Patents

Literature

42results about How to "Realize fully automatic loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

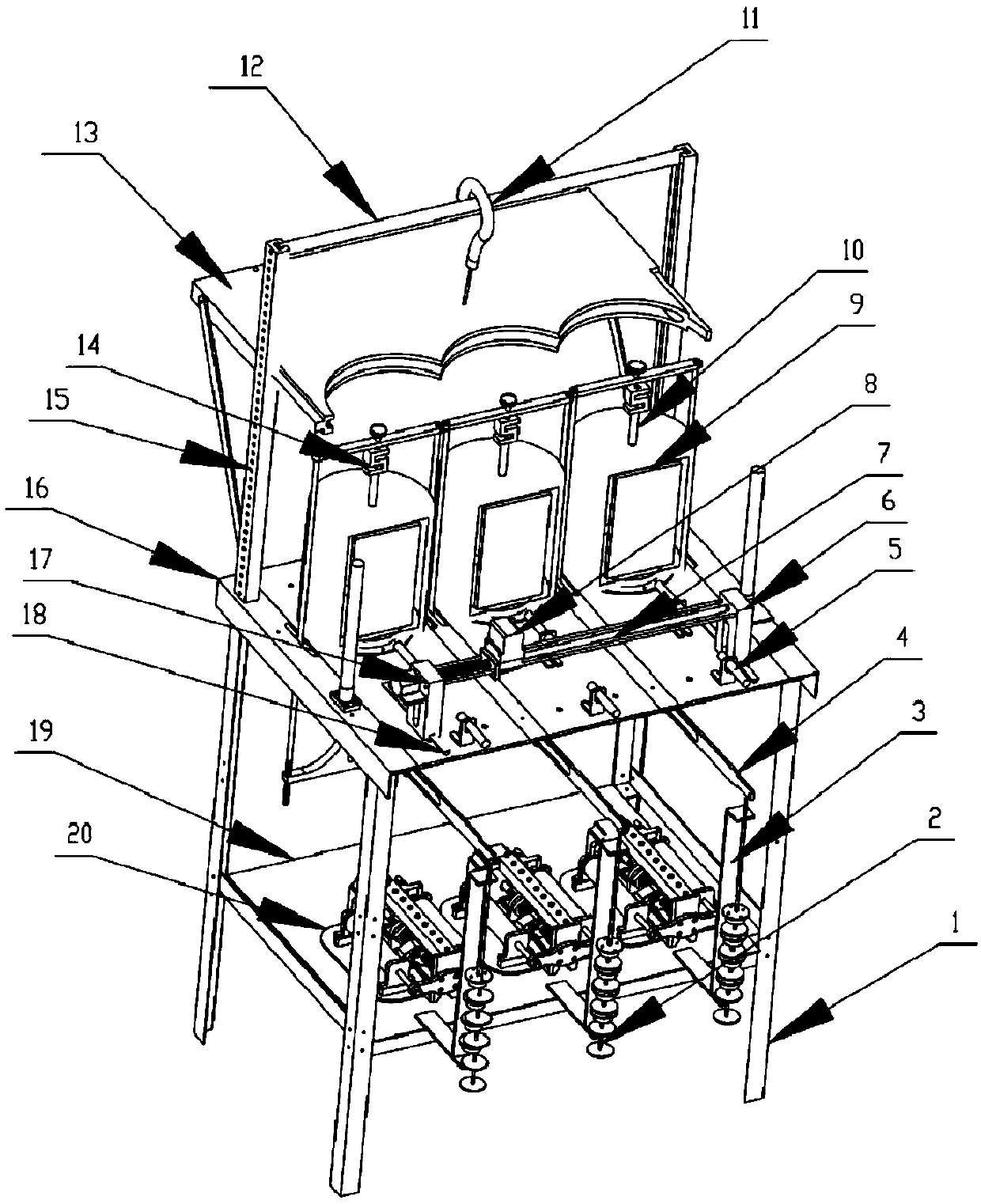

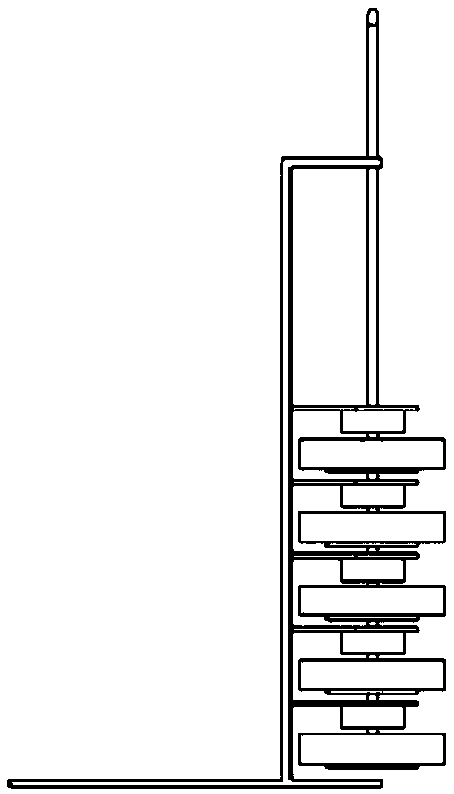

Warehouse goods storage device

InactiveCN108545389ARealize fully automatic loading and unloadingImprove loading and unloading efficiencyStorage devicesChutesLogistics managementEngineering

