Measuring apparatus for capability of explosive explosion in driving of metal

A measuring device and explosive technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of high cost, long cycle, complex test system, etc., and achieve the effect of easy popularization and application, short test cycle and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

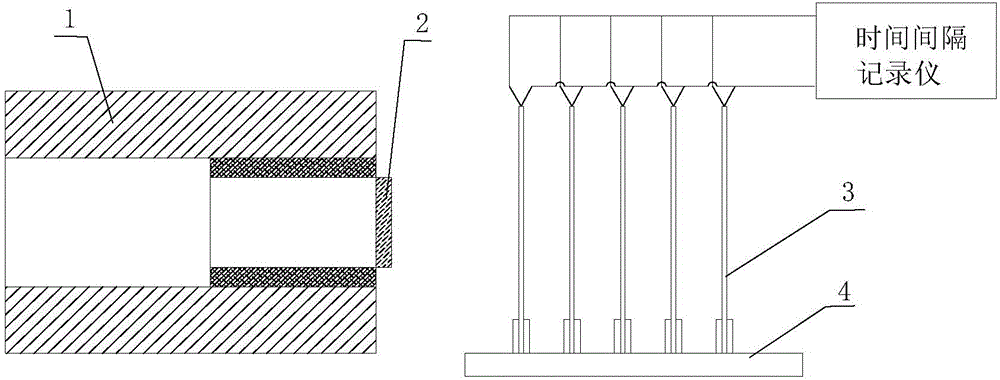

[0016] refer to Figure 1 to Figure 6 , the present embodiment gives a specific structure and manufacturing and assembly examples of an explosive detonation accelerating metal capability measuring device. The explosive detonation accelerating metal capability measuring device at least includes an explosion chamber 1, a metal flyer 2, a speed measuring target 3 and a speed measuring target support 4.

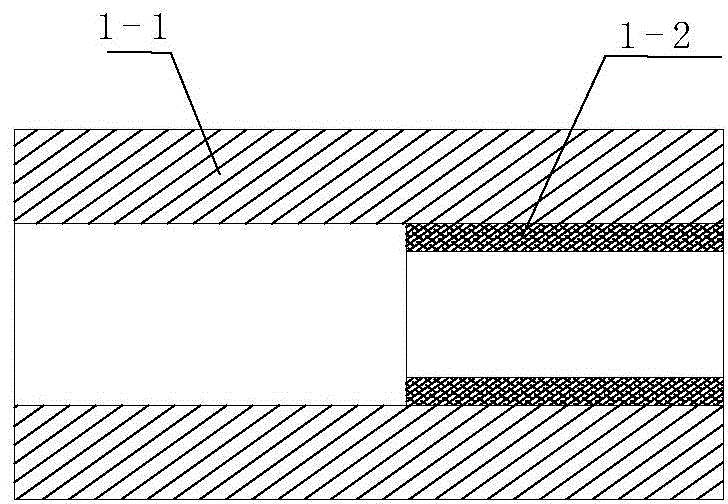

[0017] see figure 2 , the explosion chamber 1 is composed of an explosion shield 1-1 and a charge sleeve 1-2. The explosion protection body 1-1 is made of stainless steel and is cylindrical with a central through hole. The outer diameter is 300mm-400mm, the inner diameter is 30mm-70mm, and the length is 150mm-250mm. It is placed horizontally. The charging sleeve 1-2 is made of brittle materials such as ceramics or cement, and is cylindrical with a central through hole, with an outer diameter of 25mm-70mm, an inner diameter of 15mm-60mm, and a length of 15mm-60mm. Embedded in ...

Embodiment 2

[0023] This embodiment gives an example of measuring the detonation acceleration metal capability of a certain aluminum-containing explosive by using the explosive detonation acceleration metal capability measurement device manufactured in Example 1.

[0024] The formula of the aluminum-containing explosive used in this example is 76RDX / 20Al / 4 viscosity, and a cylindrical explosive column with a diameter of 40 mm and a height of 50 mm is prepared by a compression molding process.

[0025] Put the aluminum-containing explosive column into the charging sleeve 1-2, make one end surface of the aluminum-containing explosive sample flush with the right end surface of the charging sleeve 1-2, and stick the metal fly piece 2 with double-sided adhesive tape. Connect to the end face of the explosive column that is flush with the right end face of the charge sleeve 1-2; insert the charge sleeve 1-2 into the explosion protection body 1-1, so that the right end face of the charge sleeve 1-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com