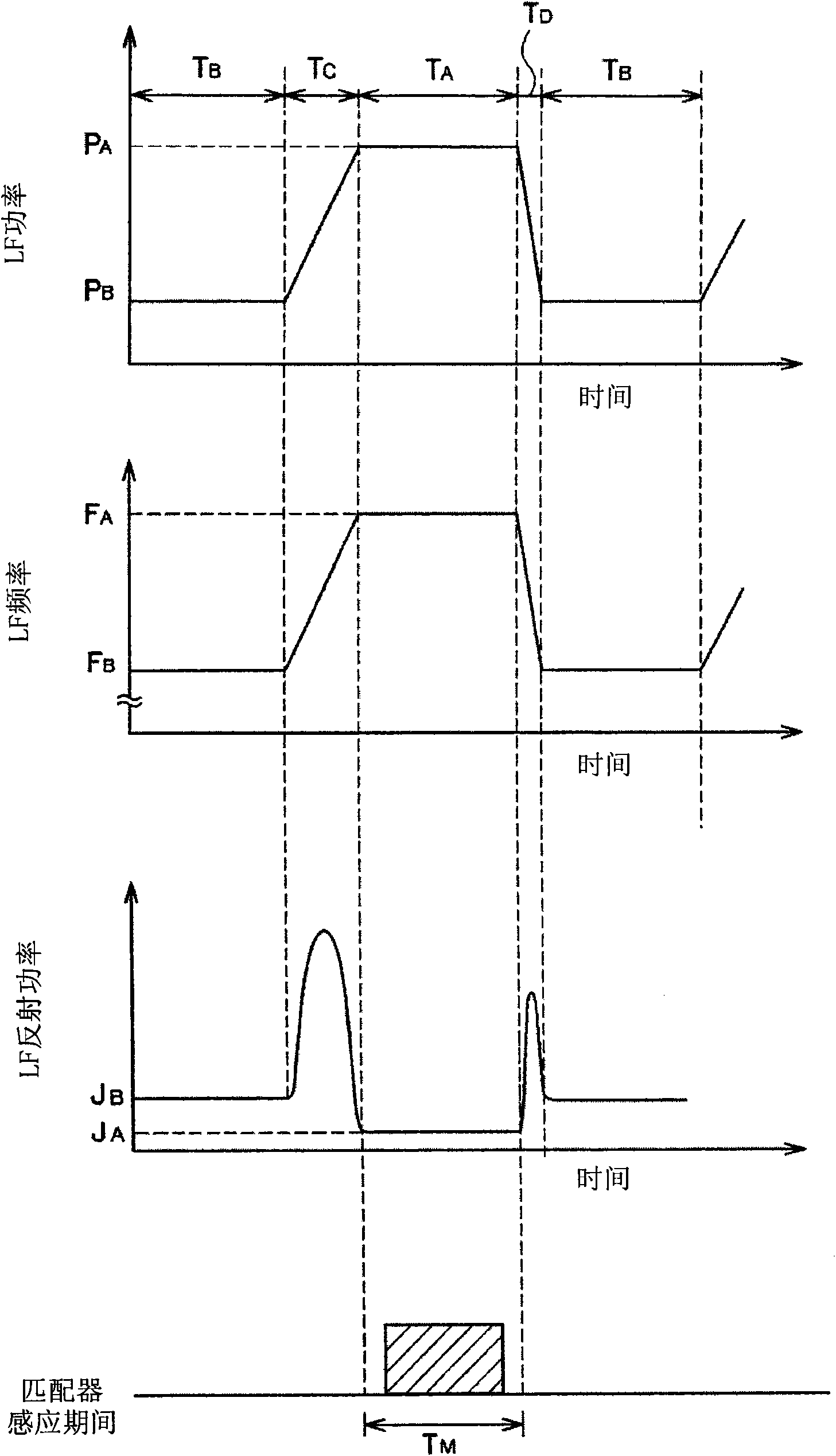

The invention provides a plasma processing device and a plasma processing method. In the manner of periodically modulating the power of the high frequency used in the plasma processing, variation of plasma impedance and reflection towards the high frequency power supply are reduced as much as possible, so as to ensure the stability and reproducibility of the plasma and the safety of the high frequency power supply. In the plasma processing device, frequency modulation is carried out on the power of the high frequency (LF) for controlling bias voltage by the characteristics corresponding to the processing, and pulse modulation is synchronously carried out on the frequency (LF frequency) thereof together with the pulse modulation of the LF power, namely, the LF frequency and the LF power have the following synchronous relationship in a period: in the time interval of the period T when the LF power is maintained as a set value P of H level, the LF frequency is also maintained as the set value F of H level, and in the time interval of the period when the LF power is maintained as a set value P of L level, the LF frequency is also maintained as the set value F of L level.

Owner:TOKYO ELECTRON LTD

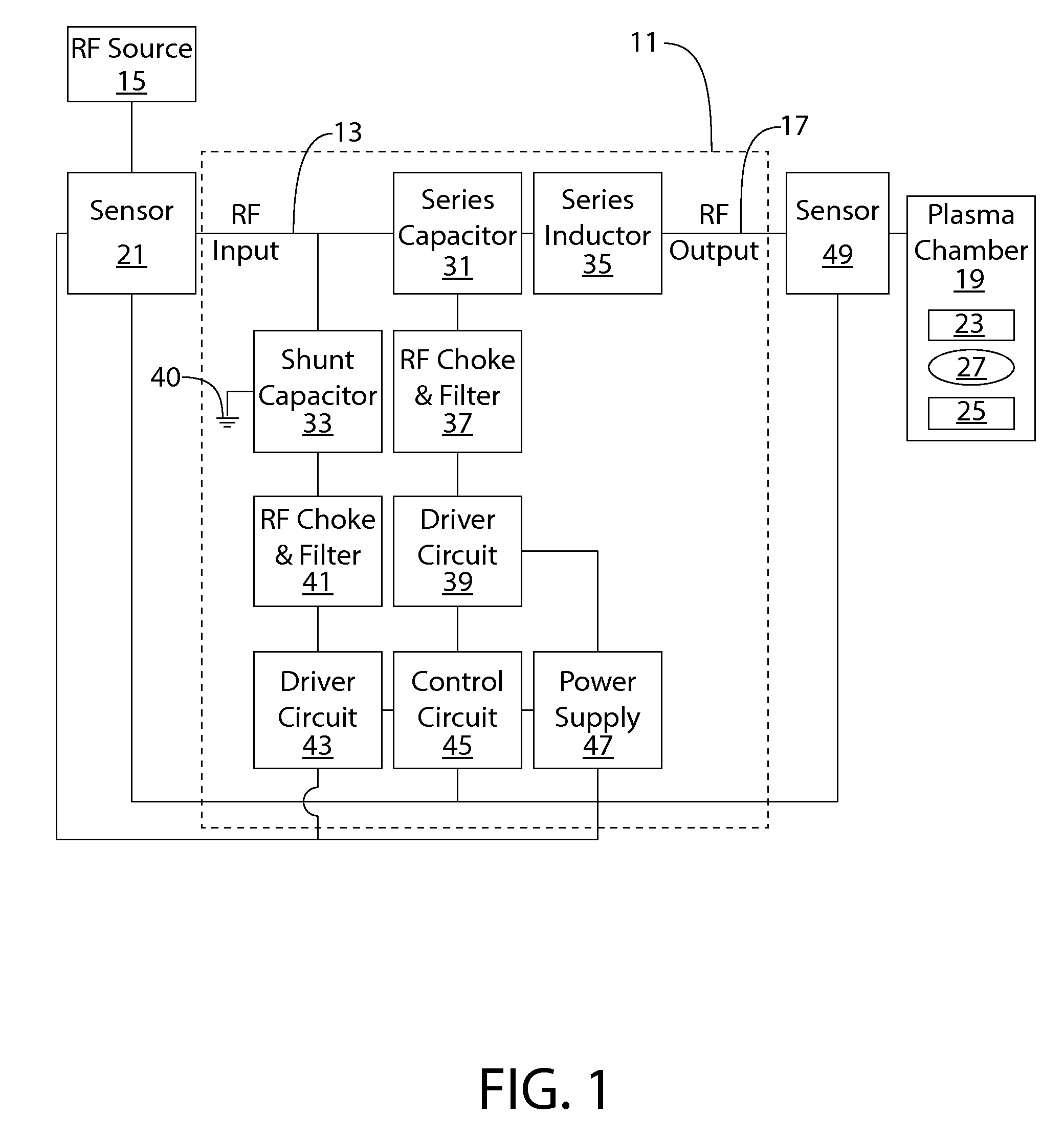

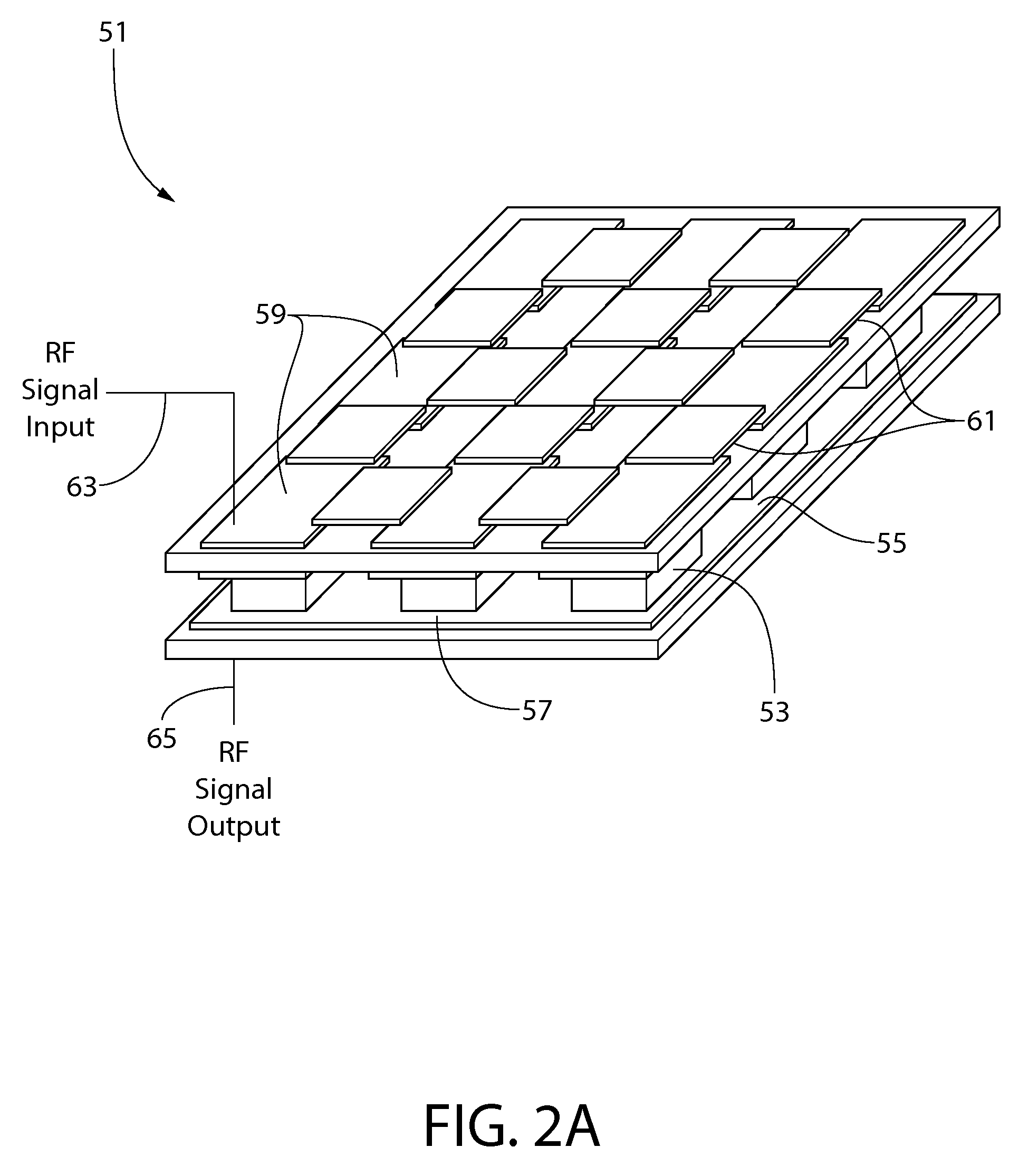

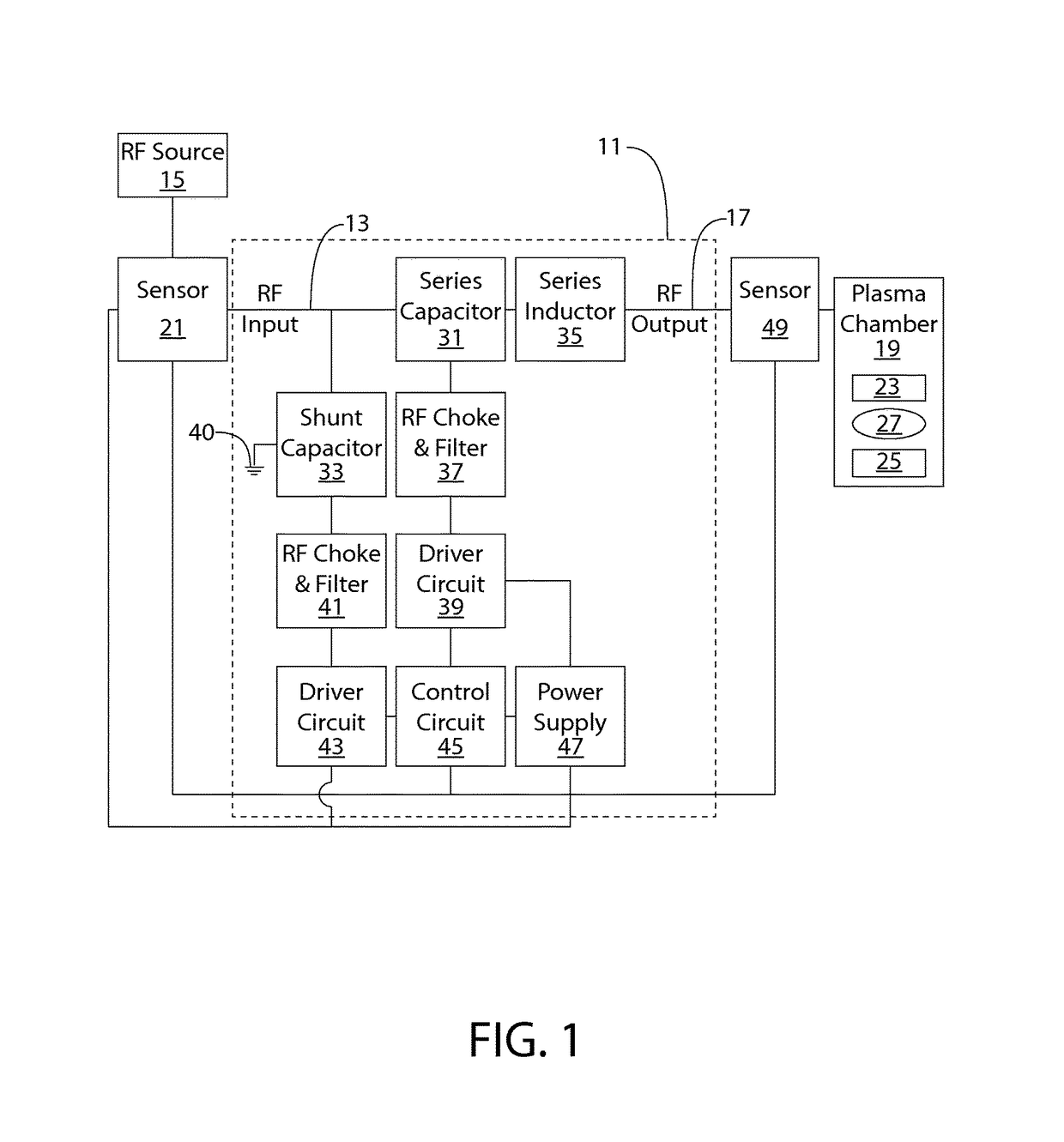

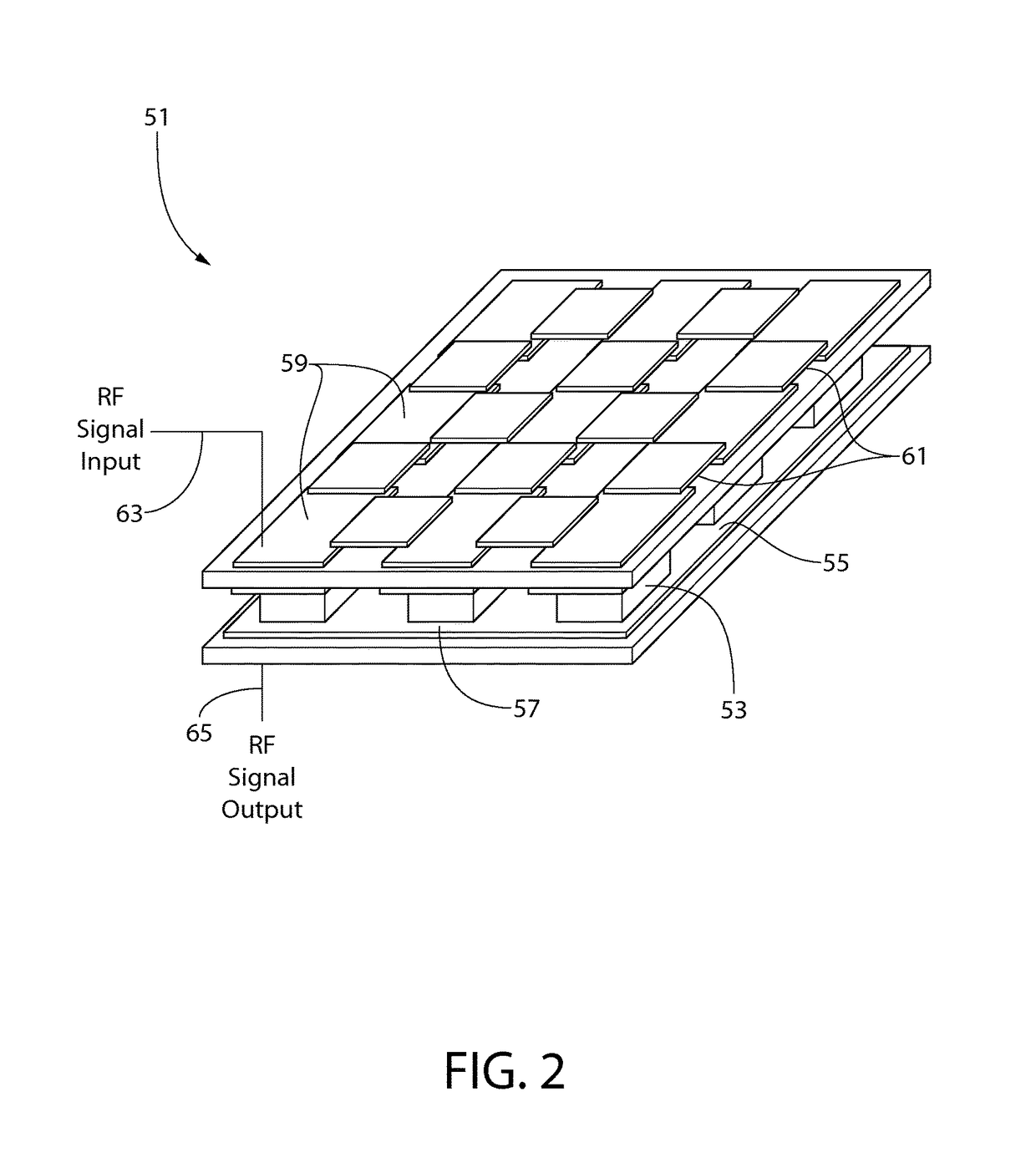

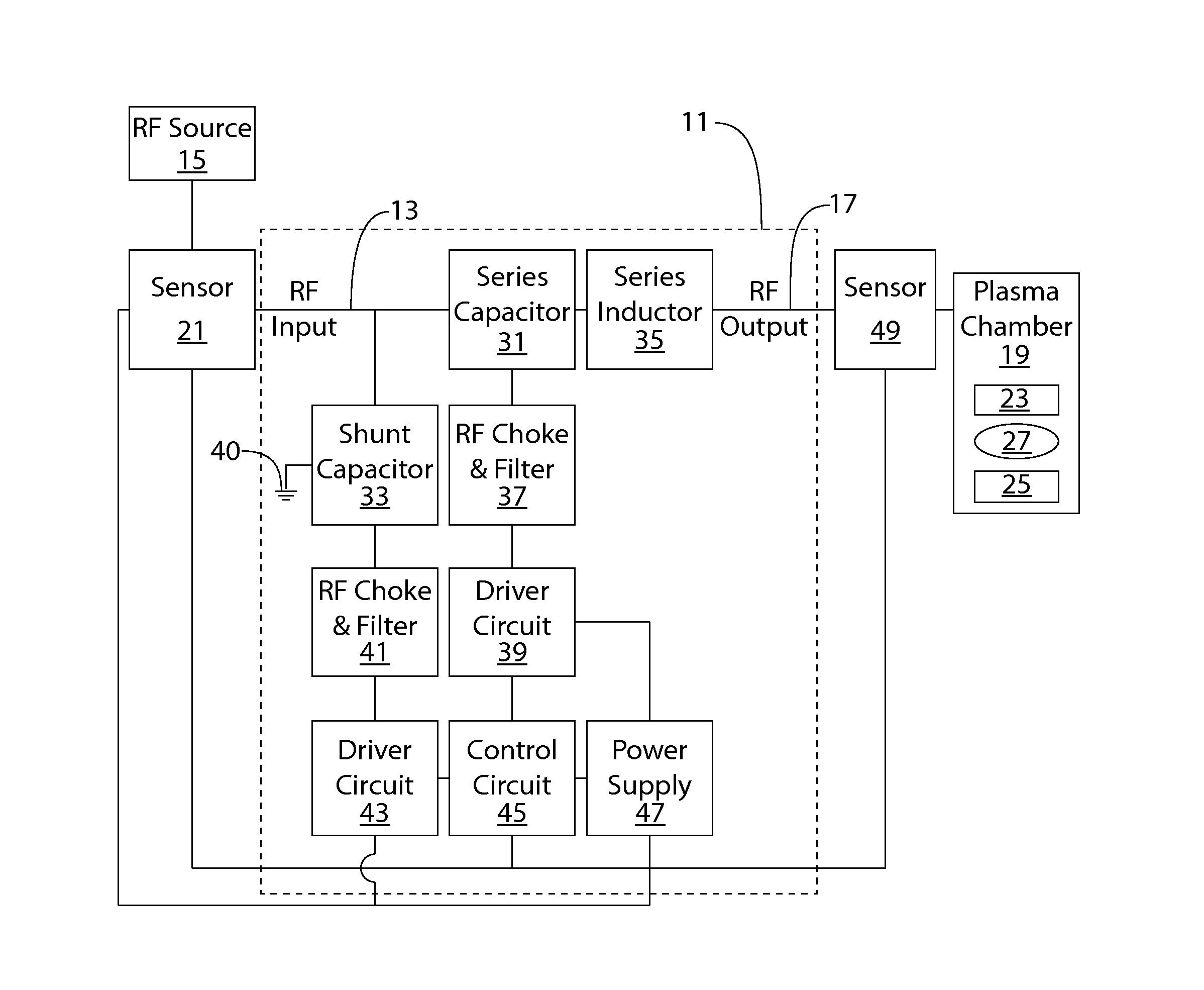

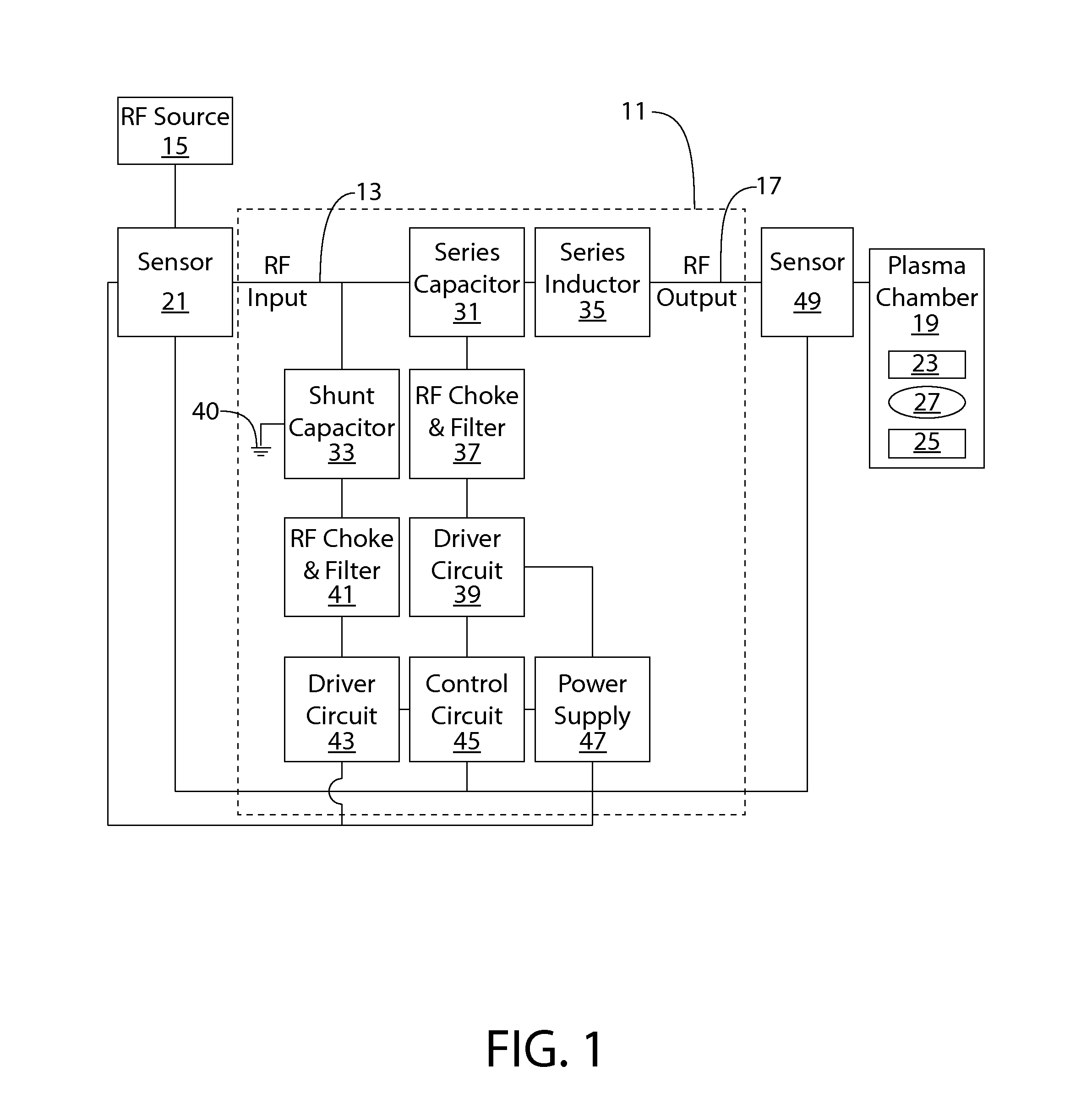

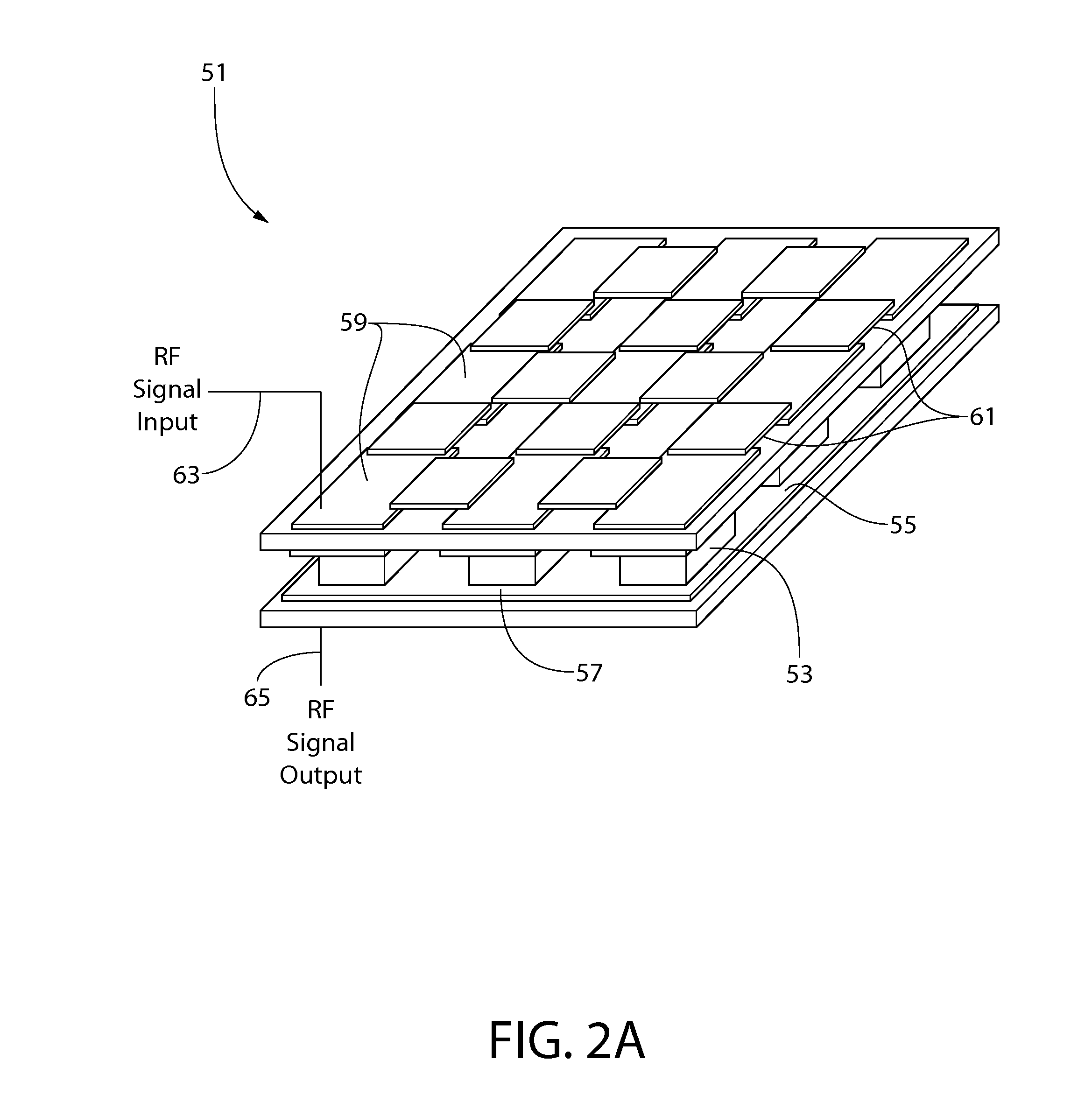

RF impedance matching network

ActiveUS9196459B2Shorten the timeImpedence matching networksMultiple-port networksPlasma impedanceControl signal

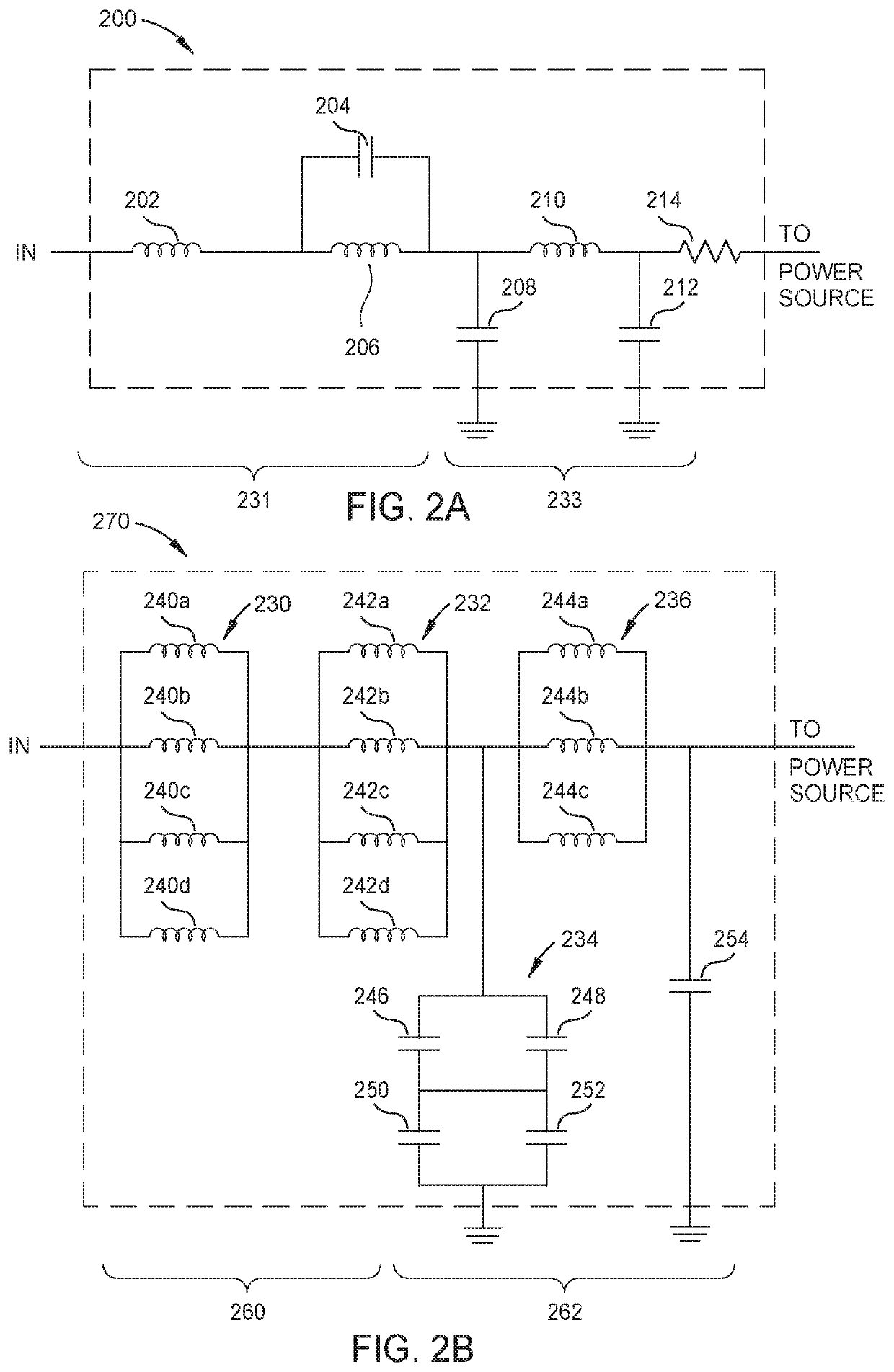

An RF impedance matching network includes an RF input; an RF output configured to operably couple to a plasma chamber; a series electronically variable capacitor (“series EVC”), the series EVC electrically coupled in series between the RF input and the RF output; and a shunt electronically variable capacitor (“shunt EVC”), the shunt EVC electrically coupled in parallel between a ground and one of the RF input and the RF output; a control circuit to control the series variable capacitance and the shunt variable capacitance, wherein the control circuit is configured to determine the variable plasma impedance of the plasma chamber, determine a series capacitance value and a shunt capacitance value, and generate a control signal to alter at least one of the series variable capacitance and the shunt variable capacitance; wherein the alteration is caused by at least one of a plurality of switching circuits.

