Fracture test sample mounting and clamping device matched with shock testing machine

A technology of impact testing machine and clamping device, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as difficulty in meeting the fracture test of small-sized samples, large energy of drop-weight fracture testing machine, affecting equipment detection accuracy, etc. , to achieve the effect of reducing equipment purchase cost, simple structure and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure and use of the clamping device for fracture test sample used in conjunction with the impact testing machine according to the present invention will be further described below through examples and in conjunction with the accompanying drawings.

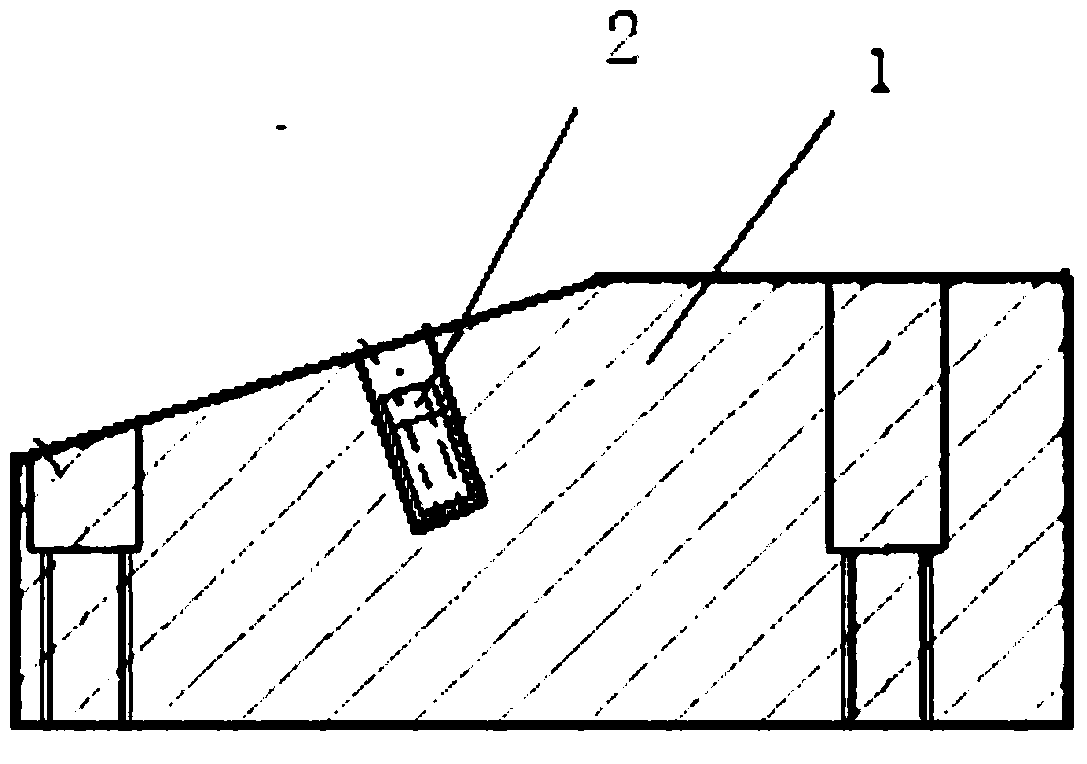

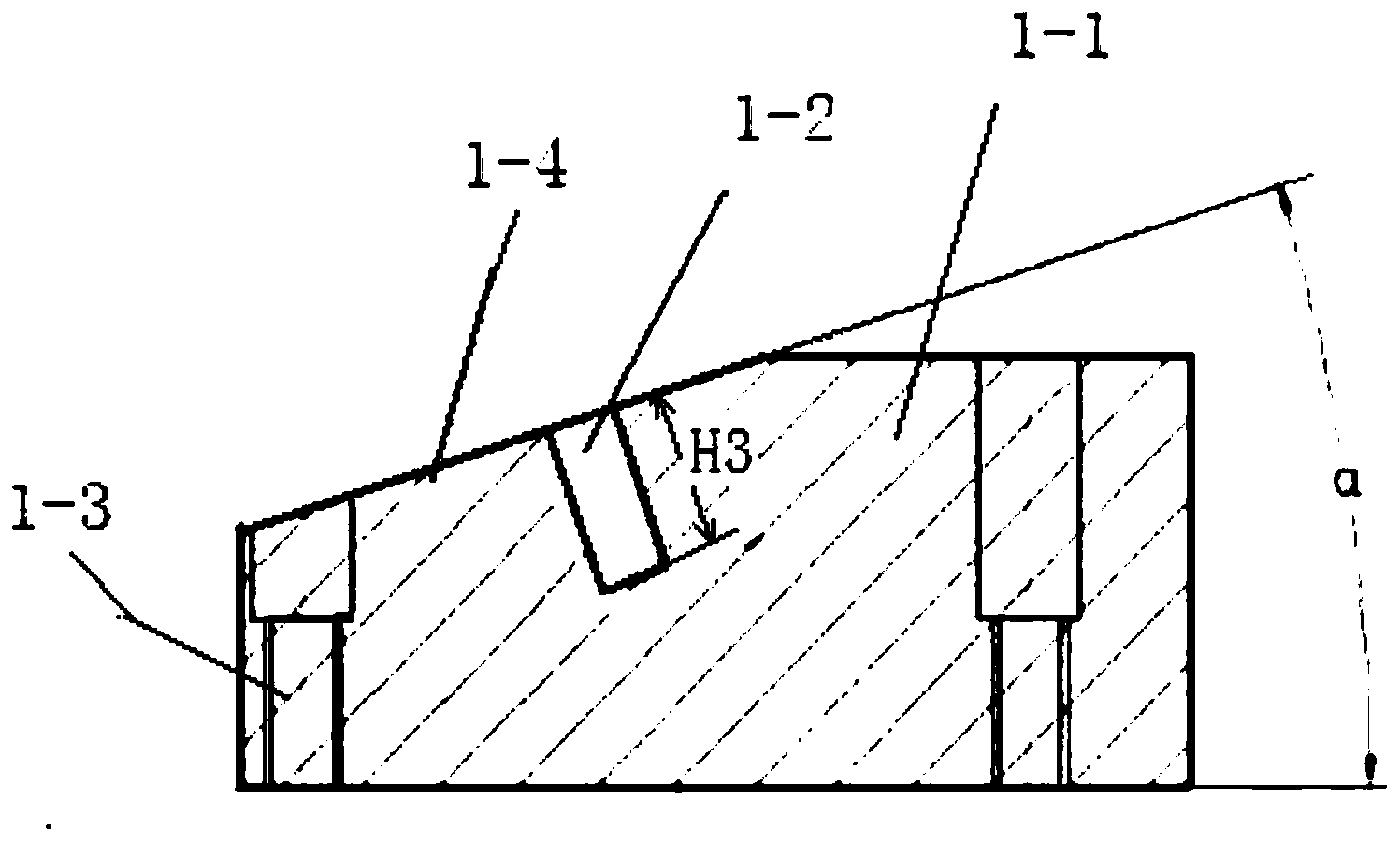

