Integral lifting template of main pylon of single-pylon cable-stayed bridge without dorsal cables and lifting construction method thereof

A single-tower without back-cable slanting and overall lifting technology, which is applied to cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of complex main tower structure, high process requirements, and difficult construction, and achieve processing, manufacturing, installation and layout Convenient, less hardware investment, good construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

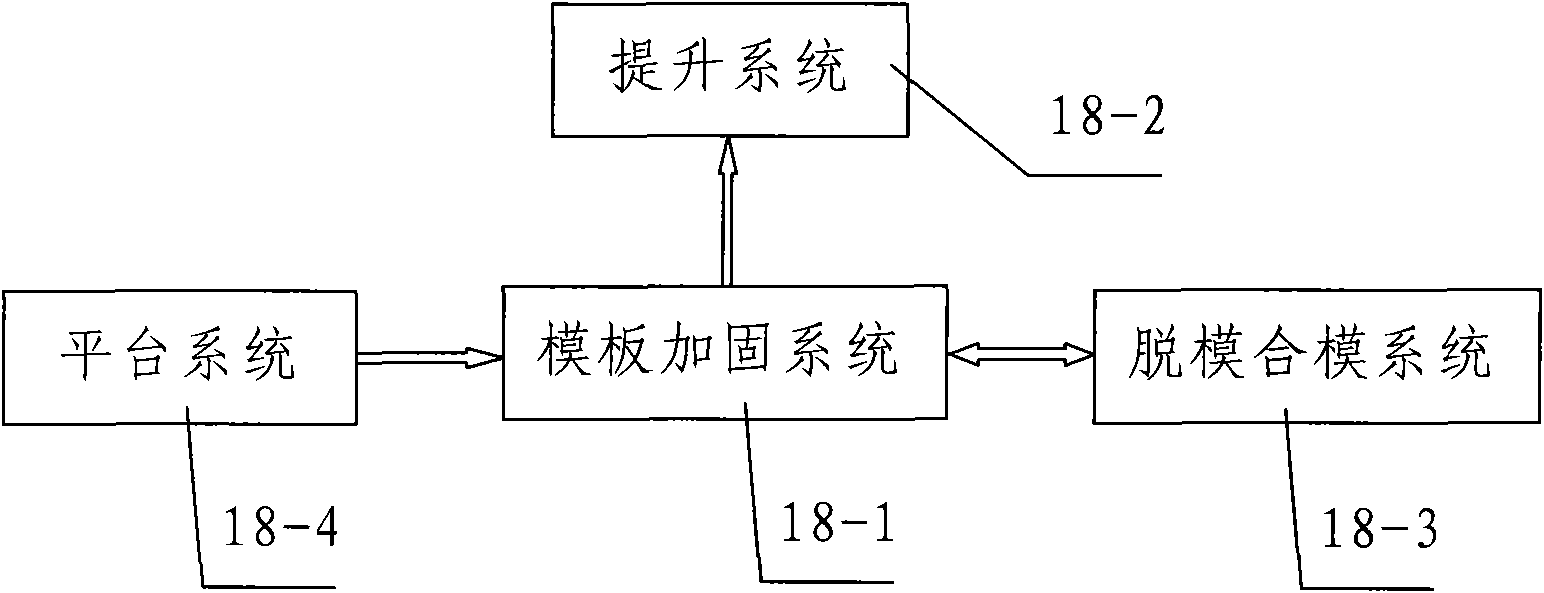