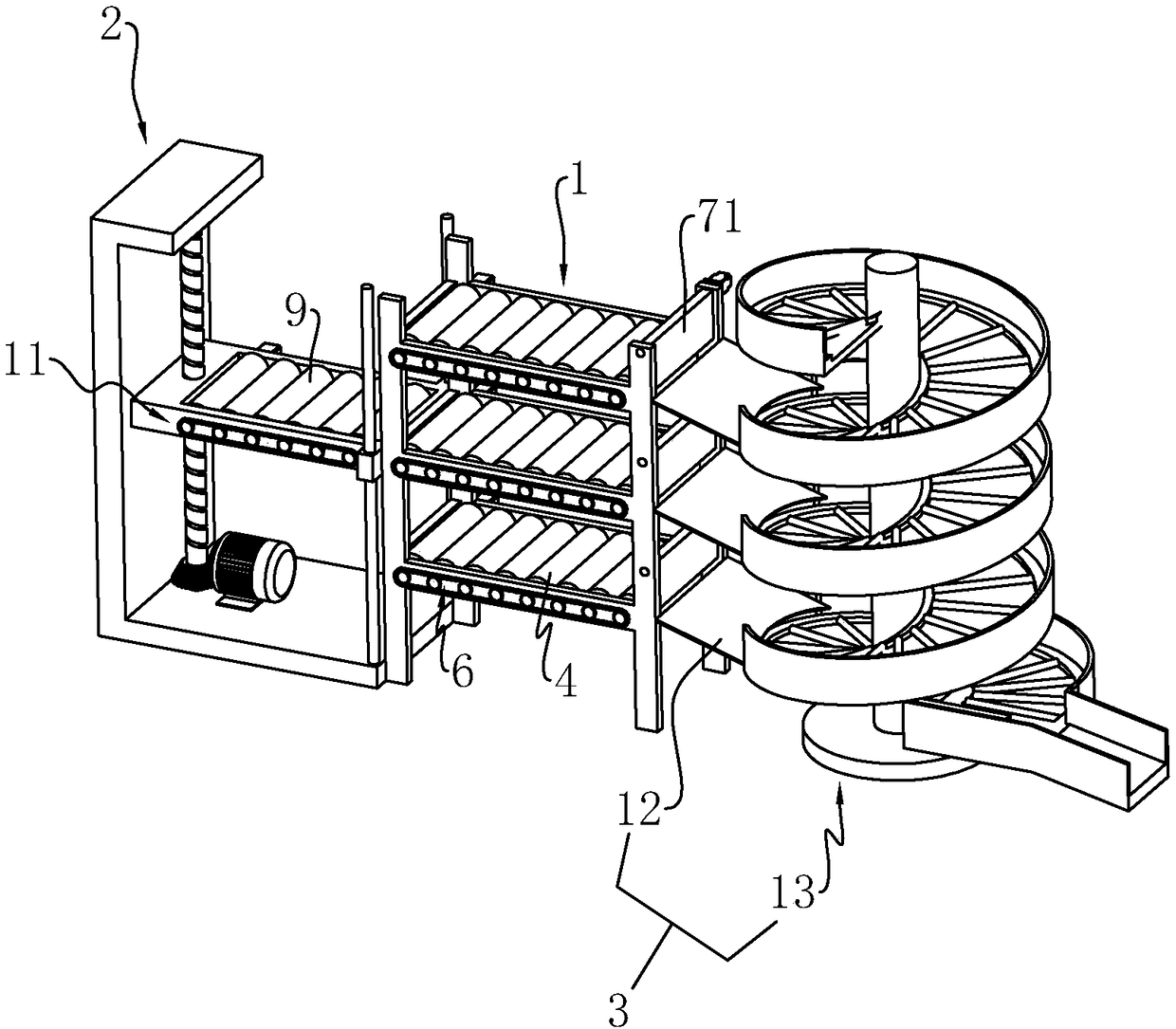

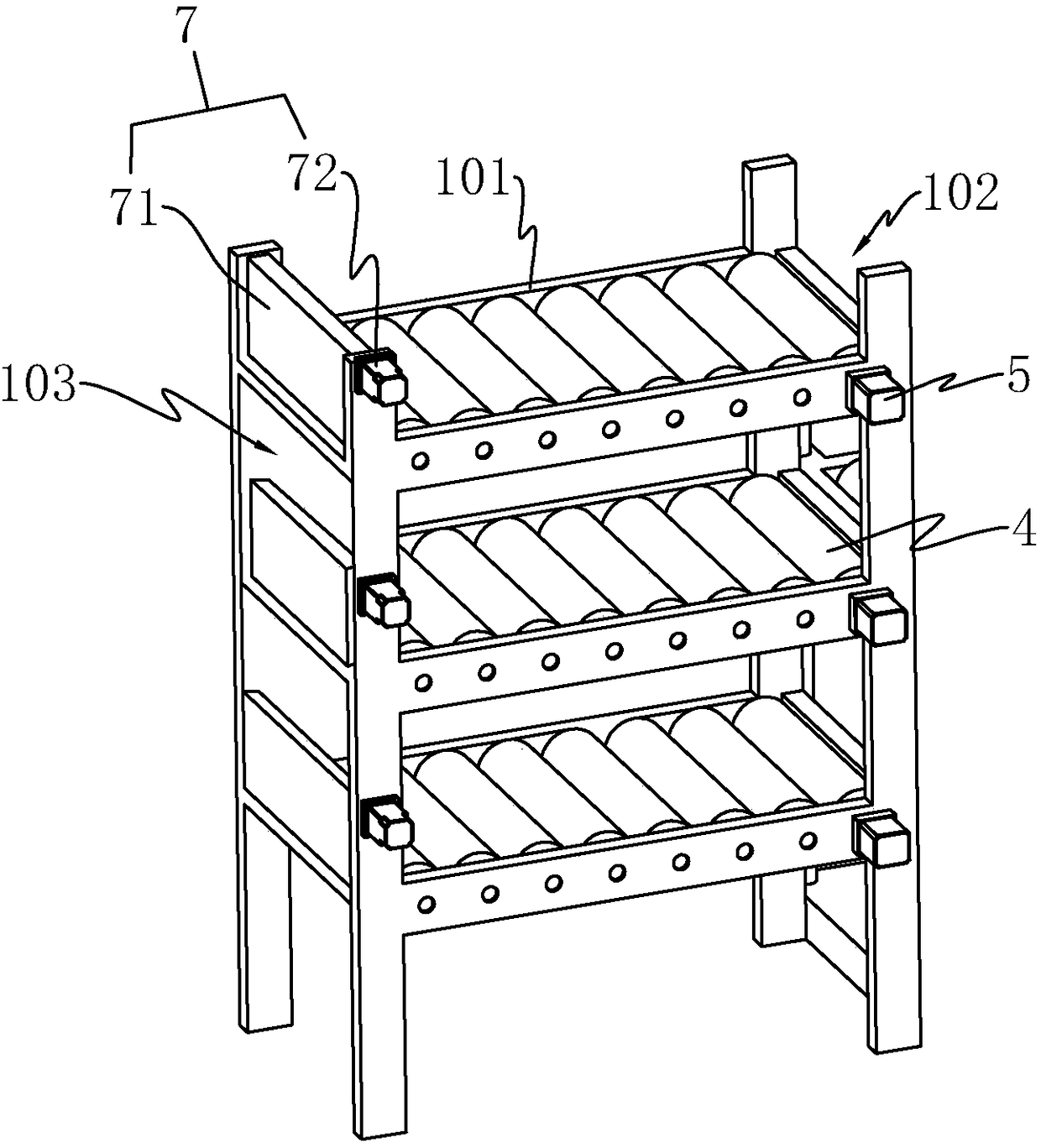

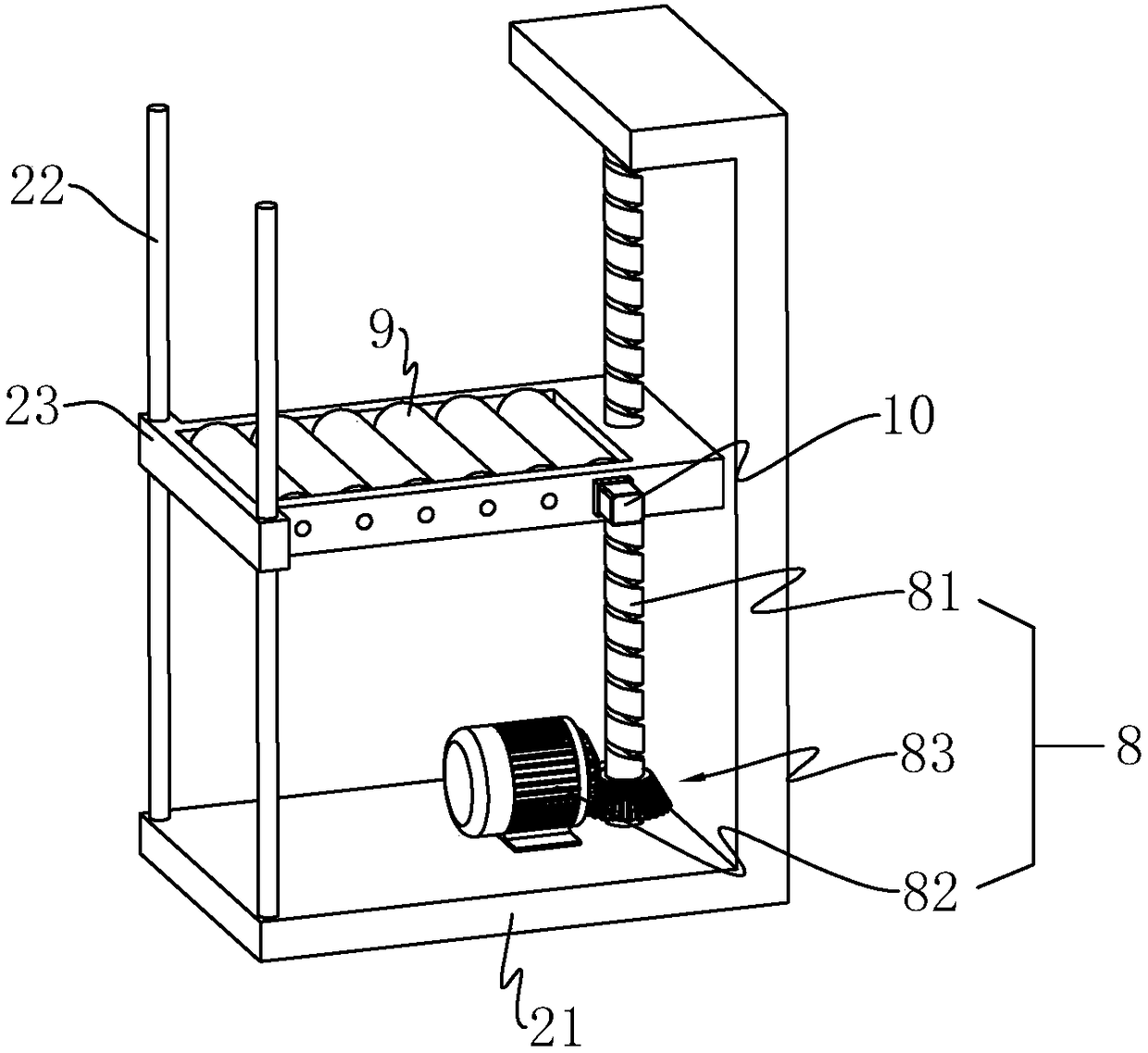

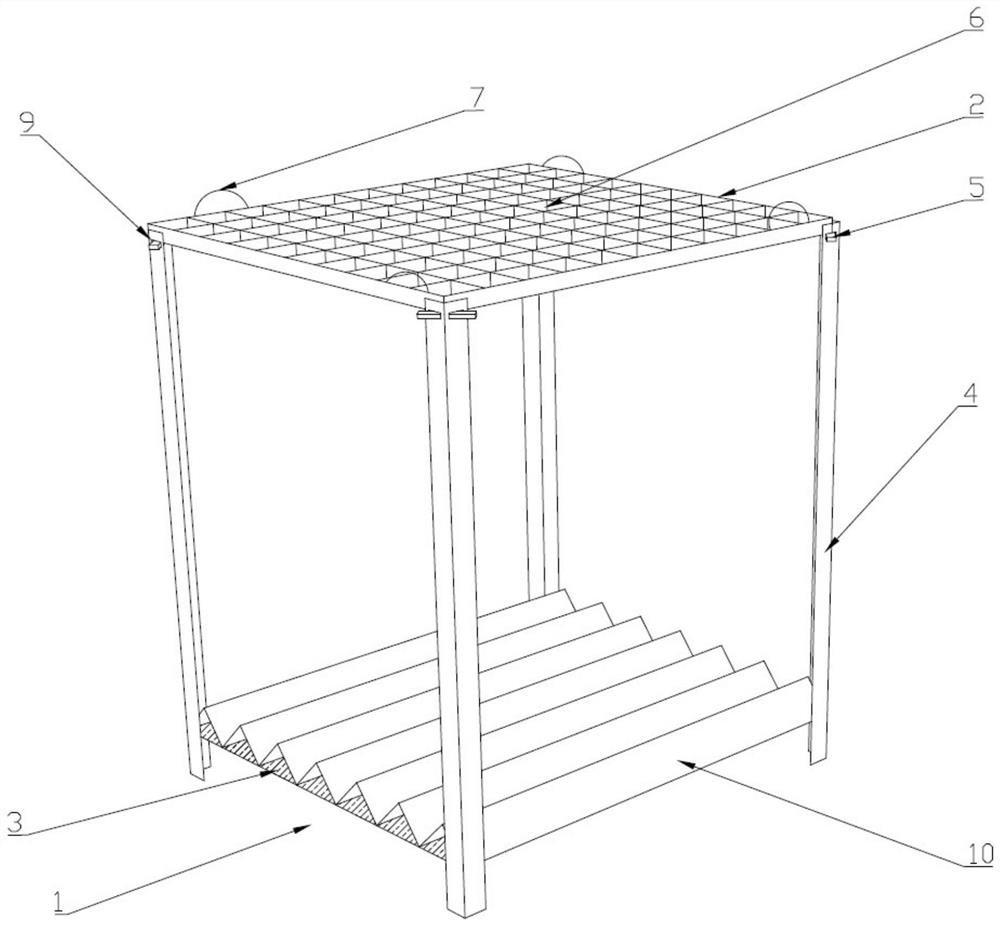

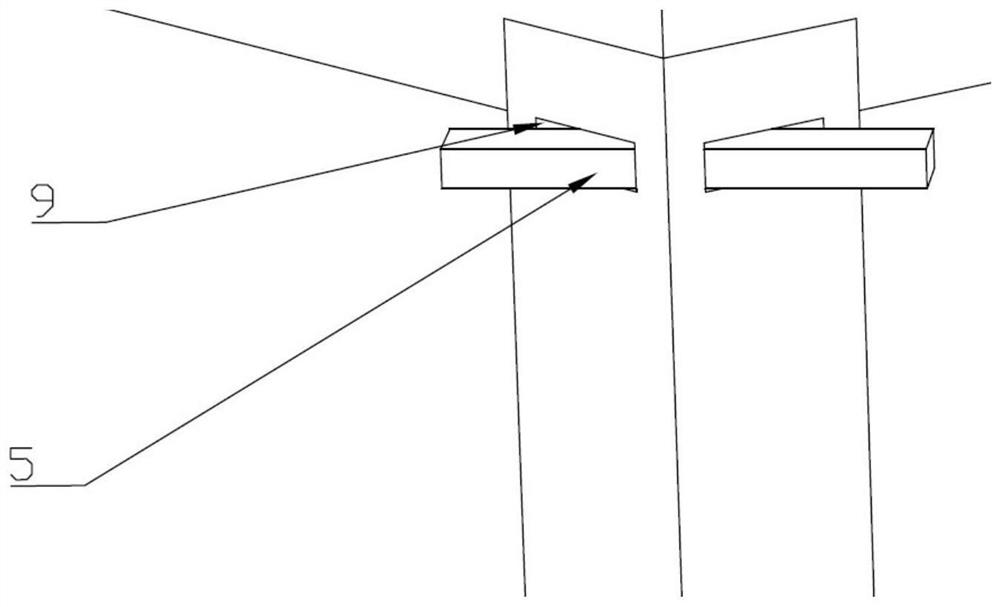

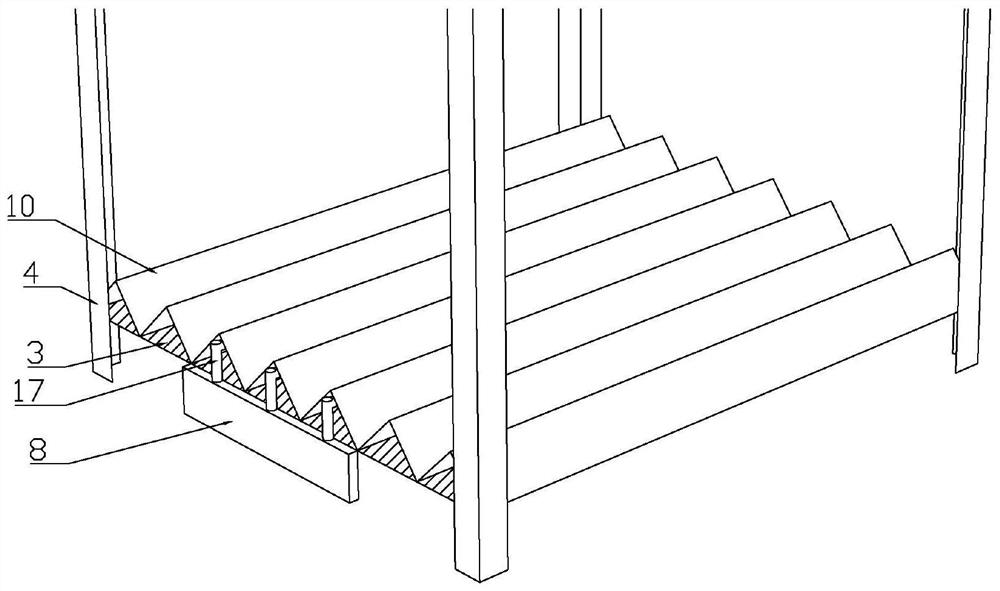

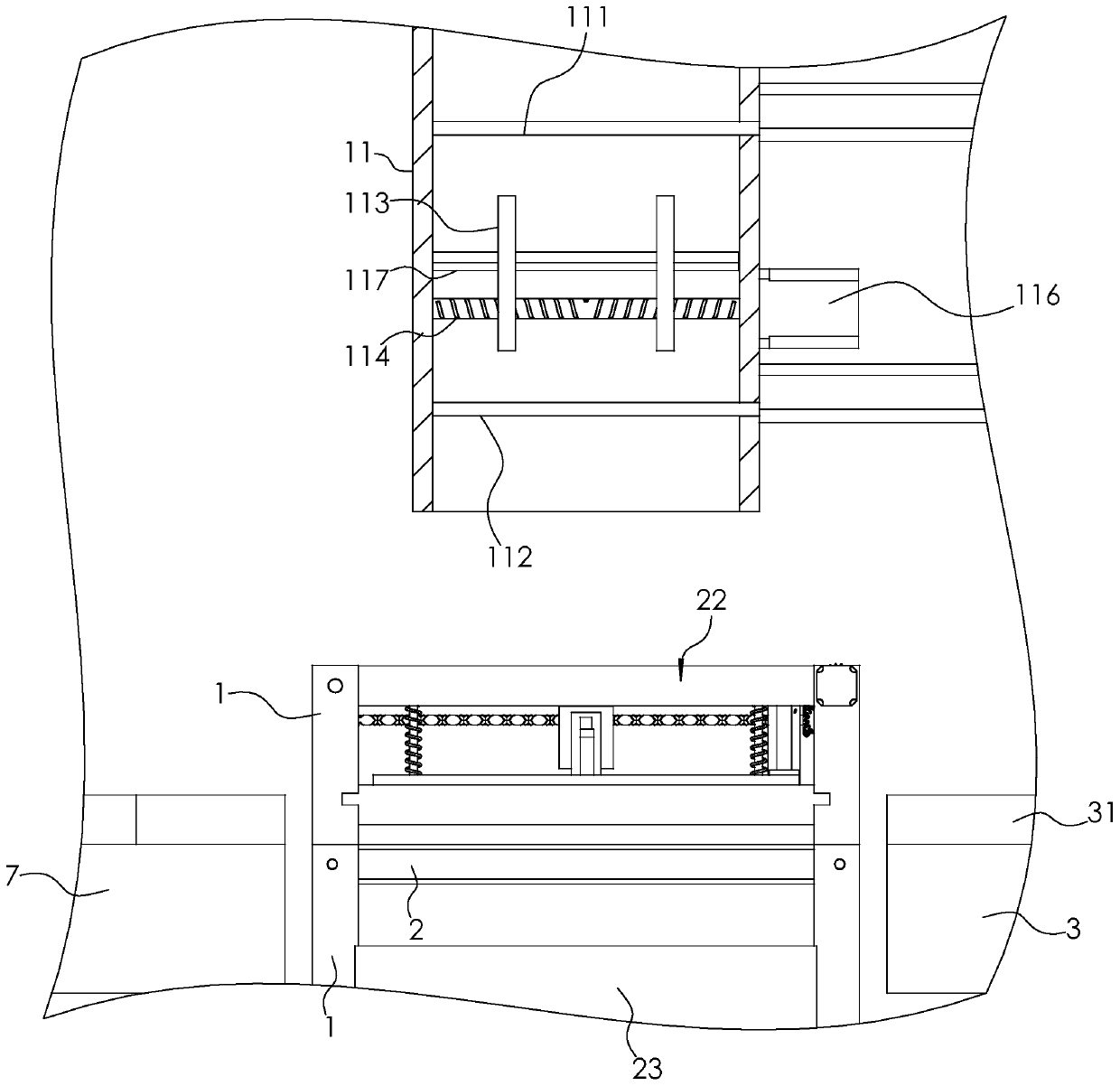

The invention discloses a warehouse goods storage device and relates to the field of warehouse storage logistics. The warehouse goods storage device comprises a storage rack main body which at least comprises two placing layers, wherein a goods inlet and a goods outlet are separately formed in two sides of each placing layer; the warehouse goods storage device also comprises a goods upper rack mechanism and a goods lower rack mechanism; the goods upper rack mechanism comprises a base, a placing table, a first driving assembly and a second driving assembly, and a third driving assemblies and barrier parts are arranged on the placing layers; the goods lower rack mechanism comprises a lower slideway and a bearing rack, the bearing rack comprises a central rod and a spiral slideway which is spirally arranged around the central rod from top to bottom, and a goods delivery port is formed in the lower end of the spiral slideway. The warehouse goods storage device provided by the invention isstable to work, convenient to operate and high in degree of automation, can improve the goods loading and unloading efficiency and reduce the labor intensity greatly, and meets the modern logistics development tendency.

