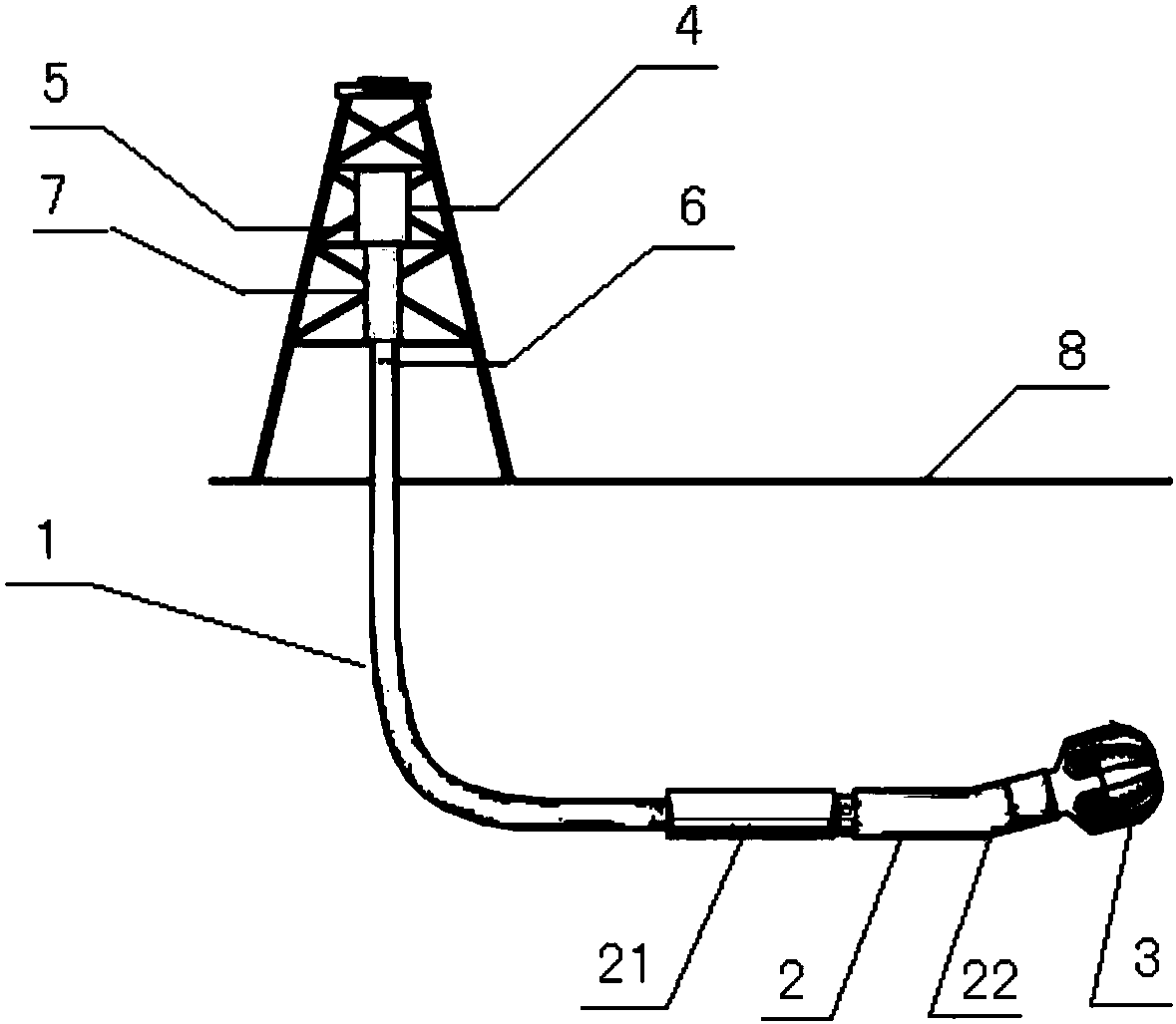

Directional sliding drilling monitoring while drilling control device and control method of directional sliding drilling monitoring while drilling control device