Owner:ASM AMERICA INC

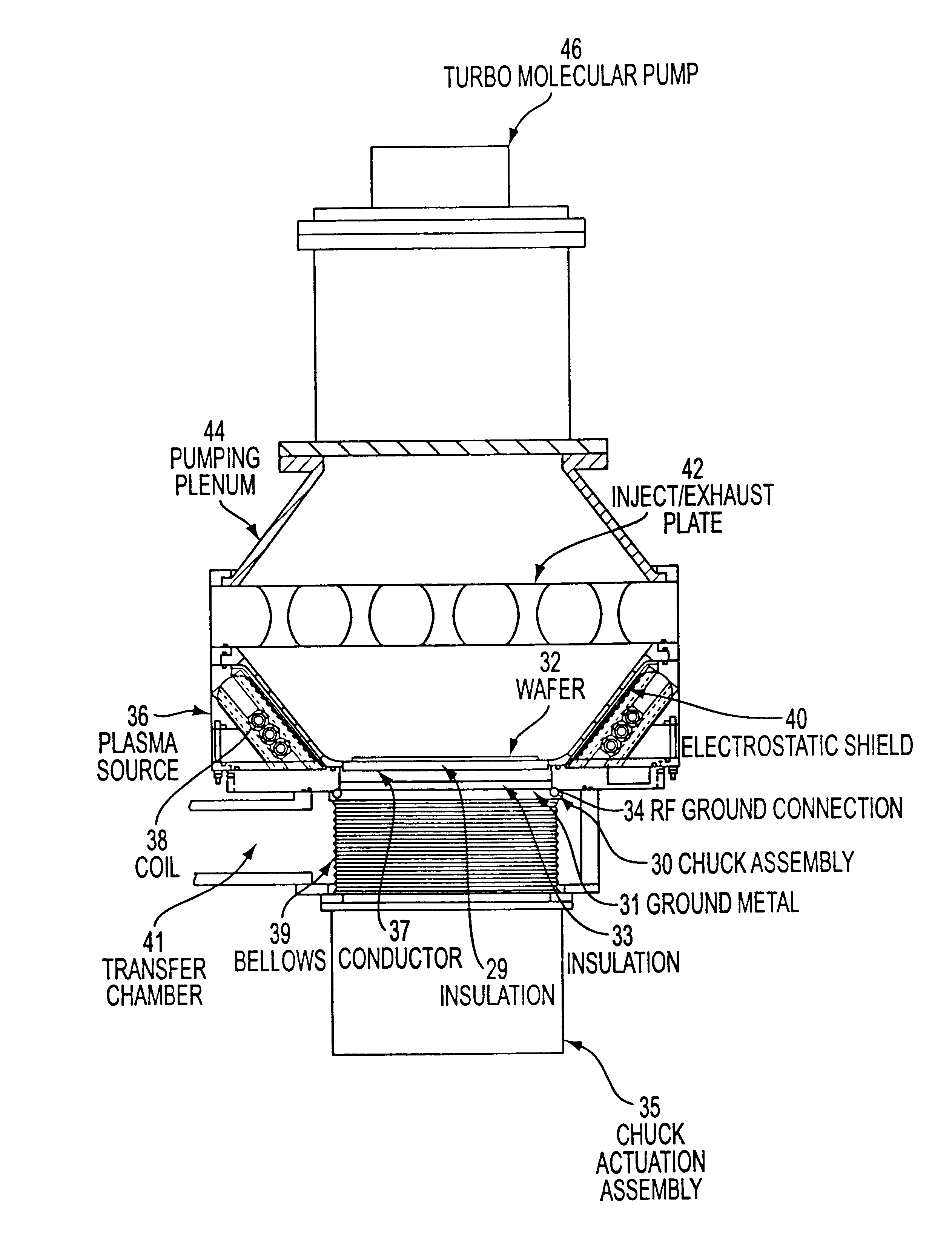

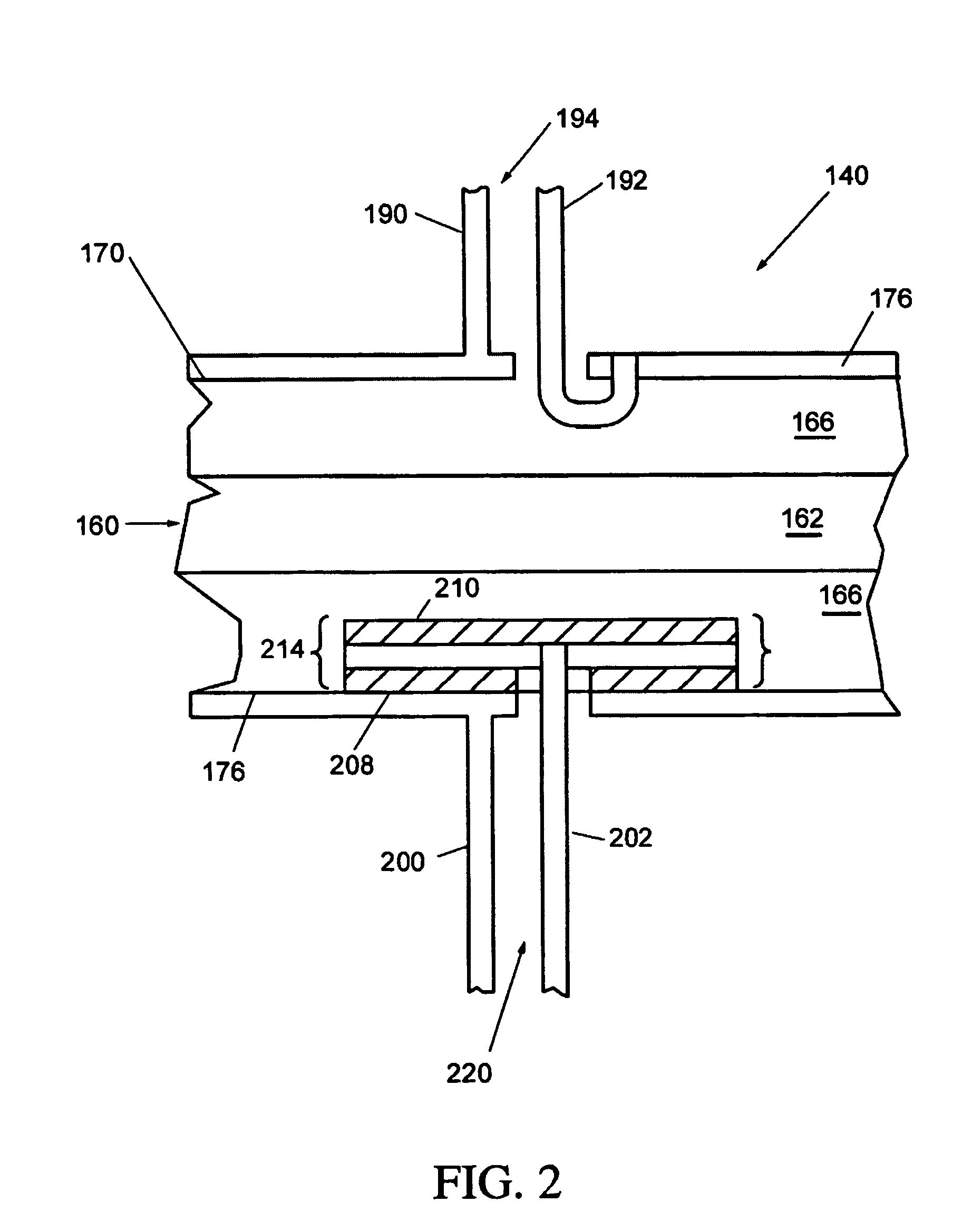

Reduced impedance chamber

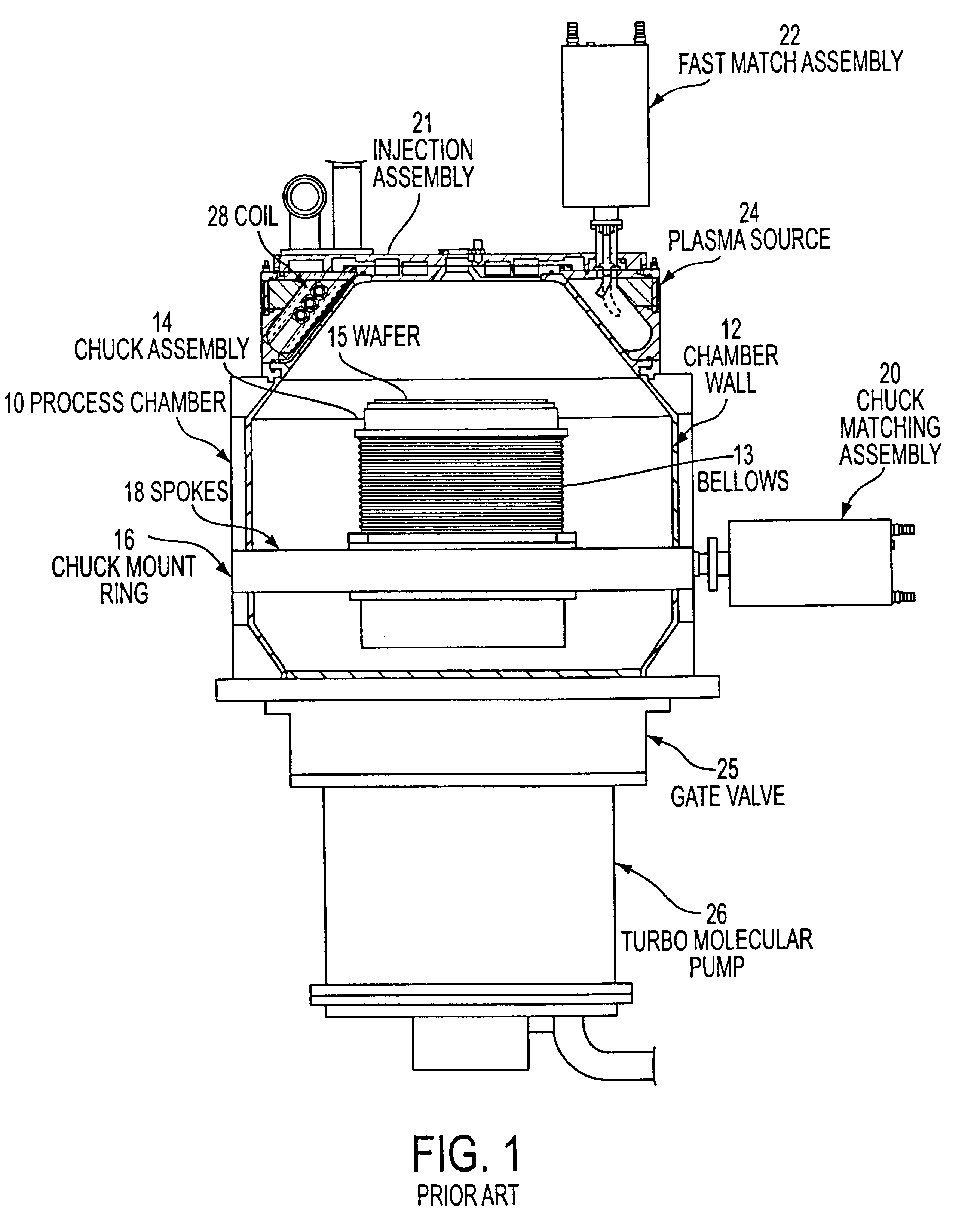

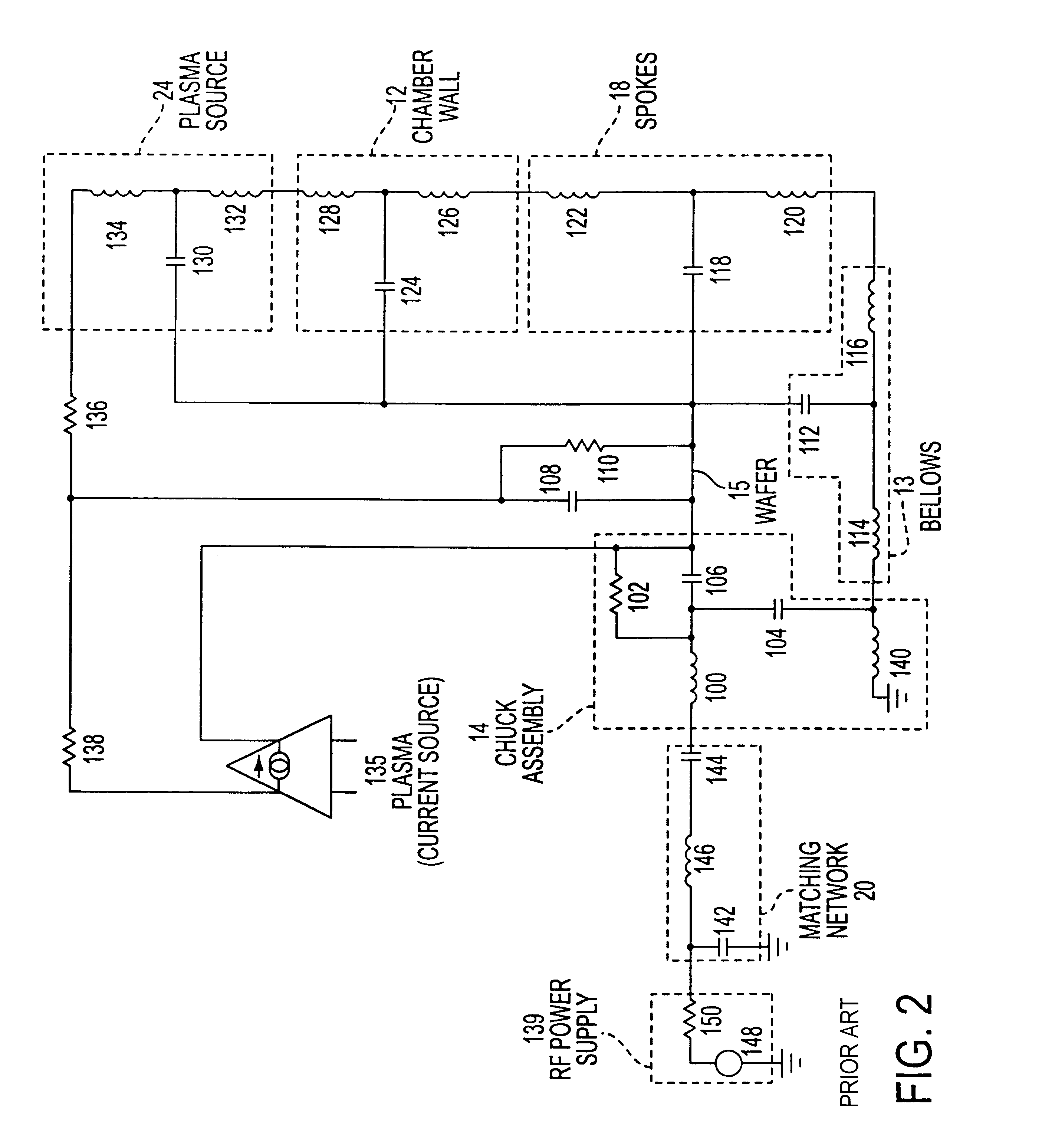

A reduced impedance chamber for plasma processing leads to operational advantages including a plasma sheath voltage that is substantially independent of plasma impedance over a range of plasma impedances. The design of such a reduced impedance chamber includes a chuck assembly, a counter electrode, and a plasma source. The chuck assembly allows mounting of a workpiece for processing and includes a driven electrode and a ground portion. The plasma source operates to generate a plasma in the chamber from process gas. A wall portion of the plasma source is directly electrically connected to the counter electrode and to the ground portion of the chuck assembly. The counter electrode may include an inject-exhaust plate that is mounted in a position opposed to the chuck assembly and that operates to inject process gas into the chamber and to exhaust effluent.

Owner:TOKYO ELECTRON LTD

Stabilizing plasma and generator interactions

ActiveUS7157857B2Stabilizing interactionIncreased fluctuationElectric discharge tubesElectric arc lampsPlasma impedanceConstant power

An approach for stabilizing the interactions between a plasma and the generator powering the plasma is provided. Reactive elements disposed between the power generator and plasma operate to modify the apparent impedance characteristics of the plasma such that the trajectory of the plasma load impedance as a function of power is substantially aligned locally with the contours of constant power output in impedance space. In this way, instabilities in the generator and plasma system are avoided because reinforcement or amplification of fluctuations in plasma impedance due to interactions between the generator and the plasma are reduced or eliminated. The reactive elements may be variable in order to align plasma trajectories and generator power contours under a range of process conditions.

Owner:AES GLOBAL HLDG PTE LTD

RF impedance matching network

ActiveUS9865432B1Shorten the timeMultiple-port networksSemiconductor/solid-state device testing/measurementCapacitancePlasma impedance

An RF impedance matching network includes an RF input configured to operably couple to an RF source, the RF source having a fixed RF source impedance; an RF output configured to operably couple to a plasma chamber, the plasma chamber having a variable plasma impedance; a series EVC; a shunt EVC; an RF input sensor; and a control circuit configured to: determine an input impedance; determine the plasma impedance; determine a first capacitance value for the series variable capacitance and a second capacitance value for the shunt variable capacitance, the determination of the first capacitance value and the second capacitance value based on the plasma impedance and the RF source impedance; generate a control signal to alter at least one of the series variable capacitance and the shunt variable capacitance to the first capacitance value and the second capacitance value, respectively.

Owner:ASM AMERICA INC

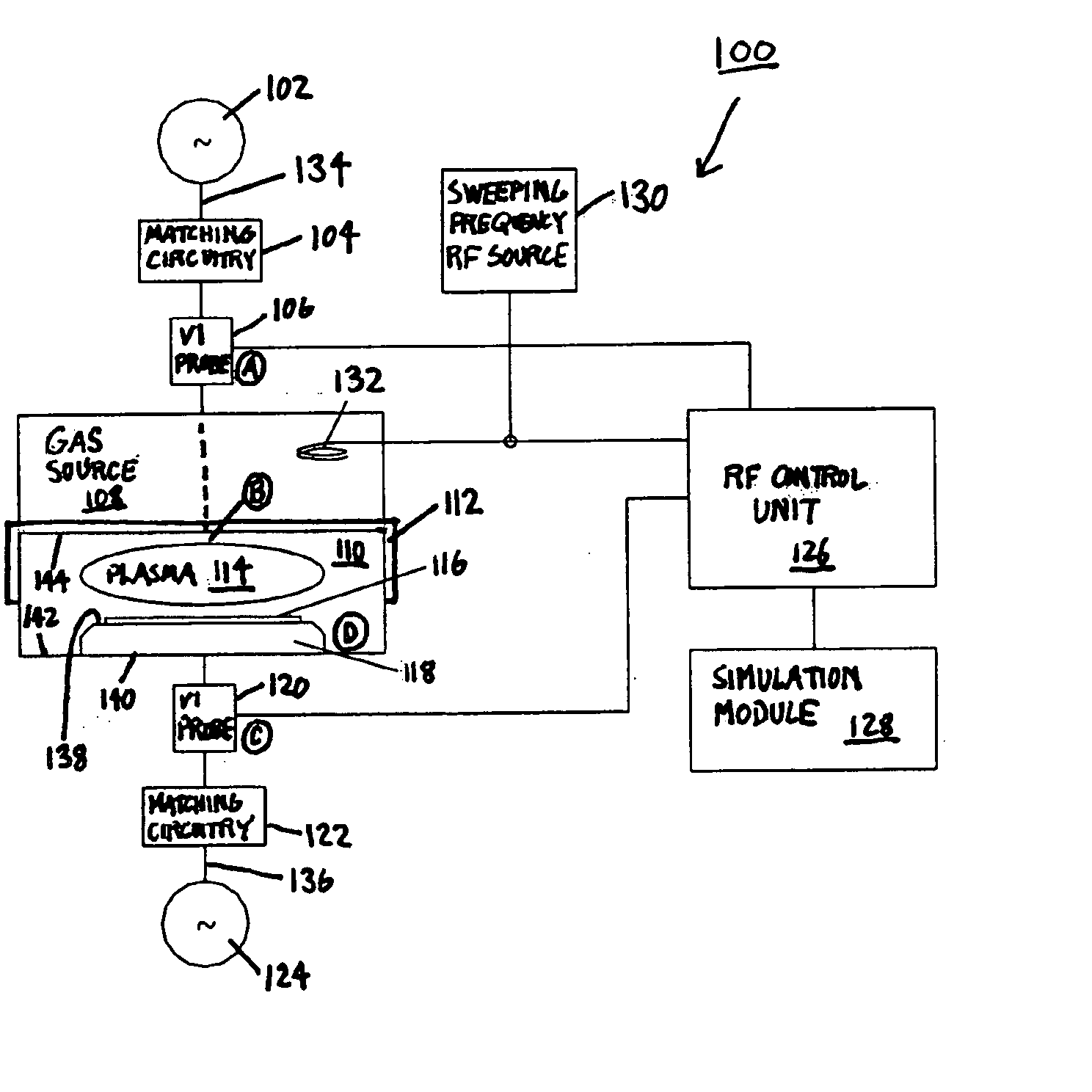

Method and apparatus for determining plasma impedance

InactiveUS20050067386A1Accurate measurementElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma impedanceEngineering

Owner:TOKYO ELECTRON LTD

Method and apparatus for detecting endpoint in a dry etching system by monitoring a superimposed DC current

InactiveUS20080026488A1Good etchingFacilitate formation of plasmaSemiconductor/solid-state device testing/measurementElectric discharge tubesElectron temperaturePlasma density

A method and apparatus for detecting the endpoint in a dry plasma etching system comprising a first electrode (e.g., upper electrode) and a second electrode (e.g., lower electrode) upon which a substrate rests is described. A direct current (DC) voltage is applied between the first electrode and a ring electrode surrounding the second electrode, and the DC current is monitored to determine the endpoint of the etching process. The DC current is affected by the impedance of the plasma, and therefore responds to many variations including, for example, the plasma density, electron / ion flux to exposed surfaces, the electron temperature, etc.

