Roof-cutting and pressure relief roadway-protecting method for end-mining equipment remove gateway of coal face

A coal mining face and retraction channel technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of low recovery rate in mining area, large size of protected coal pillar, etc. The effect of reducing the amount of remaining coal and improving the recovery rate of the mining area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described in conjunction with examples.

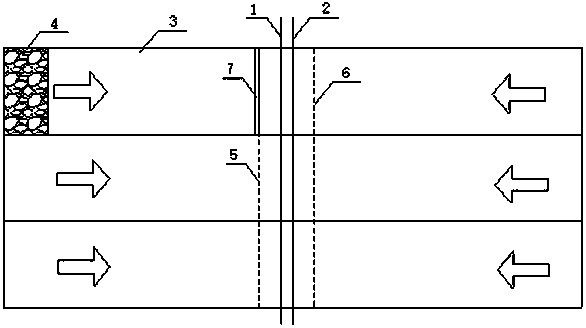

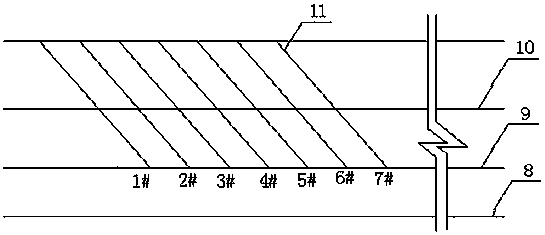

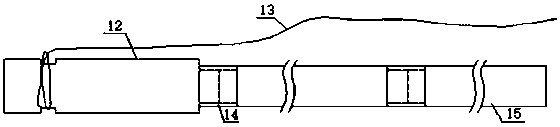

[0041] A mine adopts the layout of the mining area towards the longwall working face. The 15# coal seam with an average thickness of 5.2m is mined by the fully mechanized top coal caving process, and the average inclination angle of the coal seam is 4°. A mining area transportation roadway is arranged at the central position of the mining area and a return air roadway in the mining area, which are respectively responsible for the transportation and ventilation tasks of the mining working faces on both sides of the mining area.

[0042] In the mining area, the average step distance between the old top cycle of the fully mechanized caving face was 13m, and the width of the protective coal pillar between the production stop line and the main road in the mining area was 80m. The impact is serious. When the mining face is close to the stop line, the large roadway in the mining area is seriously deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com