A monitoring control and control method technology, applied in directional drilling, drilling automatic control system, drilling equipment, etc., can solve the problems that the drill pressure cannot be added to the drill bit, time-consuming, low efficiency, etc., and achieve mechanical penetration rate and drilling Improve efficiency and reduce the effect of not adding weight on bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

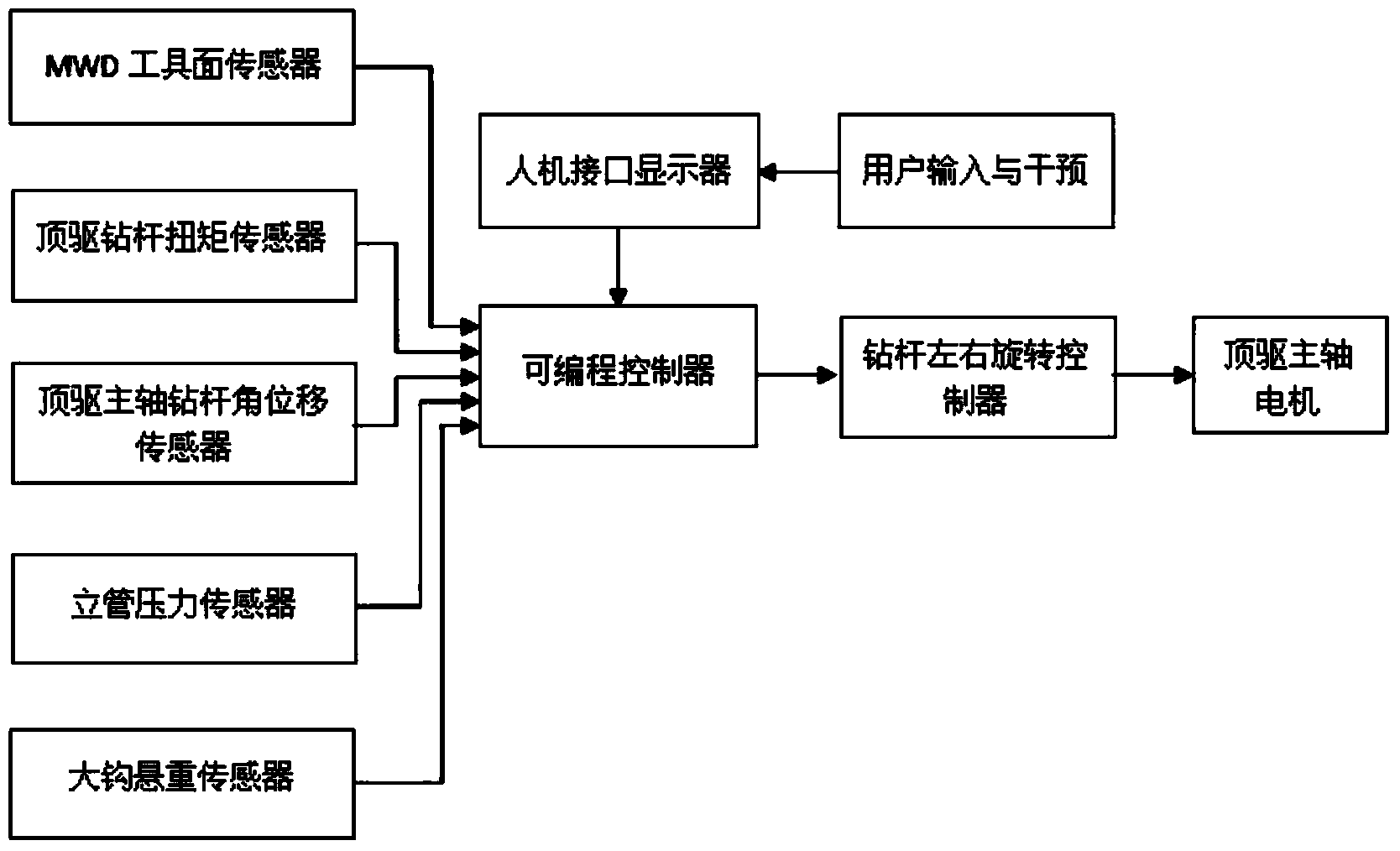

Method used

Image

Examples

Embodiment

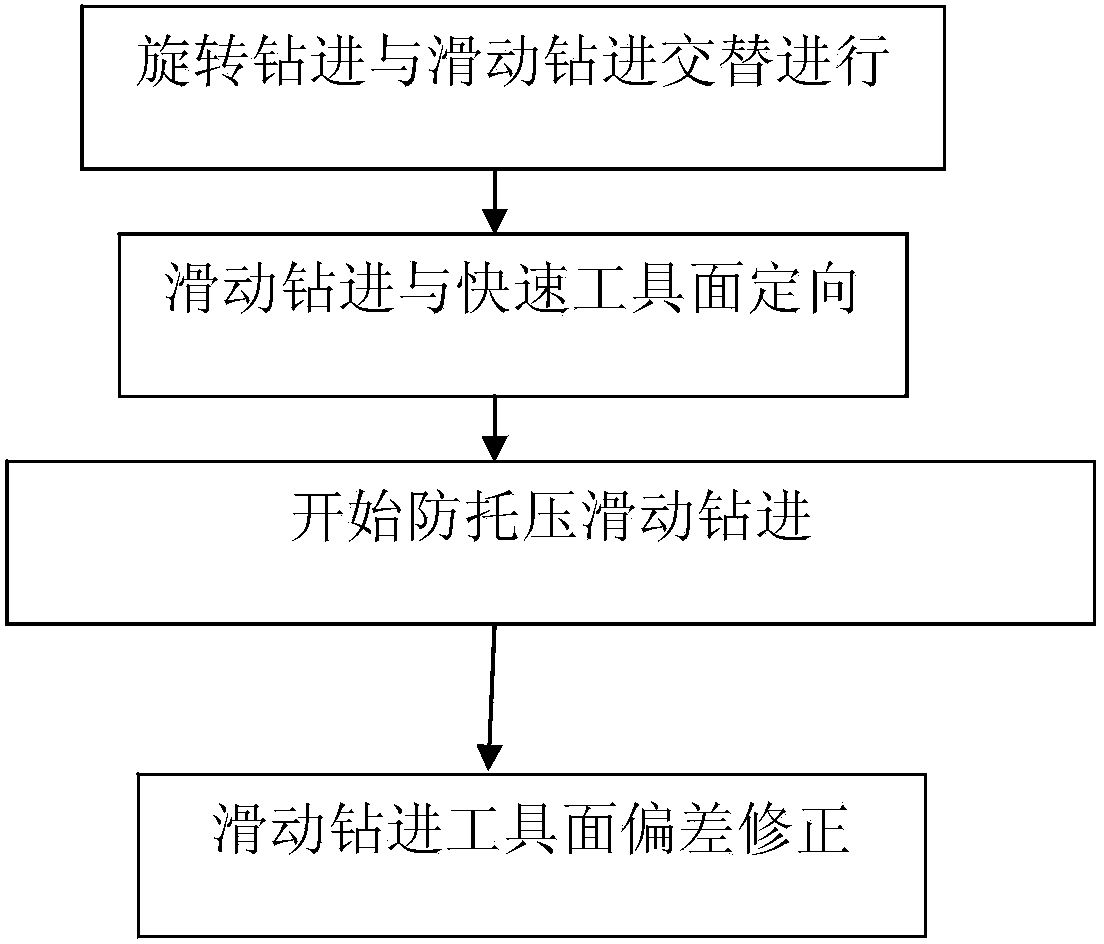

[0036] Embodiment: The control method of the monitoring and control device for directional sliding drilling while drilling, firstly, it is set that rotary drilling and sliding drilling are carried out alternately, and the wellbore has a certain well deviation and displacement, and the switch of the sliding drilling control system is turned on, and the system Power on, self-test, in the pause waiting state, other switches are off.

[0037] Step 1, first: rotate the drill string, the drill bit will circulate from the bottom, stabilize to the drilling flow rate, and keep the rotation speed of drilling; slowly lower the drill string, control the winch to achieve the best drilling pressure and the best pressure difference; Drilling speed controls drawworks to maintain optimal drilling pressure and differential pressure for rotary drilling; end rotary drilling and switch to sliding drilling.

[0038] Second: stop lowering and rotating the drilling tool, lift and lower the movable dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com