Owner:上海诺尔国际物流有限公司

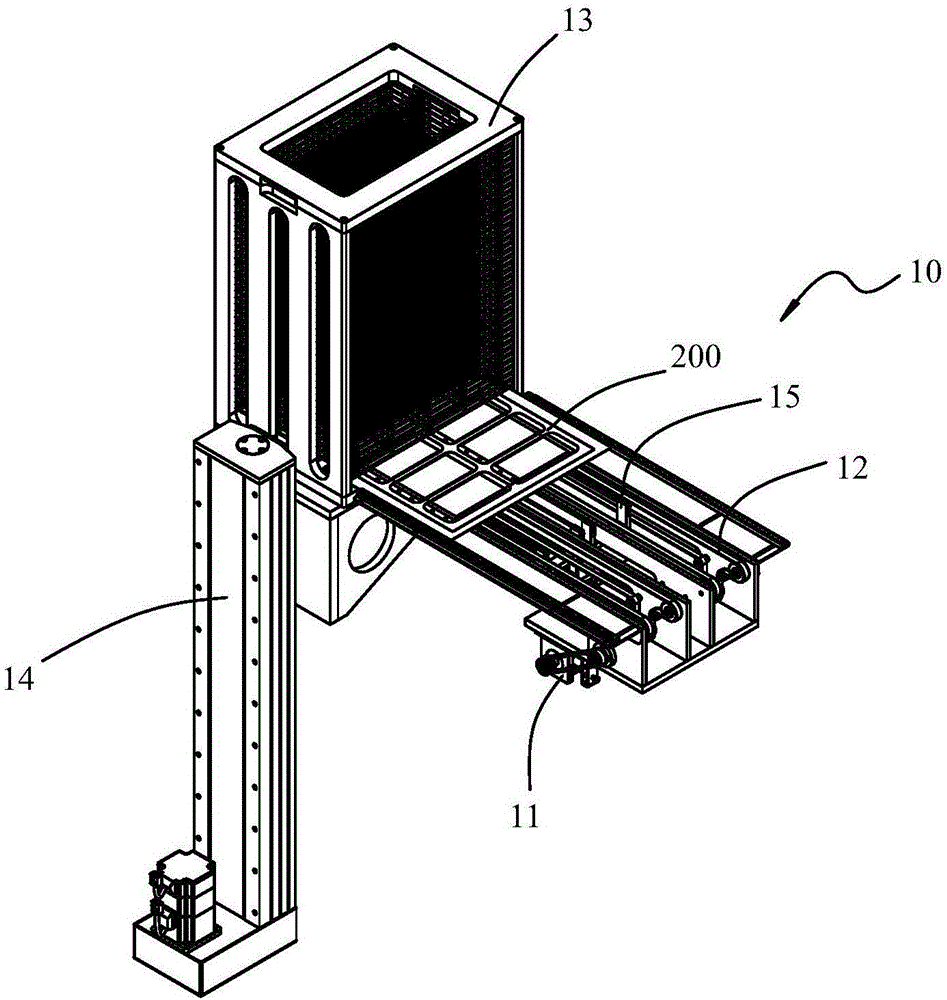

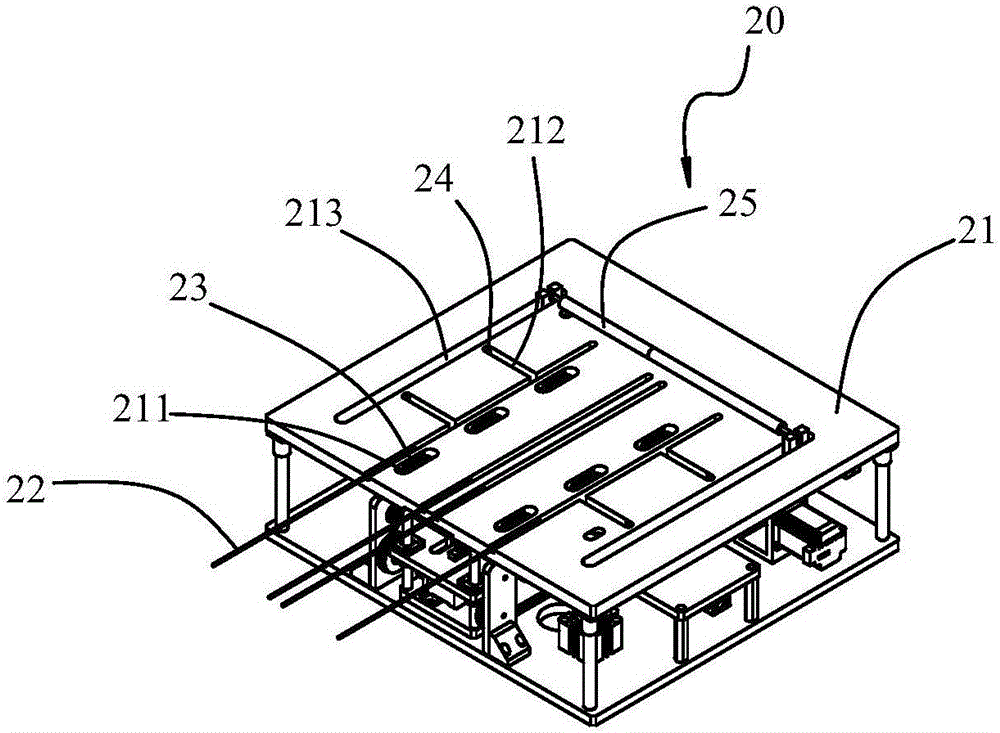

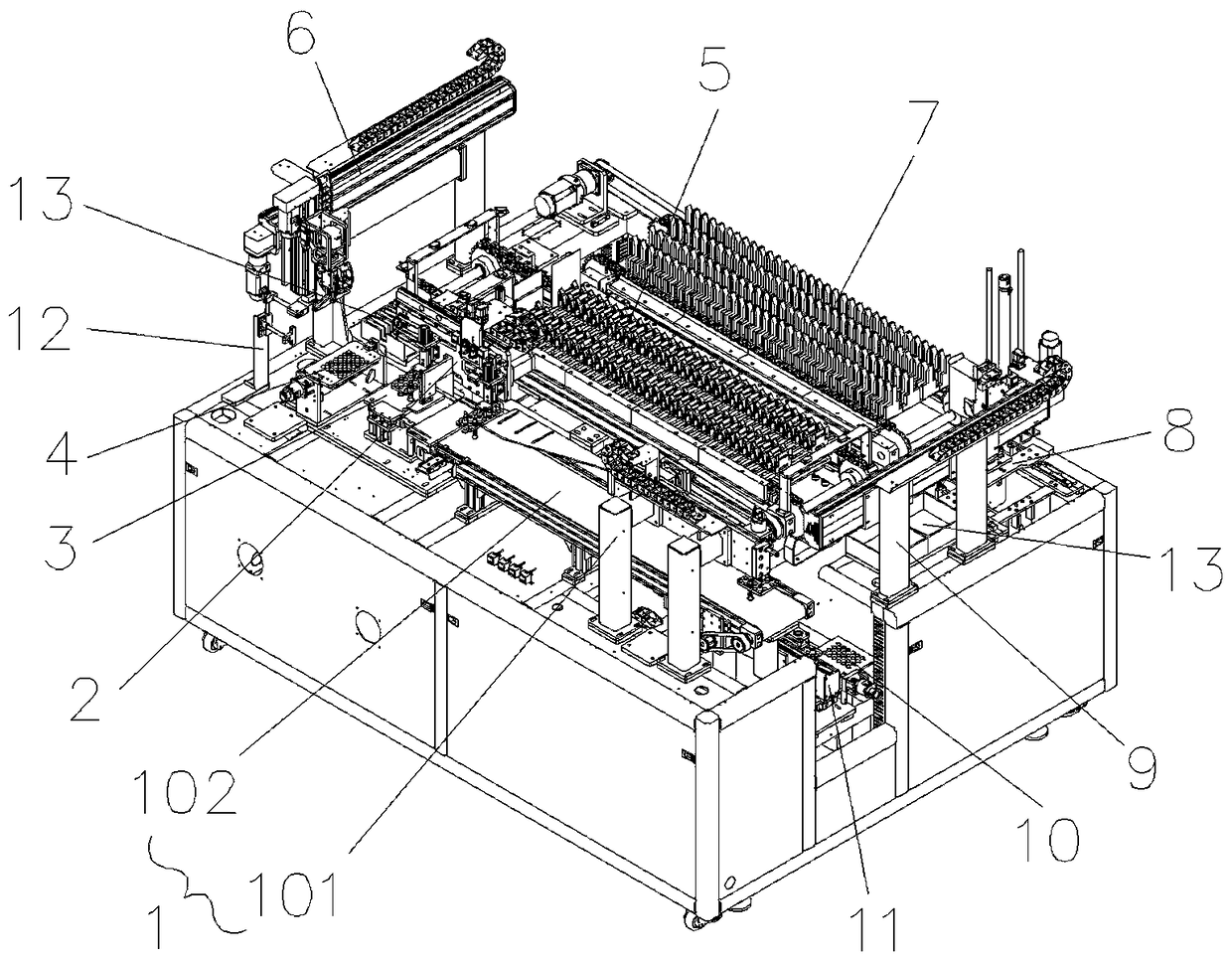

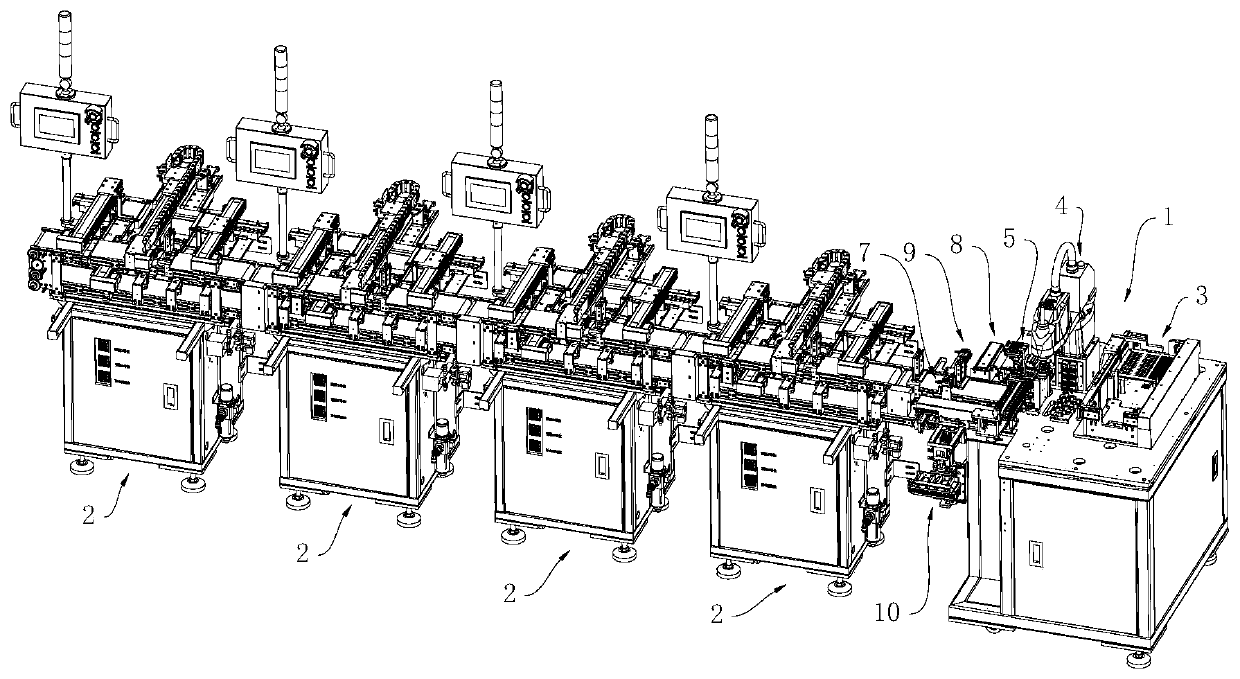

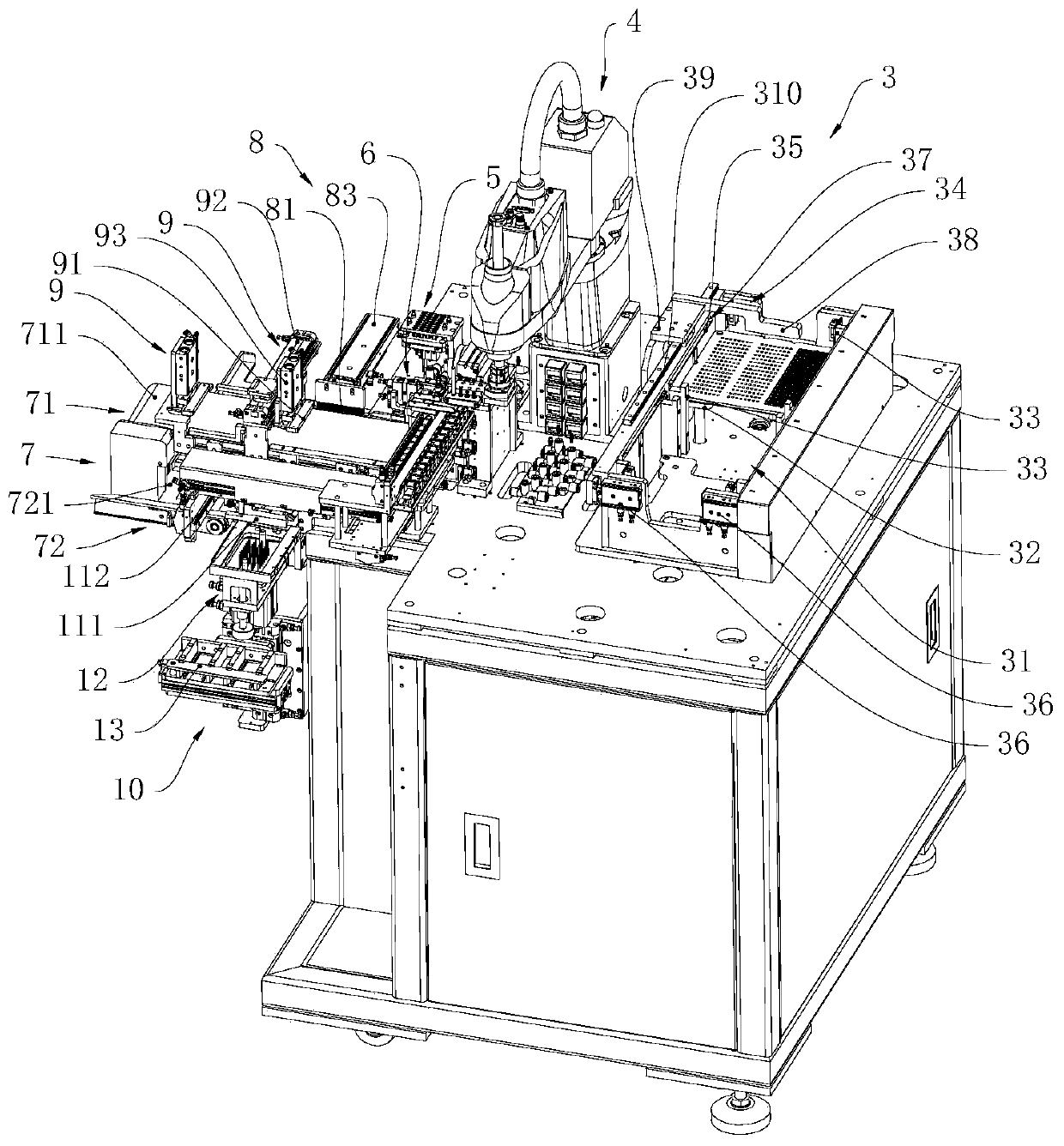

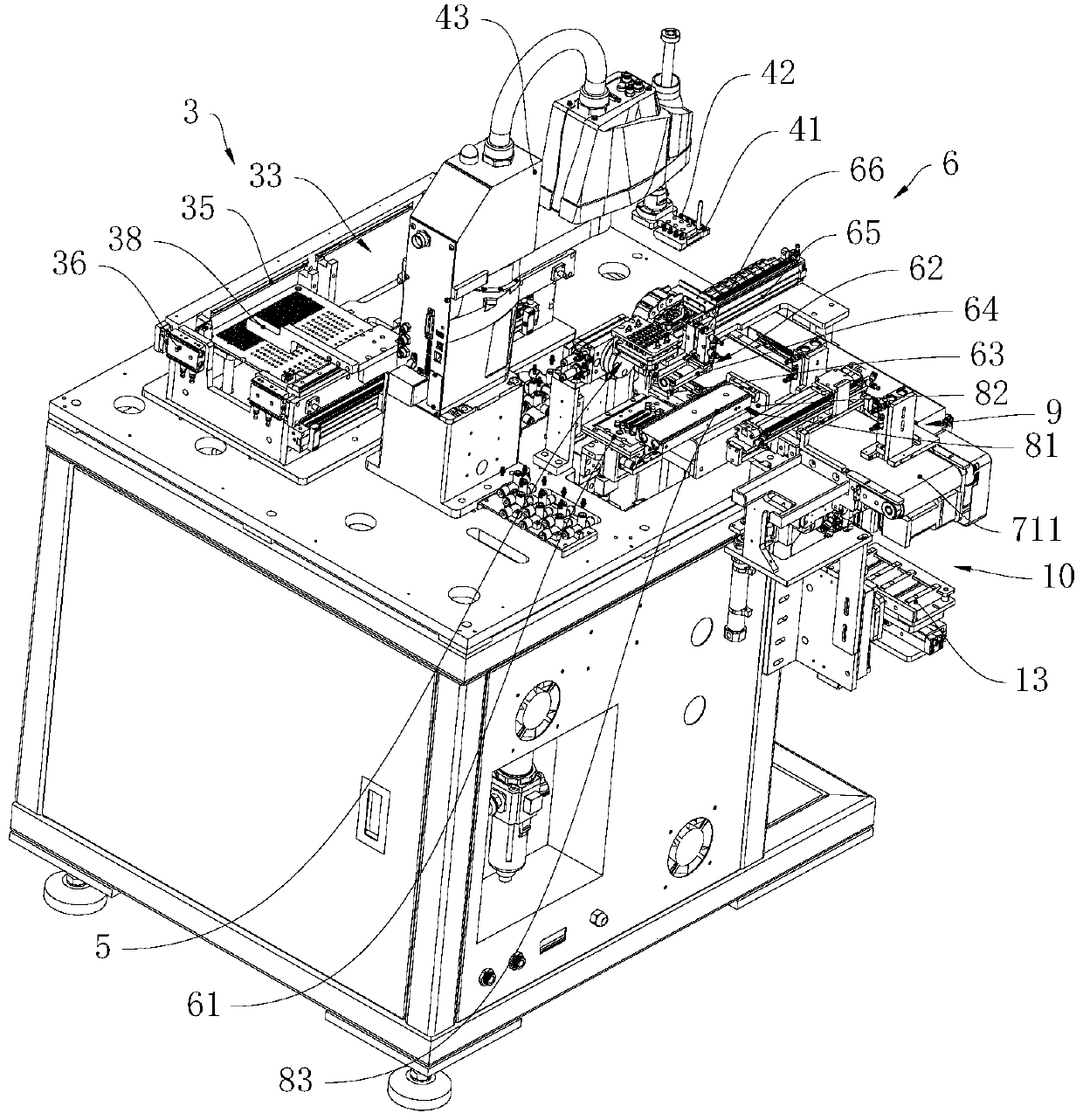

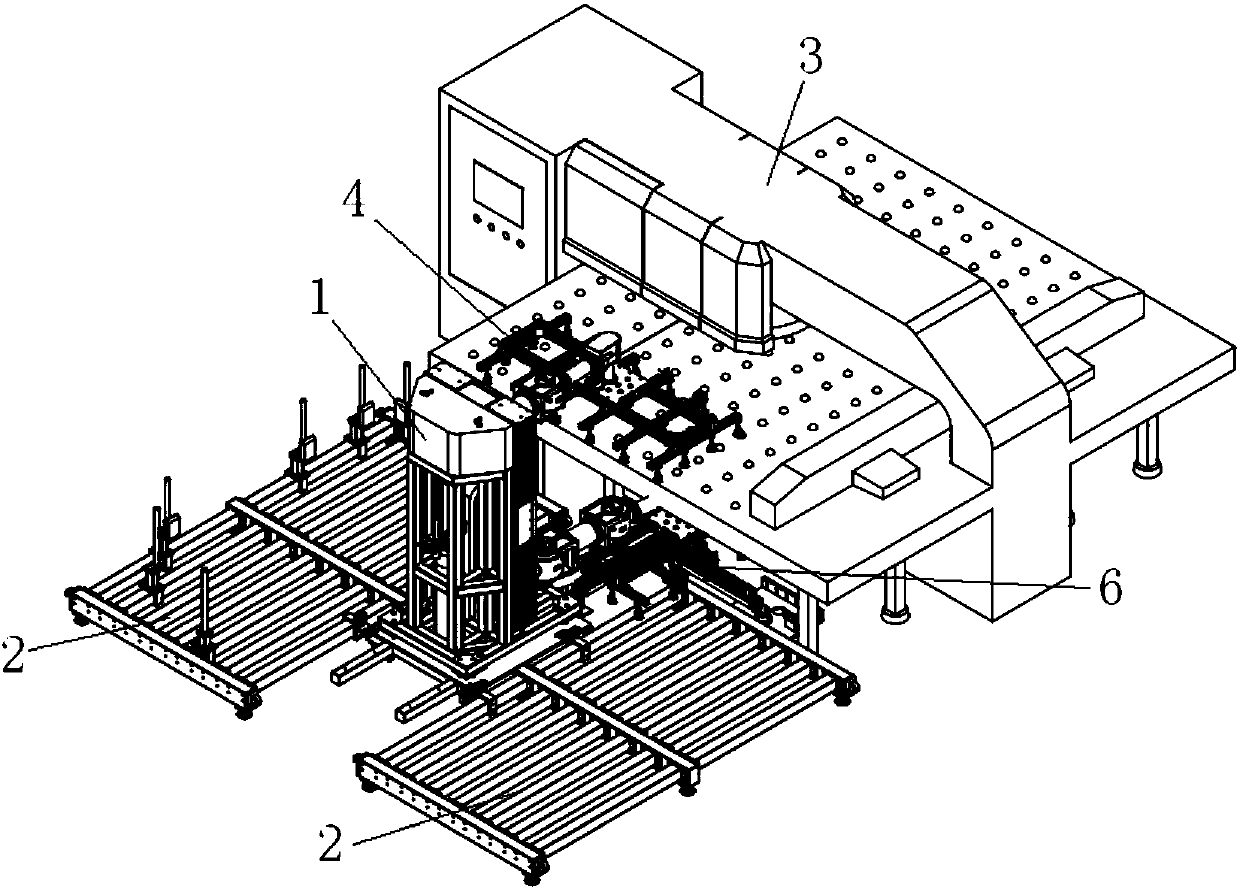

Automatic feeding and discharging machine and automatic printing system

ActiveCN106395444AReduce operating costsRealize fully automatic loading and unloadingRotary pressesArticle feedersManipulator

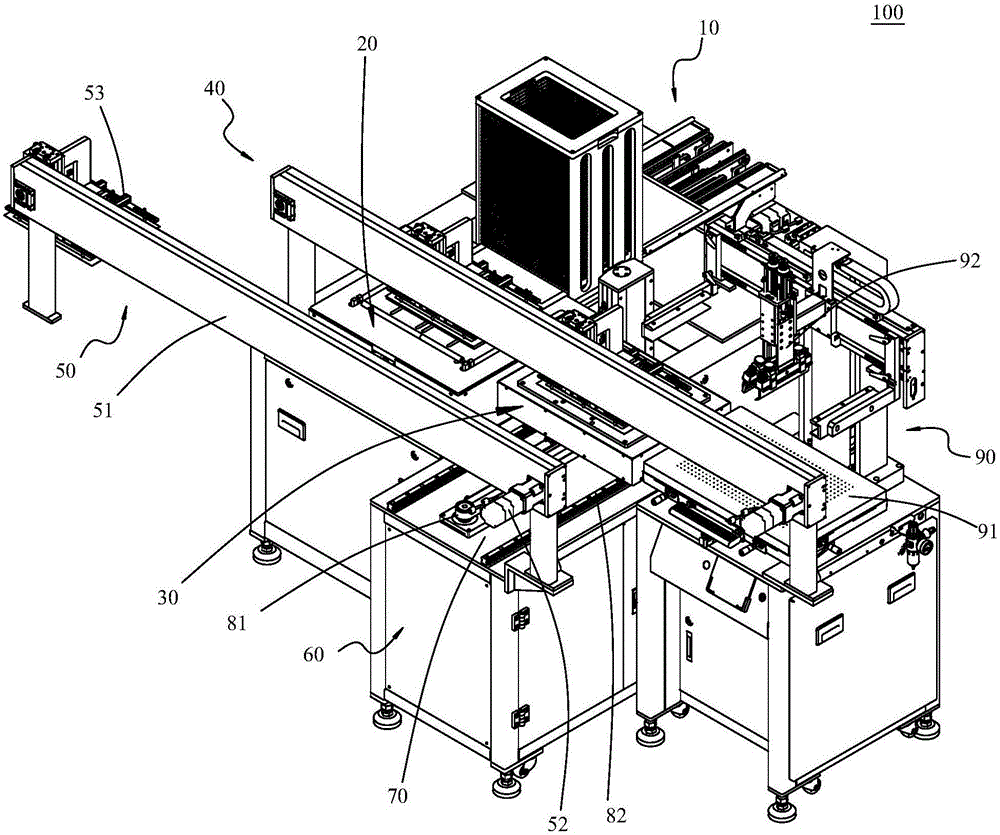

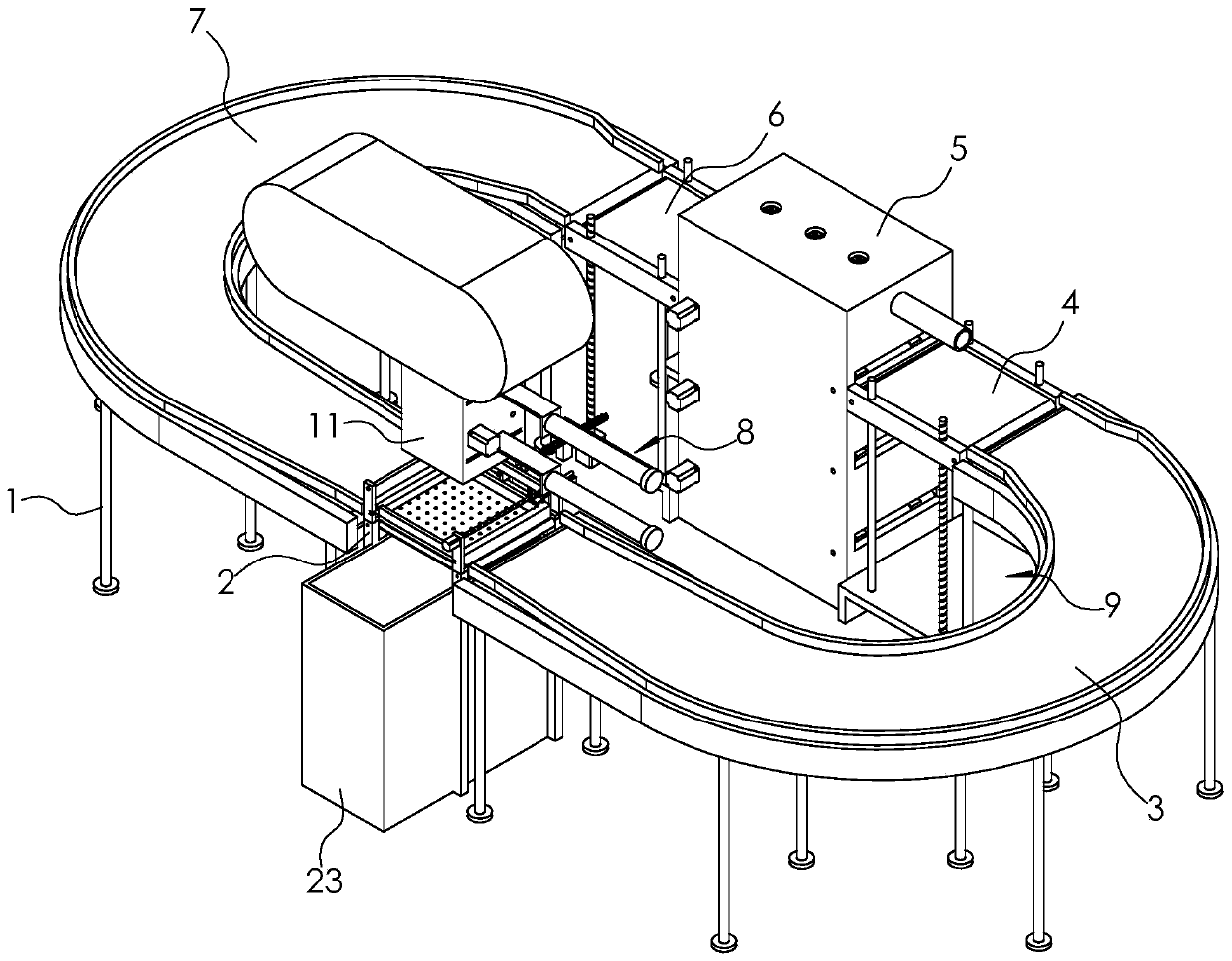

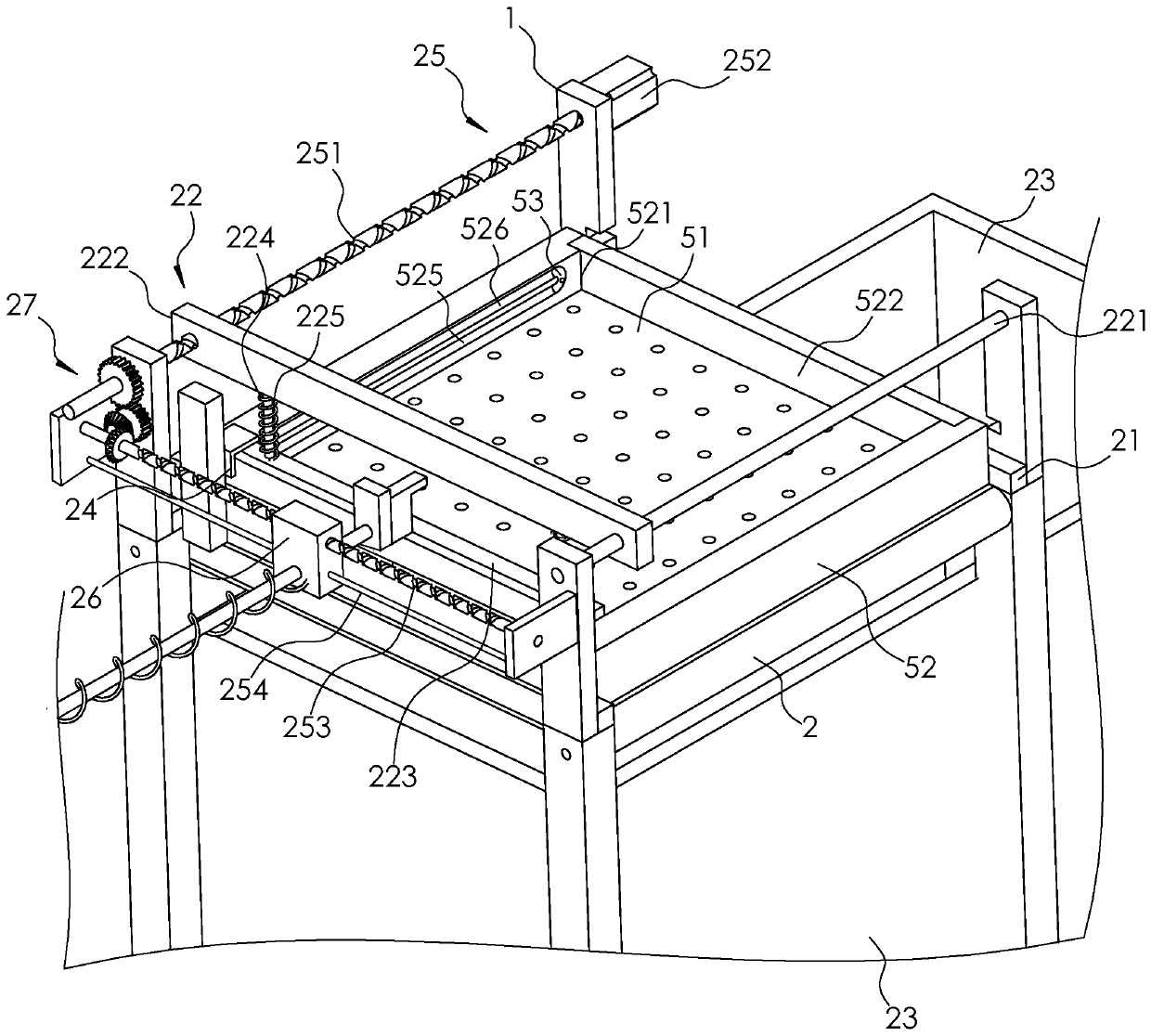

The invention relates to an automatic feeding and discharging machine and an automatic printing system. The automatic feeding and discharging machine comprises a feeding mechanism, an automatic centering aligning platform, an accurate positioning platform, a feeding manipulator and a discharging manipulator; the accurate positioning platform can slide to a sliding-out position in the direction which is perpendicular to a conveying line consisting of the automatic centering aligning platform, the accurate positioning platform and an external equipment working platform; the feeding manipulator comprises a first sucking disc group and a second sucking disc group which move synchronously; the first sucking disc group sucks a material on the automatic centering aligning platform and moves the material to the position where the accurate positioning platform is positioned, and simultaneously, the second sucking disc group sucks the material which is processed by the external equipment working platform; the first sucking disc group transfers the sucked material from the position where the accurate positioning platform is positioned to the external working platform and returns to an initial position, simultaneously, the second sucking disc group feeds the processed material to the accurate positioning platform, then, the accurate positioning platform positions the material and feeds the material to the siding-out position, and the material is delivered out through a third sucking disc group of the discharging manipulator; therefore, full-automatic feeding and discharging are realized.

