Coal seam group mining and top plate and goaf water dynamic seepage three-dimensional simulator

A simulation device and goaf technology, applied in the field of mining engineering test research, can solve problems such as roof and goaf seepage, inability to accurately grasp the trend and tendency of the upper and lower seam coal, and the distribution of inclined support pressure, roof damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

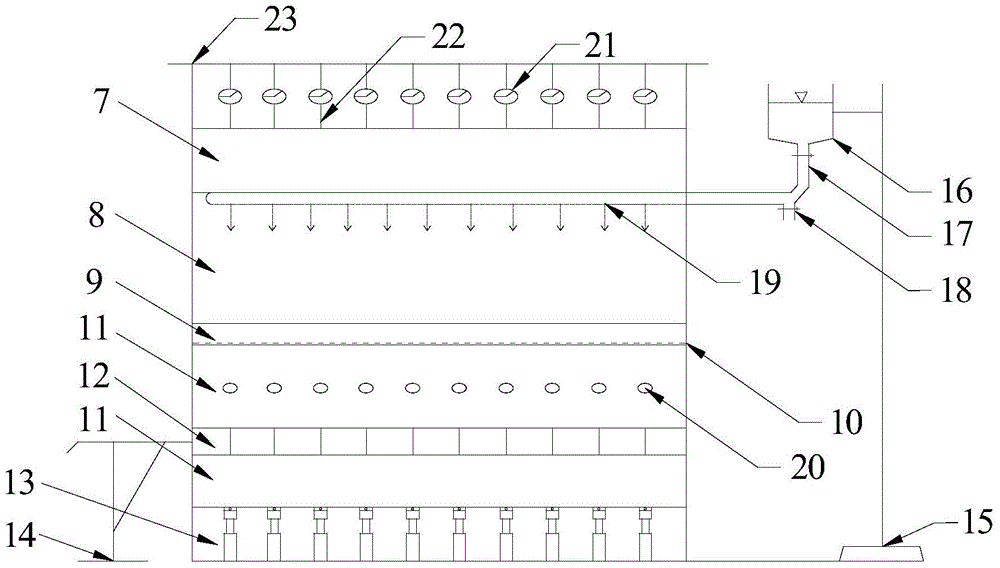

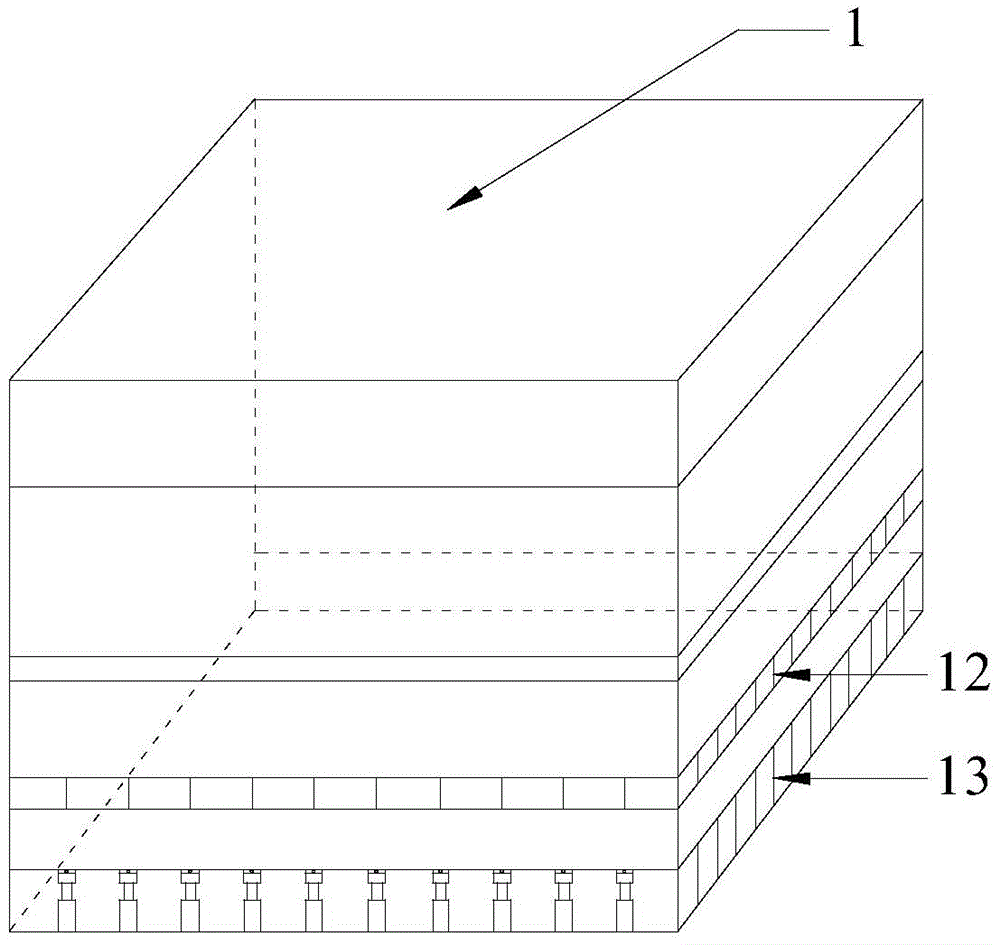

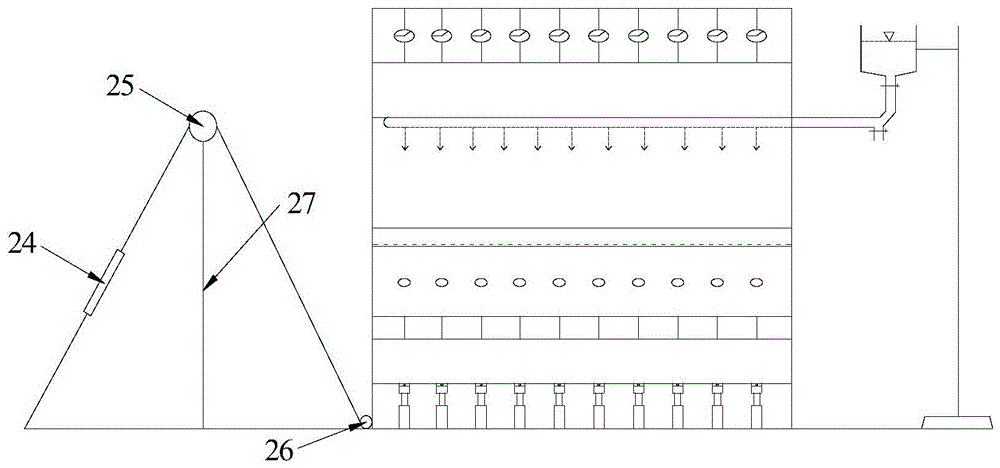

[0027] The invention patent discloses a coal seam group mining and roof and goaf water dynamic seepage three-dimensional simulation device, which belongs to the field of coal mine similar material model test simulation technology. It is mainly composed of a test bench 1, a simulated rock-soil layer paved in the test bench and an aquifer replenishment structure arranged on the side of the test bench 1. The test bench 1 is the core unit of the coal seam group mining and roof and goaf water dynamic seepage comprehensive test system, and the test bench 1 includes surrounding columns, baffles 2 on both sides of the test bench, and a front baffle 3 of the test bench. , Visible glass plate baffle 4, base and surface mobile observation device. The simulated rock and soil layer paved in the test bench includes aeolian sand loose layer 7, aquifer 8, water-resisting layer 9, bedrock layer 11, upper coal layer, bedrock layer 11 and the lowest coal layer from top to bottom. , the upper la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com