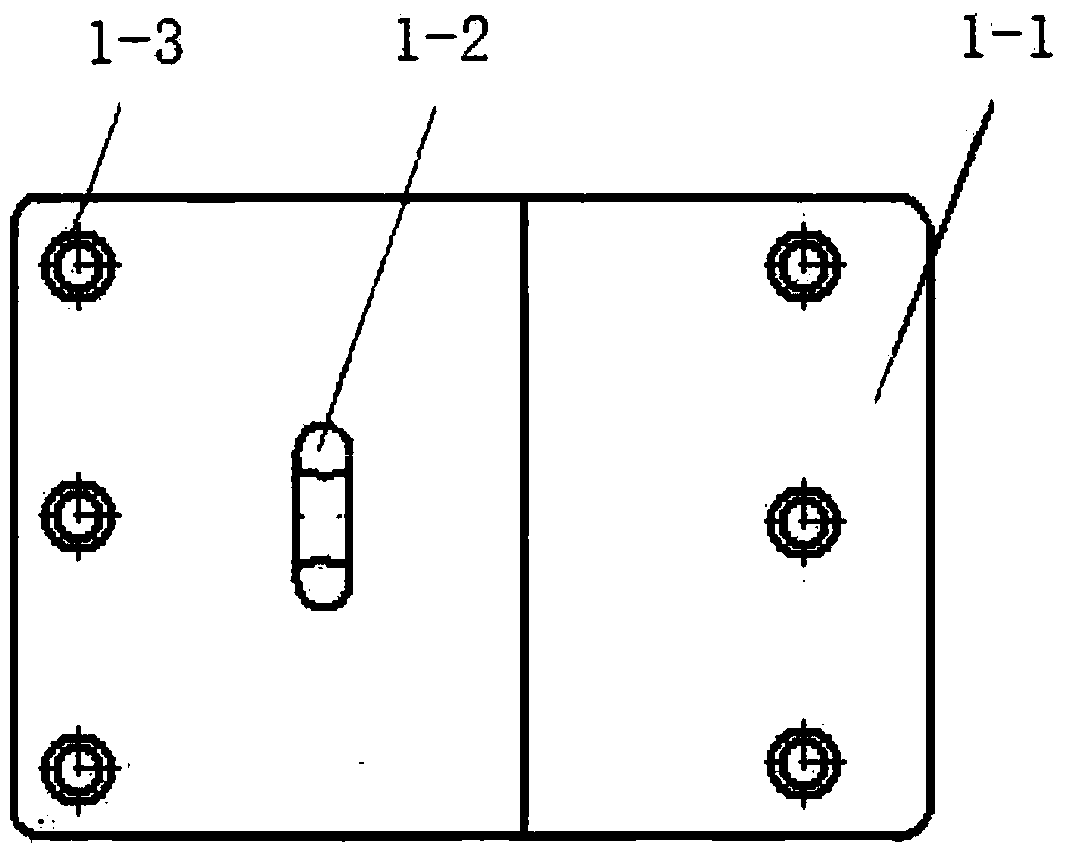

[0019] In this embodiment, the structure of the clamping device for the fracture test sample used in conjunction with the impact testing machine is as follows: figure 1 As shown, it consists of fixture 1 and block 2; the shape and structure of block 2 are as follows Figure 4 , Figure 5 As shown, it is a bar-shaped block, its bottom surface and four sides are flat, and the four sides are perpendicular to the bottom surface, and its top surface is provided with a V-shaped groove 2-2 for placing the sample. The shape and structure of fixture 1 are as figure 2 , image 3 As shown, it is a cube with a slope 1-4 on the top surface, a pad installation groove 1-2 matching the pad is provided on the slope, and the angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com