Owner:环昱自动化(深圳)有限公司

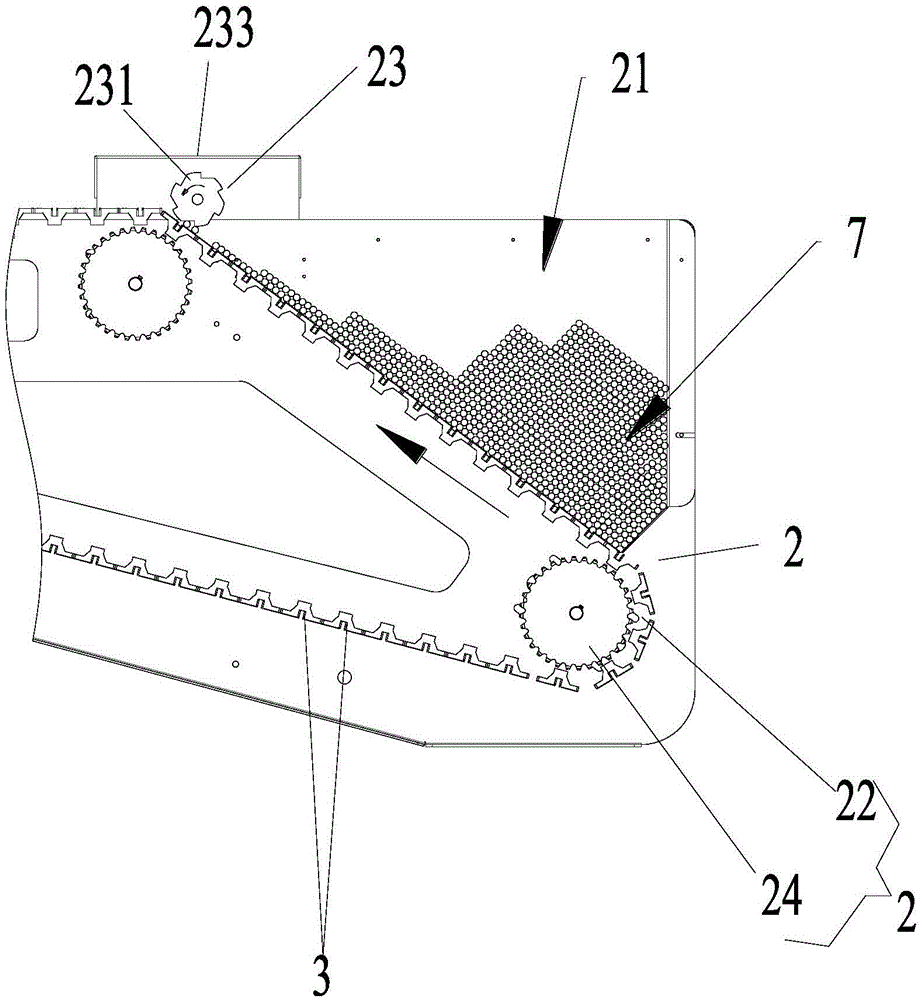

Hopper automatic charging stick bunching machine

ActiveCN105559123AGood effectRealize fully automatic loading and unloadingFood shapingMotor driveEngineering

The invention relates to the technical field of stick bunching machines, in particular to a hopper automatic charging stick bunching machine, comprising a main rack; an automatic charging mechanism, a lower die, an upper die, a bamboo stick mechanism, a stick bunching mechanism and an electric control box are arranged on the main rack; the automatic charging mechanism comprises a hopper, a conveyor belt and a material poking mechanism; the conveyor belt obliquely upwards penetrates through the hopper, is fixedly provided with the lower die, and driven by a conveying motor; the material poking mechanism is arranged above the lower die; the conveying motor drives the conveyor belt to obliquely upwards move; materials are automatically charged into the lower die; the material poking mechanism pokes excessive materials; the materials in the lower die are conveyed to be below the upper die; the bamboo stick mechanism takes a bamboo stick out and places in a V-shaped slot of the stick bunching mechanism for preparing for stick bunching; the upper die presses the materials down to gather and press the materials; the stick bunching mechanism bunches the bamboo stick into the materials, then the upper die is released, the conveyor belt continues to move forward, and the bunched materials are automatically discharged. Full automatic charging and discharging are realized; the effect is good; the stability is high and the efficiency is high.

Owner:CLOUDFOCUS DONGGUAN AUTOMATION EQUIP CO LTD

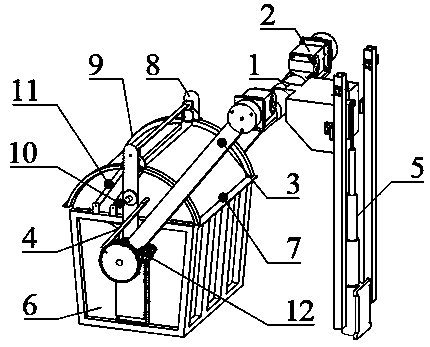

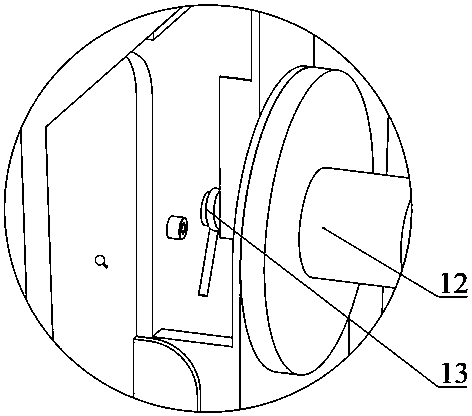

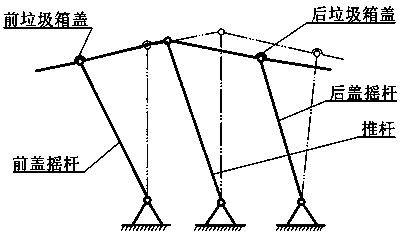

Trash dumping device

InactiveCN109850430AExtended service lifeRealize fully automatic loading and unloadingRefuse receptaclesHydraulic cylinderAutomobile platform

The invention discloses a trash dumping device. The whole set of the device comprises a manipulator and a trash can, the trash can is clamped by the manipulator to be lifted, trash can covers are opened, and the trash can is rotated to dump rubbish. The manipulator is installed on a trash car platform, the manipulator is pushed by a four-stage telescopic hydraulic cylinder to clamp the trash can to lift the trash can upwards to reach a designated position, push rods on the two sides of the trash can is pushed by a poking piece to rotate, front and rear side trash can covers are driven by the push rods to move backwards and rotate, the push rods, the trash can covers, rocking rocks and the can body are of dual-rocking-rod mechanisms, and the opening and moving of the trash can covers are achieved. A manipulator arm is driven by the stepping motor to clamp and rotate the trash can, the poking piece is restored after trashes are dumped, and the push rods are restored with the help of thetorsion springs which are installed on the inner sides of the push rods to drive the trash can covers to be restored and closed. The trash dumping device has the advantages that the designing structure is compact, the trash can service life is long, fully automatic loading and unloading of the trashes can be achieved, and therefore the labor intensity of environmental sanitation workers is significantly reduced.