Owner:TOKYO ELECTRON LTD +1

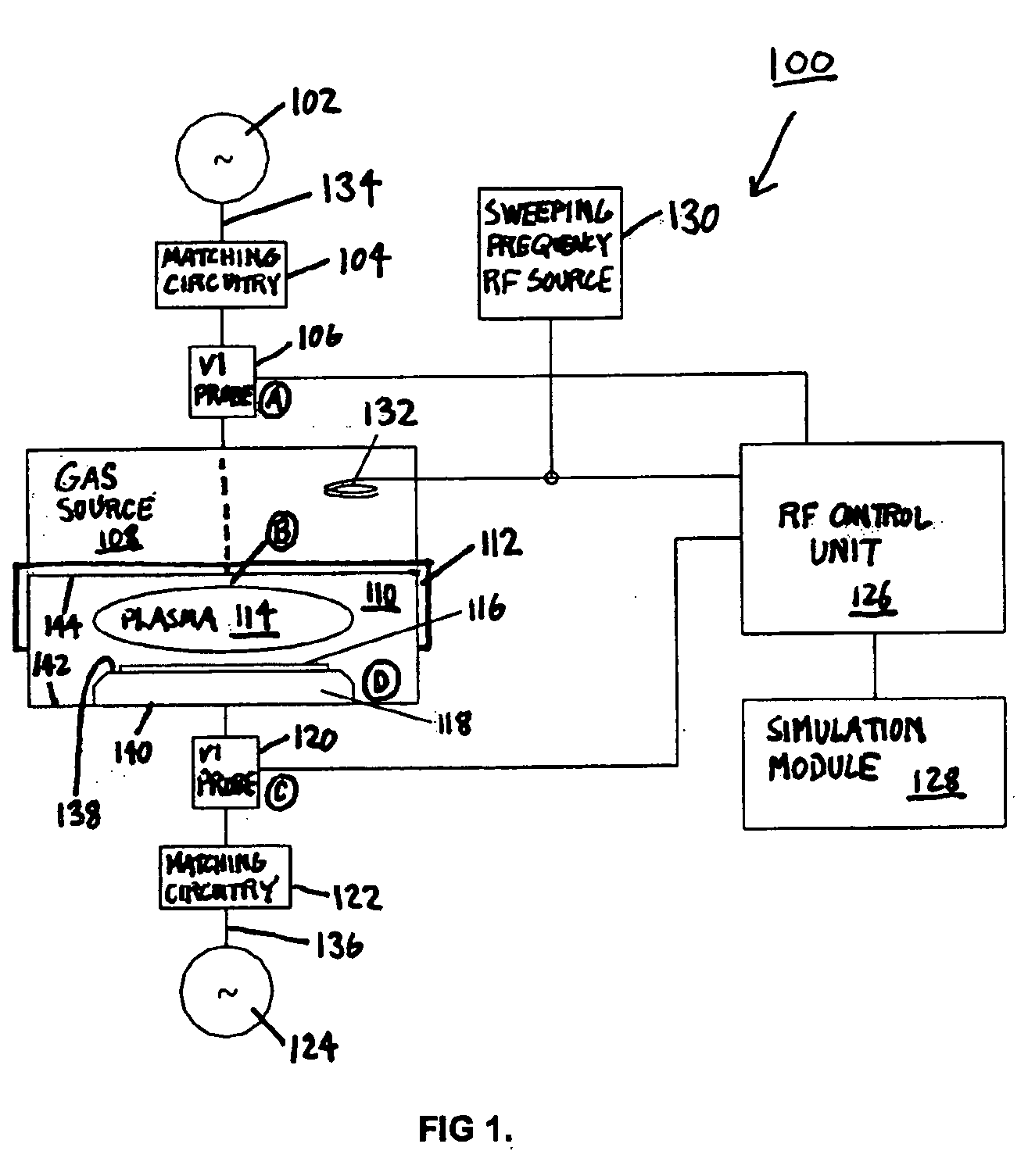

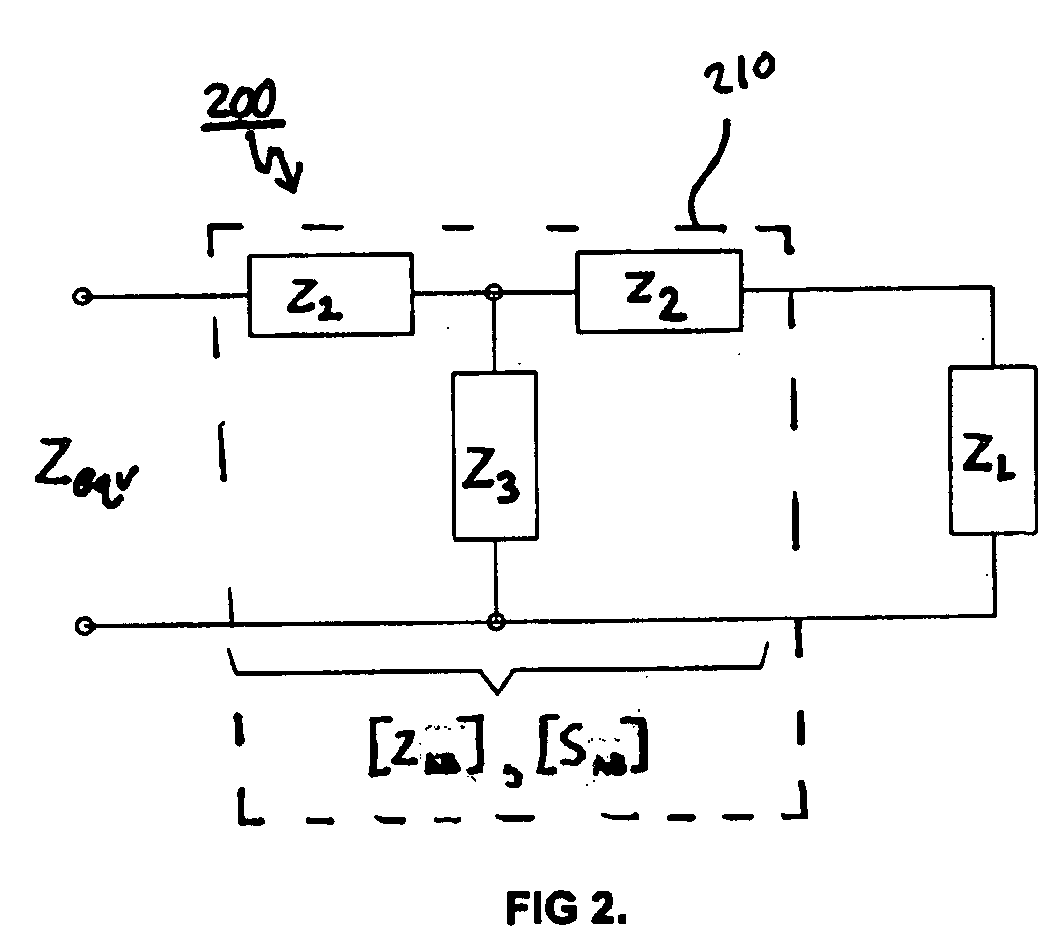

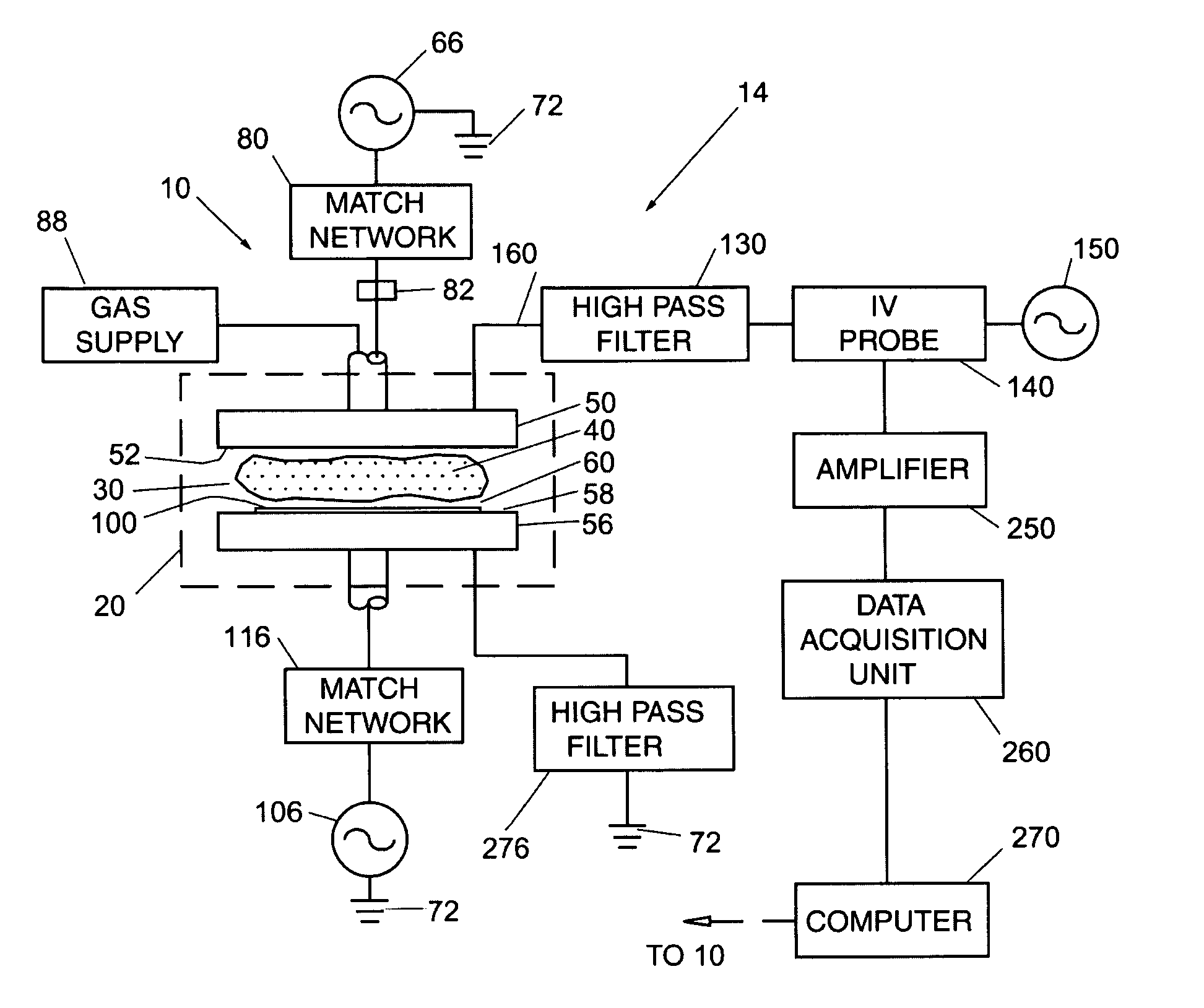

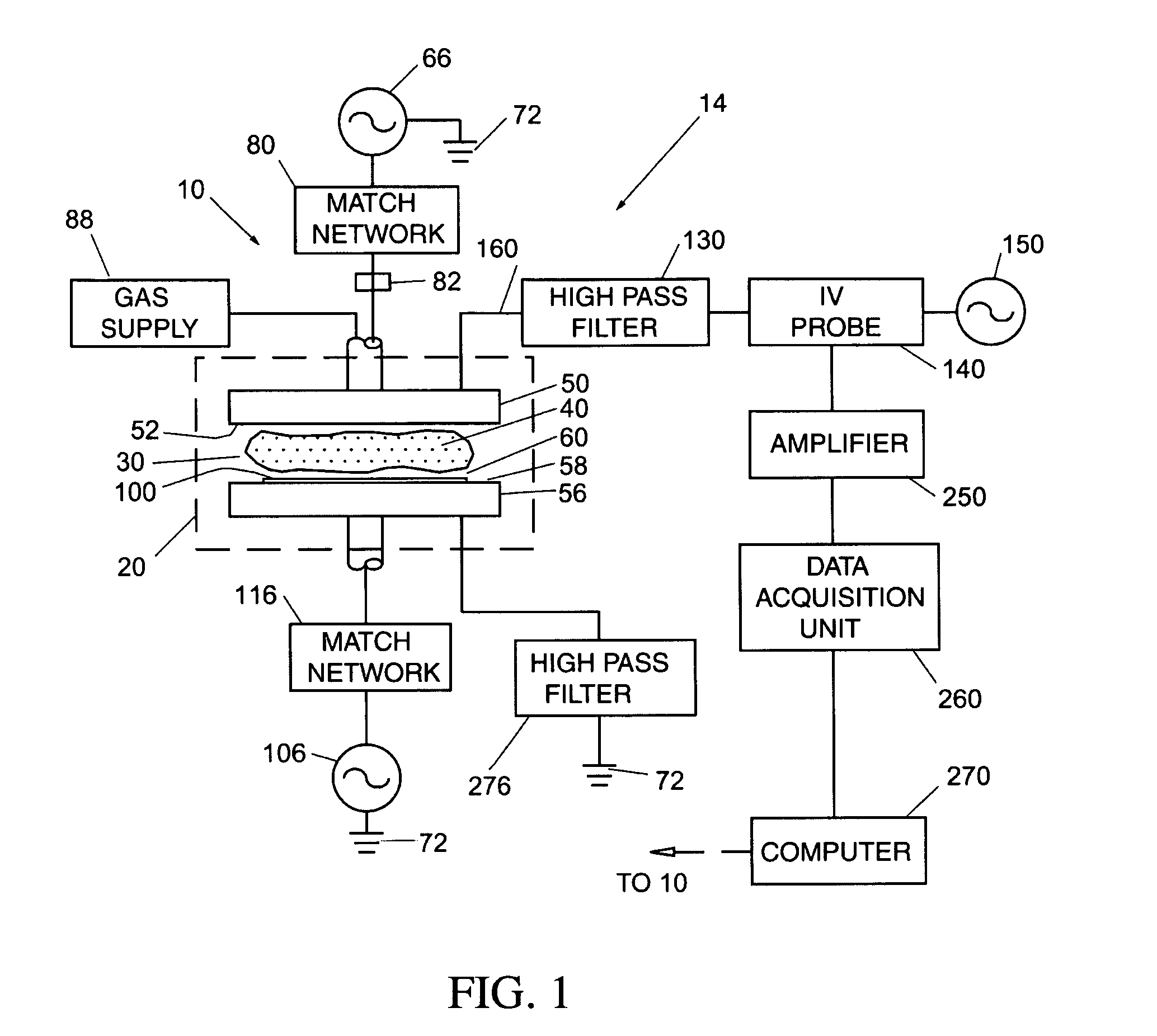

Impedance monitoring system and method

InactiveUS7019543B2Current/voltage measurementResistance/reactance/impedenceCapacitanceMeasurement device

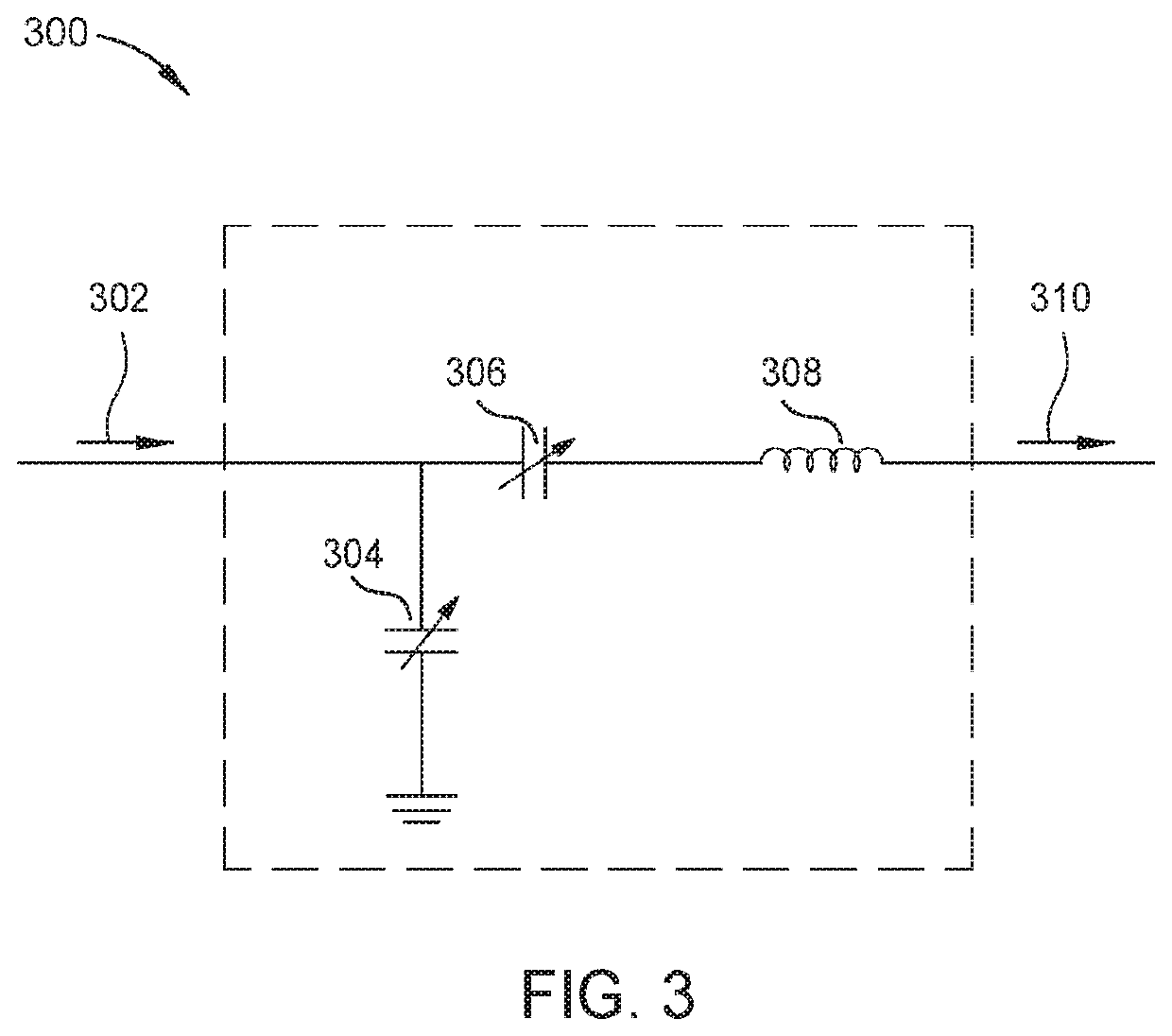

An apparatus (14) for and method of measuring impedance in a capacitively coupled plasma reactor system (10). The apparatus includes a high-frequency RF source (150) in electrical communication with an upper electrode (50). A first high-pass filter (130) is arranged between the upper electrode and the high-frequency RF source, to block low-frequency, high-voltage signals from the electrode RF power source (66) from passing through to the impedance measuring circuit A current-voltage probe (140) is arranged between the high-frequency source and the high-pass filter, and is used to measure the current and voltage of the probe signal with and without the plasma present. An amplifier (250) is electrically connected to the current-voltage probe, and a data acquisition unit (260) is electrically connected to the amplifier. A second high-pass filter (276) is electrically connected to a lower electrode (56) and to ground, so as to complete the isolation of the high-frequency circuit of the impedance measurement apparatus from the low-frequency, high-voltage circuit of the capacitively coupled plasma reactor system. A method of measuring the plasma impedance using the apparatus of the present invention is also disclosed.

Owner:TOKYO ELECTRON LTD

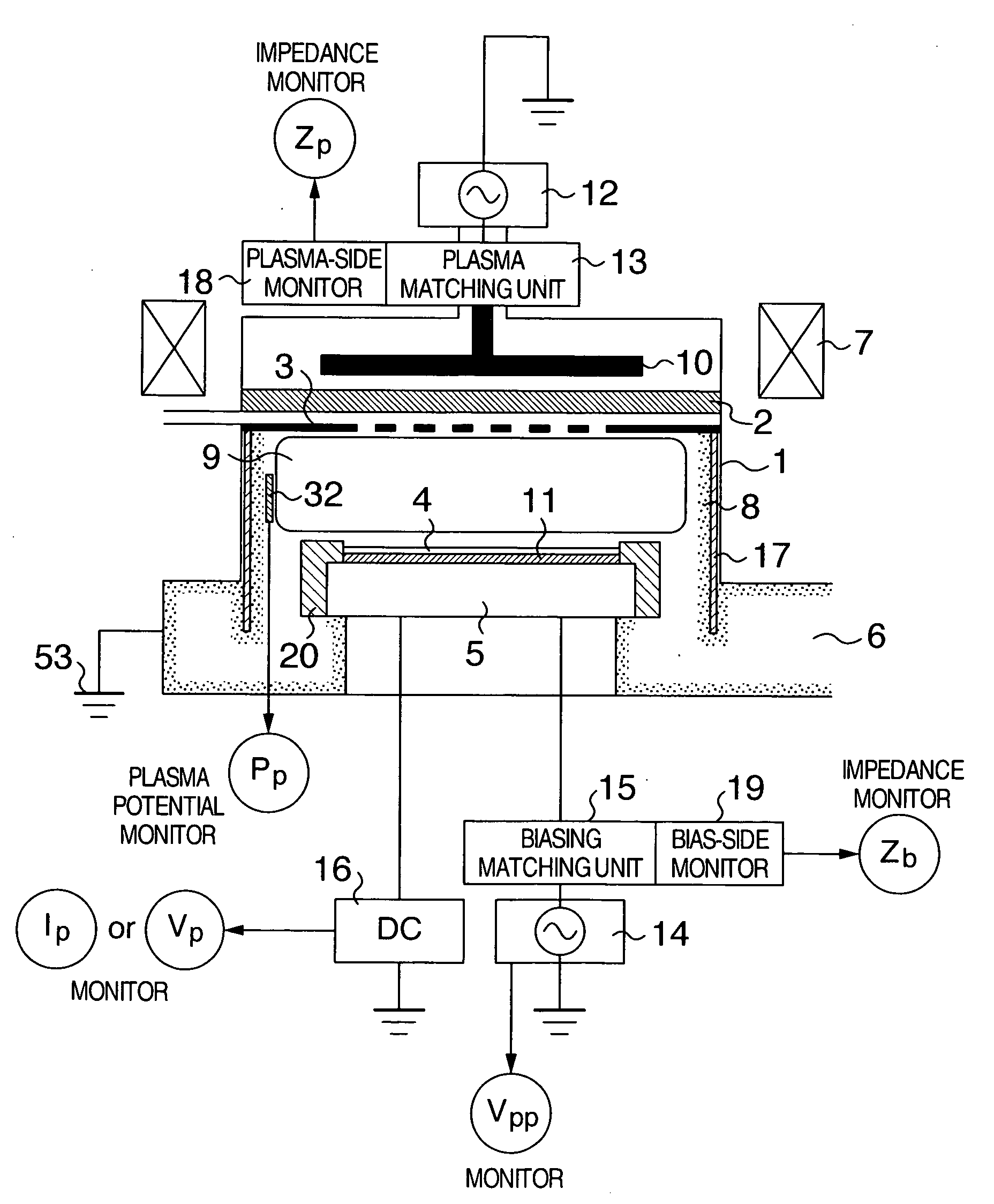

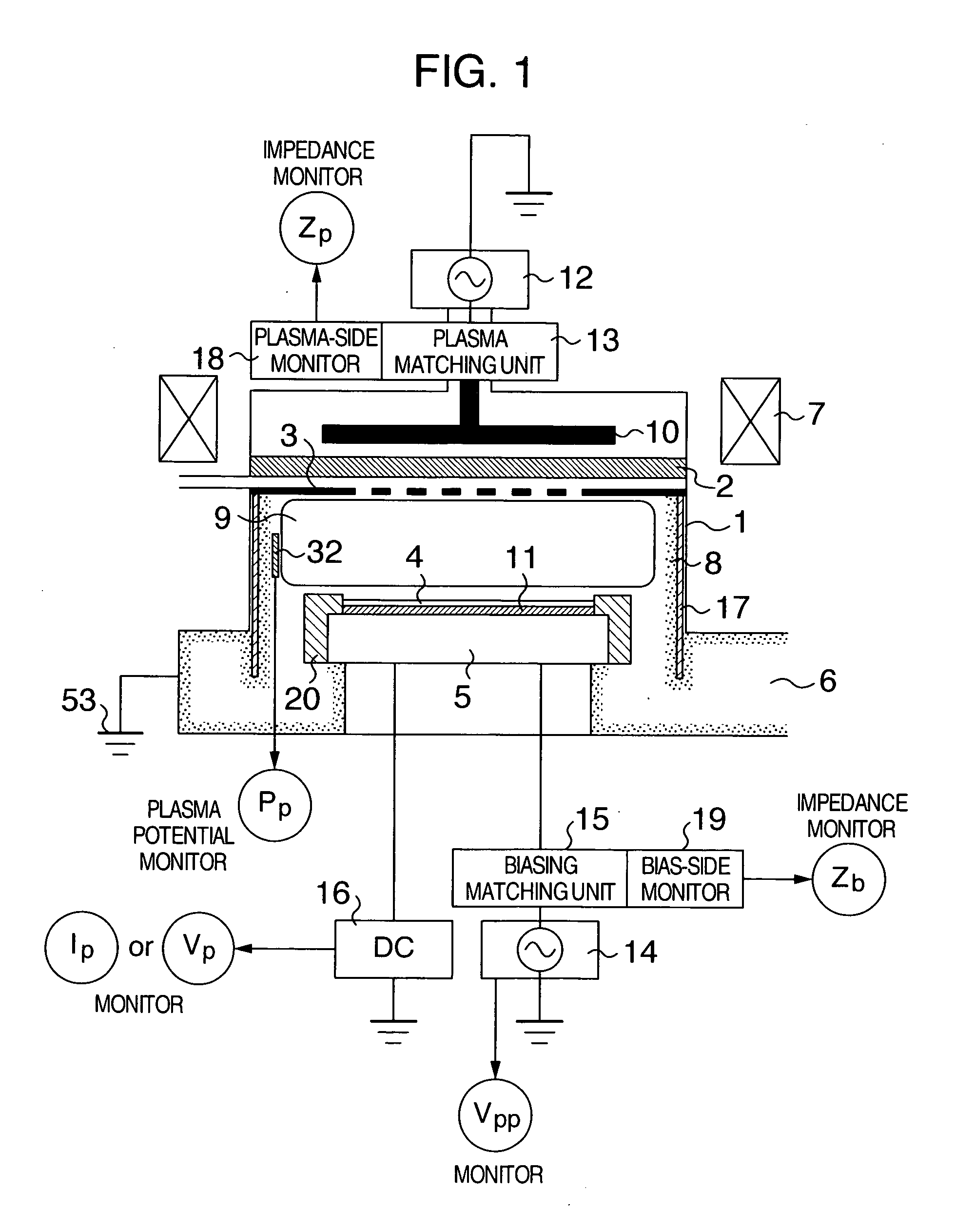

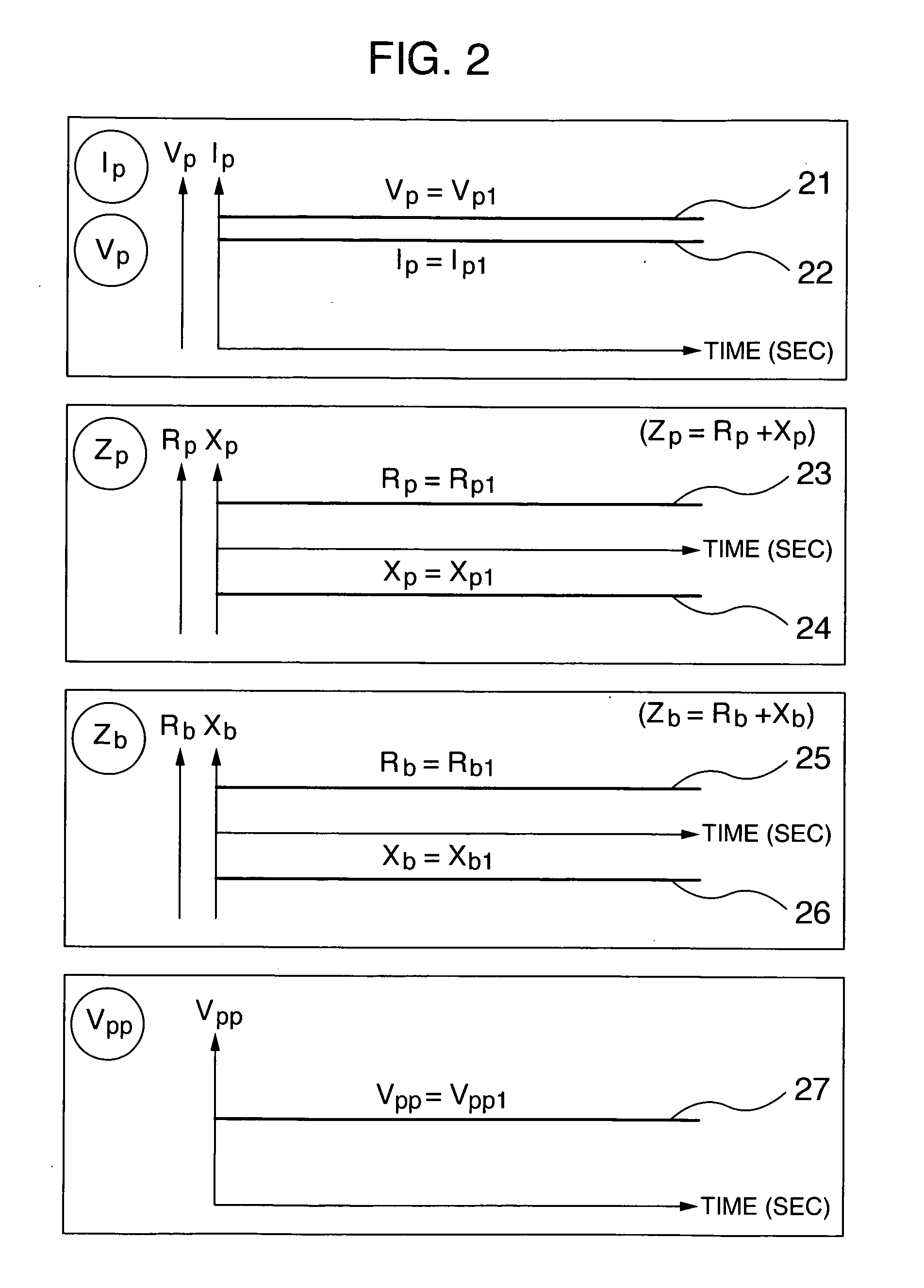

Plasma processing apparatus

InactiveUS20070215282A1Electric discharge tubesSemiconductor/solid-state device manufacturingTectorial membranePlasma impedance

A plasma processing apparatus including a chamber having an inner wall with a protective film thereon and a sample stage disposed in the chamber in which plasma is generated by supplying high-frequency wave energy to processing gas to conduct plasma processing for a sample on the sample stage using the plasma. The apparatus includes a control device which determines, based on monitor values of a wafer attracting current monitor (Ip) to monitor a current supplied from a wafer attracting power source, an impedance monitor (Zp) to monitor plasma impedance viewed from a plasma generating power source, and an impedance monitor (Zb) to monitor a plasma impedance viewed from a bias power supply, presence or absence of occurrence of an associated one of abnormal discharge in inner parts, deterioration in insulation of an insulating film of a wafer attracting electrode, and abnormal injection in a gas injection plate.

Owner:HITACHI HIGH-TECH CORP

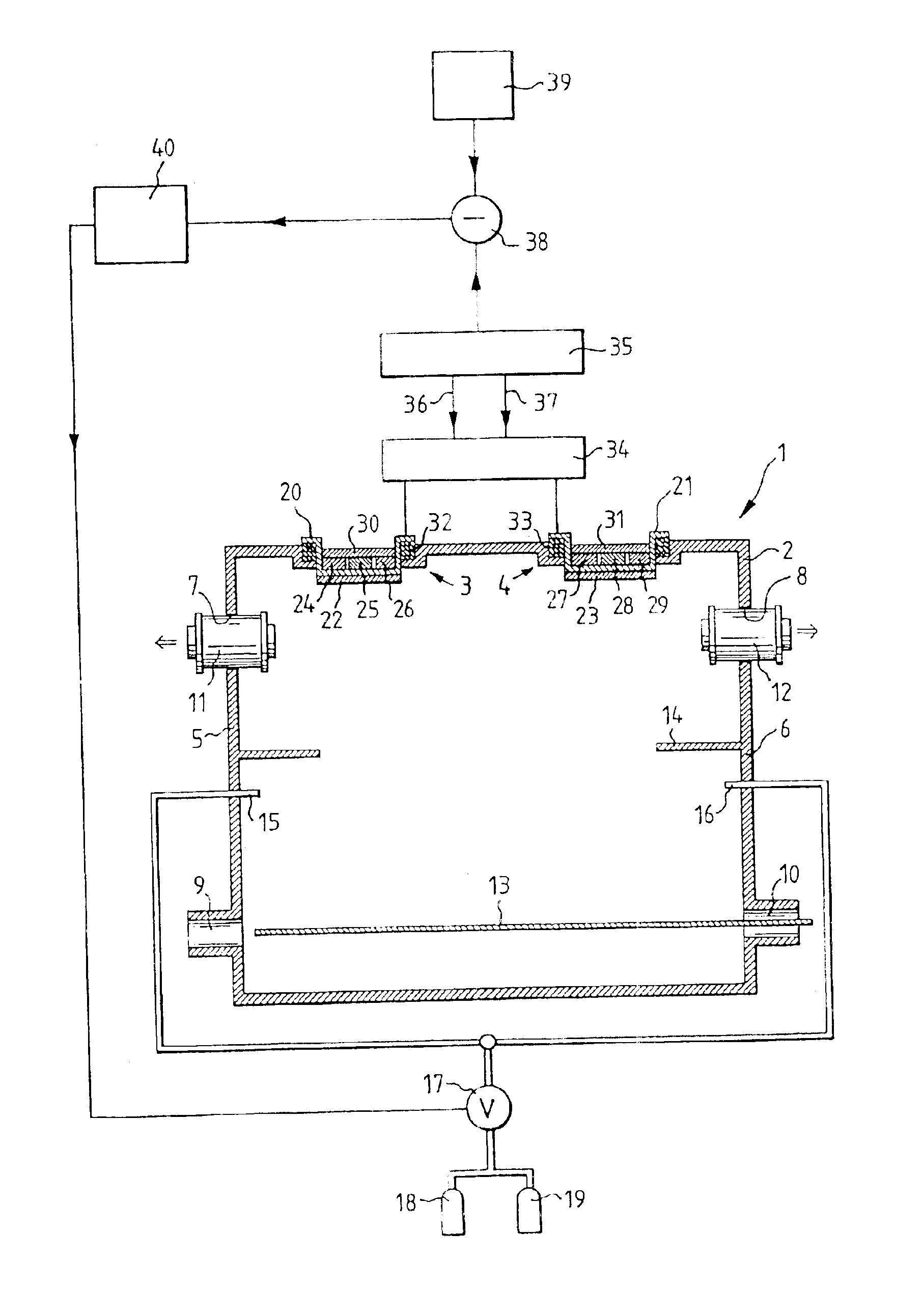

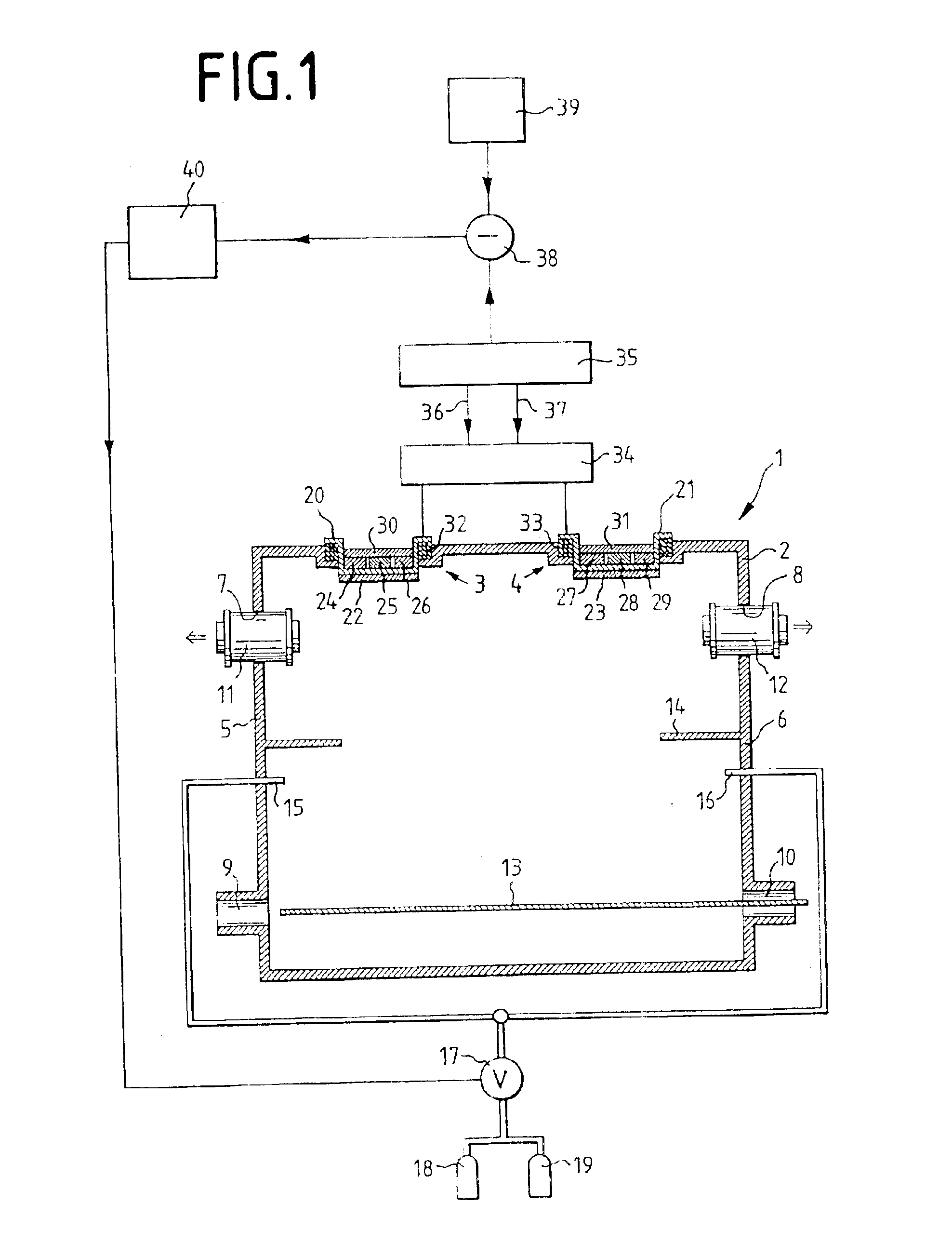

Device for the regulation of a plasma impedance

The invention relates to a device for the regulation of a plasma impedance in a vacuum chamber, wherein at least one electrode is connected to an AC generator. This AC generator is a free-running [oscillator], whose frequency adjusts to the resonance frequency of the load upon which it acts. This load comprises fixed circuit elements and a variable plasma impedance. If the plasma impedance is changed, with it the resonance frequency is also changed. The plasma impedance can thus be varied by acquisition of the resonance frequency and by presetting of a reference frequency value, for example thereby that the voltage, the current, the power or the gas inflow is varied as a function of the difference between resonance frequency and reference frequency value.

