Full-compensation elastic chain hanging construction method for high-speed rail contact network

A technology for high-speed railways and construction methods, applied in overhead lines and other directions, can solve problems such as lack of high-quality construction standards, low accuracy of pre-allocated data, and non-compliance with modern construction requirements, so as to ensure installation quality and accuracy. , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: This embodiment 1 is the embodiment of the software computing technique among the present invention.

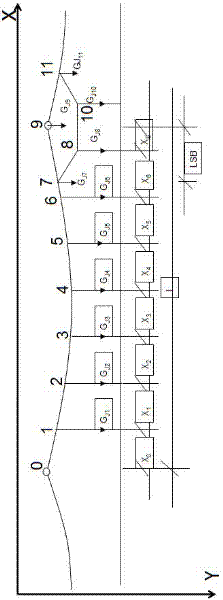

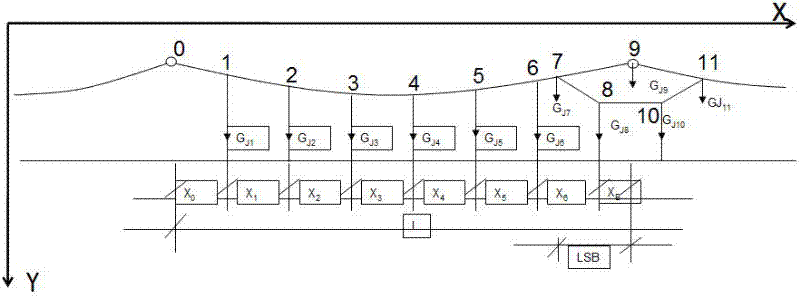

[0079] see figure 1 , establish the coordinate system as shown in the figure. For the convenience of calculation, take the position of the guide height (assuming the guide height is 5300mm) as the abscissa, and assume that the abscissa distance from the coordinate origin to node 0 is 0, that is, node 0 is ( 0,y 0 ), assuming that the height of the catenary cable at node 0 measured on site is 6.908 meters, and the guide height is 5300mm (refer to the guide height of a passenger train), then the structure height here is 6.909m-5.3m=1.608m, so the node The coordinate of 0 is (0,1.608).

[0080] Taking the suspension string length at nodes 1, 2, 3, and 4 as an example, the calculation of the suspension string length is as follows:

[0081] Step 1: Assume that the span of the two nodes 0 and 9 is 49 meters according to the on-site measurement. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com