Owner:XIANGTAN UNIV

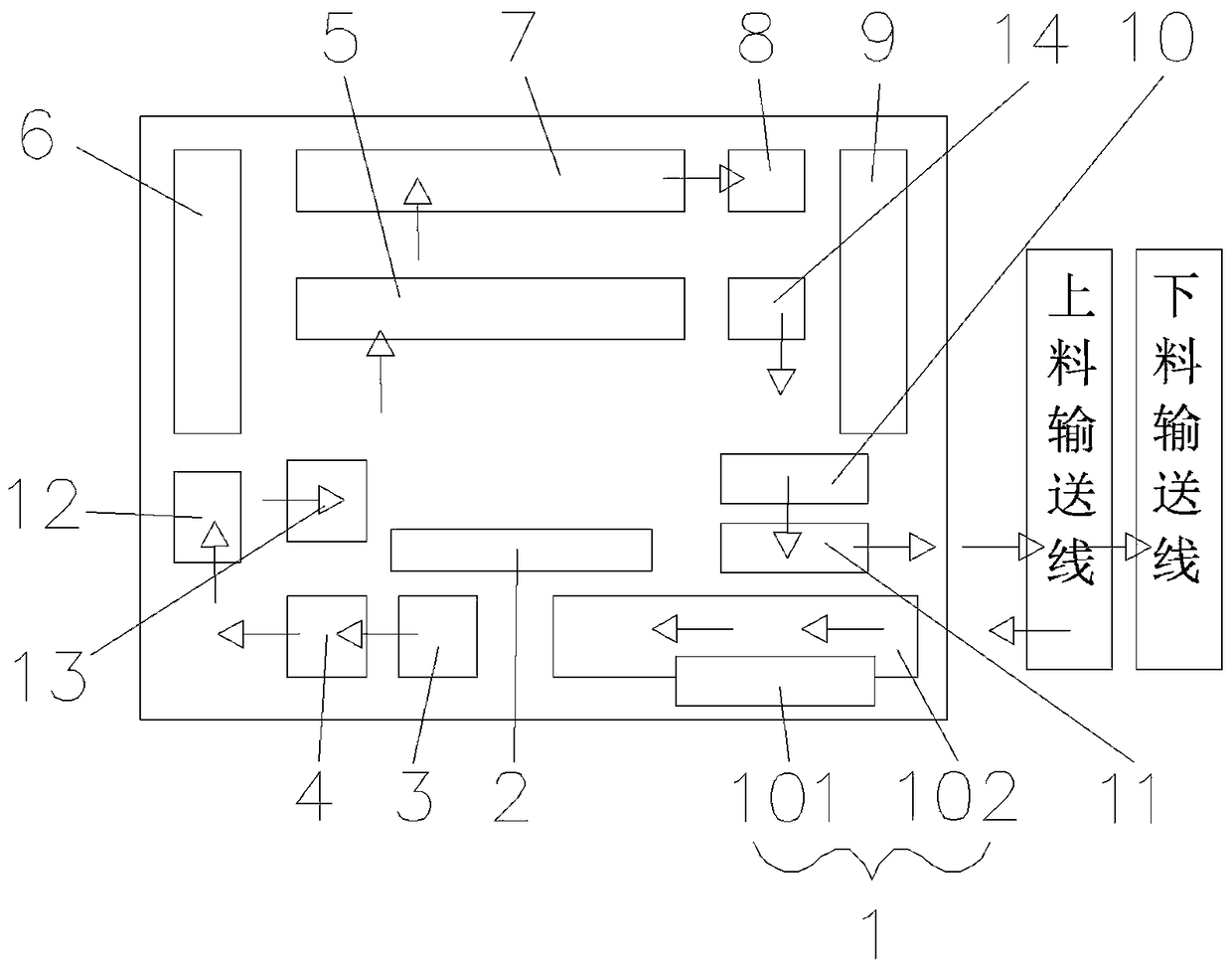

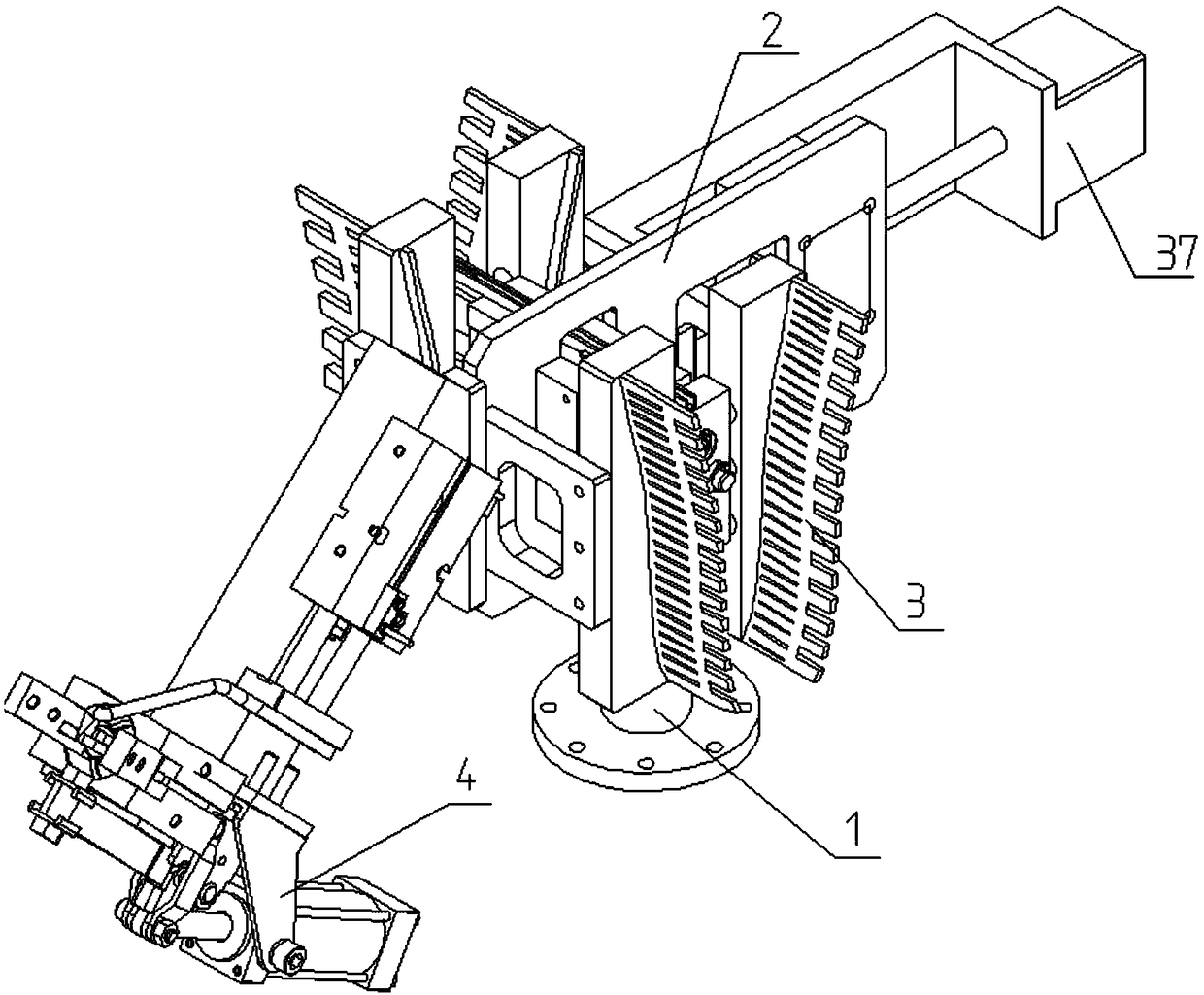

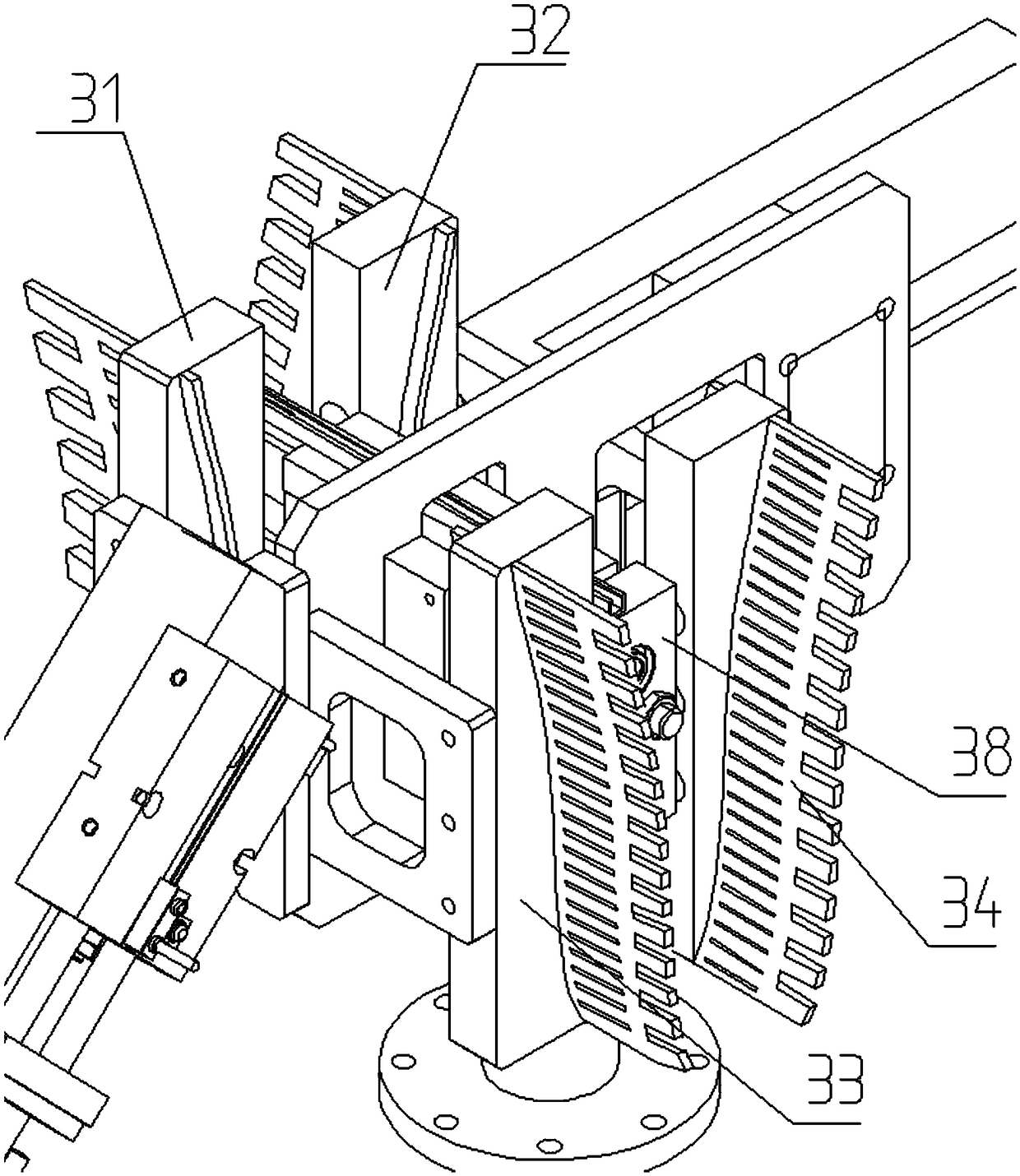

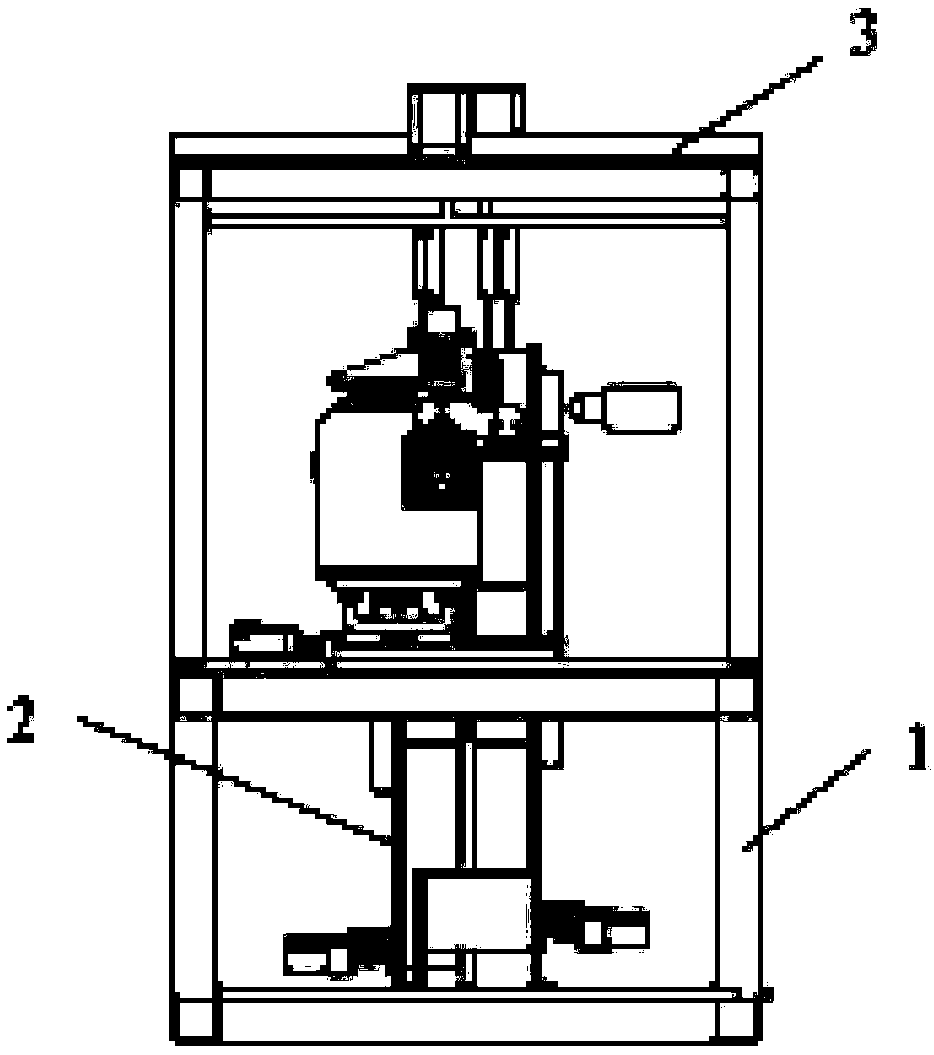

Flexible package lithium battery formation loading and unloading device

The invention discloses a flexible package lithium battery formation loading and unloading device, and aims to provide the flexible package lithium battery formation loading and unloading device withcompact mechanisms, small occupied space and high loading and unloading efficiency. According to the device, an unloading water trolley, a loading water trolley and a duplex mechanical arm are arranged in an X direction and are sequentially arranged in front and back, a loading turnover mechanism and a lug shaping mechanism are located behind the duplex mechanical arm, and the lug shaping mechanism is located on the right side of the loading turnover mechanism; a material taking and conveying module is arranged in an X direction and is arranged on the right side of the lug shaping mechanism, aloading mechanical arm is arranged in the Y direction and is arranged at one ends of the loading water trolley and the unloading water trolley, and an unloading mechanical arm is arranged in the Y direction and is arranged at the other ends of the loading water trolley and the unloading water trolley; and an unloading transverse moving mechanism is arranged in the Y direction and is arranged between one end of the unloading mechanical arm and the unloading water trolley, and the other end of the unloading mechanical arm is provided with an unloading turnover mechanism and a discharging mechanism. The device is applied to the technical field of battery loading and unloading devices.

Owner:ZHUHAI TITANS NEW POWER ELECTRONICS CO LTD

High-efficiency drilling device

ActiveCN111299637ARealize fully automatic loading and unloadingAchieve drillingPositioning apparatusMetal working apparatusEngineeringWorkbench

The invention relates to a high-efficiency drilling device. The high-efficiency drilling device comprises a workbench, a drilling machine and a location block, wherein a location hole is formed in thetop of the location block, a transversal through hole is formed in the sidewall of the location block, and holes in the two sides of the transversal through hole are a charge port and a discharge port separately; and a loading assembly, a pushing assembly, an elastic clamping assembly and a guide element are arranged on the workbench. In a drilling process, a first group of workpieces are loadedthrough the loading assembly at first, and then are pushed into the transversal through hole through the pushing assembly; and then a second group of workpieces are loaded into the transversal throughhole through the pushing assembly, the elastic clamping assembly is enabled to clamp the first group of workpieces, at this moment, the first group of workpieces and the pushing assembly clamp the second group of workpieces in the transversal through hole, the abovementioned operation is repeated, and then fully-automatic loading, unloading and drilling for the workpieces can be realized. According to the high-efficiency drilling device, the drilling efficiency for the workpieces is greatly increased.

Owner:杭州顺钢机械有限公司

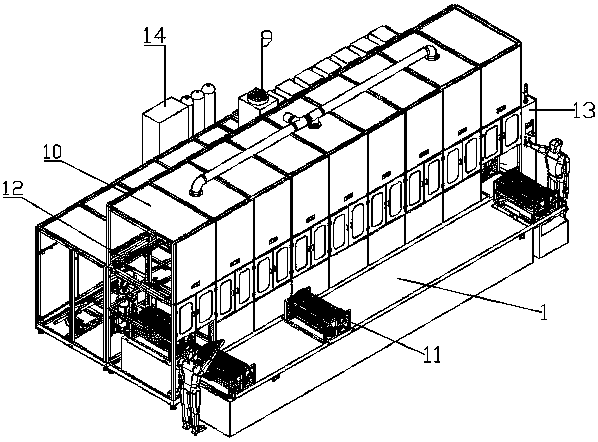

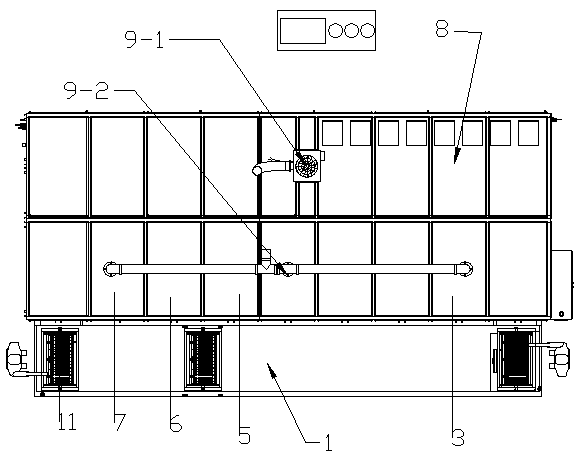

Full-automatic ultrasonic washing device aiming at tandem pump body shells and pump covers

PendingCN110947688ASave human effortImprove work efficiencyDrying solid materials without heatDrying gas arrangementsRobot handMegasonic cleaning

The invention discloses a full-automatic ultrasonic washing device aiming at tandem pump body shells and pump covers, and relates to the technical field of ultrasonic washing. The device comprises tool baskets, mechanical hands mounted on the upper portion of a rack and a function mechanism mounted on the lower portion of the rack. The function mechanism comprises multiple ultrasonic washing mechanisms, air cutting mechanisms, drying mechanisms and vacuum drying mechanisms, wherein the ultrasonic washing mechanisms, the air cutting mechanisms, the drying mechanisms and the vacuum drying mechanisms are sequentially arranged, the ultrasonic washing mechanisms, the air cutting mechanisms and the drying mechanisms are provided with rolling basket rotating mechanisms, a basket return line conveying mechanism is mounted on one side of the rack, and an air exhaust system is mounted above the rack. The mechanical hands aiming at the tandem pump body shells and pump covers carry the tool baskets to be subjected to full-automatic ultrasonic washing in grooves one by one, the washing efficiency is high, the effect is good, and manpower is saved.