Owner:APPLIED MATERIALS GMBH & CO KG

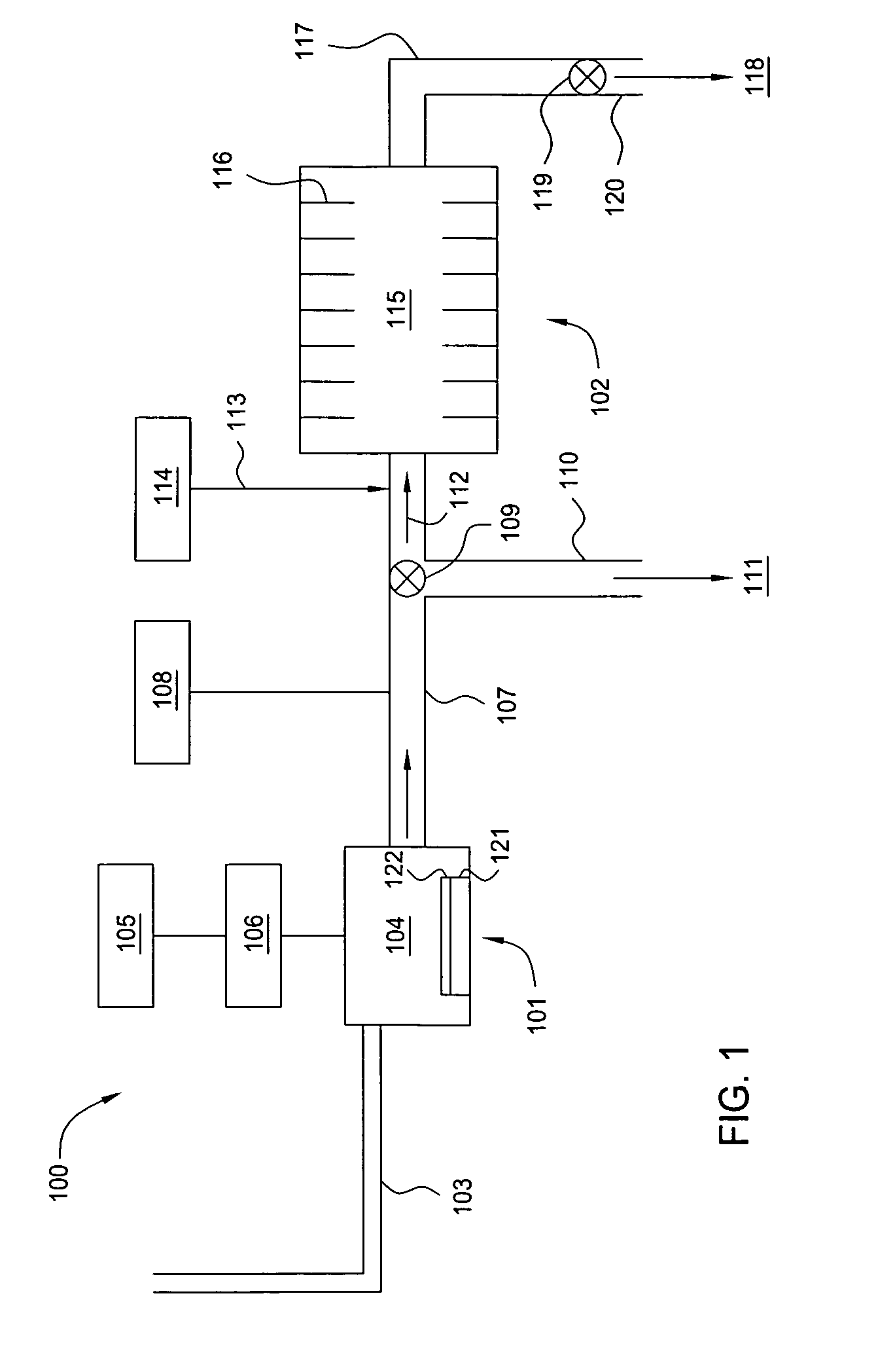

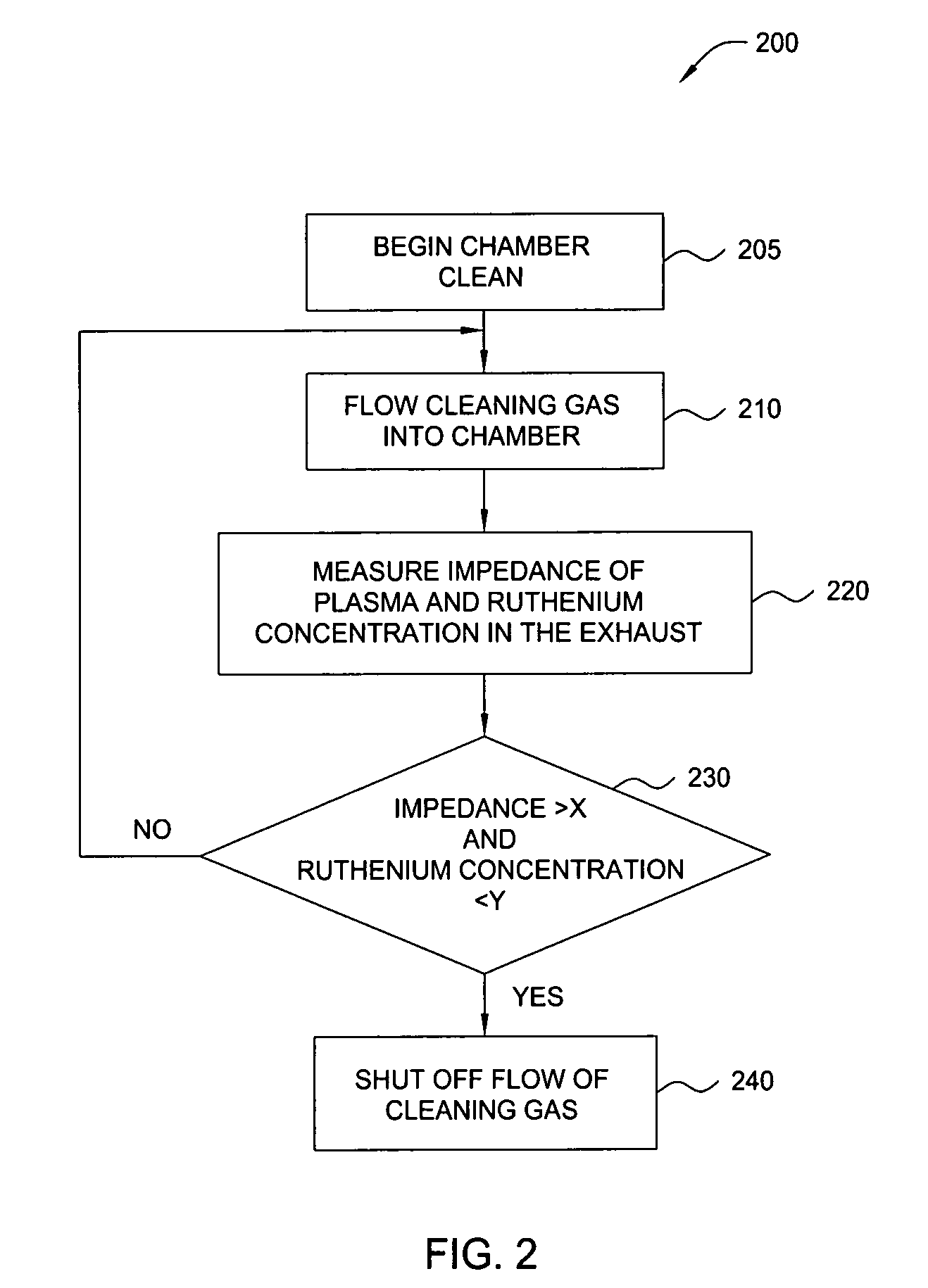

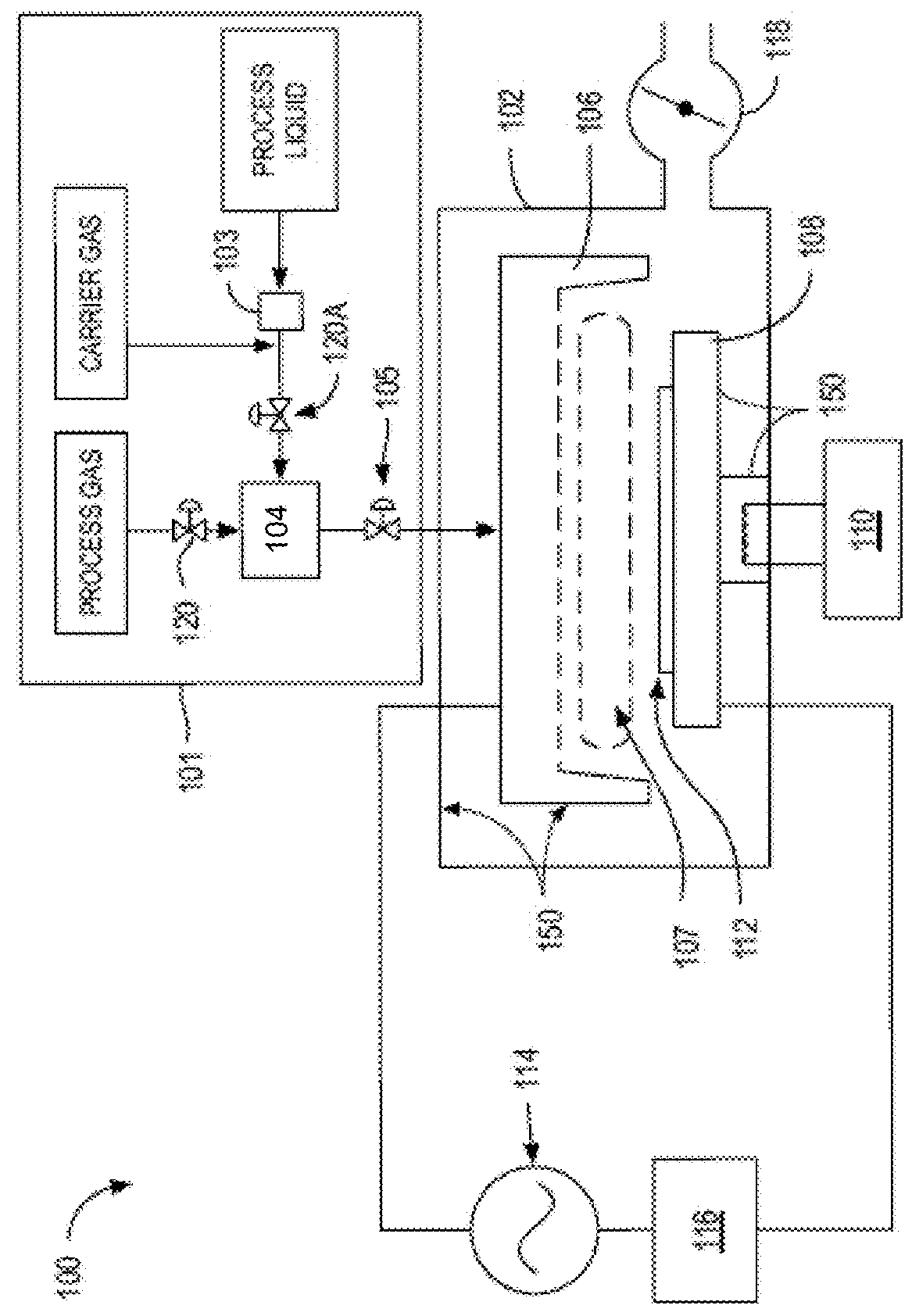

Method of recovering valuable material from exhaust gas stream of a reaction chamber

Owner:APPLIED MATERIALS INC

RF impedance matching network

ActiveUS20150200079A1Shorten the timeMultiple-port networksImpedence matching networksPlasma impedanceControl signal

An RF impedance matching network includes an RF input; an RF output configured to operably couple to a plasma chamber; a series electronically variable capacitor (“series EVC”), the series EVC electrically coupled in series between the RF input and the RF output; and a shunt electronically variable capacitor (“shunt EVC”), the shunt EVC electrically coupled in parallel between a ground and one of the RF input and the RF output; a control circuit to control the series variable capacitance and the shunt variable capacitance, wherein the control circuit is configured to determine the variable plasma impedance of the plasma chamber, determine a series capacitance value and a shunt capacitance value, and generate a control signal to alter at least one of the series variable capacitance and the shunt variable capacitance; wherein the alteration is caused by at least one of a plurality of switching circuits.

Owner:RENO TECH

Adjustable capacitor, plasma impedance matching device, plasma impedance matching method, and substrate treating apparatus

ActiveCN102568993AElectric discharge tubesCapacitor with electrode distance variationCapacitancePlasma impedance

Disclosed is a substrate treating apparatus which comprises a process chamber; an electrode configured to generate plasma from a gas supplied into the process chamber; an RF power supply configured to output an RF power; a transmission line configured to transmit the RF power to the electrode from the RF power supply; an impedance matching unit connected to the transmission line and configured to match plasma impedance; and a controller configured to output a control signal to the impedance matching unit, wherein the impedance matching unit comprises an adjustable capacitor having a plurality of capacitors and a plurality of switches corresponding to the plurality of capacitors, the plurality of switches being switched on / off according to the control signal so that capacitance of the adjustable capacitor is adjusted.

Owner:SEMES CO LTD

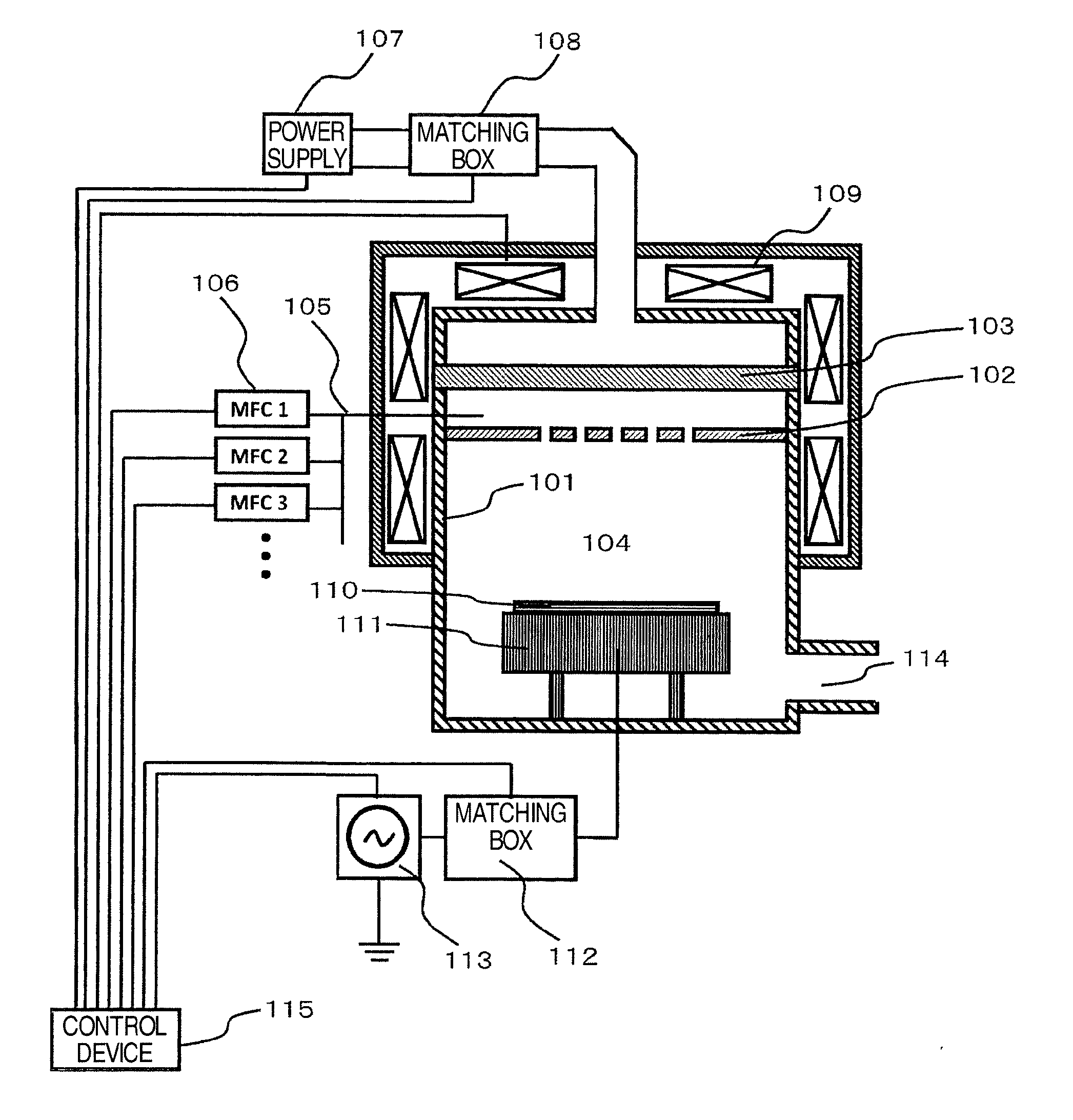

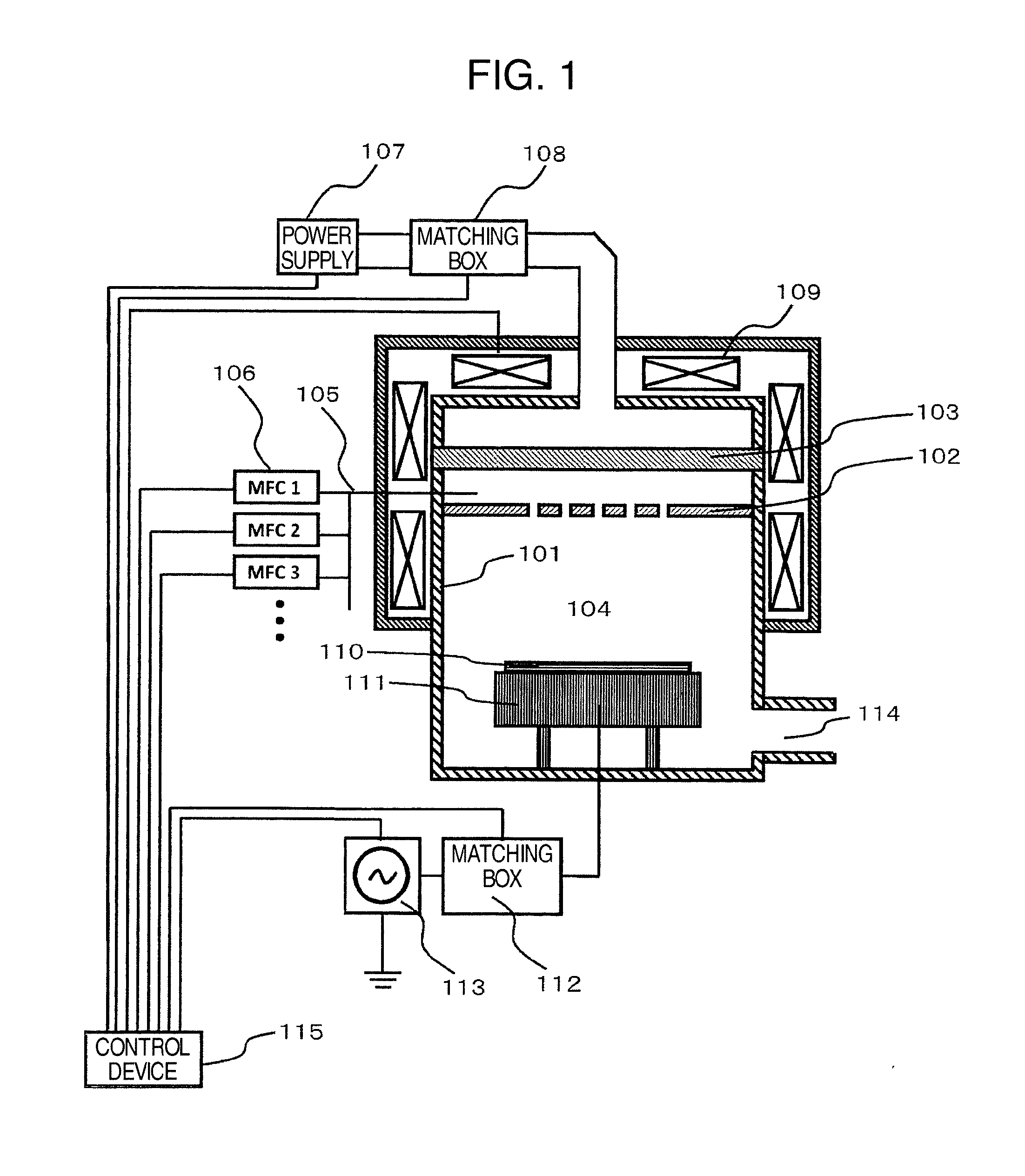

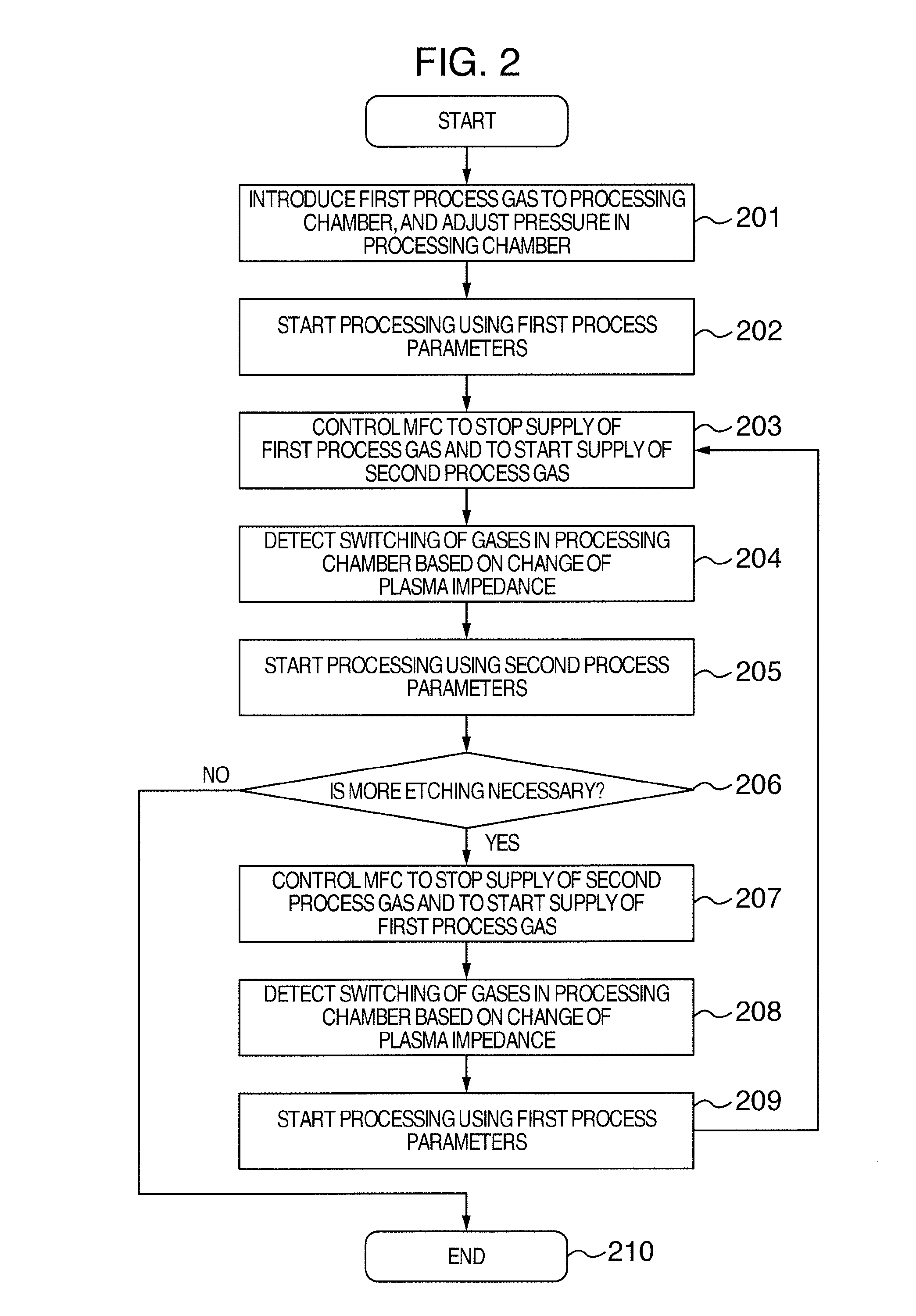

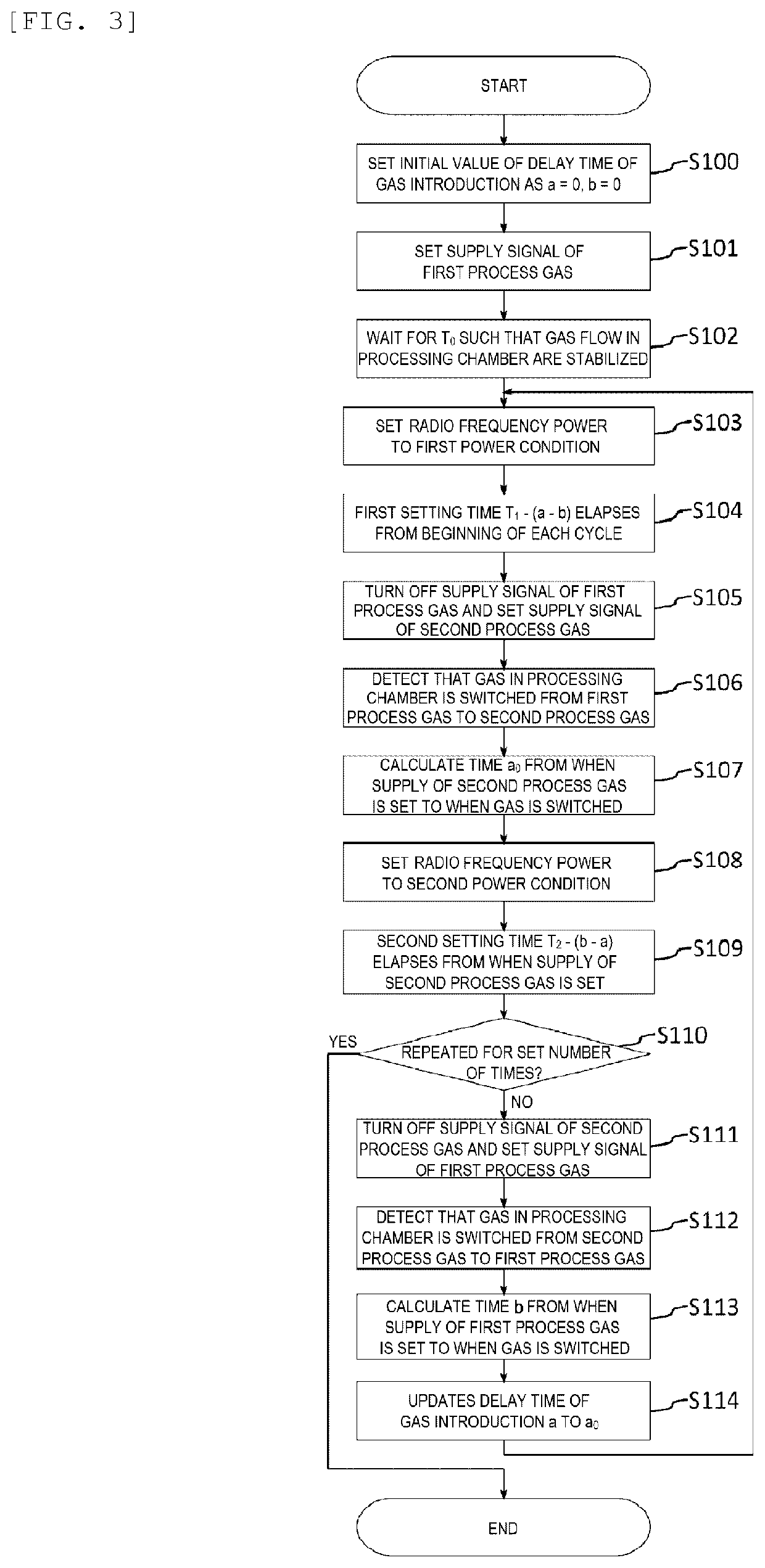

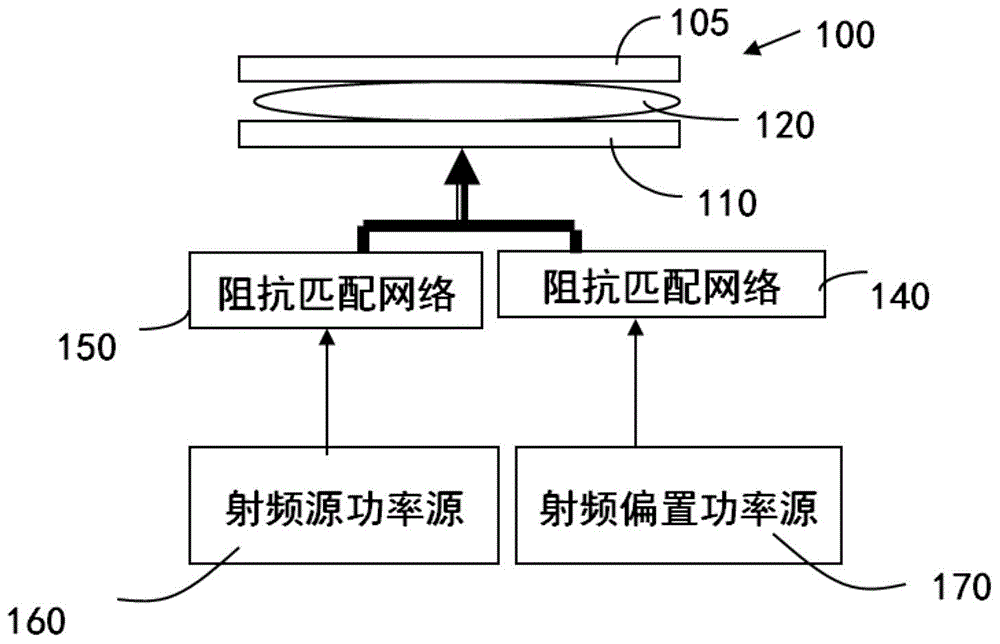

Plasma processing apparatus and plasma processing method

ActiveUS20160133530A1Improve stabilityGood shape controllabilityLiquid surface applicatorsSemiconductor/solid-state device testing/measurementPlasma impedanceEngineering

A plasma processing apparatus includes a processing chamber configured to perform a plasma processing on a sample, a first radio frequency power supply configured to generate a plasma, a sample stage configured to place the sample thereon, a second radio frequency power supply configured to supply a radio frequency power to the sample stage, a mass flow controller configured to supply a gas into the processing chamber, and a control device configured to change the radio frequency power supplied from the first radio frequency power supply or the second radio frequency power supply based on a change of plasma impedance after a first gas is switched to a second gas.

