Drop hammer structural design based on stress concentration principle and test method thereof

A technology of stress concentration and structural design, applied in the direction of applying repetitive force/pulse force to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of high price and poor anti-interference performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

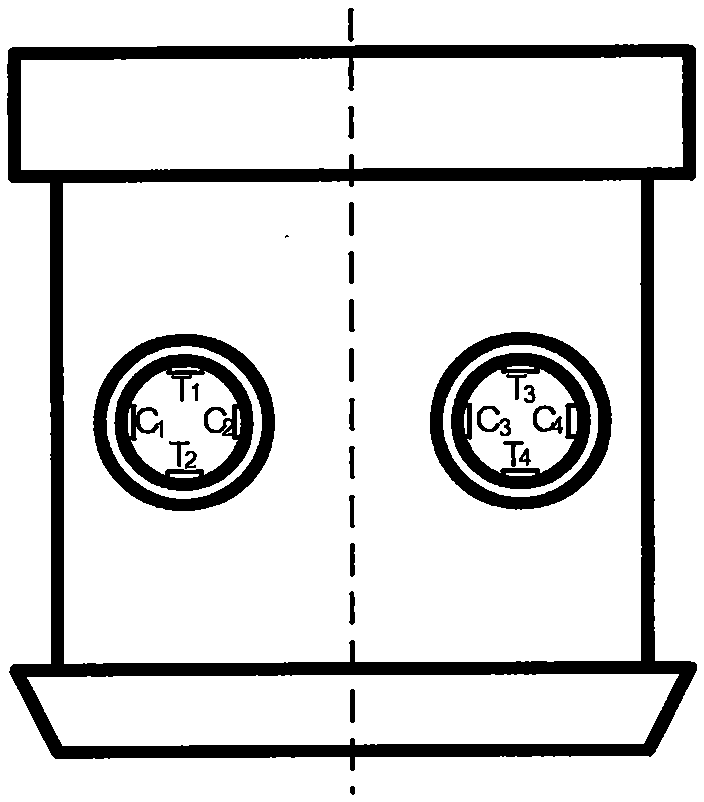

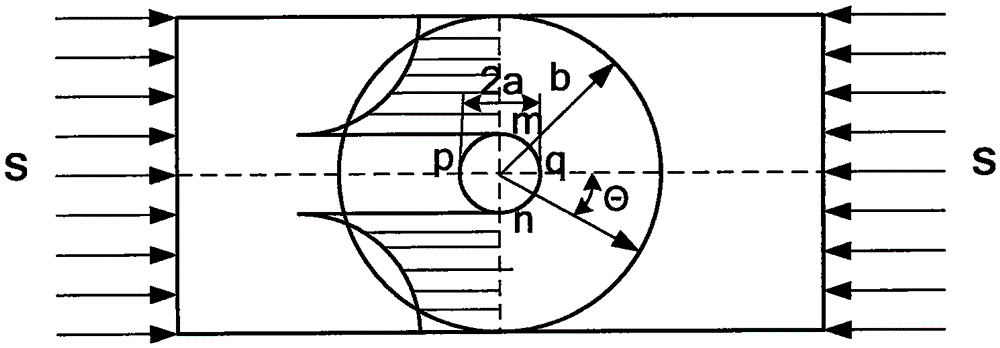

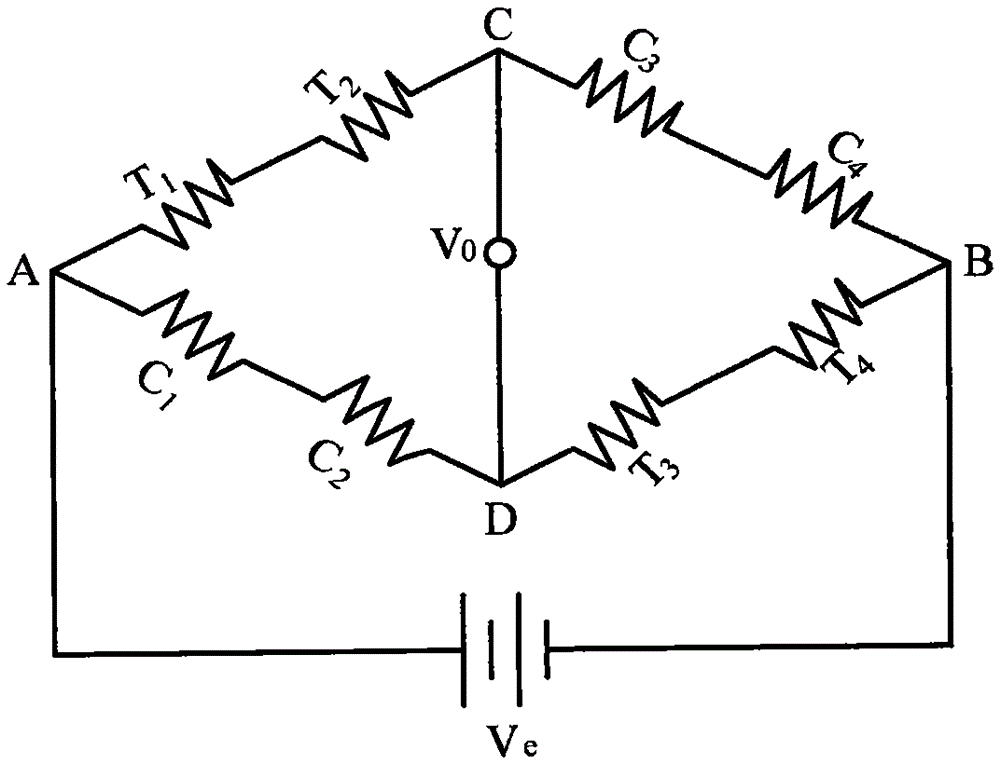

[0037] The invention adopts the principle of stress concentration to design the drop hammer structure, and adopts the double bridge circuit of the Wheatstone bridge to measure the concentrated impact force of the beam. The test method is applied to the test of the impact force of the concentrated loading of the large-scale reinforced concrete beam. The length, width and height of the beam are 1200×120×120 (mm) and specifically include the following steps:

[0038] Step S1: In order to form plane stress, the drop hammer is designed in the shape of a thin plate, and the thickness and size of the drop hammer are determined according to the specific requirements of the experiment. According to the bearing capacity of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com