Owner:BAKR ULTRASONIC TECH GRP

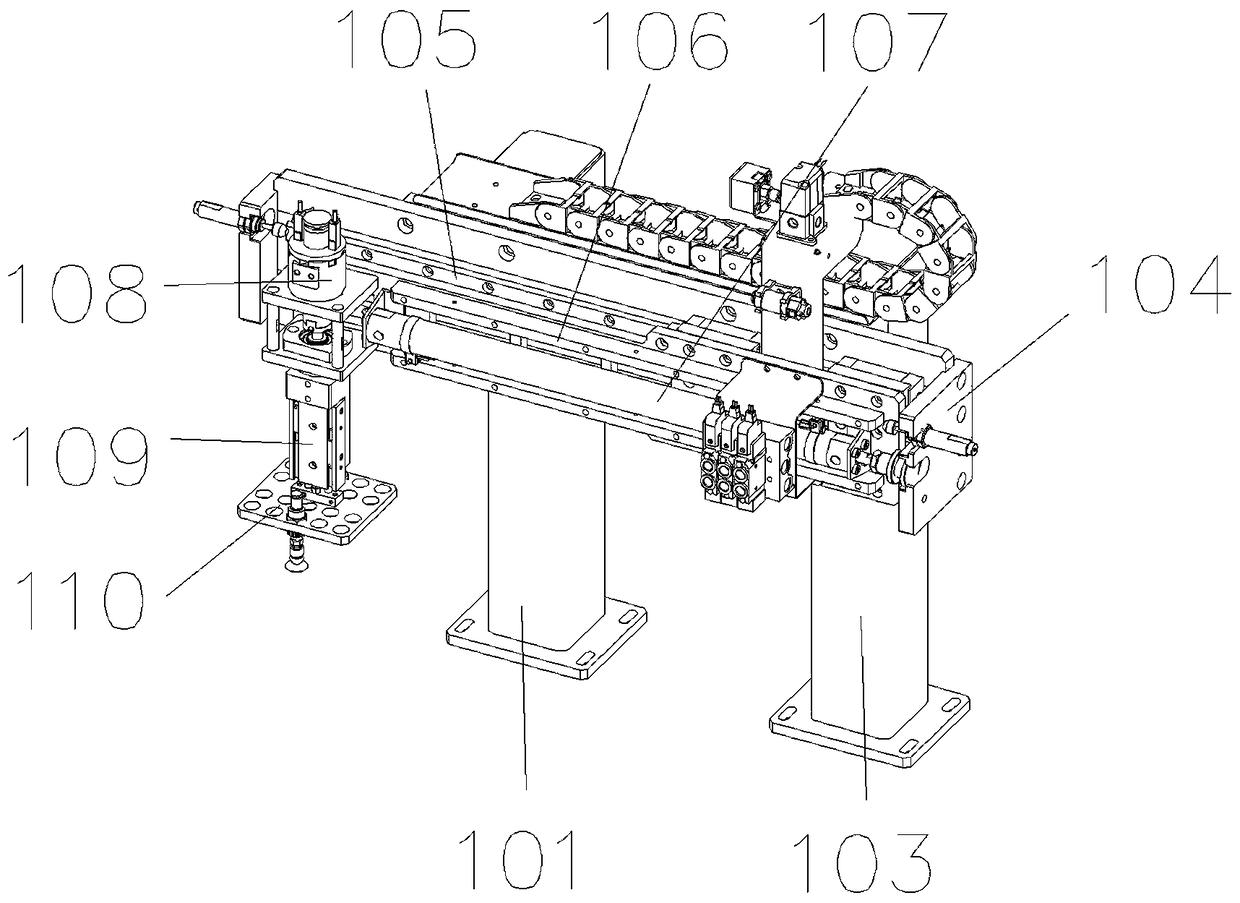

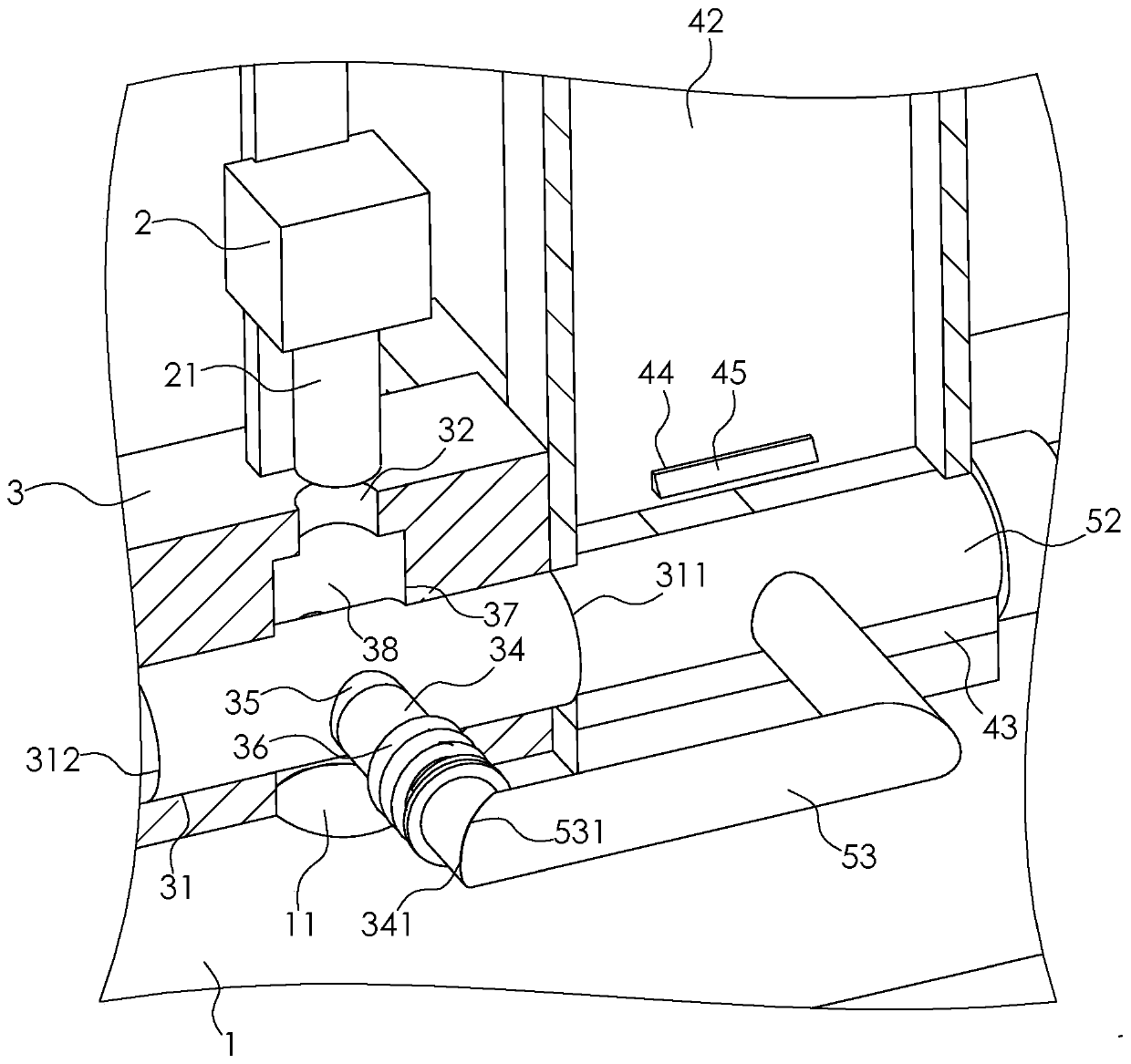

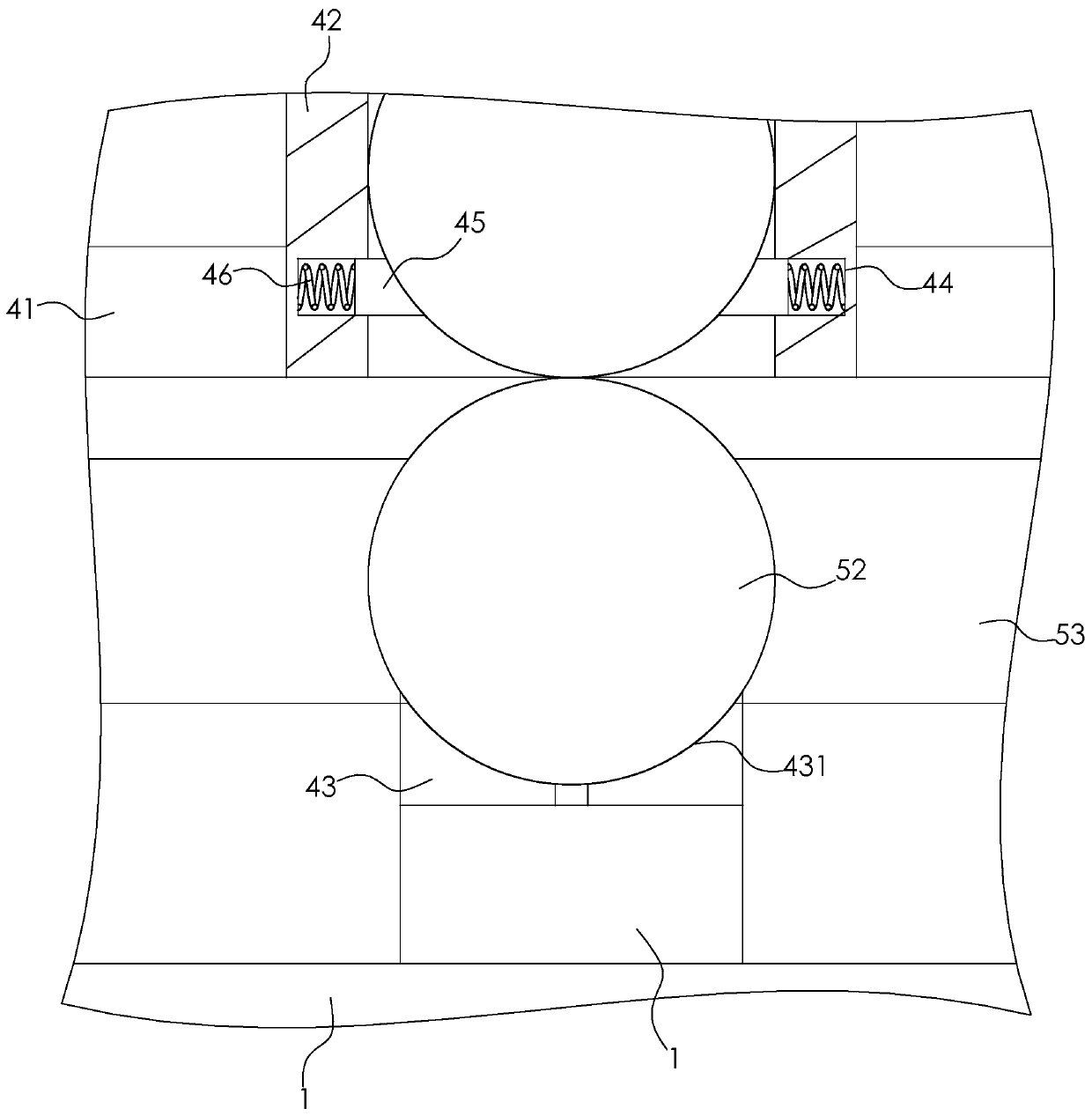

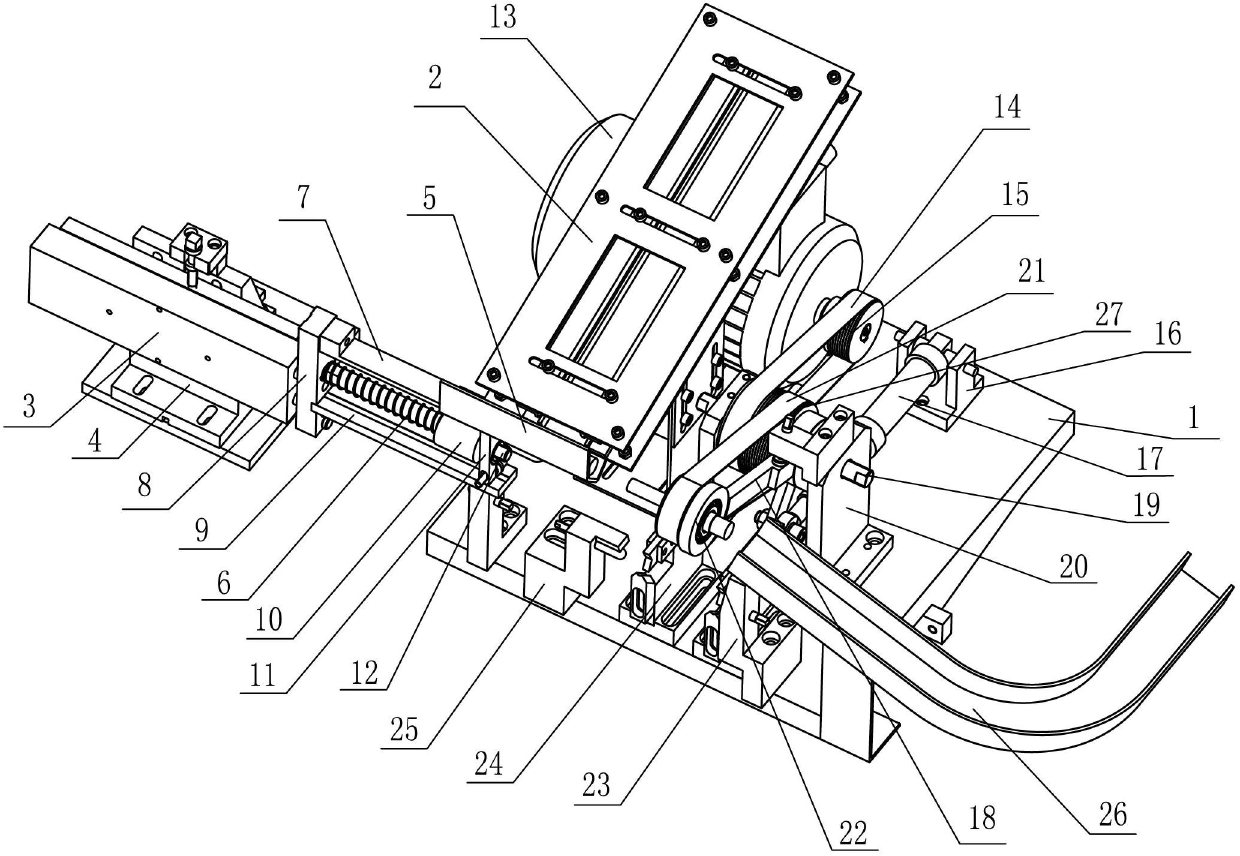

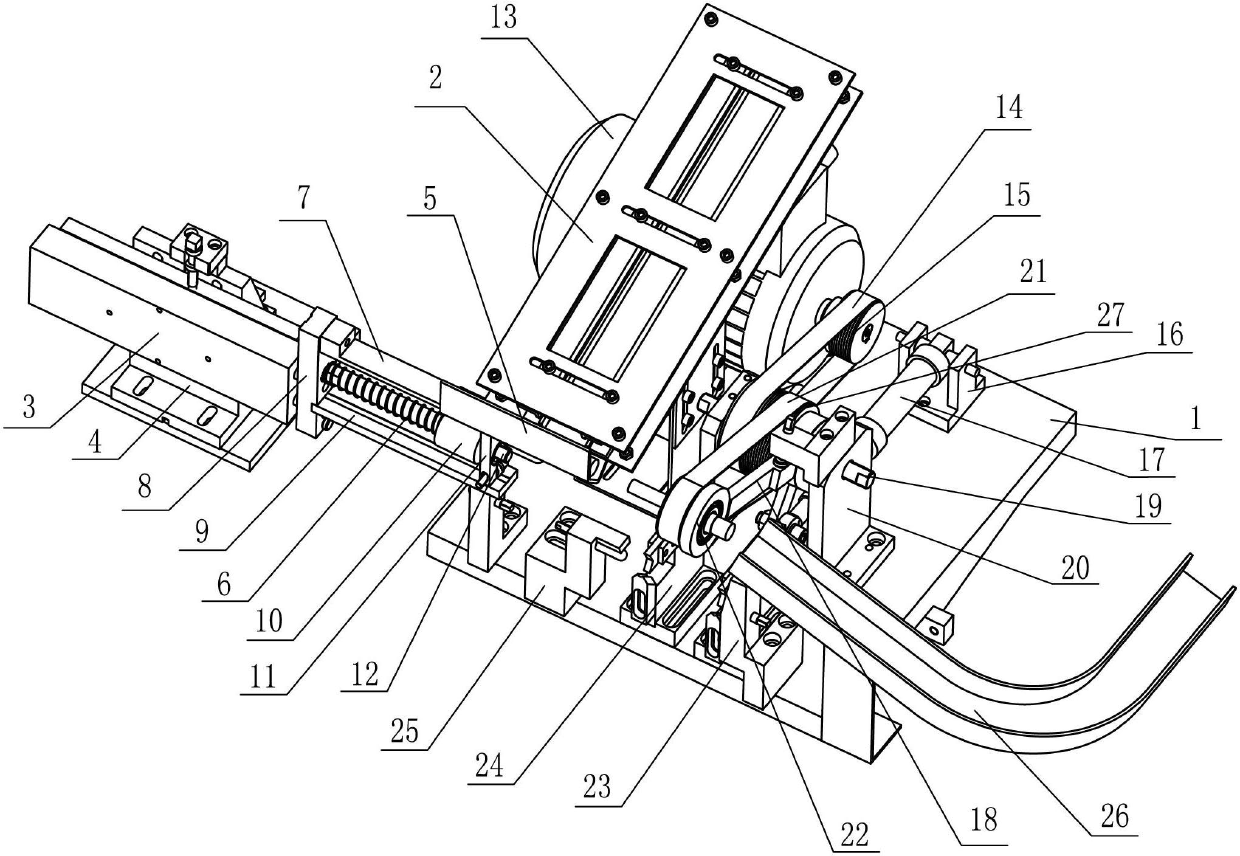

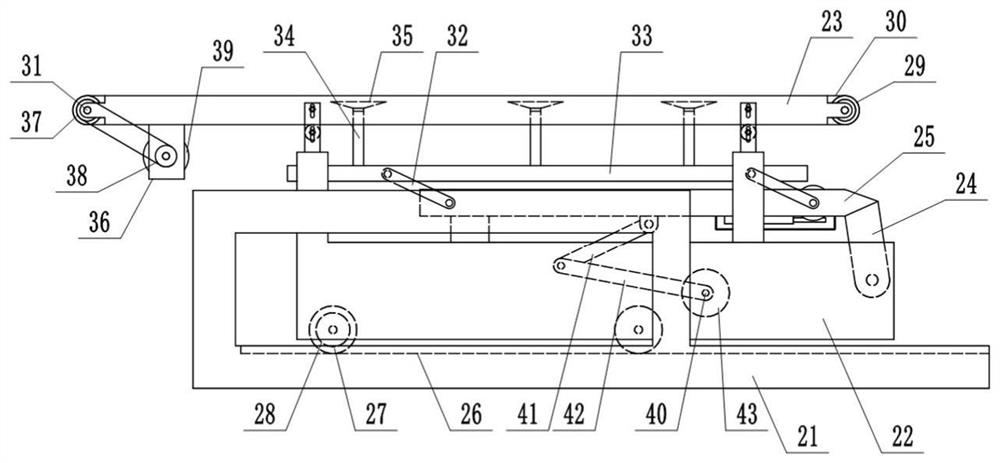

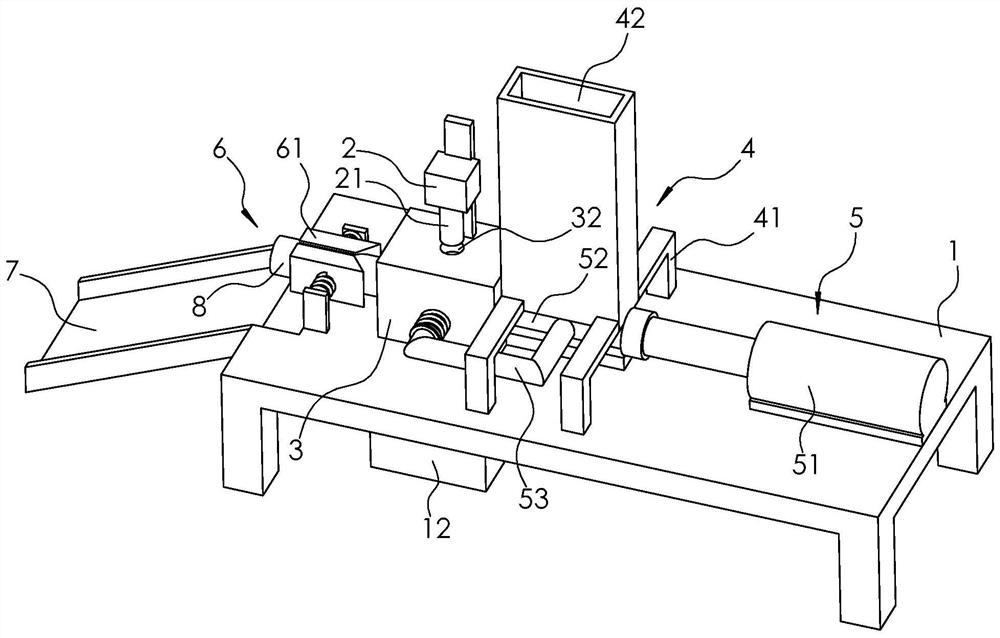

Full-automatic loading and unloading device of cylindrical grinder for machining spindle of water pump bearing

ActiveCN102672564ARealize fully automatic loading and unloadingImprove securityRevolution surface grinding machinesCylindrical grinderCylindrical grinding

The invention discloses an automatic loading and unloading device of a cylindrical grinder for machining a spindle of a water pump bearing and belongs to the field of cylindrical grinding auxiliary devices. By the conventional manual loading cylindrical grinder, the machining efficiency and the safety are low, and the labor intensity is high. The automatic loading and unloading device comprises a base, a directional arrangement mechanism, a transverse pushing mechanism, a clamping rotary mechanism, a rocker arm transmission mechanism and a discharging rolling path which are arranged on the base, wherein the transverse pushing