Owner:HITACHI HIGH-TECH CORP

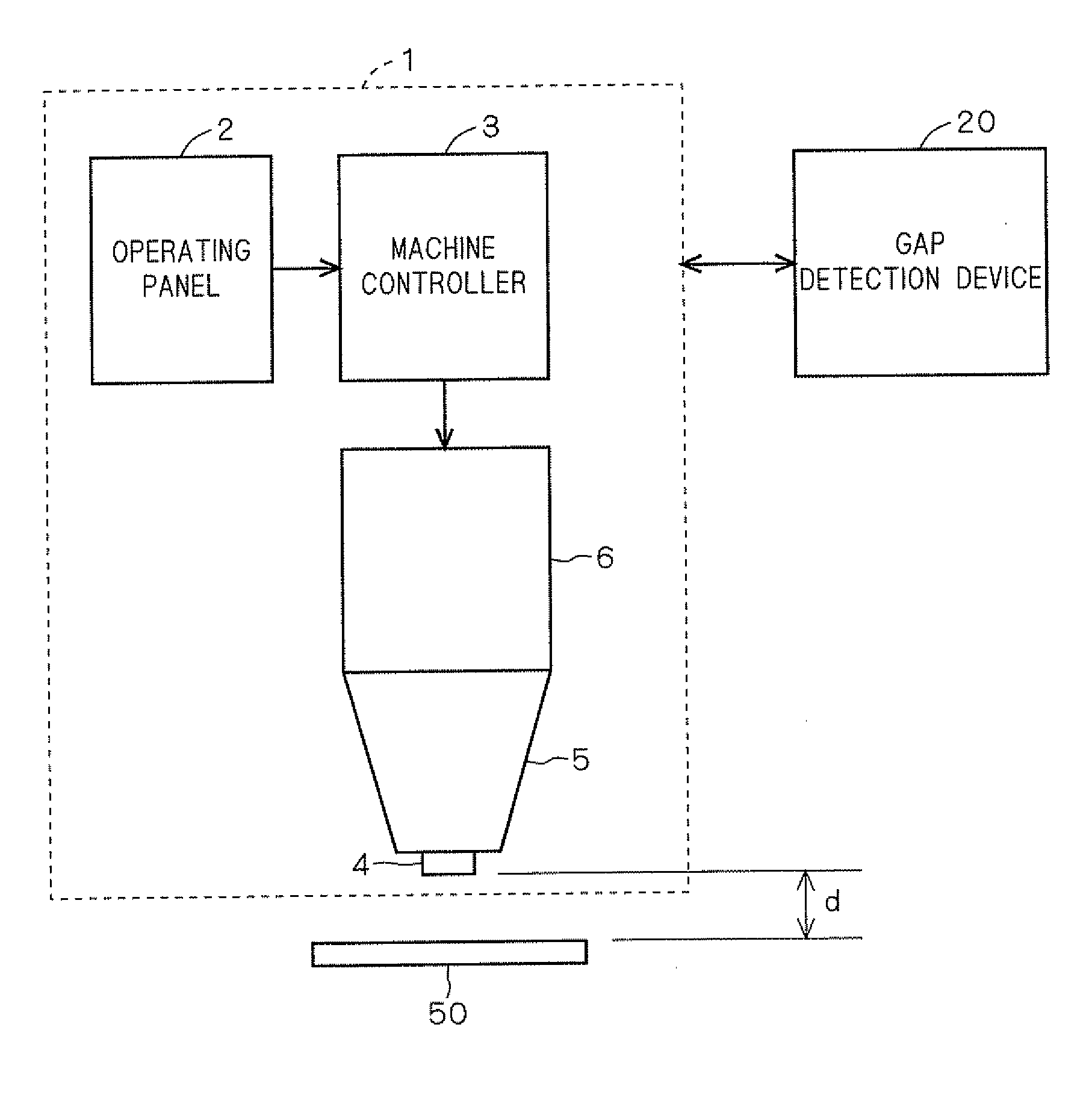

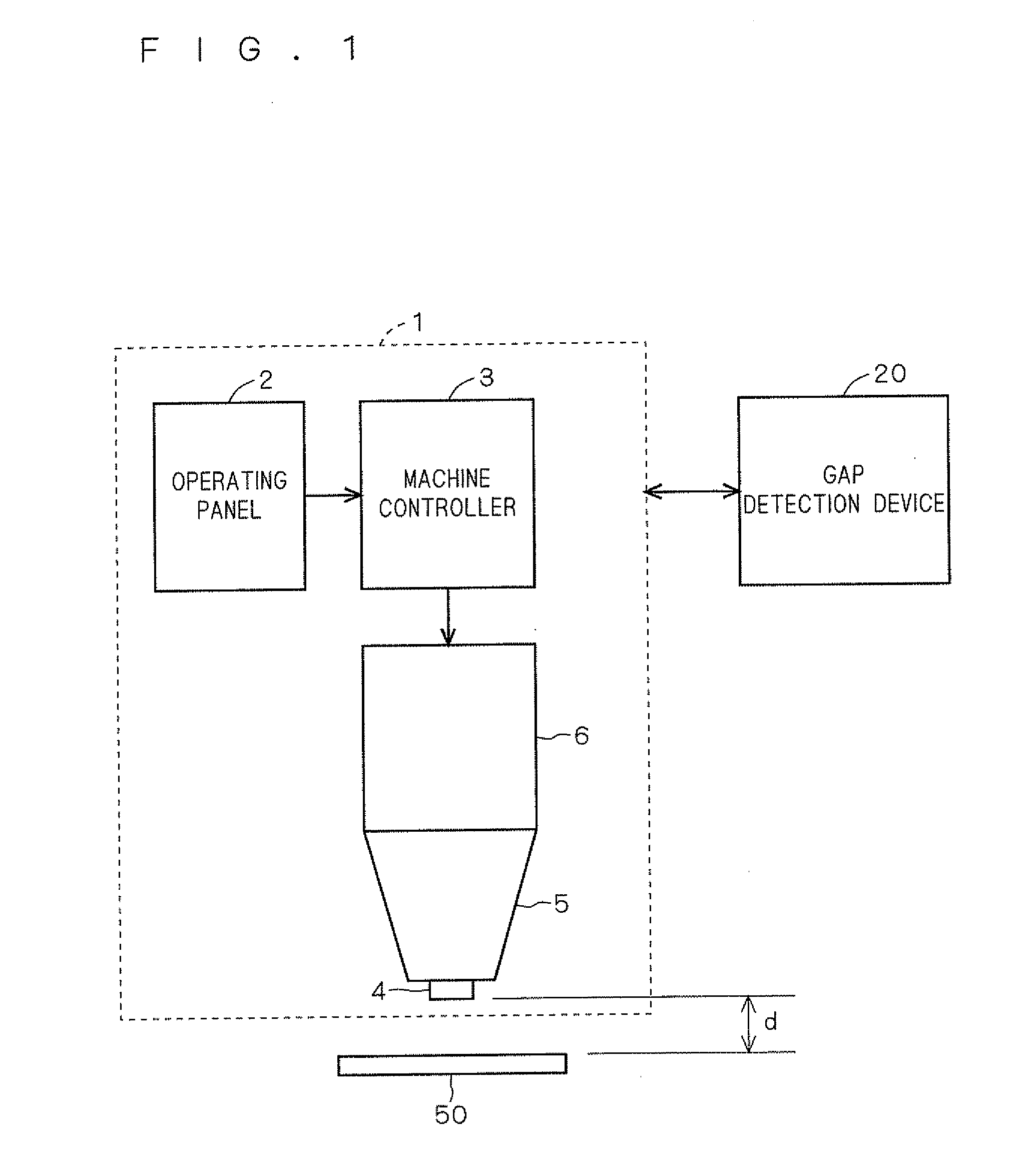

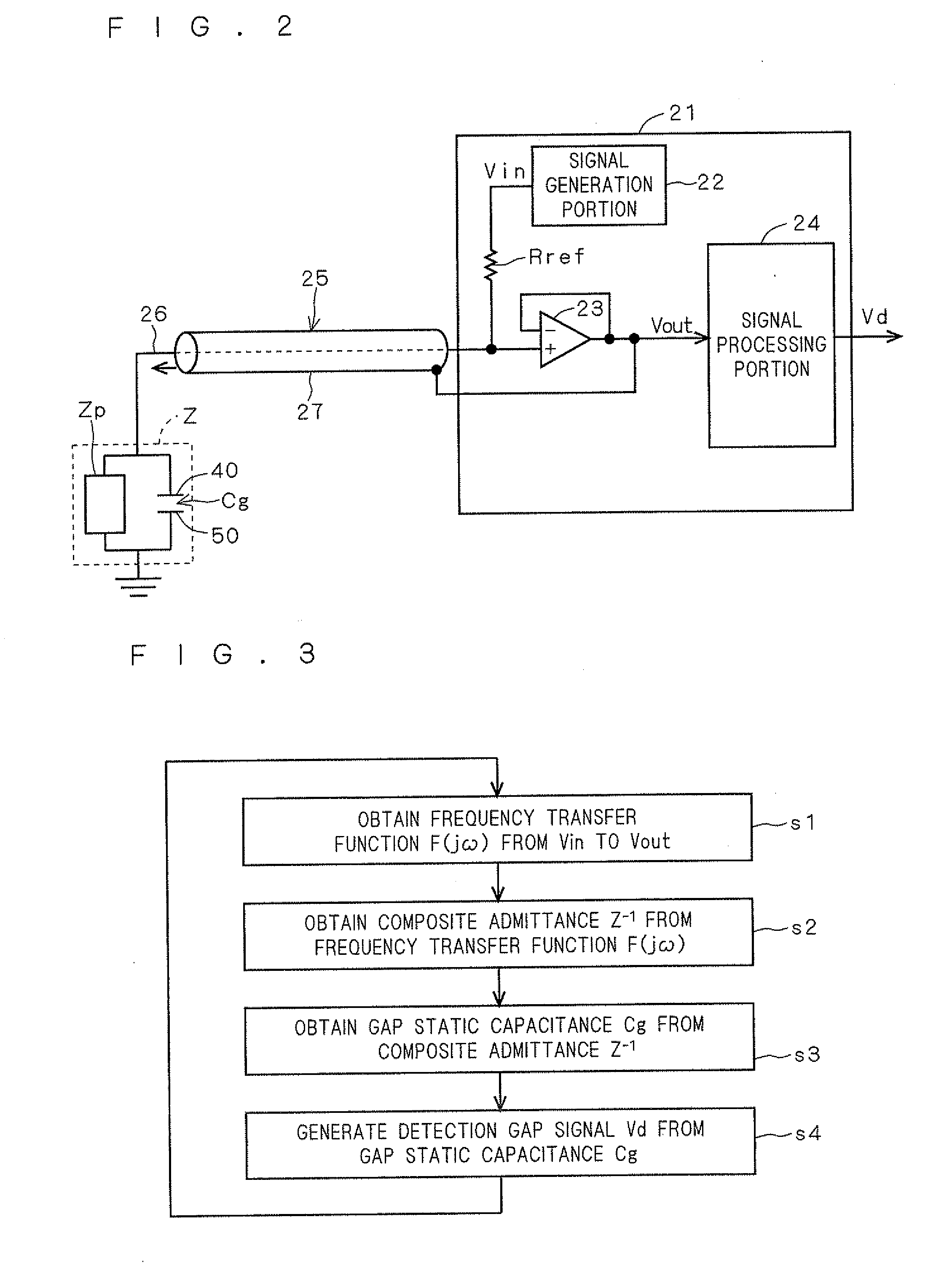

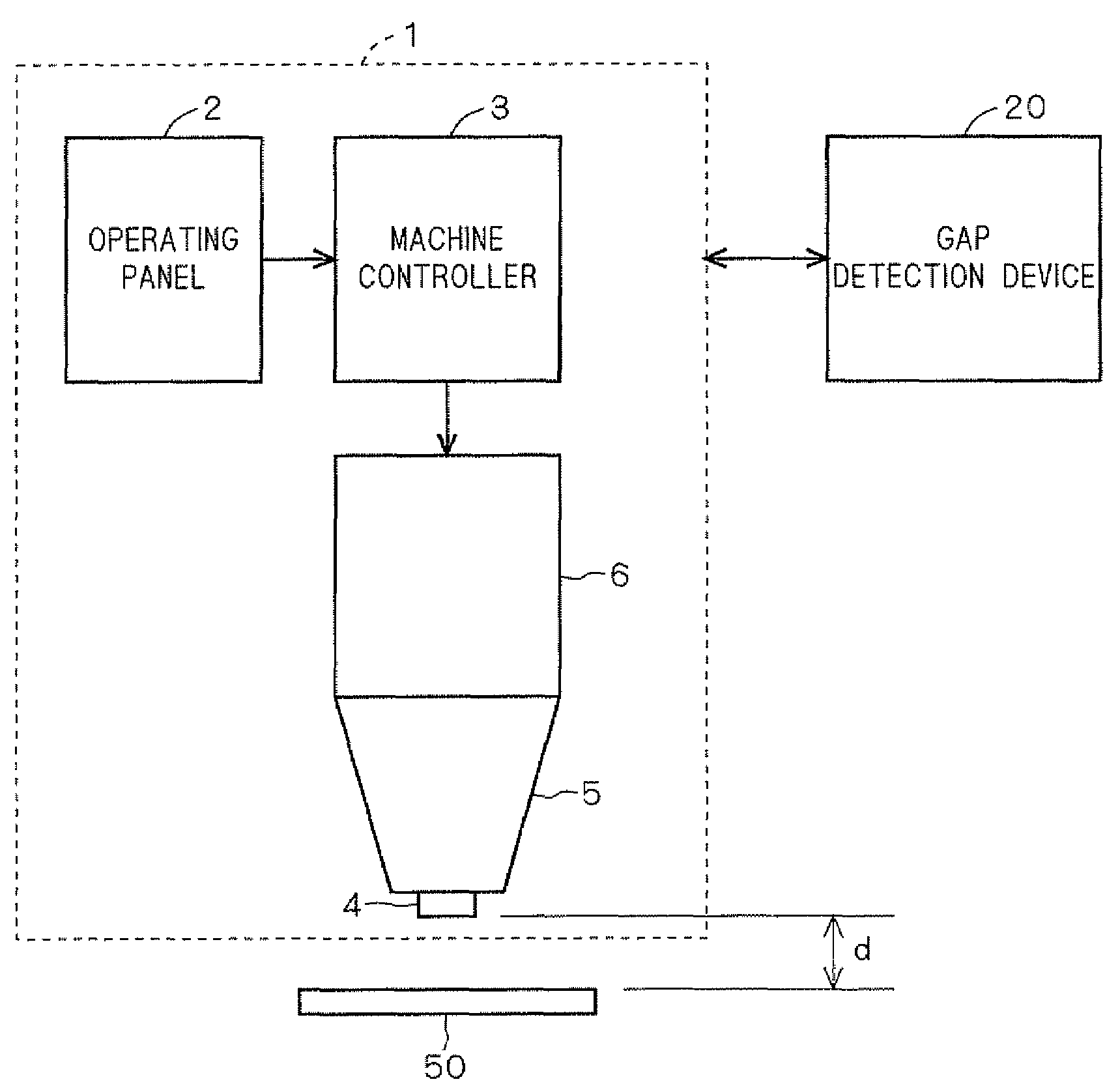

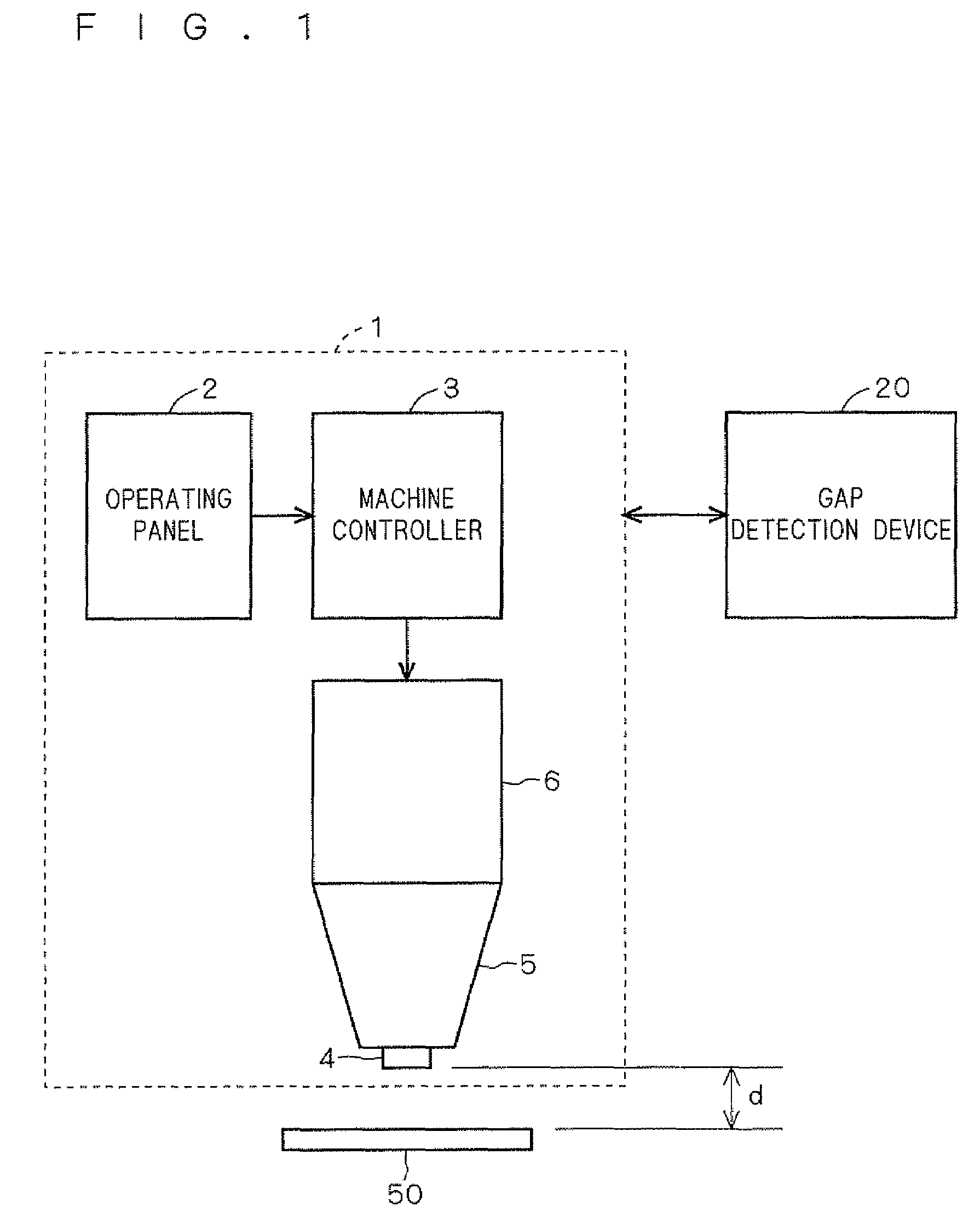

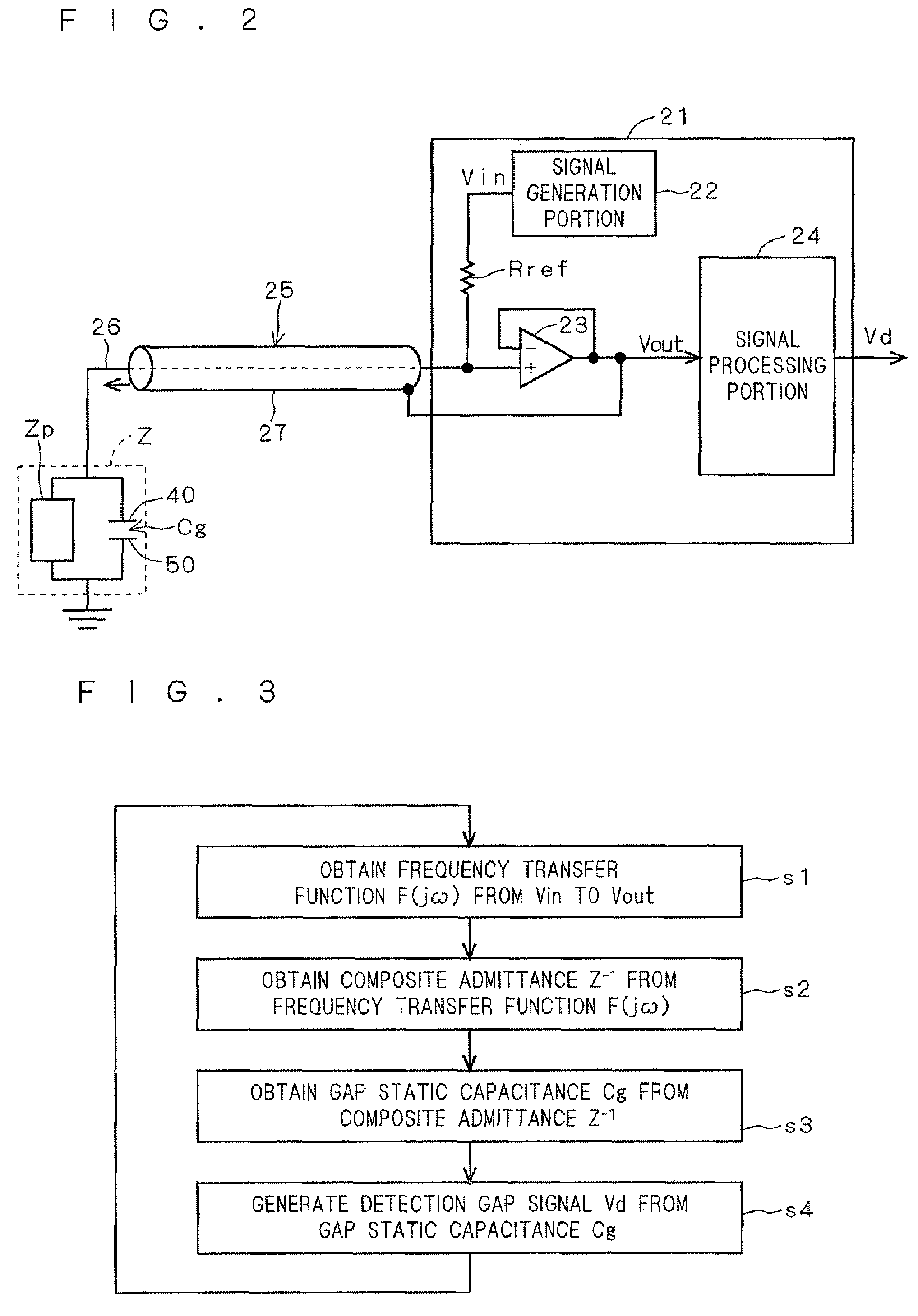

Gap detection device for laser beam machine, laser beam machining system and gap detection method for laser beam machine

InactiveUS20070284348A1Improve accuracyHigh precision machiningResistance/reactance/impedenceArc welding apparatusCapacitanceElectrical resistance and conductance

A signal processing portion obtains the reciprocal of a composite impedance of gap static capacitance and a plasma impedance, obtains composite static capacitance which is the sum of the gap static capacitance and a static capacitance component included in the plasma impedance from an imaginary part of the reciprocal, and obtains a resistance component included in the plasma impedance from a real part of the reciprocal. A gap detection device obtains the static capacitance component by using a model representing the characteristics of the reciprocal of the plasma impedance and the resistance component and obtains the gap static capacitance by subtracting the static capacitance component from the composite static capacitance. The gap detection device obtains a gap from the obtained gap static capacitance. Thus provided is a technique to detect a gap between a nozzle of a laser beam machine for outputting a laser beam and an object to be machined with high accuracy.

Owner:MITSUBISHI ELECTRIC CORP

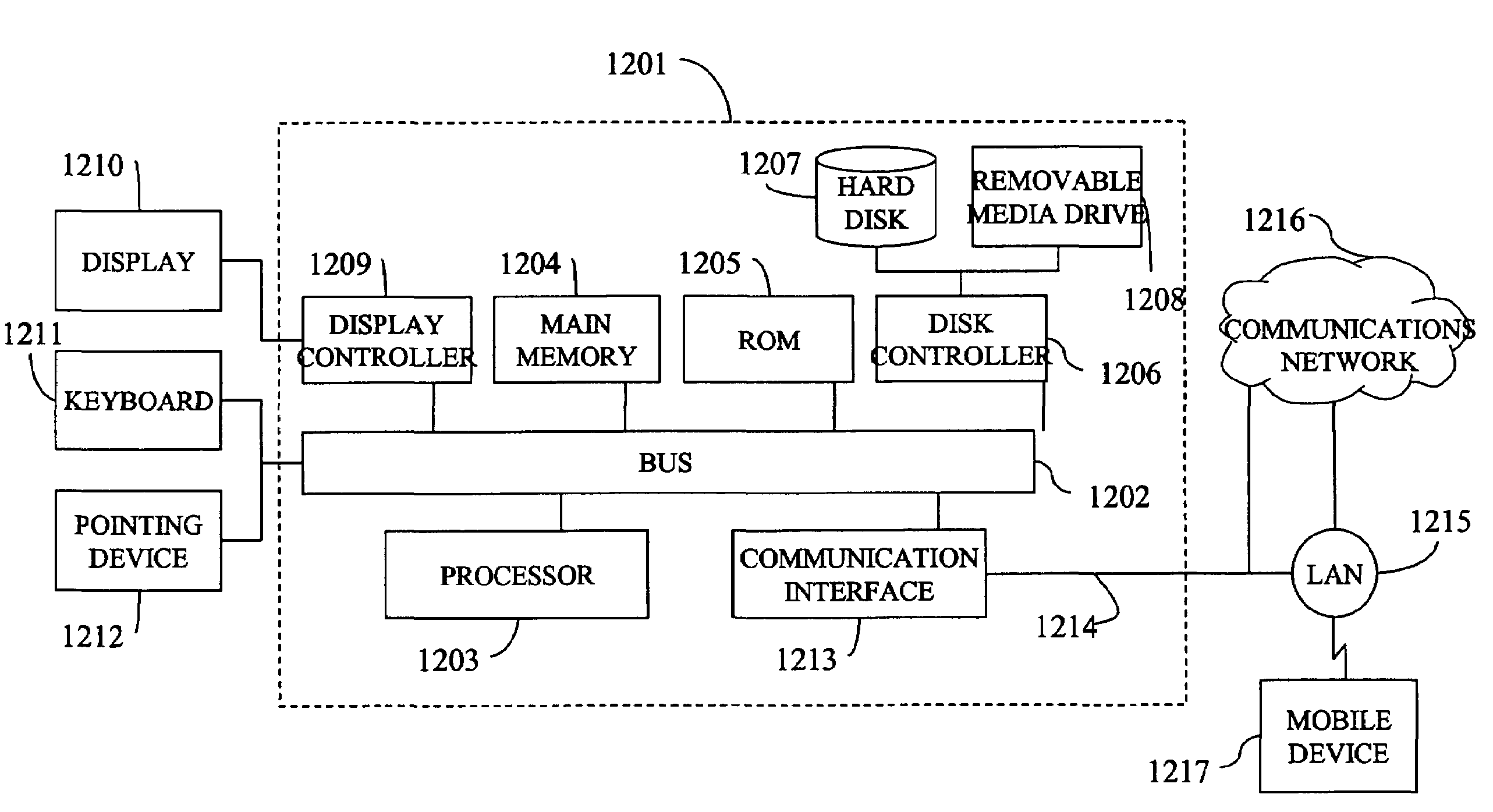

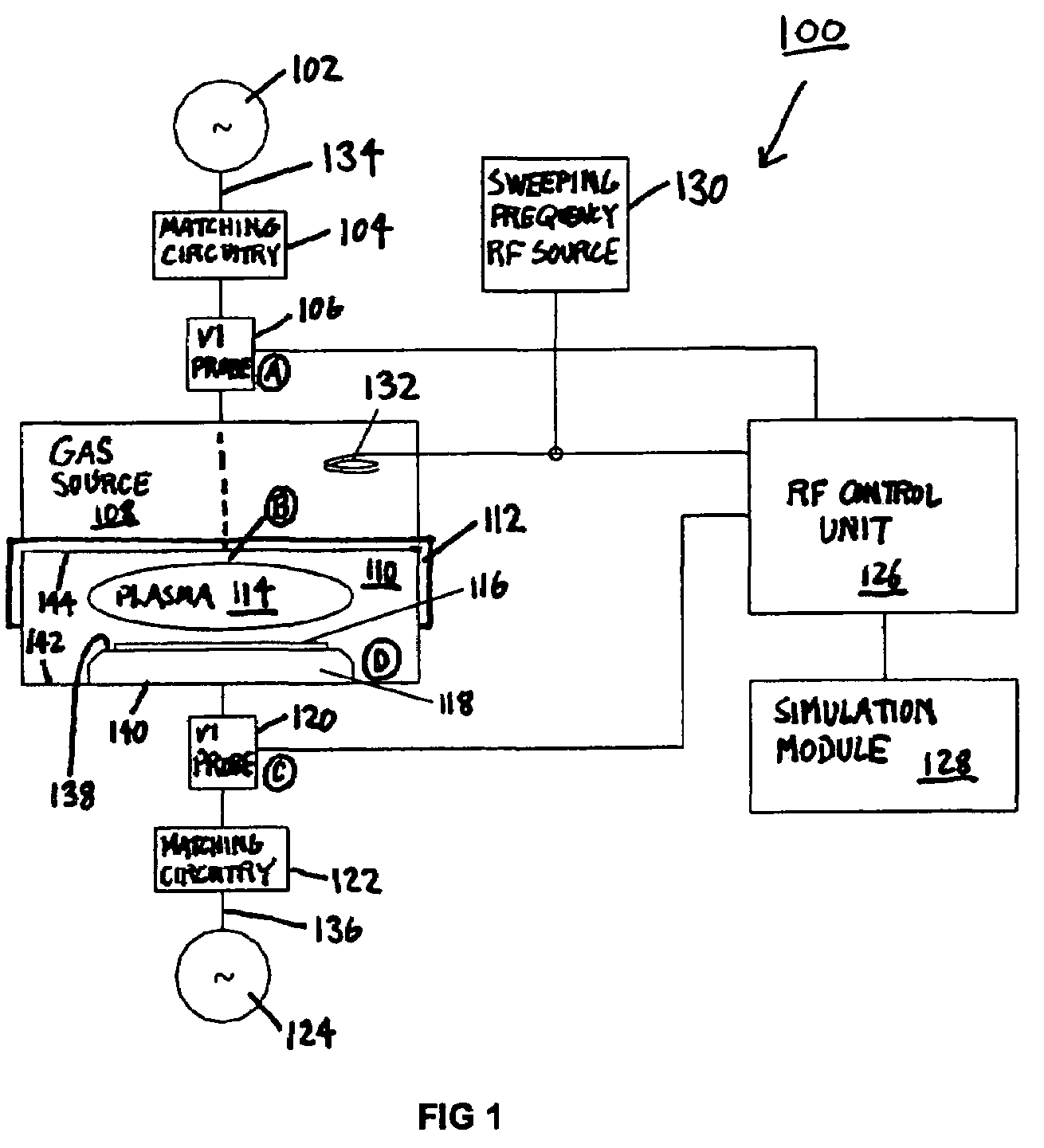

Method and apparatus for determining plasma impedance

InactiveUS7015414B2Accurate measurementElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma impedanceEngineering

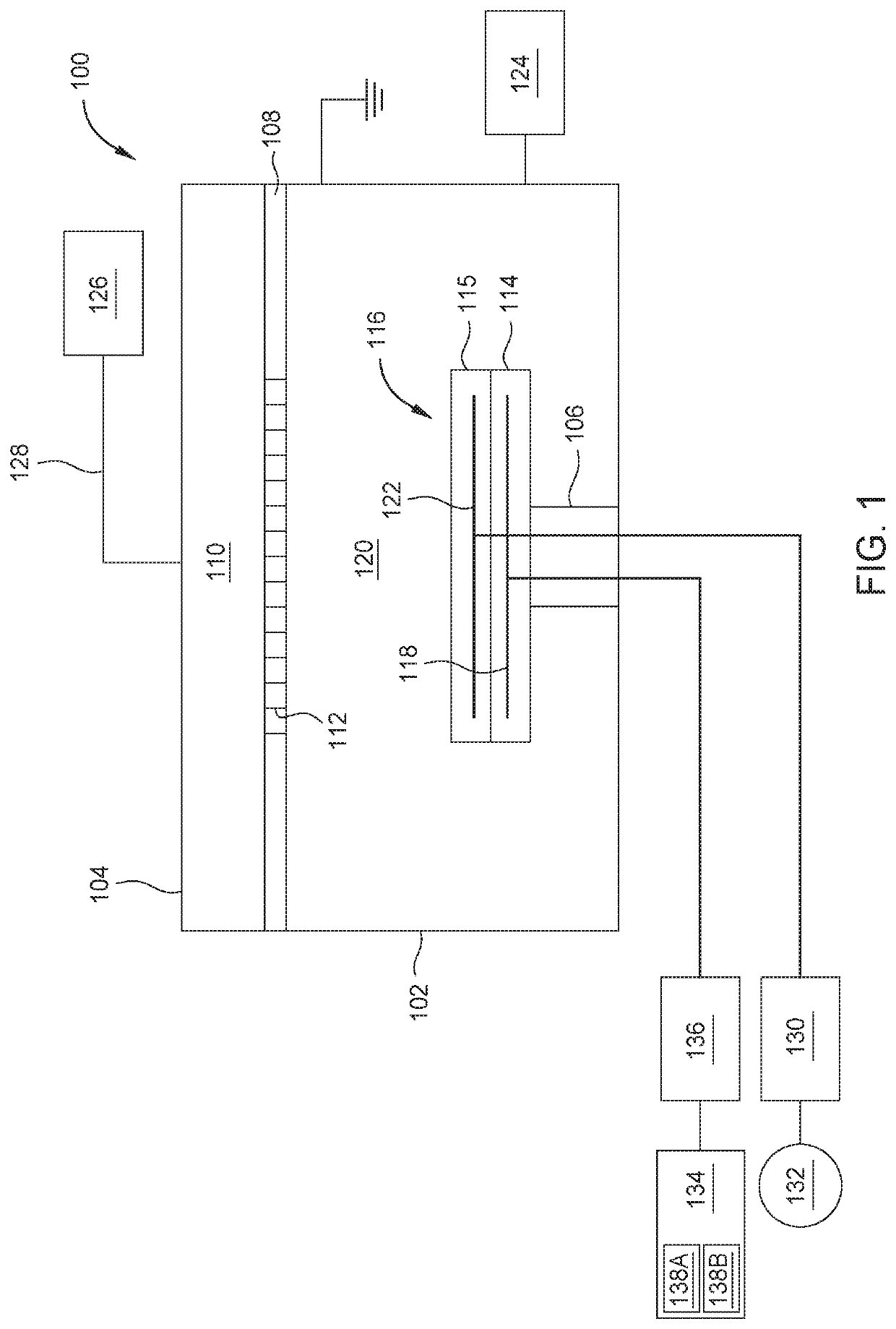

A plasma processing system, method, and computer readable medium for measuring plasma impedance. The system includes a chamber configured to contain a plasma and including a chuck within an interior area of the chamber, the chuck including a support surface and a bottom surface, and a first voltage-current probe positioned at a first position located exterior to the chamber and on a radio-frequency transmission line between the chamber and a power source. The system also includes a simulation module connected to the first voltage-current probe and arranged to solve, based on measurements transmitted from the first voltage-current probe, a radio-frequency model of the radio-frequency transmission line between the first position and a second position located within the chamber.

