Temperature-regulating load-regulating frequency-regulating impact test machine

A technology of impact testing machine and cyclic load, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., which can solve the problems that the test temperature, impact frequency and impact energy cannot be adjusted at the same time, and achieve low manufacturing cost, convenient preparation, and excellent structure. unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

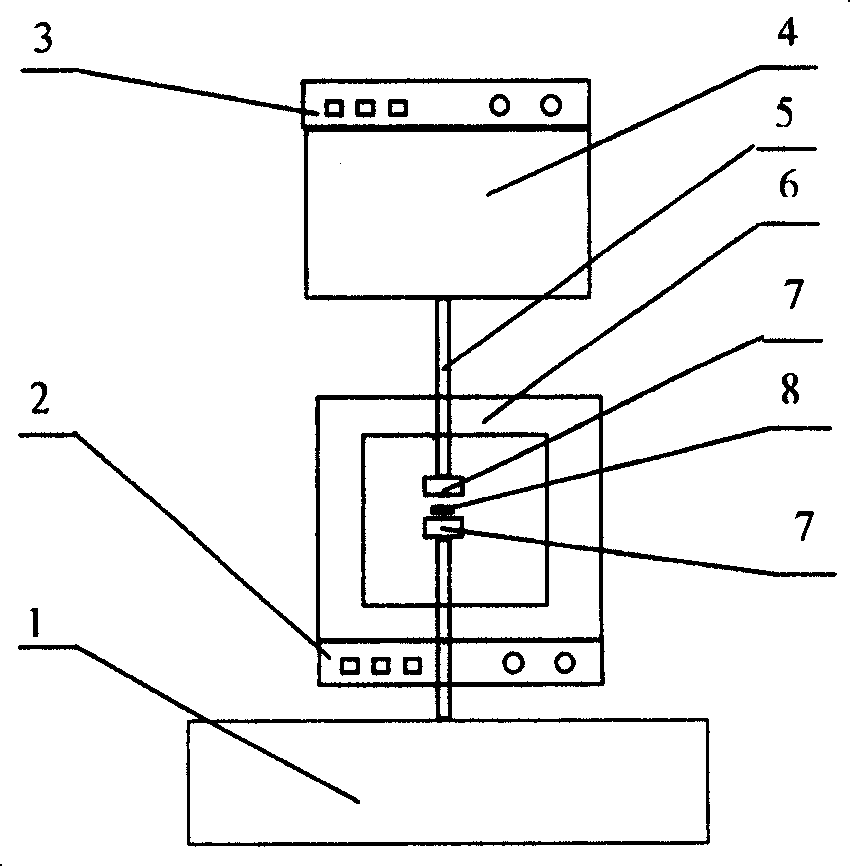

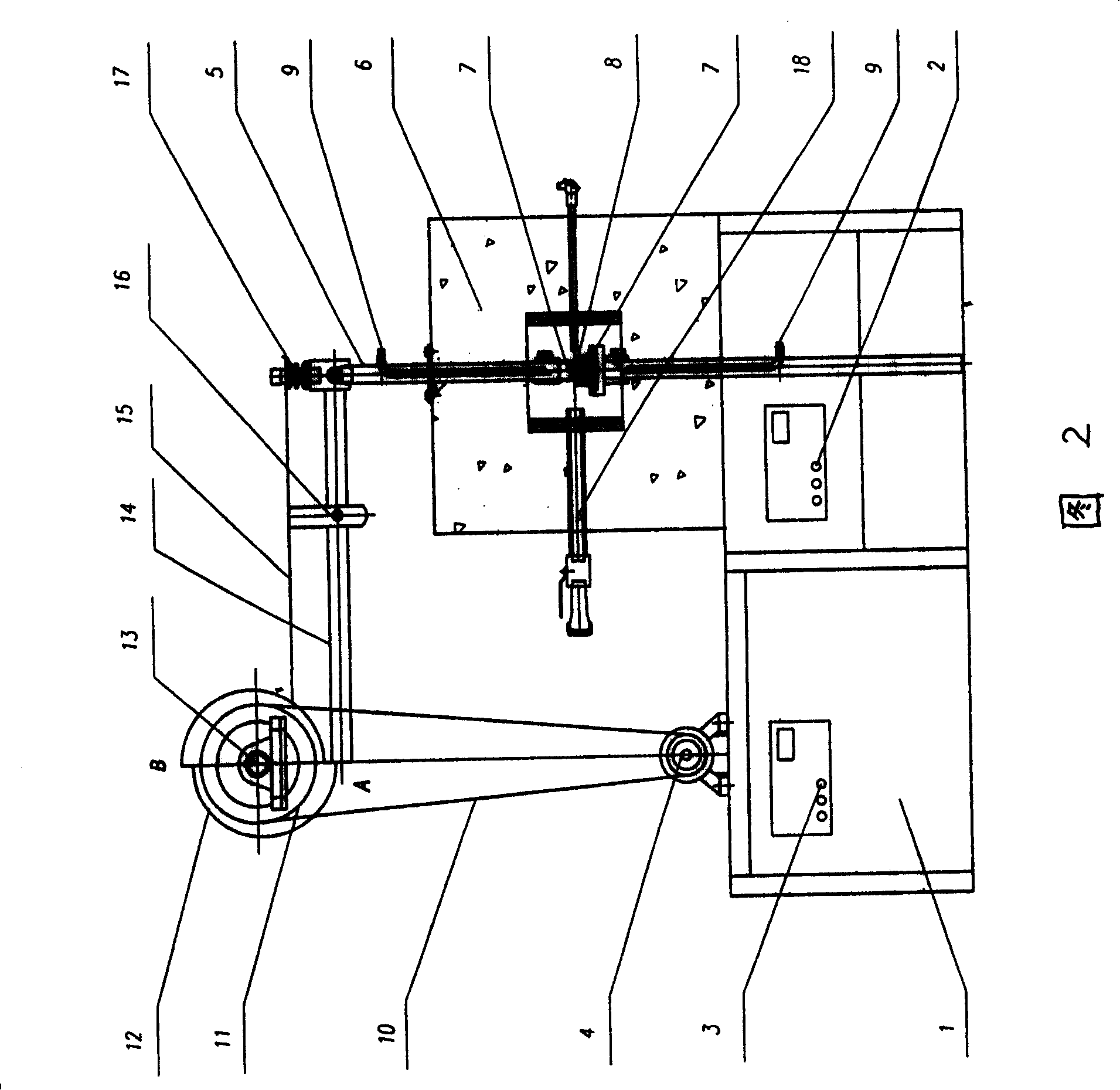

[0014] As shown in Figure 2, the speed regulating motor 4 is fixed on the workbench 1 by screws, and the speed regulating motor 4 and the transmission disc 11 are connected by a belt 10, which drives the transmission disc 11 and the cam 12 to rotate clockwise around the cam rotating shaft 13, and achieve deceleration. Crossbeam connecting rod 14 is fixed on the support 15, and one end links to each other with cam 12, and spring 17 is placed on the other end, and can rotate around crossbeam rotating shaft 16. When the cam 12 rotates, the spring 17 is compressed. When the cam 12 rotates to point A, the compression of the spring 17 reaches the maximum. When the cam 12 rotates beyond the point A, the spring is released, pushing the vertical connecting rod 5 and The impact head 7 moves downwards to perform an impact on the sample 8 placed in the open-close heating device 6, and cooling water 9 is passed into the vertical connecting rod 5 for protection. The workbench 1 continues t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com