A kind of vanadium-silicon alloy target material and preparation method thereof

A silicon alloy and target technology, applied in the field of vanadium-silicon alloy target material and its preparation, can solve the problems affecting the stability of thin film sputtering preparation, failure to obtain vanadium-silicon alloy target, target density and structural fluctuations, etc. , to achieve the effect of simple powder making method, good sputtering performance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

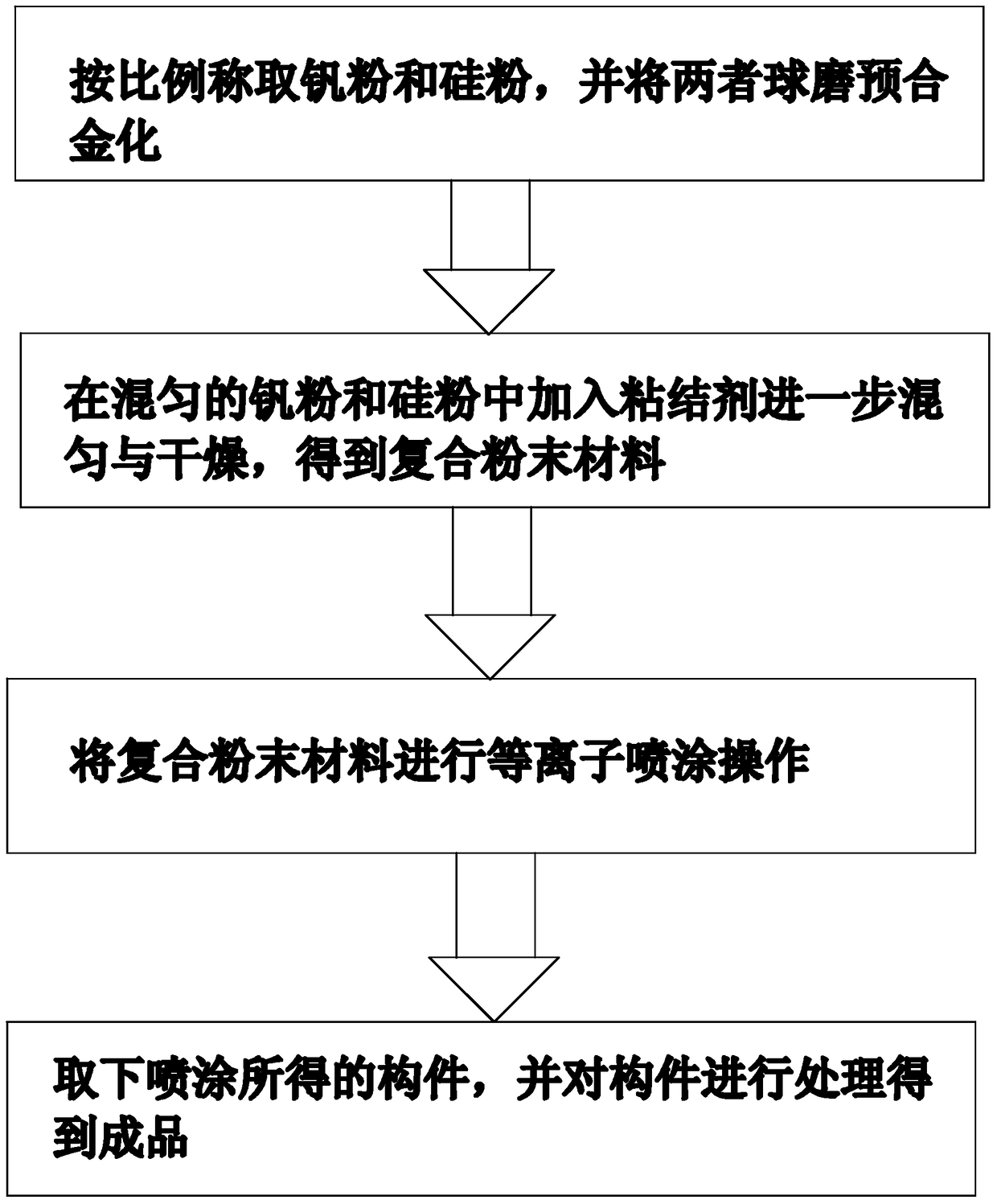

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Use vanadium powder with a particle size of 50-300um and a purity greater than 99.5%, and then calculate according to the vanadium-silicon mass ratio of 95:5-60:40, add silicon powder with a particle size of 30-150um and a purity greater than 99.5%, and roll Mix with the mixer, set the speed at 60-100r / min, and the duration is about 0.5-2h. The main function of this step is to fully mix the vanadium powder and silicon powder for the next step of mixing with the binder. Be prepared, because the binder is viscous, if the vanadium powder and silicon powder are directly mixed with the binder, the vanadium powder and silicon powder cannot be mixed.

[0025] Step 2: Put the above-mentioned vanadium-silicon composite powder into the ball milling tank of the centrifugal ball mill, add 200-300ml and 0.5-0.75kg of ethanol into the ball milling tank, and grind for 4-24 hours at 100-300r / min under an argon atmosphere, and put The ground powder is taken out and placed in a f...

Embodiment 2

[0031] Step 1: Use vanadium powder with a particle size of 50-150um and a purity of 99.5-99.9%, and then calculate according to the mass ratio of vanadium to silicon of 95:5-60:40, add the corresponding quality of silicon powder (particle size 5-20um), and use a drum mixer Mix well, the speed is 60~100r / min, and the time is 0.5~2h. The effect of this step is the same as that of step 1 in Example 1.

[0032] Step 2: Weigh the alkyd varnish, measure 200# gasoline, the volume ratio of the two is 1:30~3:30, add the two into the mixer, set the speed of the mixer at 60~100r / min, and stir for 15min~ 30min prepared into a binder for use. The binder prepared in this step is durable and has strong viscosity, and can strongly bind vanadium powder and silicon powder together.

[0033] Step 3: Put the composite powder in step 1 into the mixer, pour the binder prepared in step 2, start the mixer, set the stirring speed to 60~100r / min, and the time is 1~3h, the stirring process will Sligh...

Embodiment 3

[0040] Step 1: Use vanadium powder with a particle size of 5-20um and a purity greater than 99.5%, and then calculate according to the vanadium-silicon mass ratio of 95:5-60:40, add silicon powder with a purity greater than 99.5% and a particle size of less than 10um, and roller mix Mix with the material machine, the speed is 60-100r / min, and the time is 0.5-2h. The effect of this step is the same as that of step 1 of Examples 1 and 2.

[0041] Step 2: Put the above-mentioned vanadium-silicon composite powder into the ball mill tank of a centrifugal ball mill, add 200-300ml of ethanol and 0.5-0.75kg of hard alloy balls into the ball mill tank, and grind at 100-300r / min under an argon atmosphere for 4 ~24h, take out the ground powder and place it in the fume hood for 10~30mins. The effect of this step is the same as that of step 2 of Example 1.

[0042] Step 3: Put the composite powder in step 2 into a blender, add 1.25-12.5 parts of polyethylene glycol PEG400, 12-96 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com