Method for refining crystal grains in ultra-pure copper or copper alloy

A technology of copper alloy and pure copper, which is applied in the direction of metal extrusion control equipment, metal extrusion, metal extrusion die, etc., can solve the problems of many impurities, unstable sputtering, poor sputtering film, etc., and achieve thin film deposition High rate, low plasma impedance, and the effect of improving grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

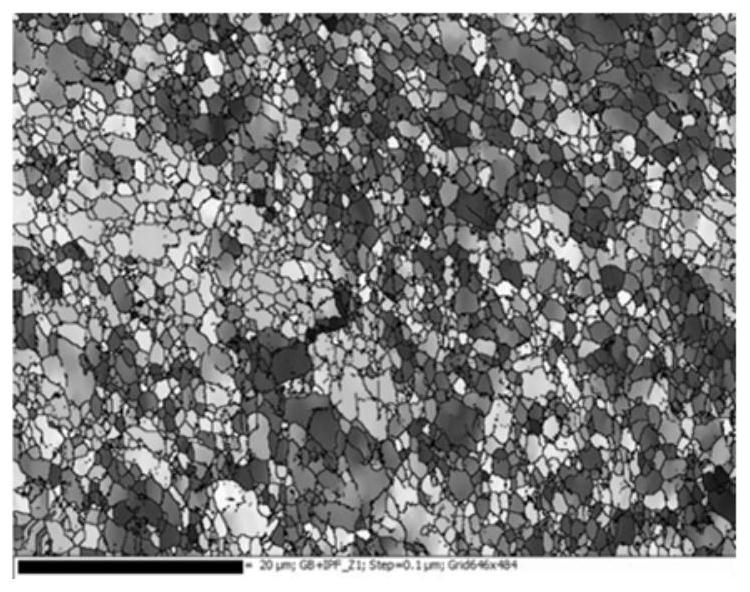

Embodiment 1

[0044] The invention provides a method for refining crystal grains in ultra-high-purity copper. The refining method includes: heating an ultra-high-purity copper billet, and then sequentially performing the first equal-angle extrusion and the second equal-angle extrusion. extrusion, such as Figure 9 shown;

[0045] The ultra-high-purity copper billet is obtained by hot extrusion, and the end temperature of preheating before hot extrusion is 820°C;

[0046] The end point temperature of the heating is 222°C;

[0047] The inner angle of the extrusion die in the first equal radial angular extrusion is 88°, and the outer die angle is 17°;

[0048] The number of extrusion passes in the first equal radial angular extrusion is 6 times;

[0049] The inner angle of the extrusion die in the second equal radial angular extrusion is 100°, and the outer die angle is 30°;

[0050] The number of extrusion passes in the second equal radial angular extrusion is 9 times;

[0051] After any...

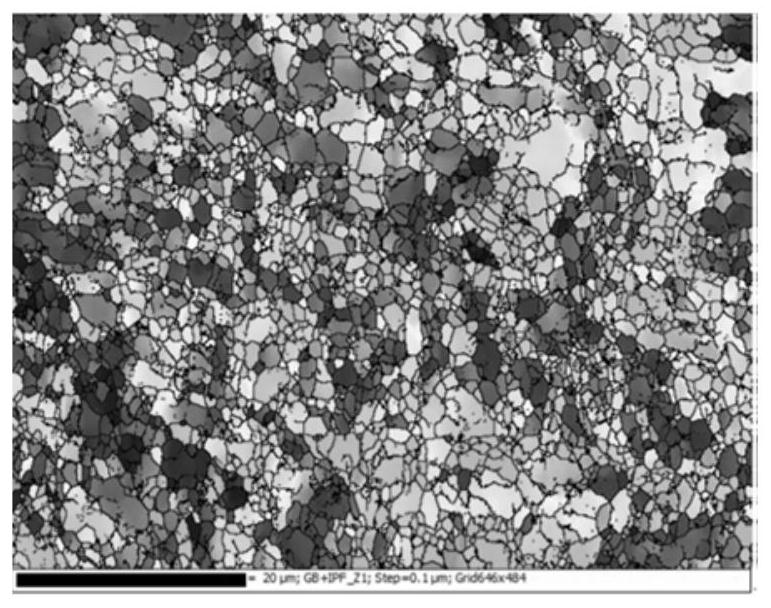

Embodiment 2

[0054] The invention provides a method for refining crystal grains in an ultra-high-purity copper alloy. The refining method includes: heating an ultra-high-purity copper alloy billet, and then sequentially performing the first equal-diameter angular extrusion and the second etc. radial extrusion;

[0055] The ultra-high-purity copper alloy billet is obtained by forging;

[0056] The end temperature of the heating is 200°C;

[0057] The inner angle of the extrusion die in the first equal radial angular extrusion is 85°, and the outer die angle is 20°;

[0058] The number of extrusion passes in the first equal radial angular extrusion is 4 times;

[0059] In the second equal radial extrusion, the inner angle of the extrusion die is 110°, and the outer die angle is 36°;

[0060] The number of extrusion passes in the second equal radial angular extrusion is 8 times;

[0061] After any pass of extrusion in the extrusion, the ultra-high-purity copper or copper alloy is rotated ...

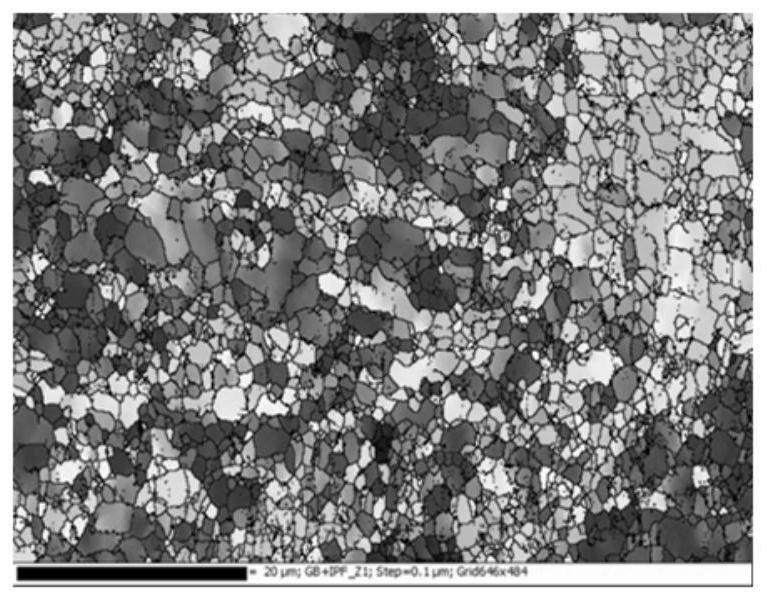

Embodiment 3

[0064] The invention provides a method for refining crystal grains in ultra-high-purity copper. The refining method includes: heating an ultra-high-purity copper billet, and then sequentially performing the first equal-angle extrusion and the second equal-angle extrusion. extrusion;

[0065] The ultra-high-purity copper billet is obtained by hot extrusion, and the end temperature of preheating before hot extrusion is 900°C;

[0066] The end temperature of the heating is 180°C;

[0067] The inner angle of the extrusion die in the first equal radial angular extrusion is 80°, and the outer die angle is 25°;

[0068] The number of extrusion passes in the first equal radial angular extrusion is 5 times;

[0069] The inner angle of the extrusion die in the second equal radial angular extrusion is 120°, and the outer die angle is 33°;

[0070] The number of extrusion passes in the second equal radial angular extrusion is 4 times;

[0071] After any pass of extrusion in the extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com