Manufacturing method of tungsten target

A production method and target technology, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of rough surface of tungsten target material, affecting the sputtering effect of sputtering process, substrate damage, etc. To achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

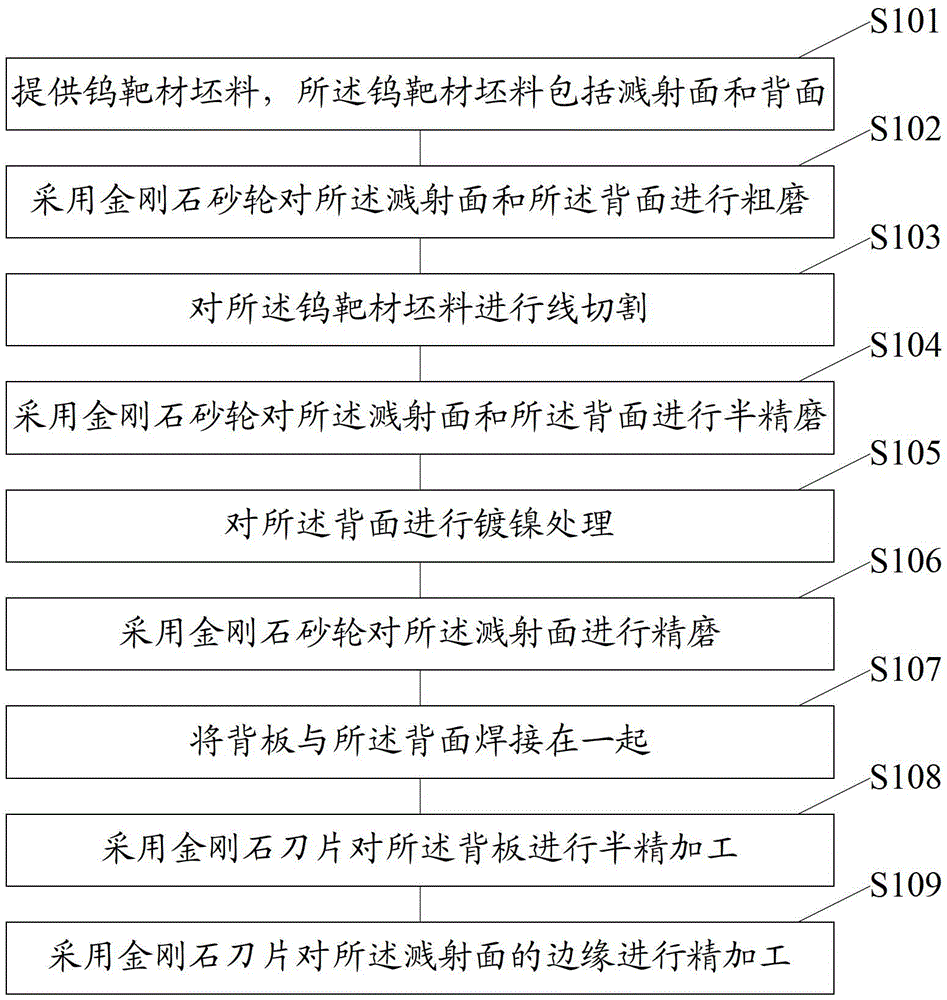

Method used

Image

Examples

Embodiment Construction

[0034] In the prior art, ordinary cutting tools are used to process tungsten target blanks. The tungsten target blanks are prone to corners during the processing, and the surface of the formed tungsten target is rough, which affects the sputtering effect of the subsequent sputtering process, and even Discharge will occur, causing damage to the substrate to be coated; moreover, the tool wear is serious during the processing, and the fracture is more frequent, resulting in the high production cost of the tungsten target

[0035] The present invention uses a diamond grinding wheel as a tool for rough grinding, semi-finishing grinding and fine grinding of tungsten target material blanks. Due to the high hardness and good wear resistance of diamond, the tungsten target material blanks are not prone to drop corners during the processing process. The sputtering performance of the tungsten target is good. At the same time, the diamond grinding wheel has low loss during the processing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com