Impact test apparatus and impact test method

A technology of impact test and impact force, applied in the direction of measuring device, testing material strength using one impact force, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

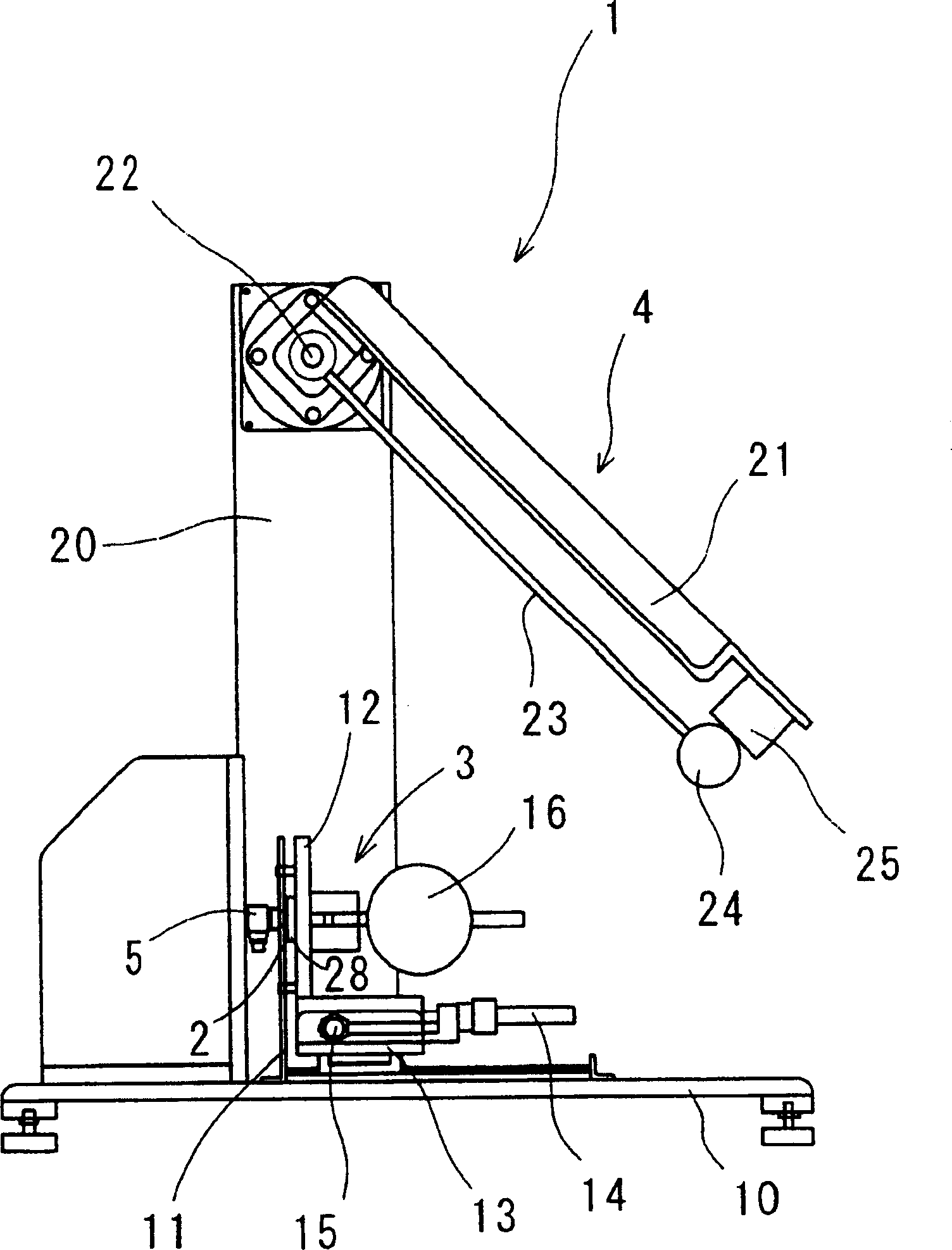

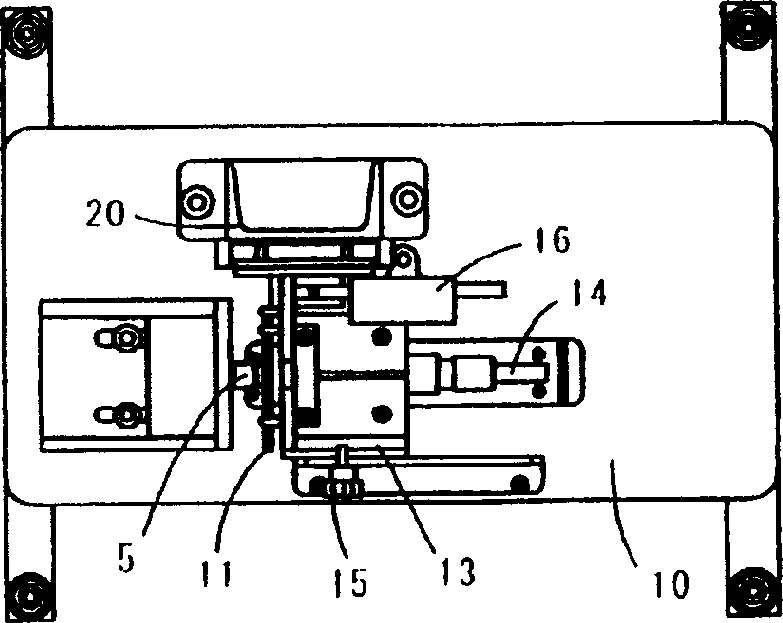

[0027] First, refer to Figure 1 to Figure 4 A schematic configuration of the impact test apparatus of the first embodiment will be described.