Owner:TOKYO ELECTRON LTD

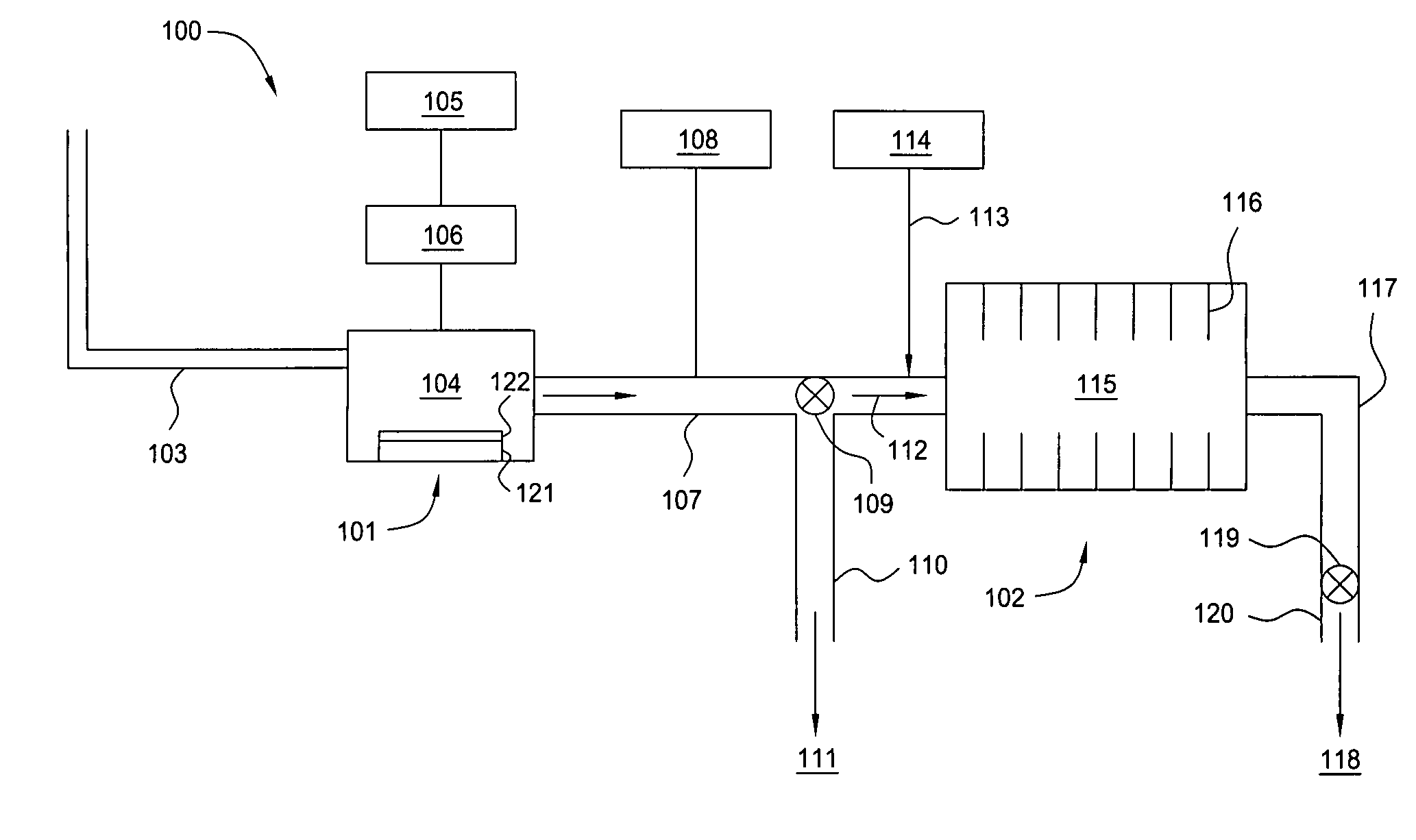

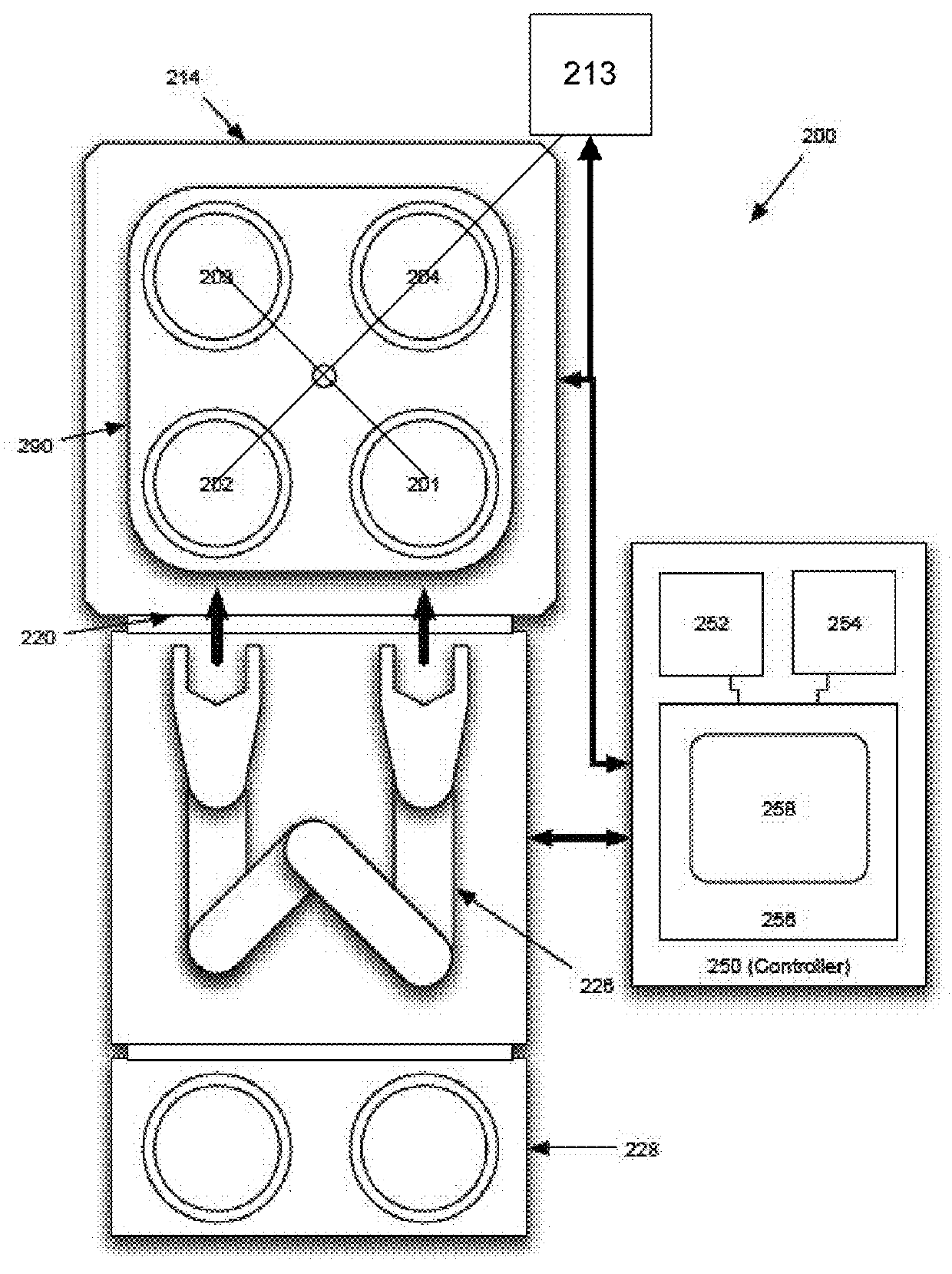

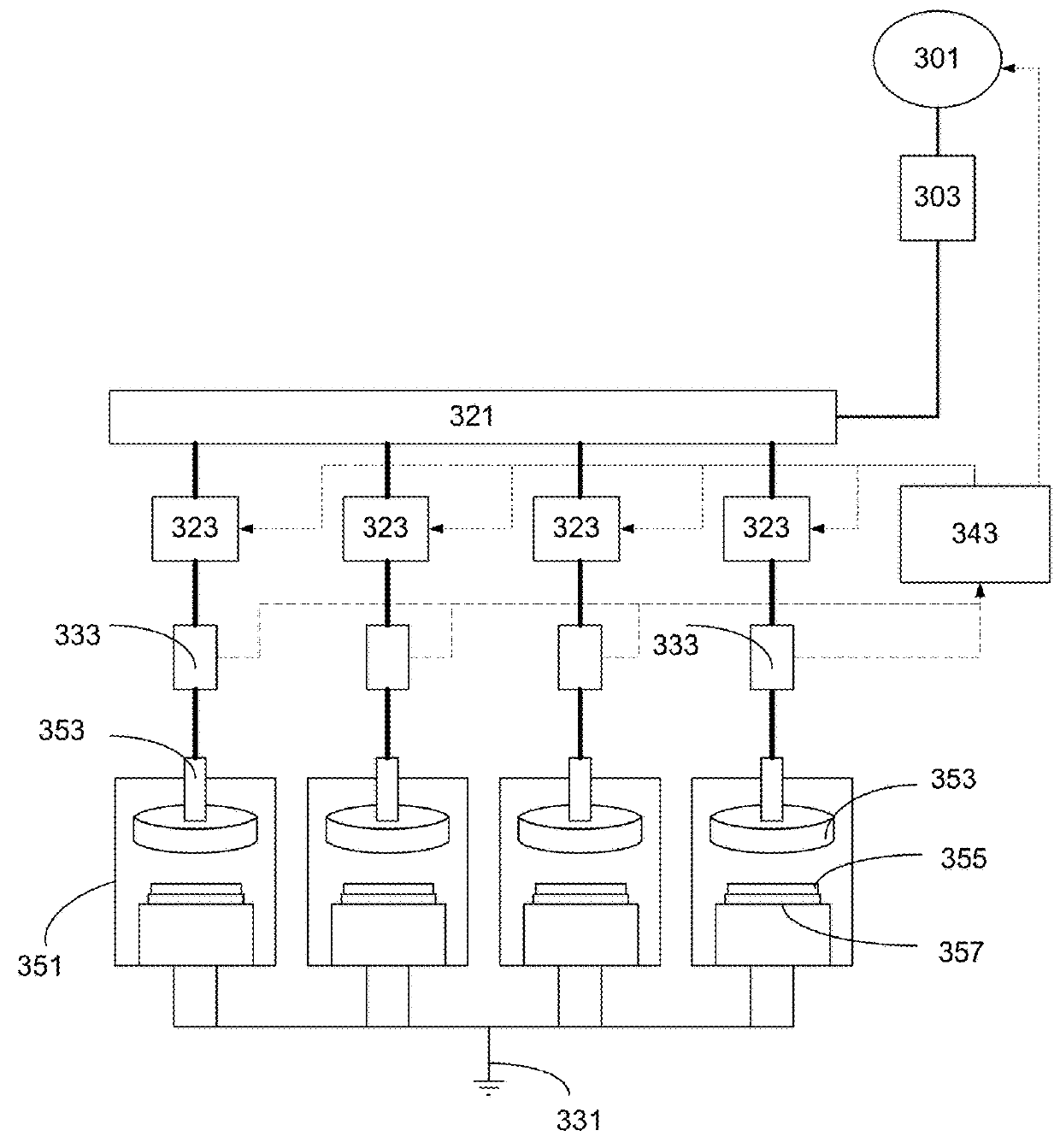

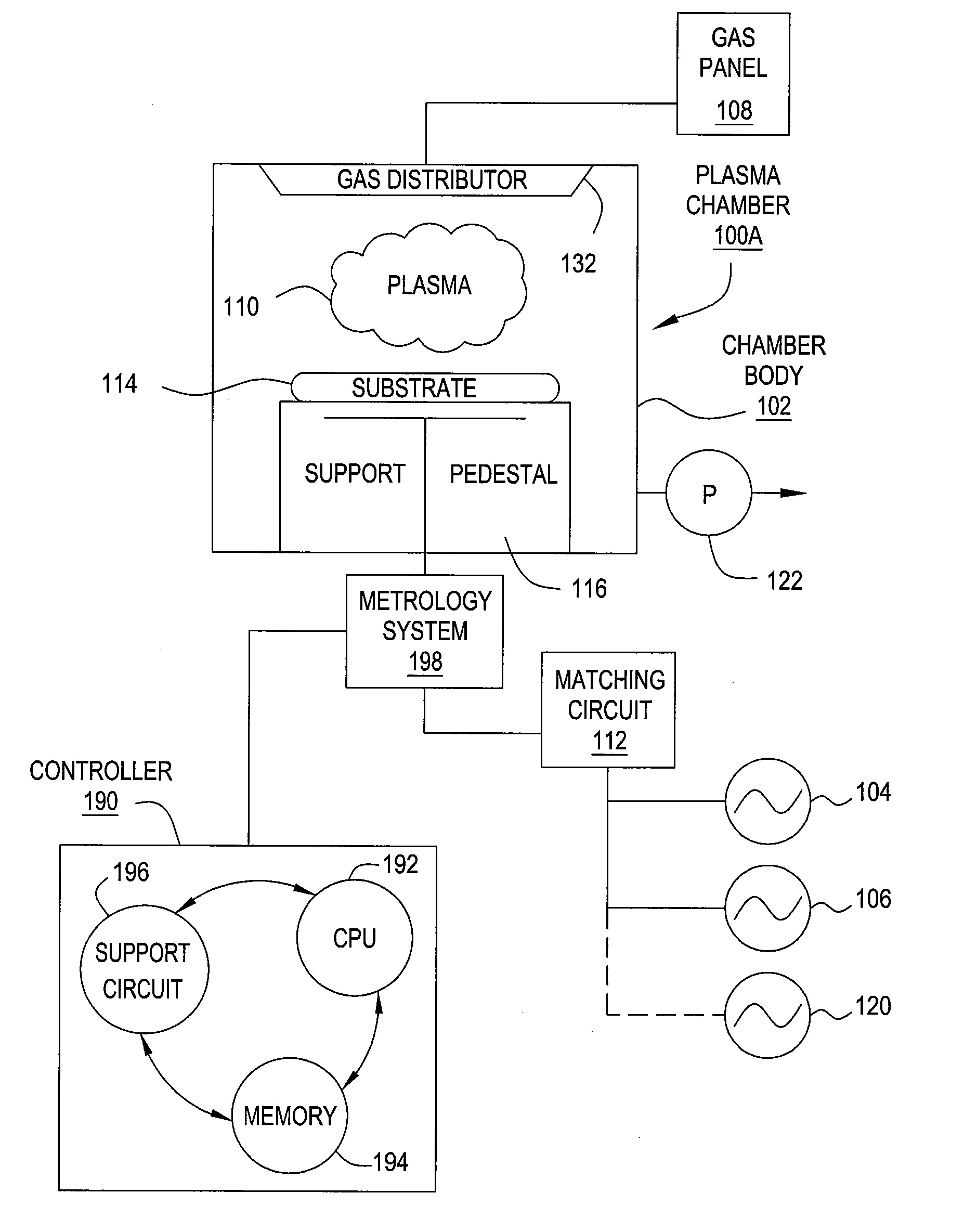

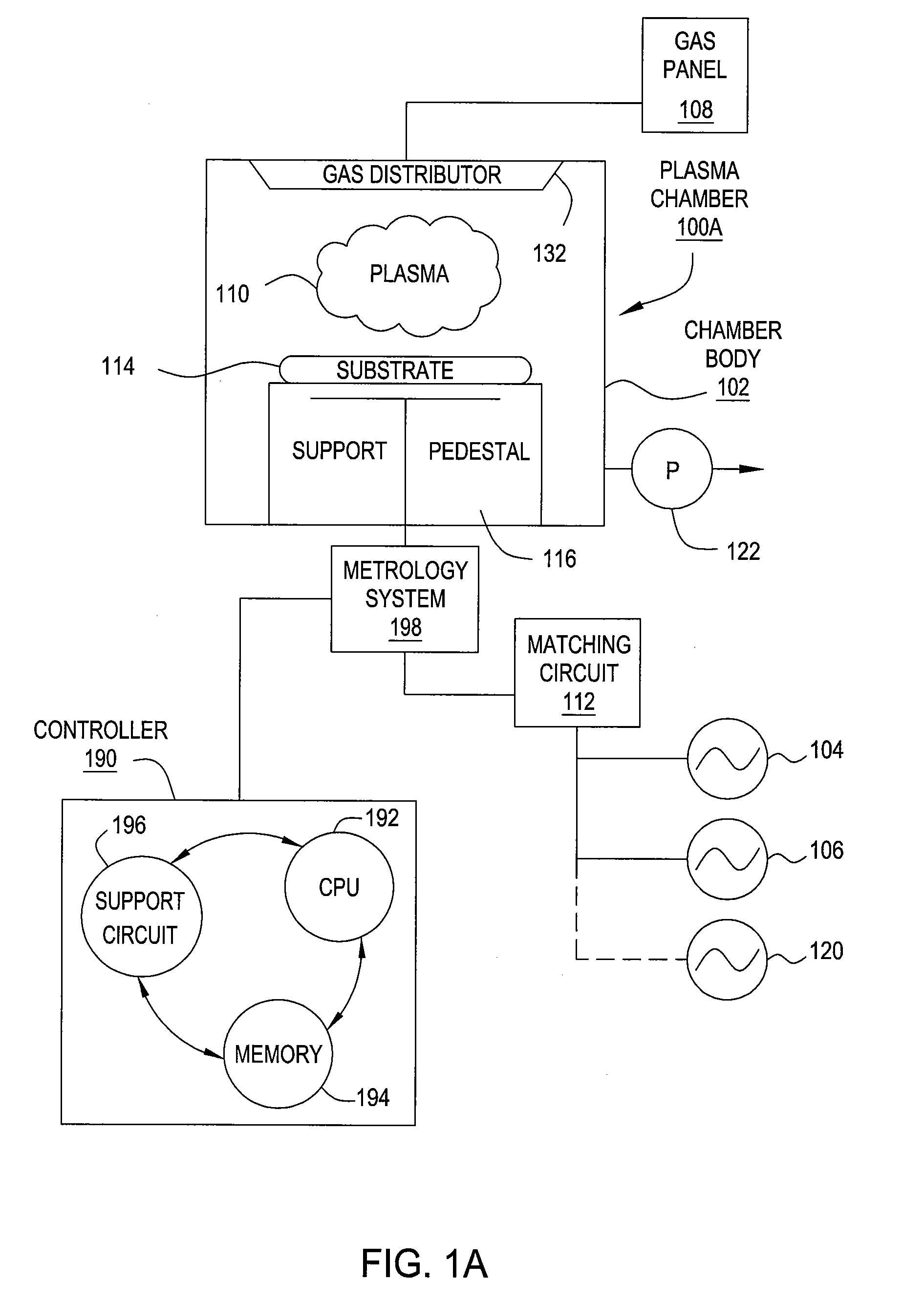

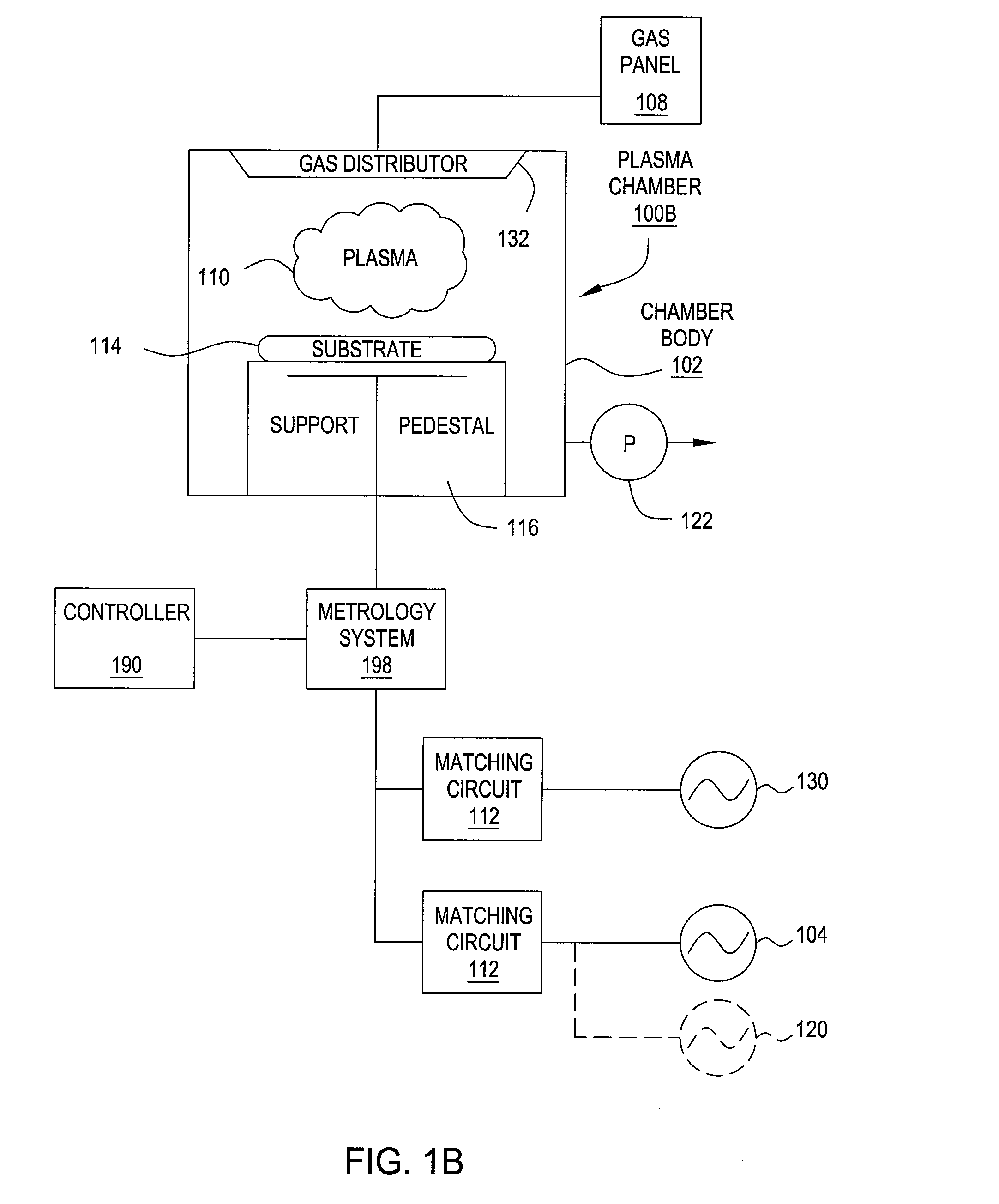

Multi-station plasma reactor with RF balancing

ActiveUS20180163302A1Reduce station to stationReduce variationElectric discharge tubesSemiconductor/solid-state device manufacturingPower parameterEngineering

Apparatuses for multi-station semiconductor deposition operations with RF power frequency tuning are disclosed. The RF power frequency may be tuned according to a measured impedance of a plasma during the semiconductor deposition operation. In certain implementations of the apparatuses, a RF power parameter may be adjusted during or prior to the deposition operation. Certain other implementations of the semiconductor deposition operations may include multiple different deposition processes with corresponding different recipes. The recipes may include different RF power parameters for each respective recipe. The respective recipes may adjust the RF power parameter prior to each deposition process. RF power frequency tuning may be utilized during each deposition process.

