Ultrasonic detection method for bonding quality

A technology for ultrasonic detection and bonding quality, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc. It can solve problems such as the difficulty in determining the side where debonding occurs, the difficulty in distinguishing the leading edge of composite blades, and the inconsistent thickness of the leading edge of the blade. , to achieve the effect of high reliability, high reliability and fast scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

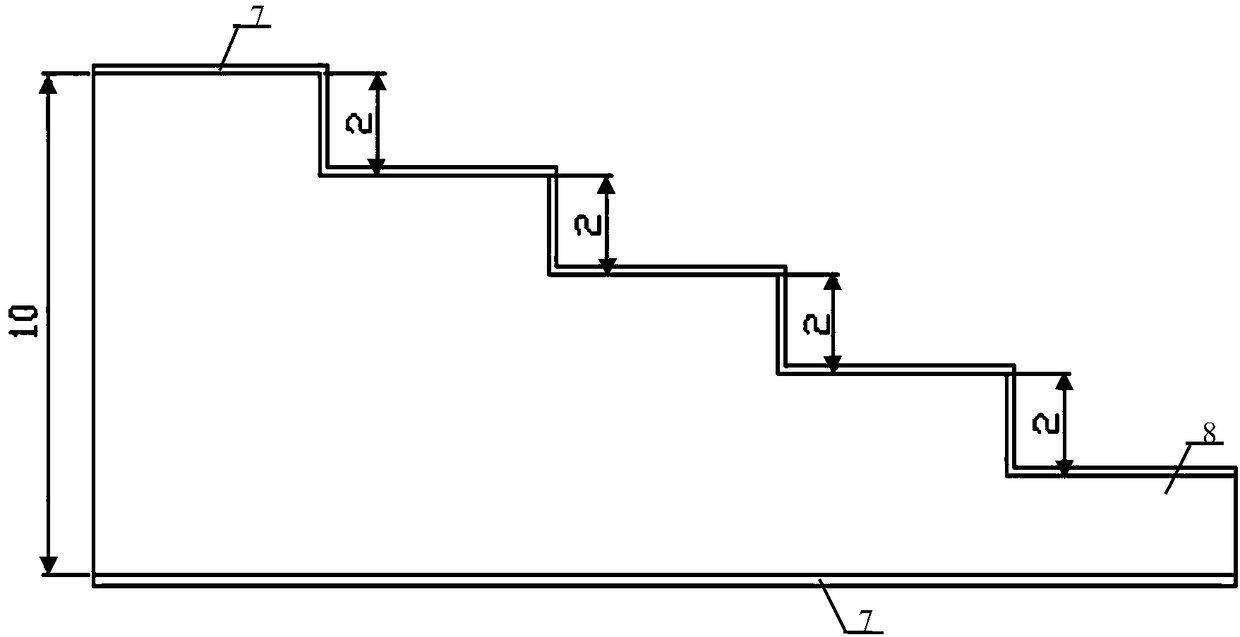

[0042] Taking the method of the present invention to realize the ultrasonic detection of the bonding quality of the leading edge of a CFRP composite blade with a thickness of 2 to 10 mm and the nickel alloy wrapping skin with a thickness of 0.2 mm as an example, the steps are as follows:

[0043] 1. Exclude defective composite material blades at the leading edge before wrapping:

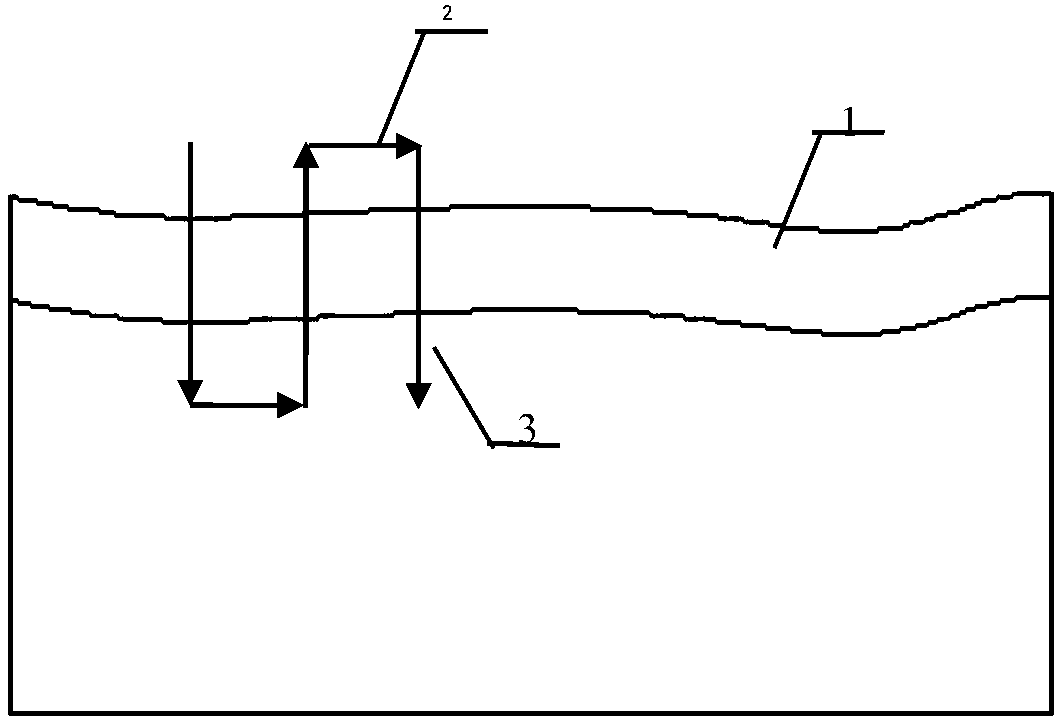

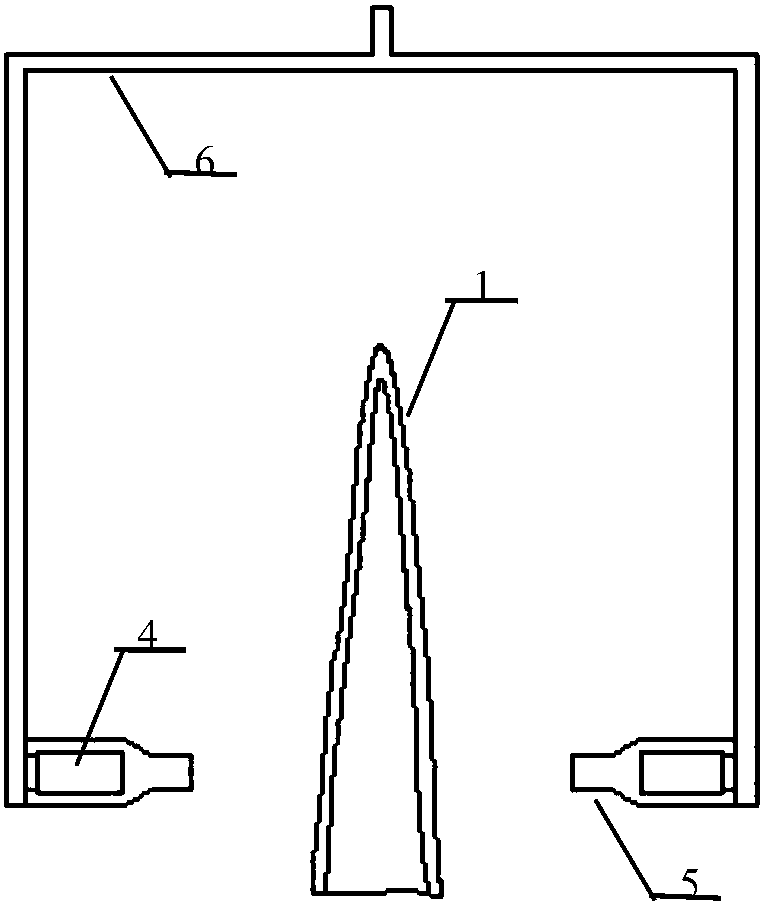

[0044] (1) see figure 1 and 2, using ultrasonic water spray penetrating C-scan automatic scanning equipment for scanning, this equipment includes ultrasonic probe 4, water spray jacket 5, probe arm 6, the frequency of transmitting and receiving ultrasonic probe 4 is 2.25MHz, which can ensure sufficient Ultrasonic energy penetrates the inspected part and can ensure high detection sensitivity; the scanning step is 1mm, the C-scan scanning direction 3 is perpendicular to the direction of the leading edge, and the C-scan stepping direction 2 is parallel to the direction of the leading edge, ensuring hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com