[0028] Such as Figure 1 to Figure 4 As shown, the impact test device 1 in the first embodiment is composed of the following components: a holding device 3, which is used to hold a test piece 2 with any active force; an impact application device 4, which is used to The test piece 2 applies an impact stress; a force sensor 5, as an impact force sensing device, is used to sense the impact force acting on the test piece 2 by the impact application device 4; a high-speed camera 6, as a displacement A detection device for detecting displacement of the test piece when the impact applying device 4 applies impact force to the test piece 2; and an output device 7 for synchronizing the signal from the force sensor 5 with the signal from the high-speed camera 6 , and output an impact stress-strain characteristic curve, which is used as the imp...

Embodiment 2

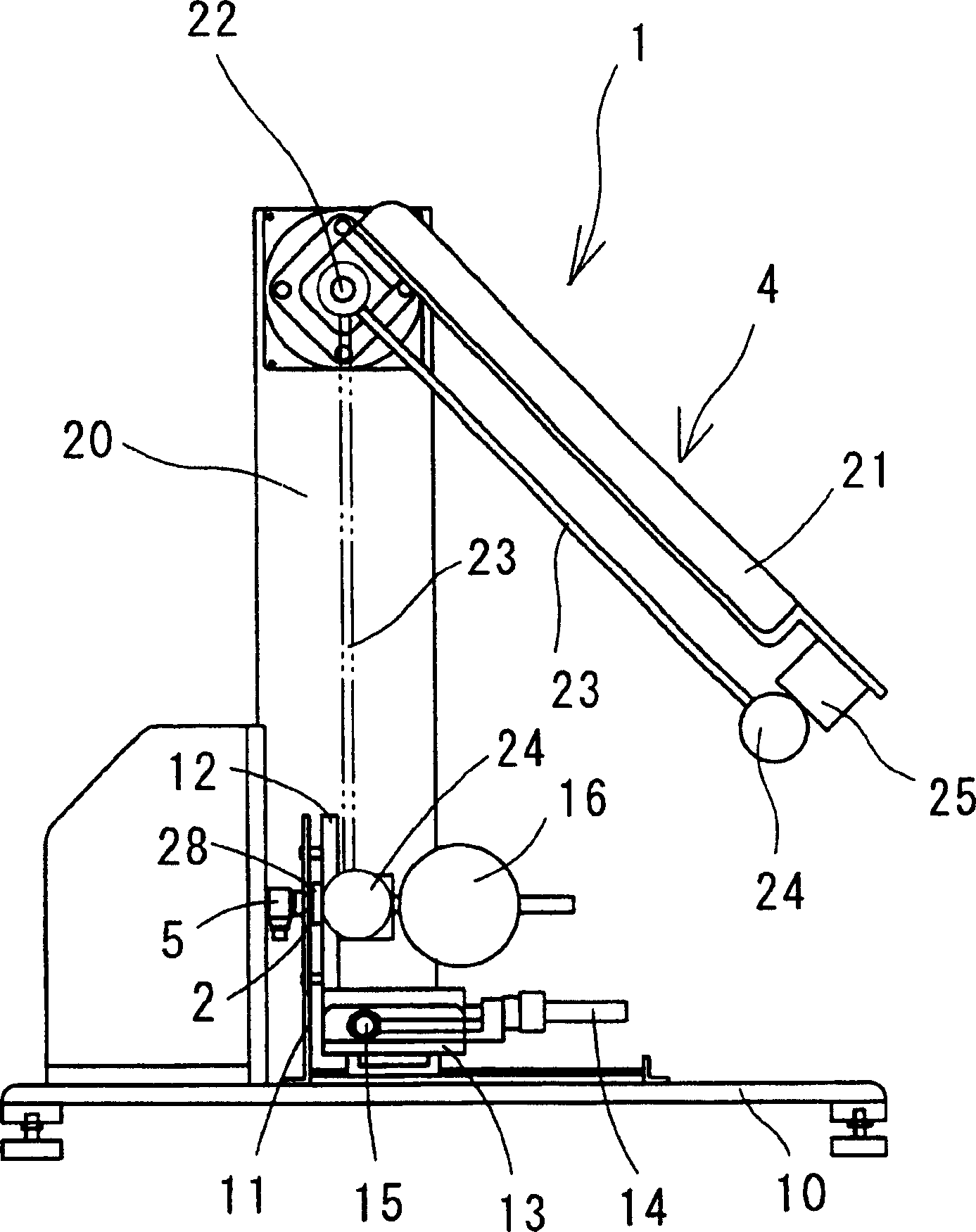

[0054] Below, will refer to Figure 7 to Figure 9 The schematic configuration of the impact test apparatus of the second embodiment will be described. Here, in the following description, as in Figure 1 to Figure 4 The same reference numerals in the shown configuration and the like of the first embodiment impact test apparatus 1 designate the same or equivalent components as the configuration and the like of the first embodiment impact test apparatus 1 .

[0055]The schematic configuration and control structure of the impact test device in the second embodiment are almost identical to the corresponding structure of the impact test device 1 in the first embodiment.

[0056] However, if Figure 7 to Figure 9 As shown, the impact test device 51 of the second embodiment is different from the structure of the impact test device 1 of the first embodiment, because the holding device 3 and the impact applying device 4 on which the force sensor 5 is fixed are arranged in a constant t...

Embodiment 3

[0086] Such as Figure 11 As shown, for example, an acceleration sensor 81 is fixed at a position close to the collision between the hammer 24 and the support plate 28 to replace the design of using the above-mentioned high-speed camera 6 to measure the displacement of the test piece 2, and when the hammer 24 collides with the support plate 28 On collision, the acceleration is integrated twice. With such a design, the displacement of the specimen 2 can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com