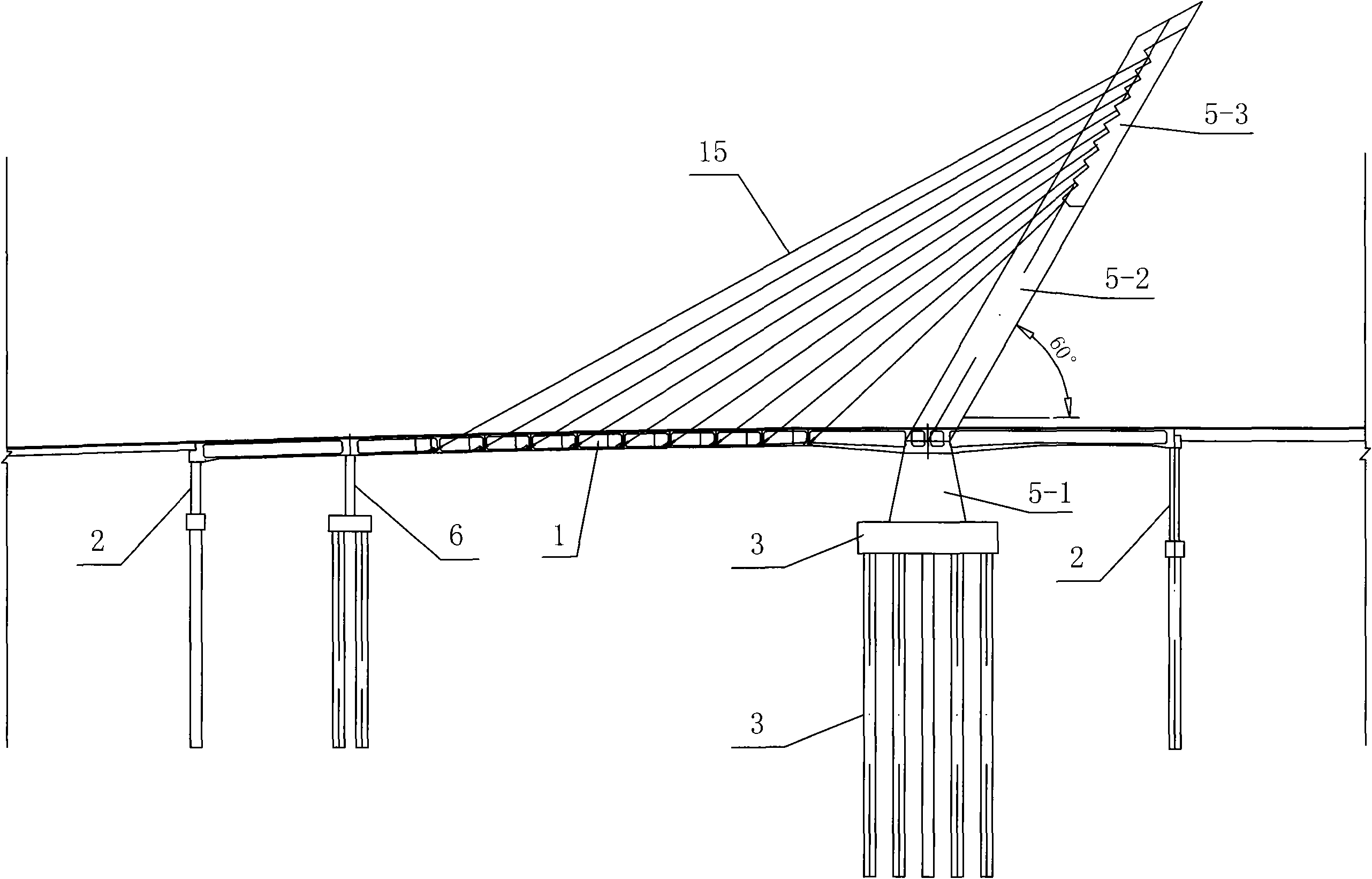

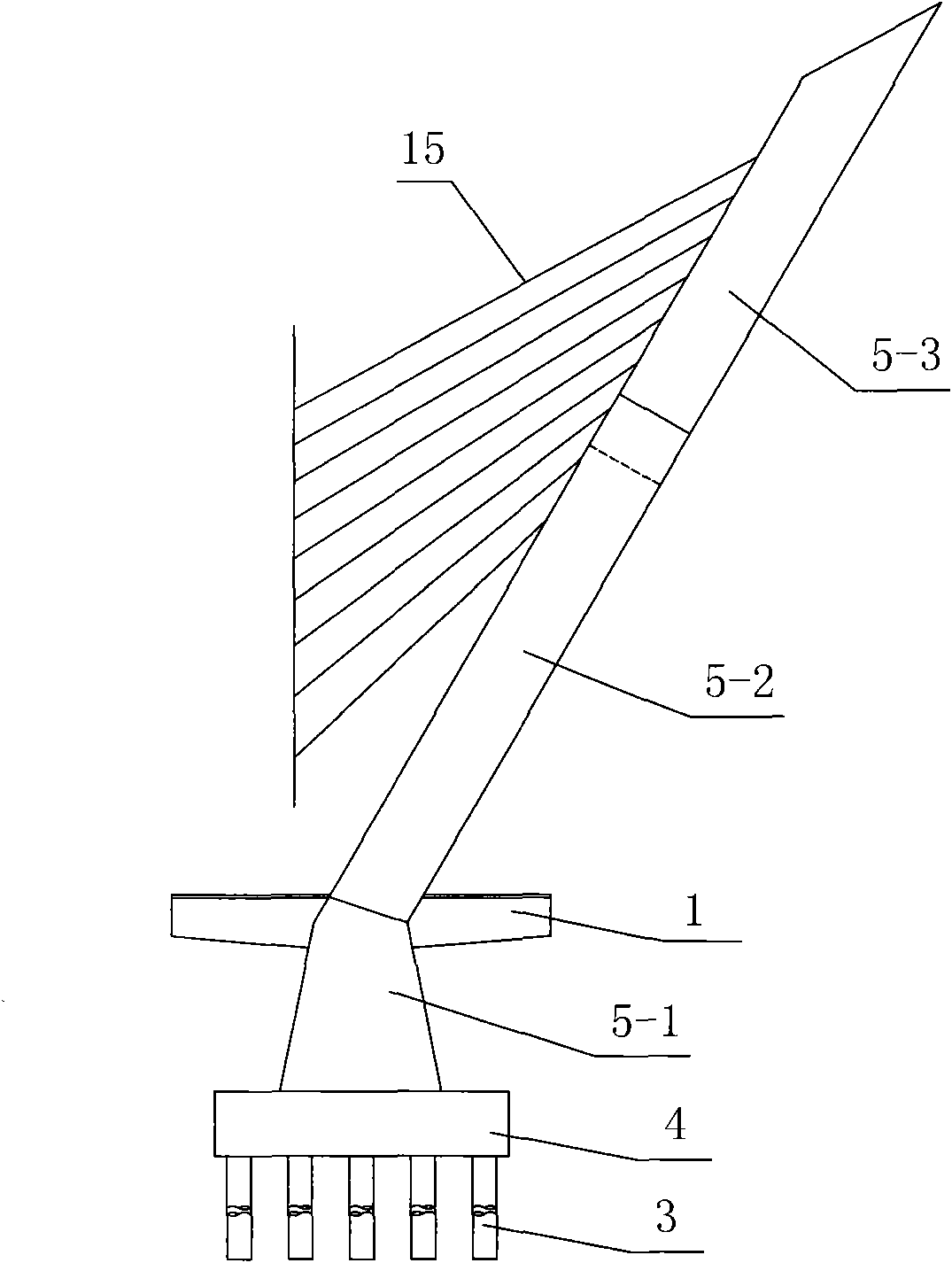

[0059] Such as figure 1 , Figure 6 , Figure 7 and Figure 8 The overall lifting formwork for the main tower of a single-tower cable-stayed bridge without back cables is shown, including a formwork reinforcement system 18-1 for the main tower of the cable-stayed bridge that needs to be constructed by segmental pouring. The upward extension direction of the tower lifts the formwork reinforcement system 18-1 upwards as a whole, the lifting system 18-2, the demoulding and clamping system 18-3 used in conjunction with the formwork reinforcement system 18-1, and the formwork reinforcement system 18-3 are respectively arranged 18-1 top and bottom platform systems 18-4 for construction personnel to walk on, the lifting system 18-2 is installed on the formwork reinforcement system 18-1. The formwork reinforcement system 18-1 includes a formwork for forming, a forming formwork frame arranged on the outside of the formwork for forming, and a tie rod system for temporarily fixing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com