Owner:LAM RES CORP

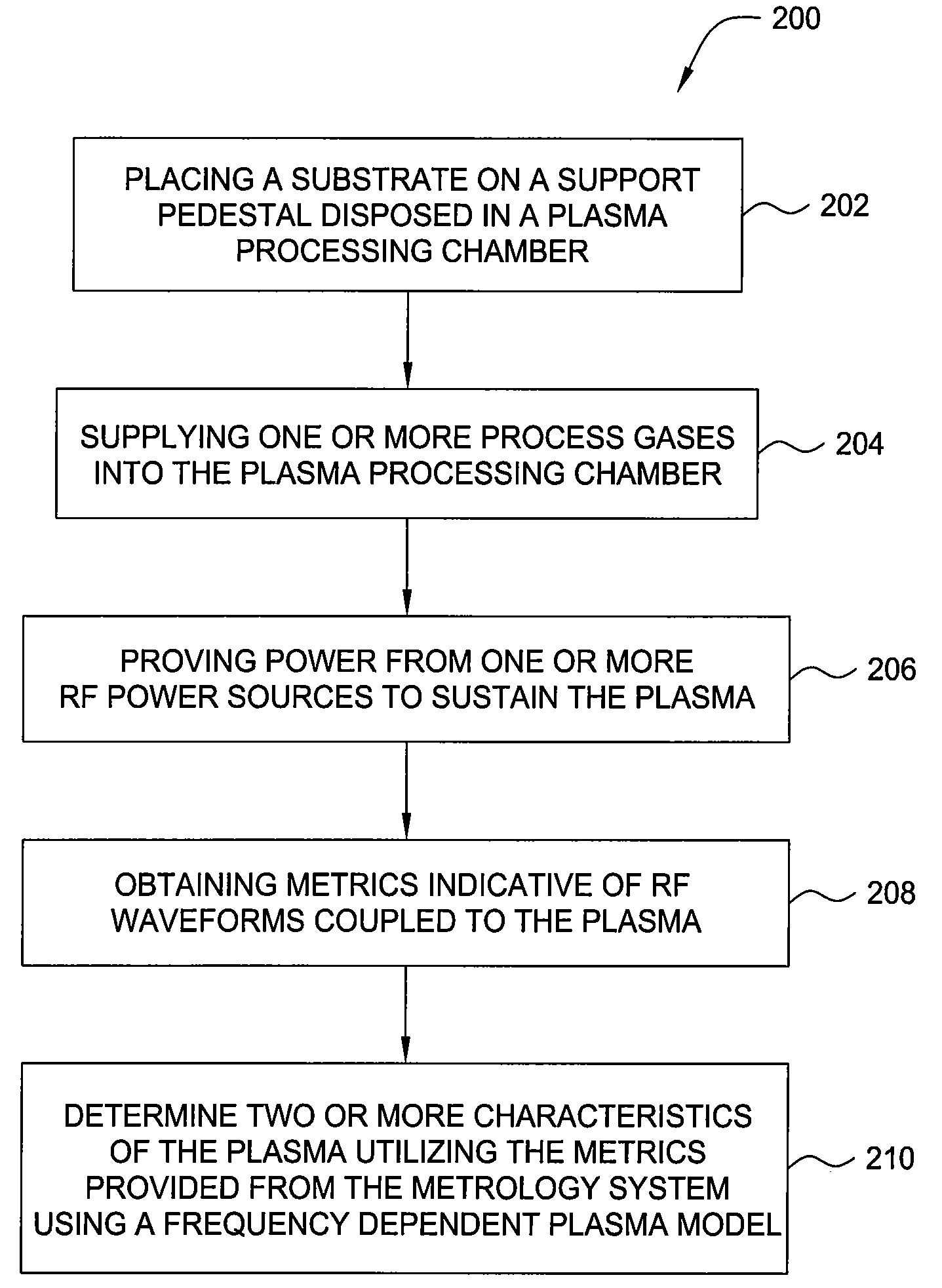

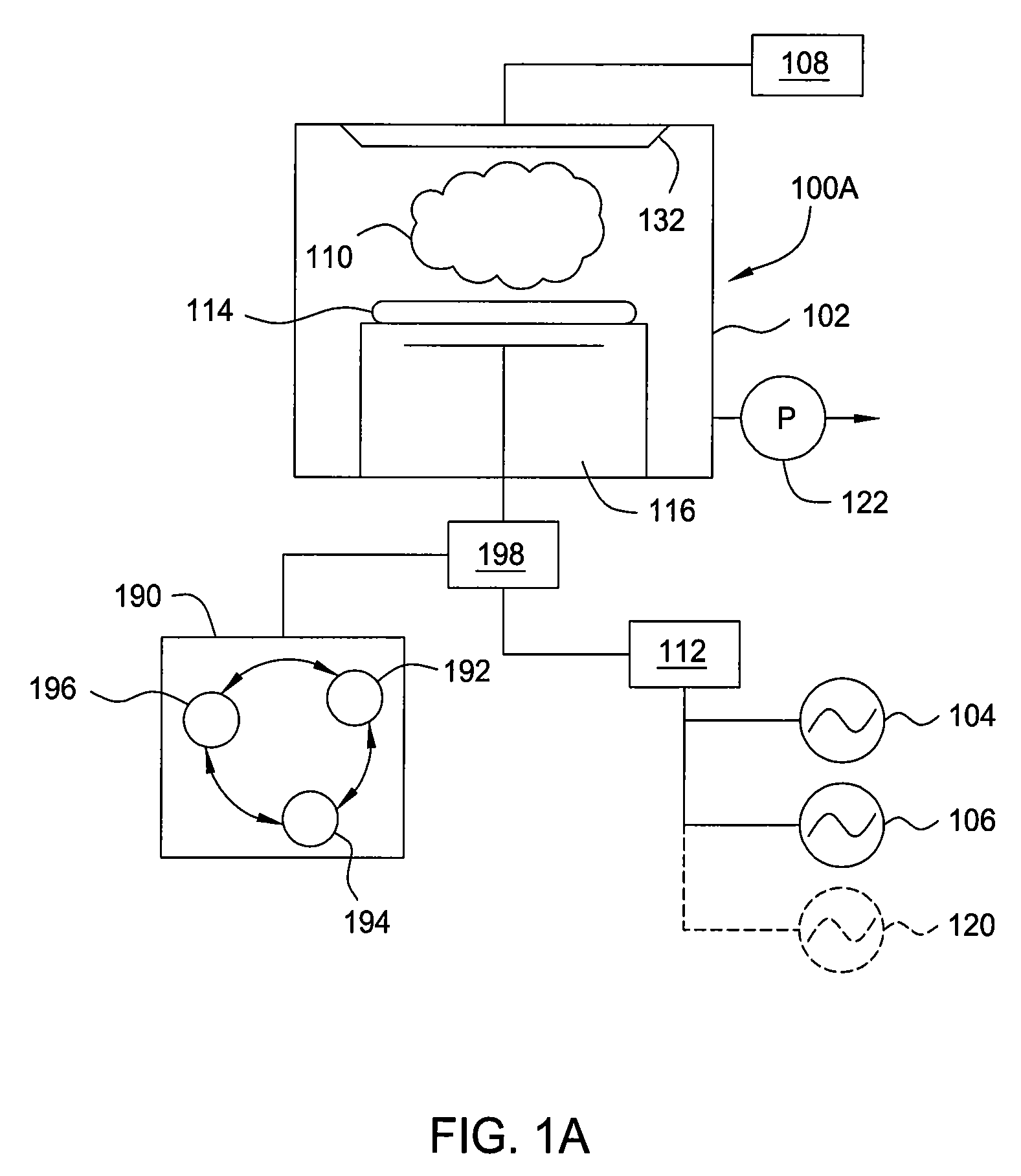

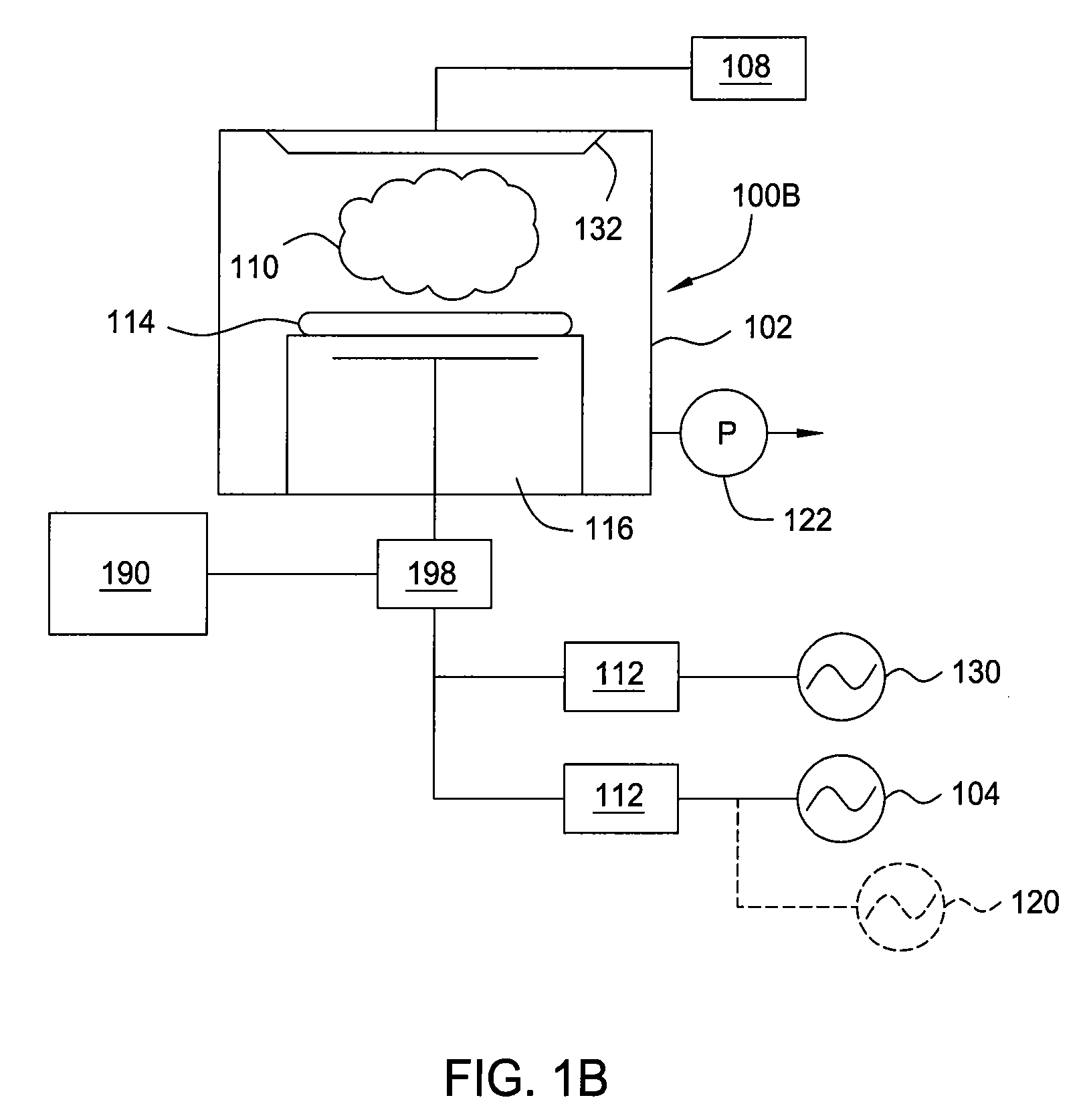

Method for determining plasma characteristics

InactiveUS20070289359A1Spectral/fourier analysisAnalysing fluids using sonic/ultrasonic/infrasonic wavesPlasma impedanceElectrical current

Methods for determining characteristics of a plasma are provided. In one embodiment, a method for determining characteristics of a plasma includes obtaining metrics of current and voltage information for first and second waveforms coupled to a plasma at different frequencies, determining at least one characteristic of the plasma using the metrics obtained from each different frequency waveform. In another embodiment, the method includes providing a plasma impedance model of a plasma as a function of frequency, and determining at least one characteristic of a plasma using model. In yet another embodiment, the method includes providing a plasma impedance model of a plasma as a function of frequency, measuring current and voltage for waveforms coupled to the plasma and having at least two different frequencies, and determining ion mass of a plasma from model and the measured current and voltage of the waveforms.

Owner:APPLIED MATERIALS INC

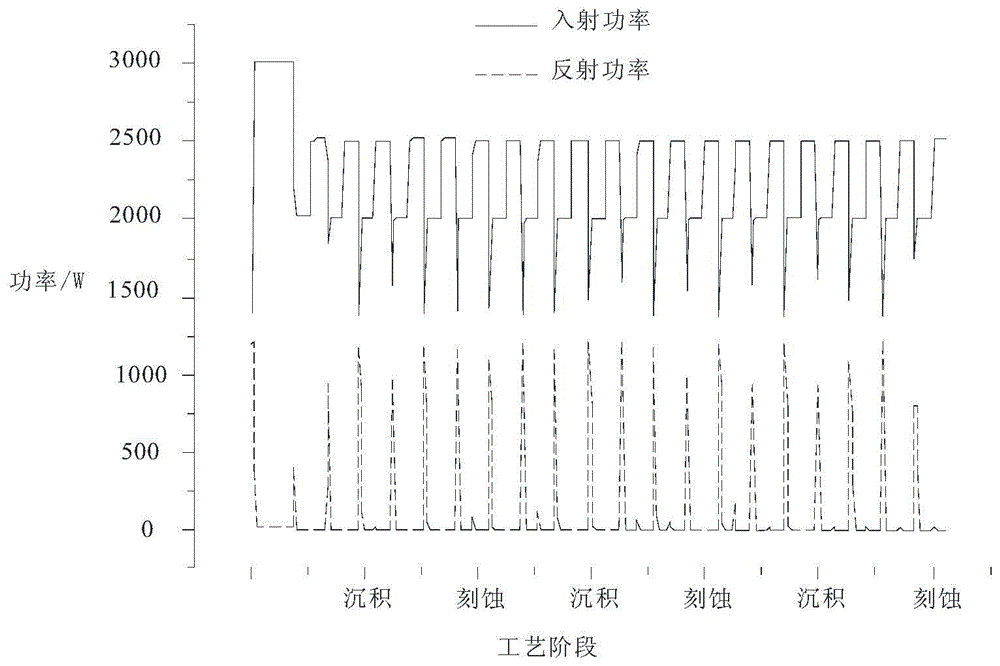

Plasma etching method, plasma etching device and RF source system thereof

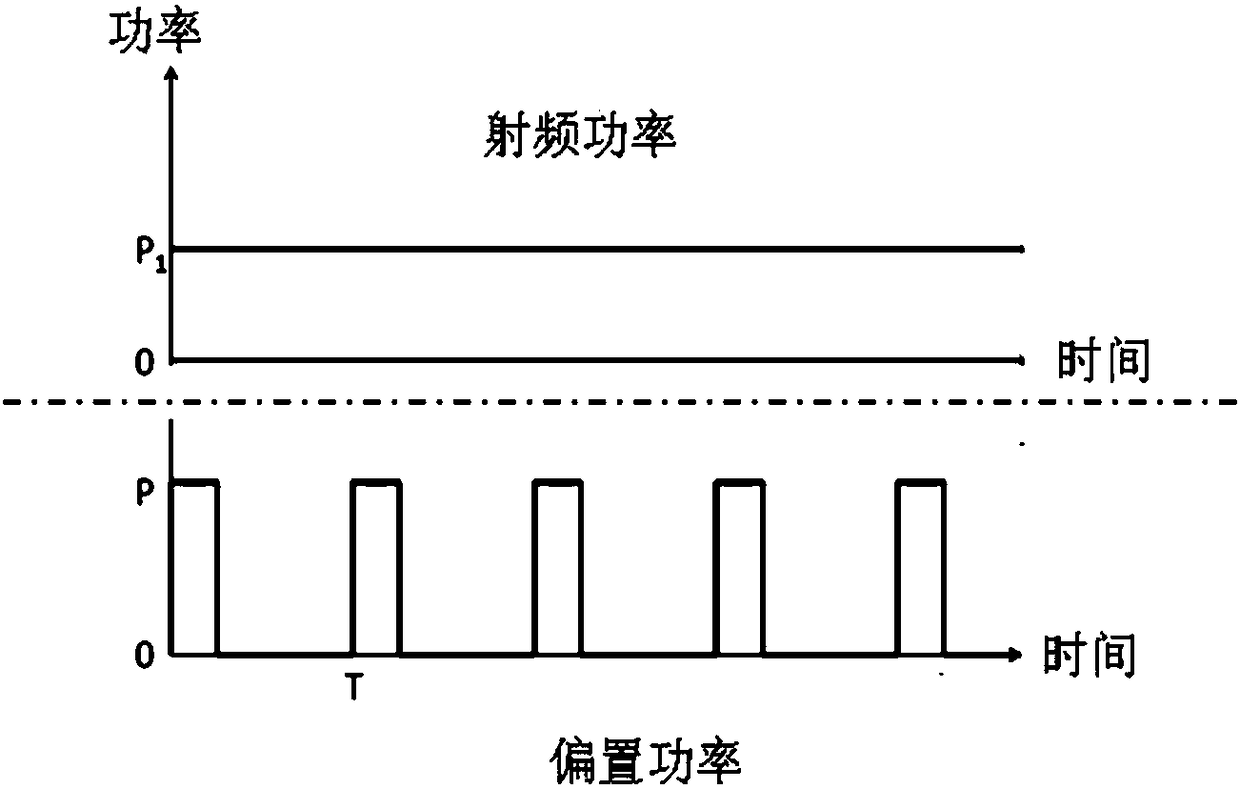

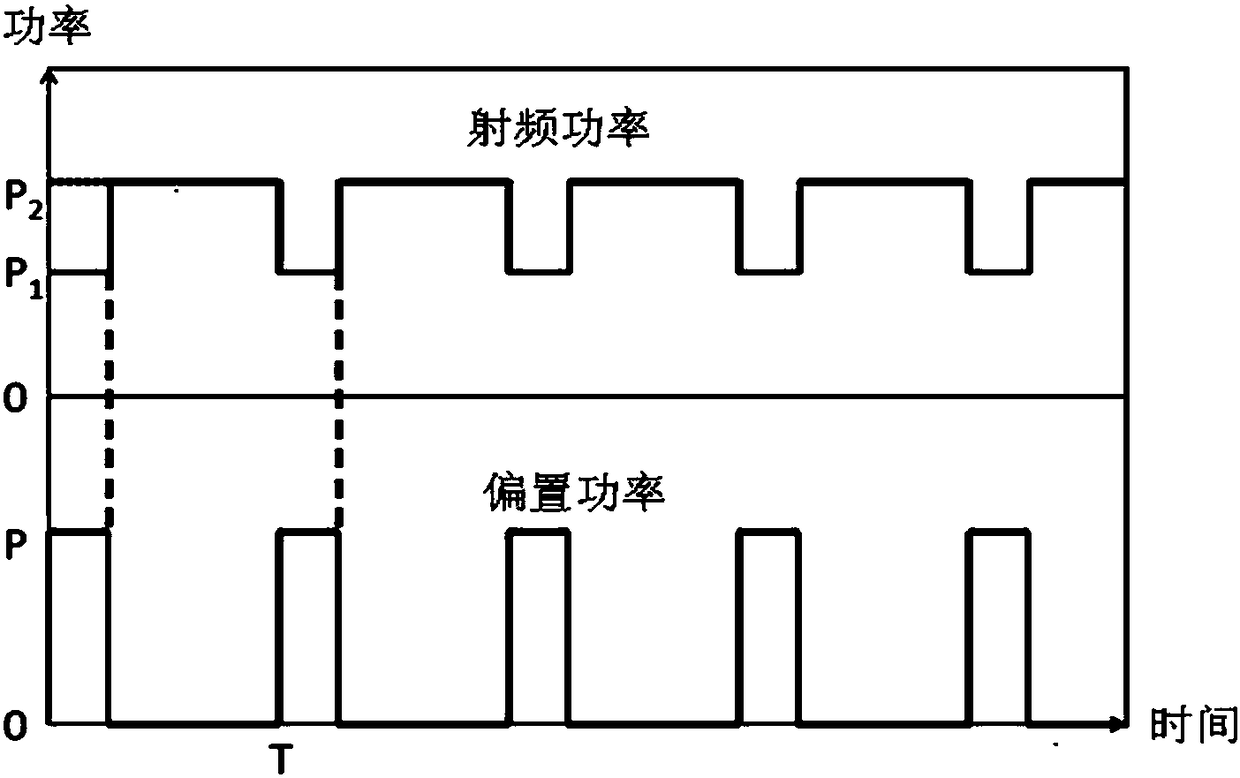

The invention provides a plasma etching method, a plasma etching device and an RF source system thereof, wherein the method, the device and the system are used for improving RF power outputting stability. The plasma etching method comprises a plurality of working periods, wherein each period comprises two steps: a first step, applying and keeping a bias power (P) and an RF power (P1); and a secondstep, setting the bias power to zero and simultaneously increasing the RF power (P2). In the period, the frequency of the RF power is unchanged. In a more preferably embodiment, plasma impedance in the period is kept stable.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

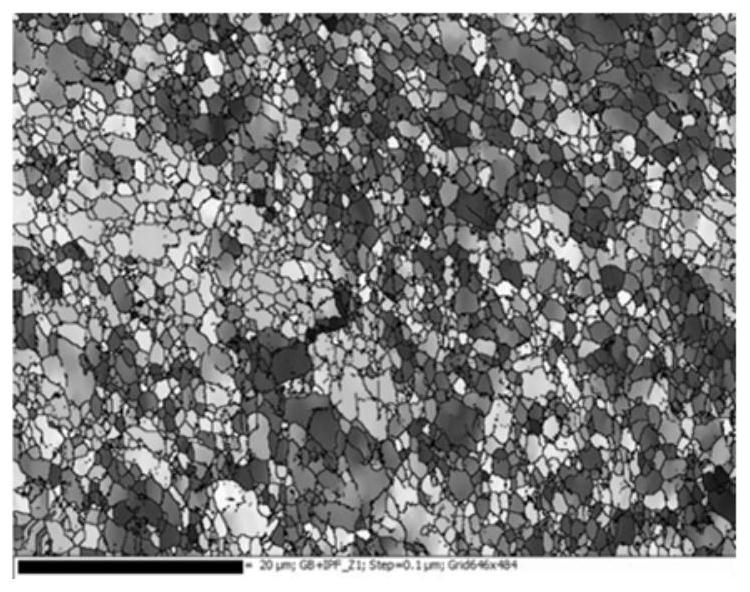

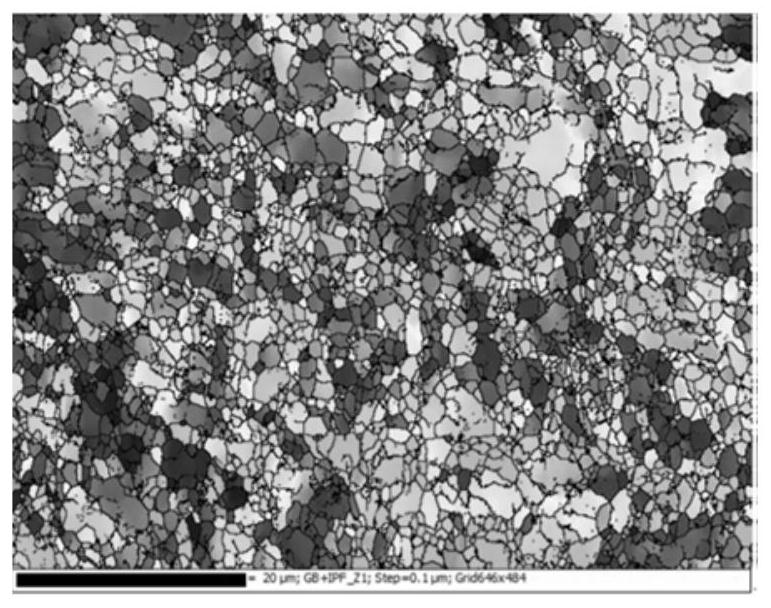

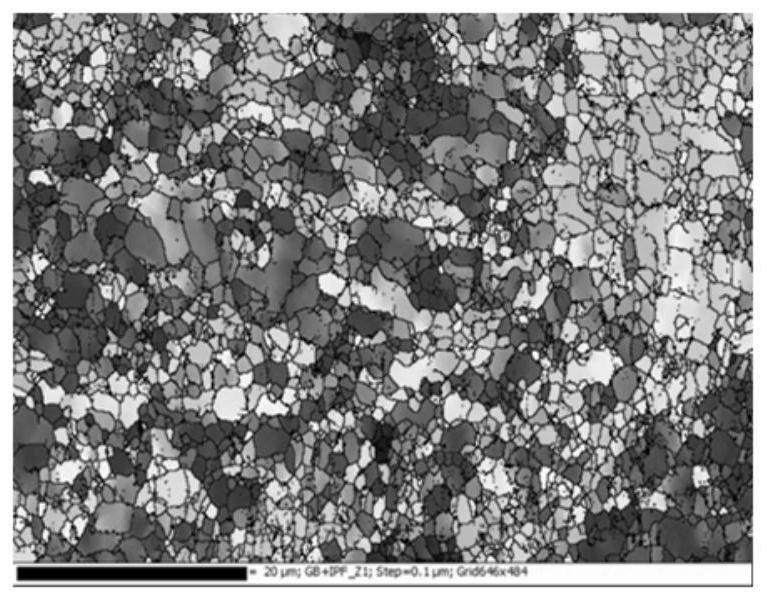

Method for refining crystal grains in ultra-pure copper or copper alloy

ActiveCN112453088AGood sputtering performanceIncrease deposition rateExtrusion diesExtrusion control devicesPlasma impedanceThin membrane

The invention relates to a method for refining crystal grains in ultra-pure copper or copper alloy. The refining method comprises the steps of: heating an ultra-pure copper or copper alloy blank; andthen sequentially carrying out first equal channel angular pressing and second equal channel angular pressing. According to the method provided by the invention, by adopting the specific equal channelangular pressing process, crystal grains are refined to the specification of below 5mum so as to ensure that a target material has good sputtering performance when being sputtered by adopting the refined ultra-pure copper or copper alloy; and furthermore, by the refining method, when in use, the target material is low in plasma impedance, high in thin film deposition rate and good in thin film thickness uniformity.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for determining plasma characteristics

InactiveUS20070294043A1Spectral/fourier analysisLiquid surface applicatorsPlasma impedanceElectrical current

Methods for determining characteristics of a plasma are provided. In one embodiment, a method for determining characteristics of a plasma includes obtaining metrics of a plasma at two different frequencies, and determining at least one characteristic of the plasma utilizing the metrics. In another embodiment, a method for determining characteristics of a plasma includes obtaining metrics of current and voltage information for first and second waveforms coupled to a plasma at different frequencies, determining at least one characteristic of the plasma using the metrics obtained from each different frequency waveform. In another embodiment, the method includes providing a plasma impedance model of a plasma as a function of frequency, and determining at least one characteristic of a plasma using model.

Owner:APPLIED MATERIALS INC

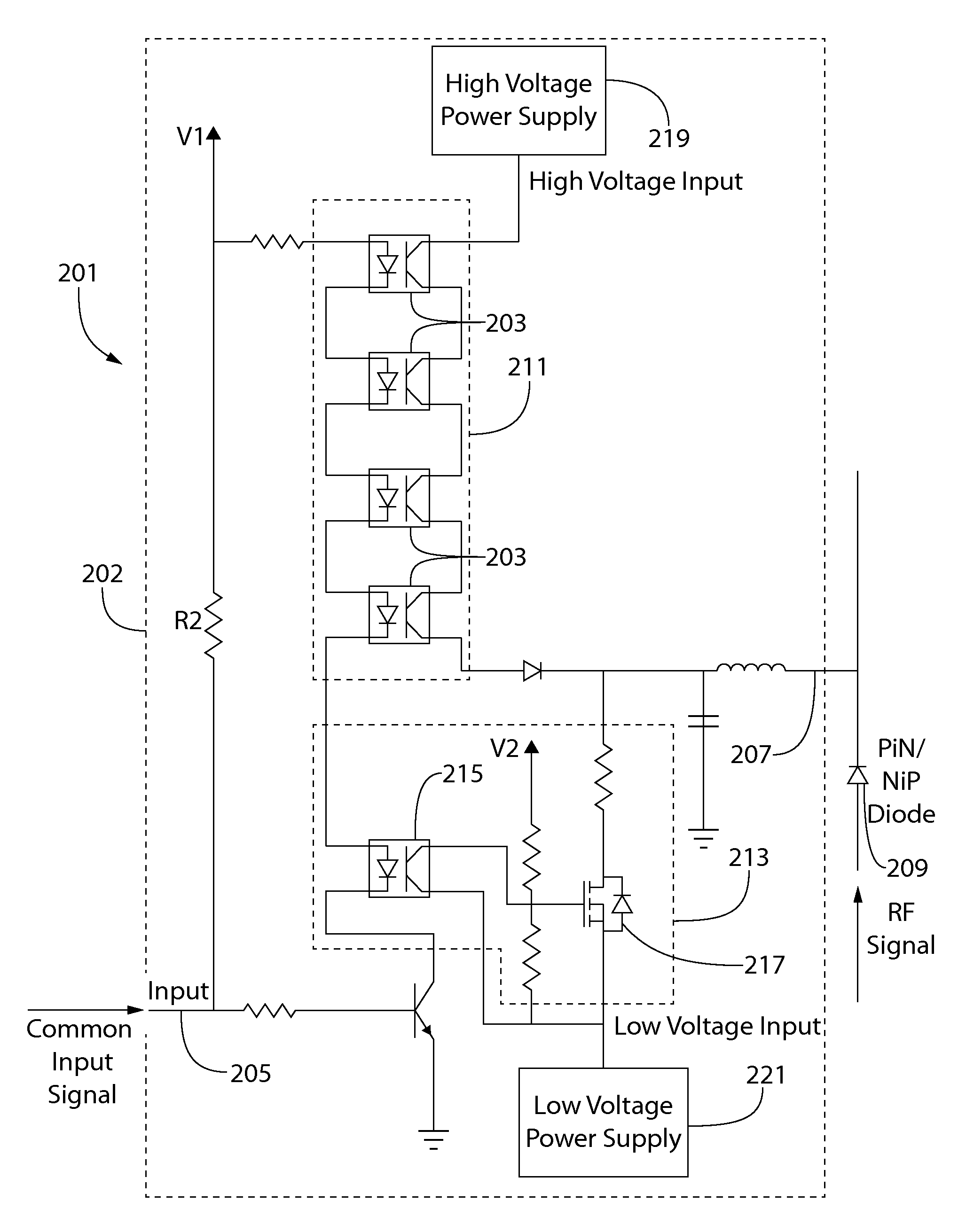

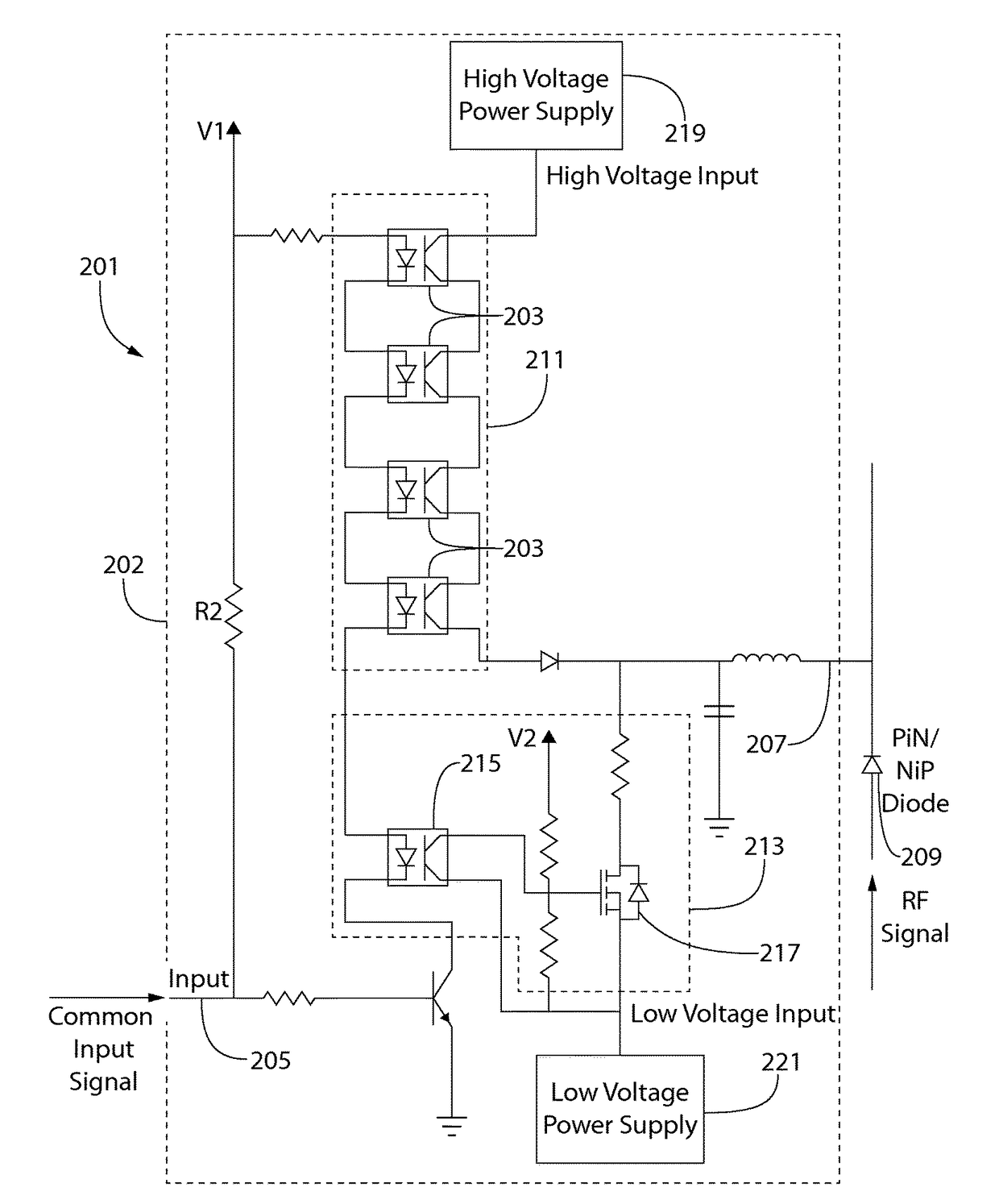

RF electrostatic chuck filter circuit

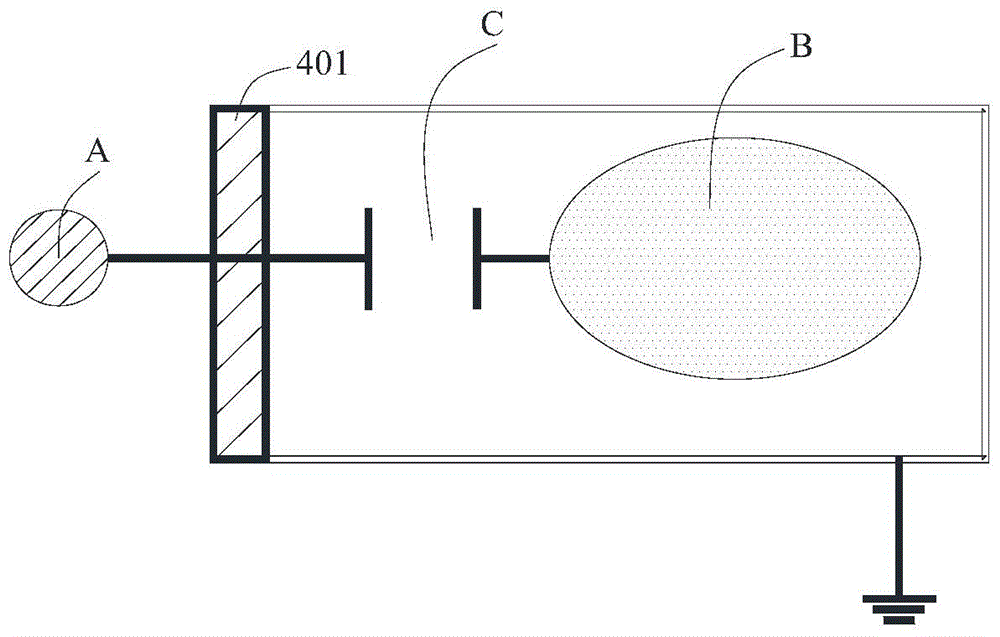

Embodiments described herein relate to apparatus and methods for substantially reducing an occurrence of radio frequency (RF) coupling through a chucking electrode. The chucking electrode is disposed in an electrostatic chuck positioned on a substrate support. The substrate support is coupled to a process chamber body. An RF source is used to generate a plasma in a process volume adjacent to the substrate support. An impedance matching circuit is disposed between the RF source and the chucking electrode is disposed in the electrostatic chuck. An electrostatic chuck filter is coupled between the chucking electrode and the chucking power source.

Owner:APPLIED MATERIALS INC

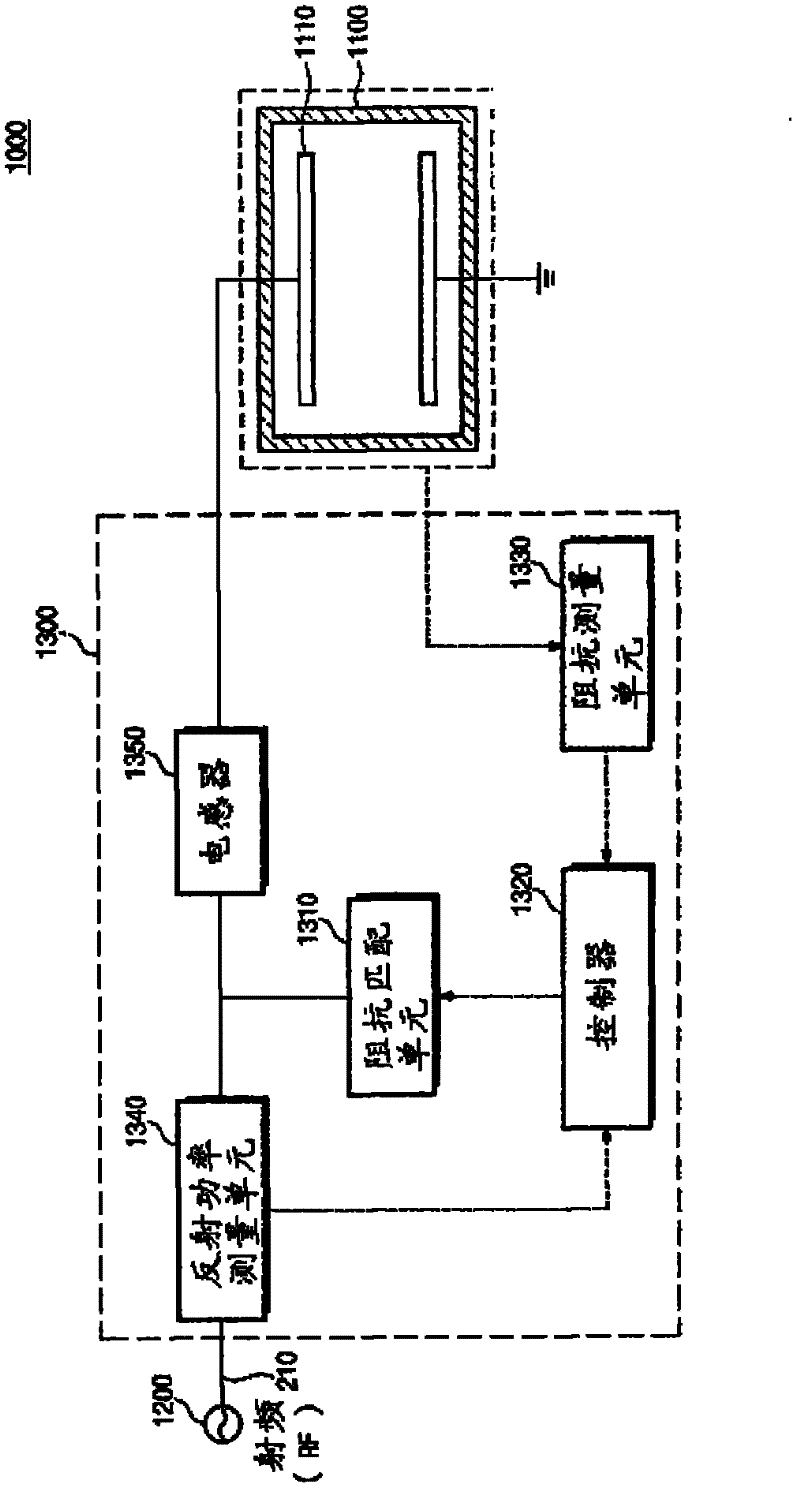

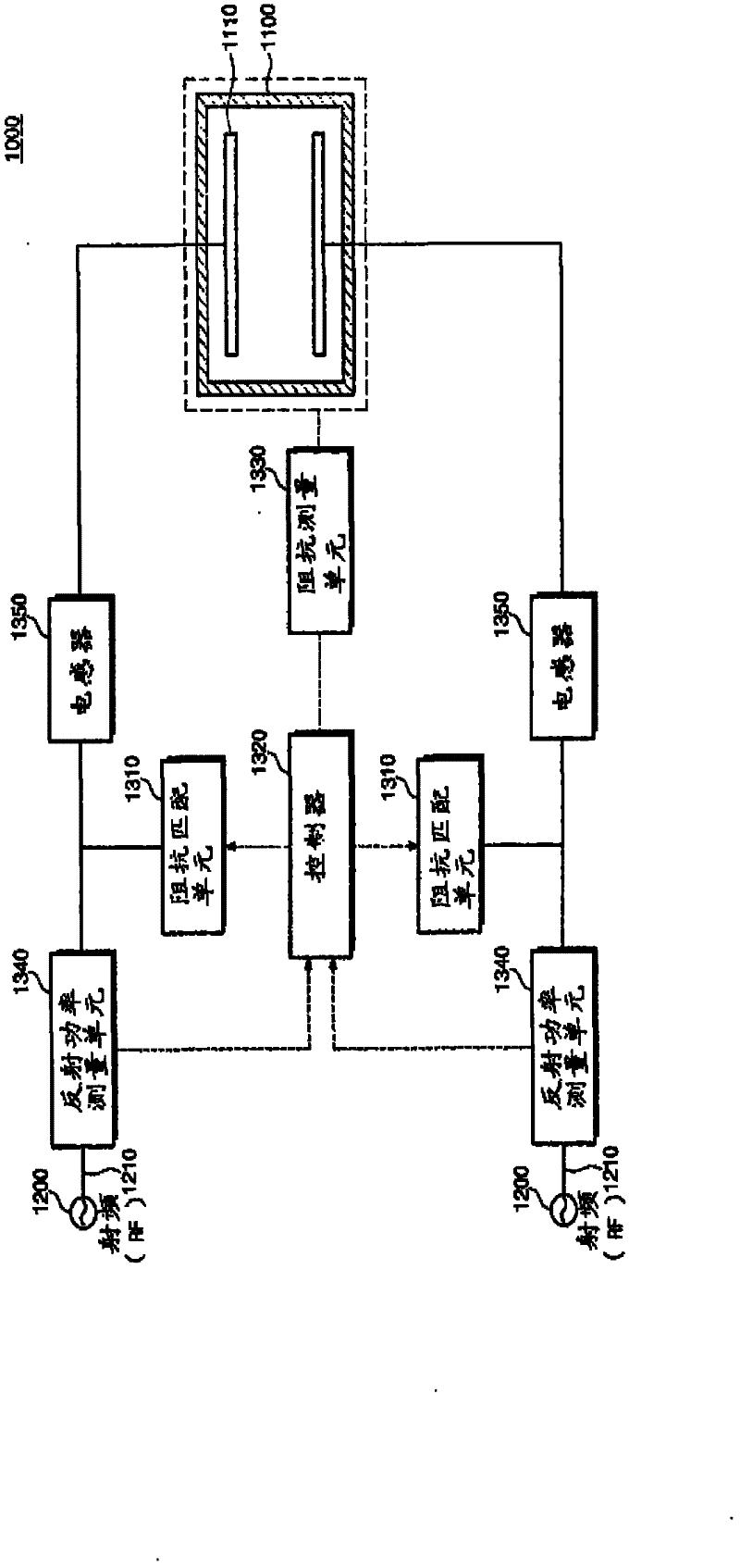

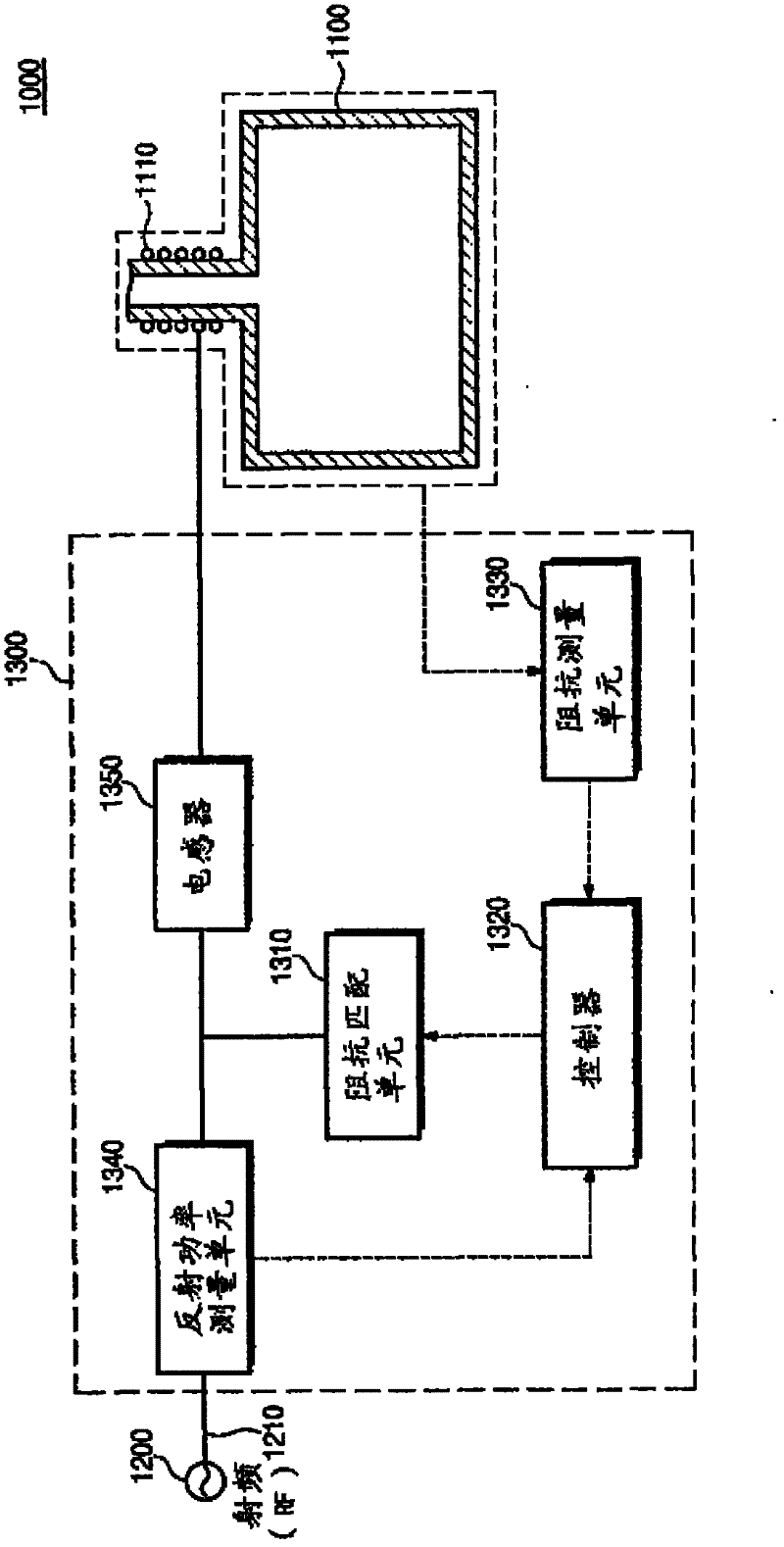

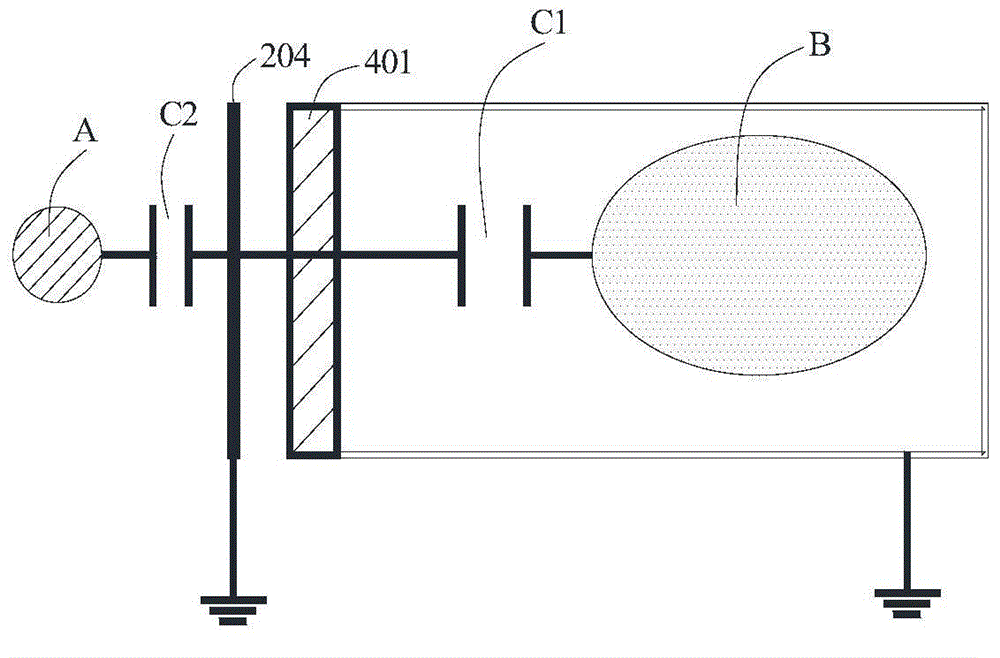

Plasma generation device and semiconductor processing device

ActiveCN106328472AAchieve matchingEasy to control etching morphologyElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricPlasma impedance

A plasma generation device provided by the present invention comprises a dielectric window, an induction coil surrounding the dielectric window and an impedance matching device, and also comprises a Faraday shielding member arranged between the dielectric window and the induction coil. The present invention also provides a semiconductor processing device. According to the plasma generation device provided by the present invention, the current transmission on the surface of the induction coil is not influenced by the plasma state perturbation any more, so that at work, the plasma generation device provided by the present invention does not generate the phenomena that the plasma quenches, the impedance matching device is matched again, etc., and accordingly, the plasma impedance matching can be realized rapidly, and further the etching morphology of a semiconductor substrate during a Bosch etching technical process is controlled more easily, and the repeatability of the Bosch process is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

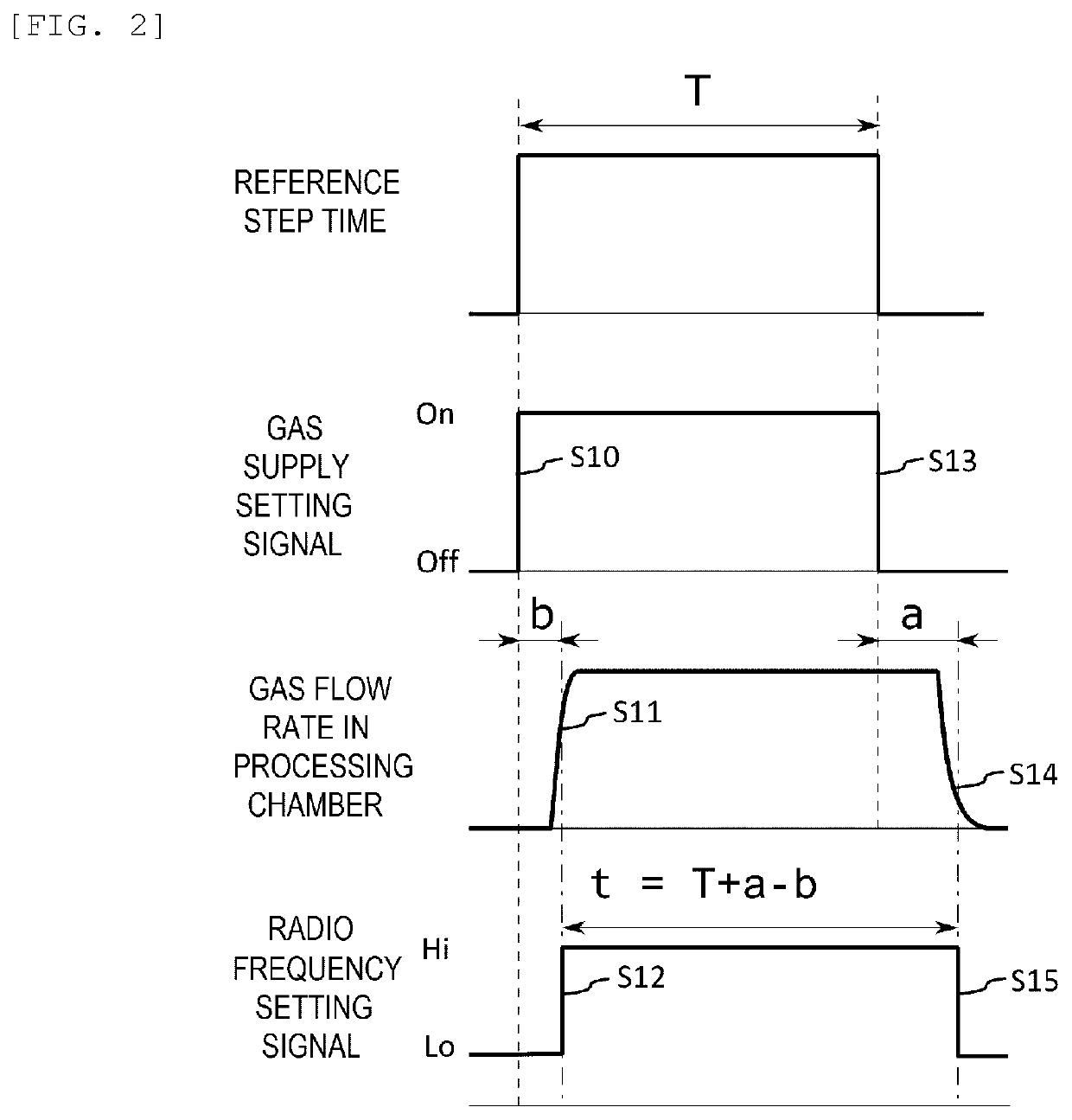

Plasma processing apparatus and plasma processing method

ActiveUS20200402809A1Electric discharge tubesSemiconductor/solid-state device manufacturingPlasma impedanceEngineering

A plasma processing apparatus, including a processing; a first radio frequency power source; a sample stage on which the sample is placed; a second radio frequency power; and a control device configured to control, when the second radio frequency power source is controlled based on a change in a plasma impedance, which is generated when a first gas that is a gas for a first step is switched to a second gas that is a gas for a second step, such that the second radio frequency power is changed from a value of the second radio frequency power in the first step to a value of the second radio frequency power in the second step, and a supply time of the first gas such that a supply time of the second radio frequency power in the first step is substantially equal to a time of the first step.

Owner:HITACHI HIGH-TECH CORP

Gap detection device for laser beam machine, laser beam machining system and gap detection method for laser beam machine

InactiveUS7557589B2Improve accuracyHigh precision machiningResistance/reactance/impedenceArc welding apparatusElectrical resistance and conductanceCapacitance

A signal processing portion obtains the reciprocal of a composite impedance of gap static capacitance and a plasma impedance, obtains composite static capacitance which is the sum of the gap static capacitance and a static capacitance component included in the plasma impedance from an imaginary part of the reciprocal, and obtains a resistance component included in the plasma impedance from a real part of the reciprocal. A gap detection device obtains the static capacitance component by using a model representing the characteristics of the reciprocal of the plasma impedance and the resistance component and obtains the gap static capacitance by subtracting the static capacitance component from the composite static capacitance. The gap detection device obtains a gap from the obtained gap static capacitance. Thus provided is a technique to detect a gap between a nozzle of a laser beam machine for outputting a laser beam and an object to be machined with high accuracy.

Owner:MITSUBISHI ELECTRIC CORP

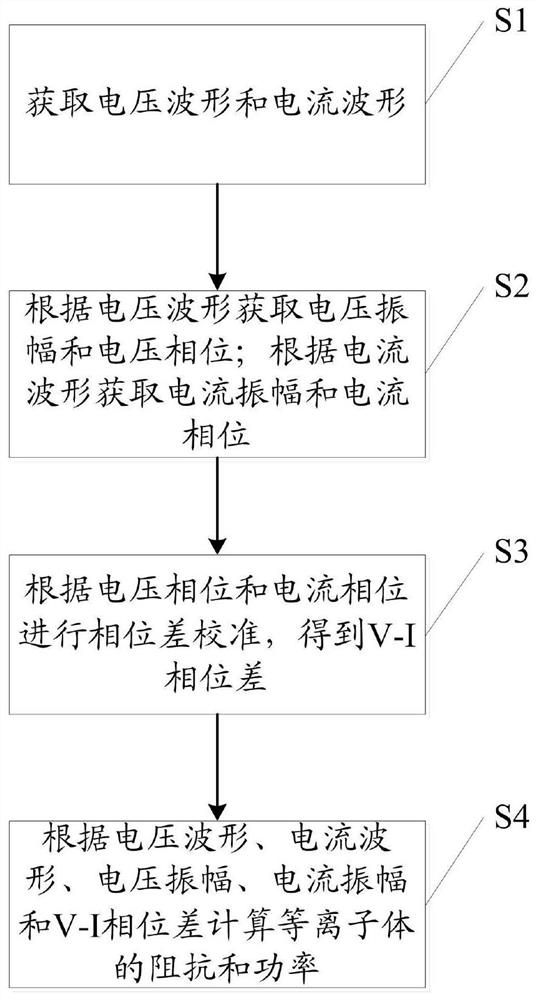

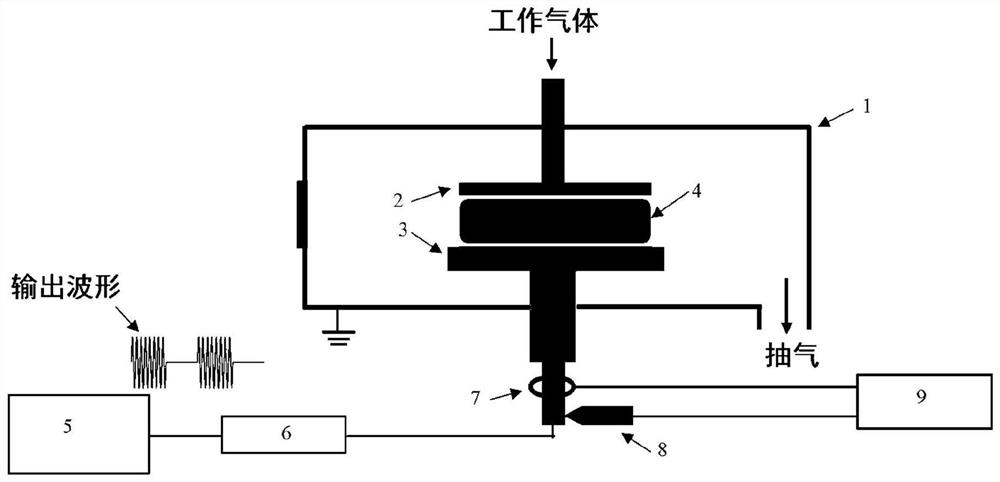

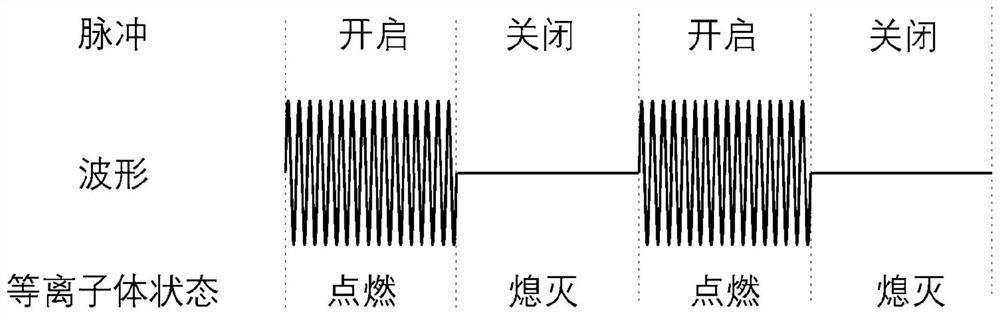

Method and device for measuring impedance and power of plasma

InactiveCN113015307AImprove accuracyDirect measurement of RF powerPlasma techniqueVoltage amplitudeEngineering

The invention relates to a method and a device for measuring impedance and power of plasma. The method comprises the following steps: acquiring a voltage waveform and a current waveform; acquiring a voltage amplitude and a voltage phase according to the voltage waveform; acquiring a current amplitude and a current phase according to the current waveform; performing phase difference calibration according to the voltage phase and the current phase to obtain a V-I phase difference; and calculating the impedance and power of the plasma according to the voltage waveform, the current waveform, the voltage amplitude, the current amplitude and the V-I phase difference. Aiming at the problems in the prior art, pulse modulation is carried out on a pulse radio frequency power supply, and the evolution process of radio frequency power and plasma impedance along with time is further obtained by prolonging the pulse turn-off time and calibrating the V-I phase difference; when the plasma is stable, stable-state (continuous wave-driven) plasma can absorb power.

Owner:DALIAN UNIV OF TECH

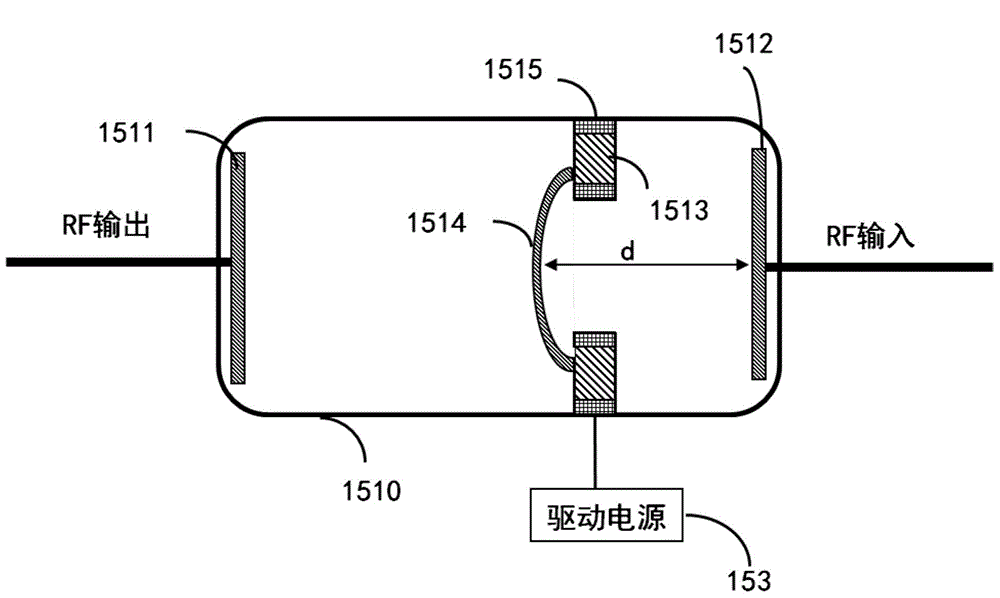

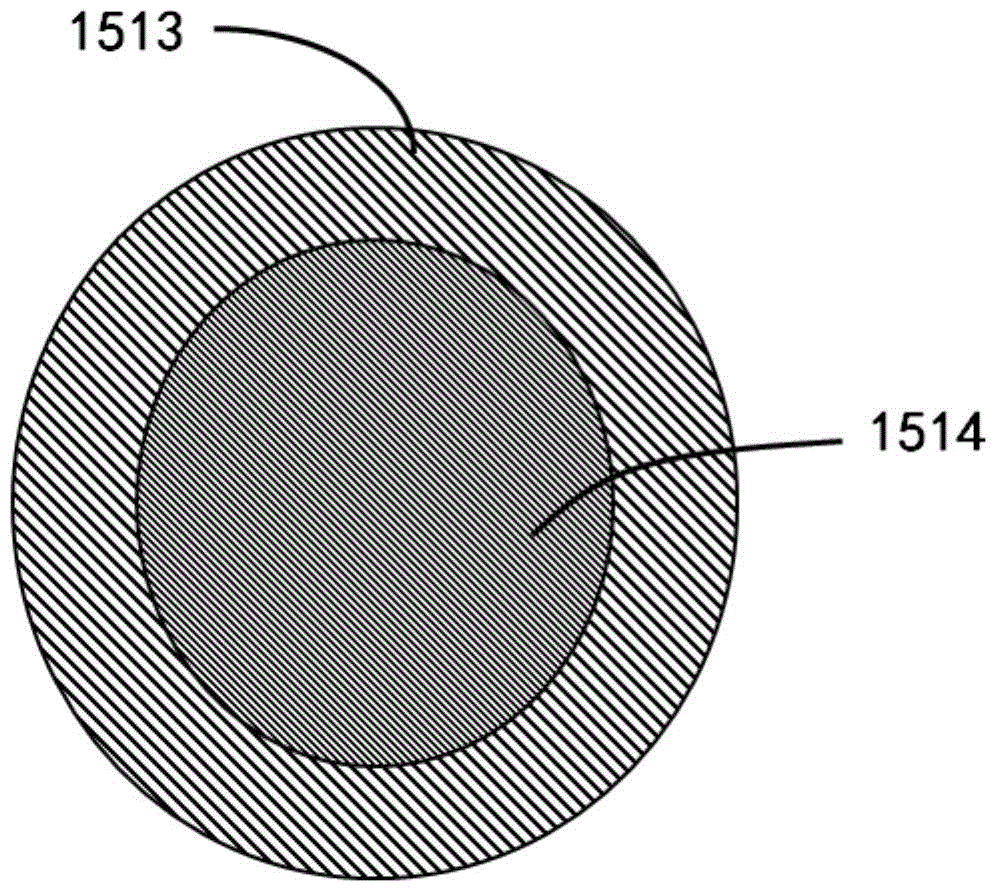

Impedance matching network for plasma reactor

ActiveCN104682917AQuickly change capacitance valueImplement resizingImpedence matching networksElectric discharge tubesCapacitanceElectricity

The present invention provides an impedance matching network for a plasma reactor, which comprises at least one inductor and at least one variable capacitor unit, wherein the variable capacitor unit comprises at least one variable vacuum capacitor; the variable vacuum capacitor comprises two parallel electrode plates; an annular piezoelectric ceramic plate is arranged between the two electrode plates; the annular piezoelectric ceramic plate is connected with a driving power supply; and an arc-shaped electrode plate is arranged in the hollow region of the annular piezoelectric ceramic plate. The variable vacuum capacitor in the impedance matching network described in the present invention uses the inverse piezoelectric effect of piezoelectric ceramic material; when alternating driving voltage is applied to piezoelectric ceramics, the piezoelectric ceramics can rapidly generate telescopic motion along a voltage loading direction, so that the distance of the arc-shaped electrode plate relative to the other electrode plate is changed; accordingly, the capacitance value of the variable vacuum capacitor is rapidly changed to realize that the size of the variable vacuum capacitor can be regulated within microsecond magnitude; and the need that plasma impedance is rapidly changed with the output of a radio frequency power source is satisfied.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com