mechanism comprises a supporting plate and a pushing mechanism; the supporting plate is supported on a material outlet of the directional arrangement mechanism and supports the lowest workpiece of workpieces arranged in lines by the directional arrangement mechanism; the clamping rotary mechanism comprises a workpiece chuck and a motor; the workpiece chuck is in transmission connection with the motor through belts and belt pulleys; the workpiece chuck is provided with a clamping hole; a lifting transmission mechanism comprises a swinging rocker arm and a driving mechanism for driving a rocker arm to swing up and down; the workpiece chuck is supported by a supporting sleeve and arranged on the top of the rocker arm of the rocker arm transmission mechanism; the supporting plate is positioned on the left side of the clamping hole; and the discharging rolling path is supported on the right side of the clamping hole. By adoption of the automatic loading and unloading device, the workpieces can be automatically loaded and unloaded.

Owner:浙江盛达机器人科技有限公司

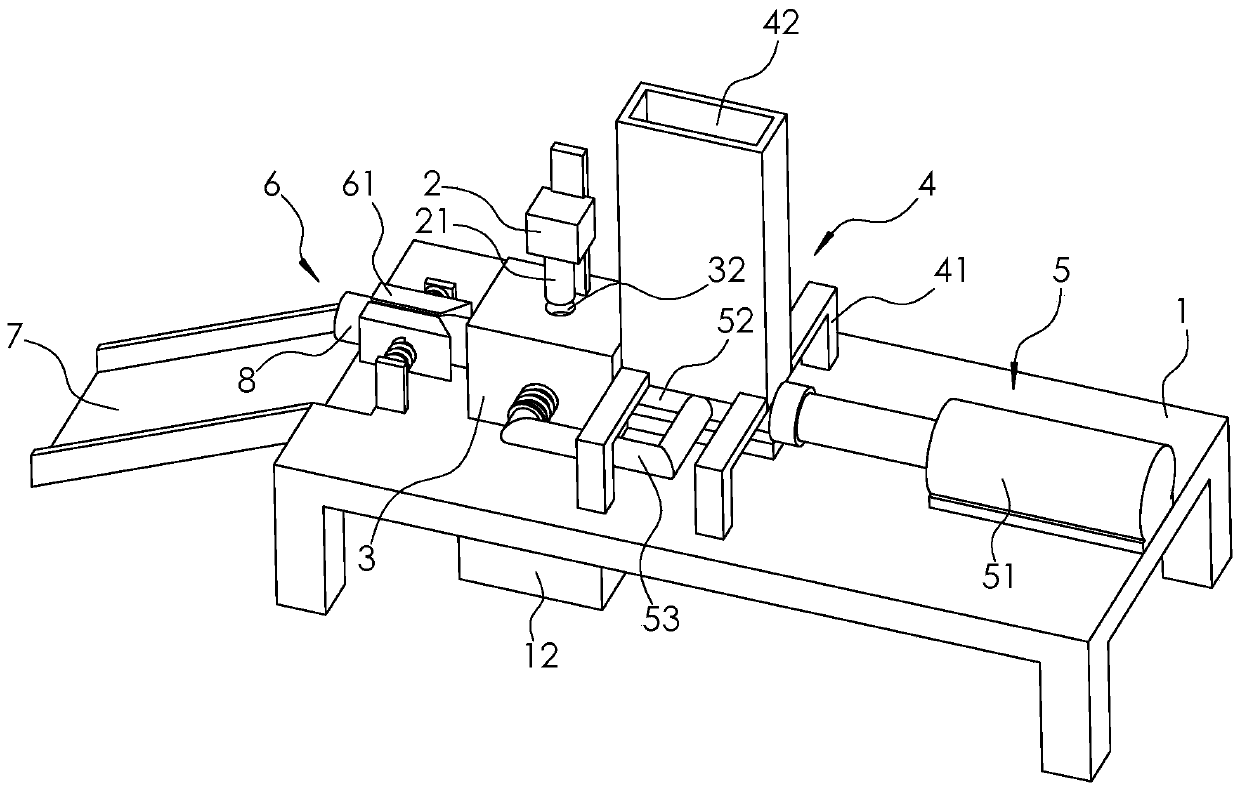

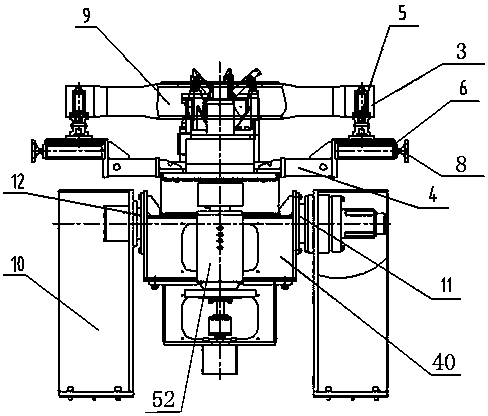

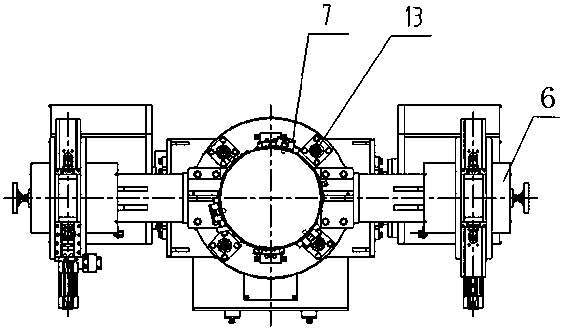

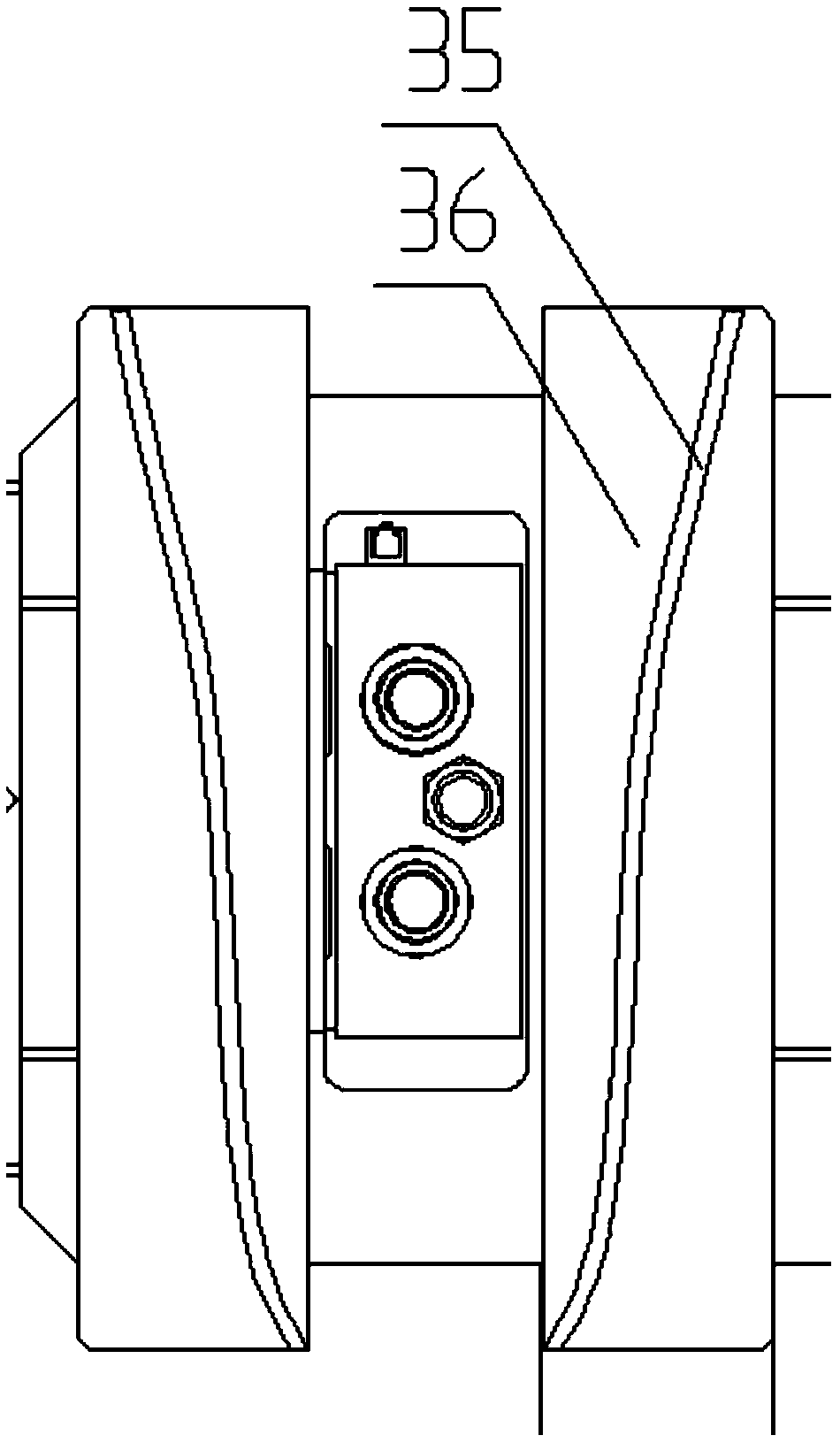

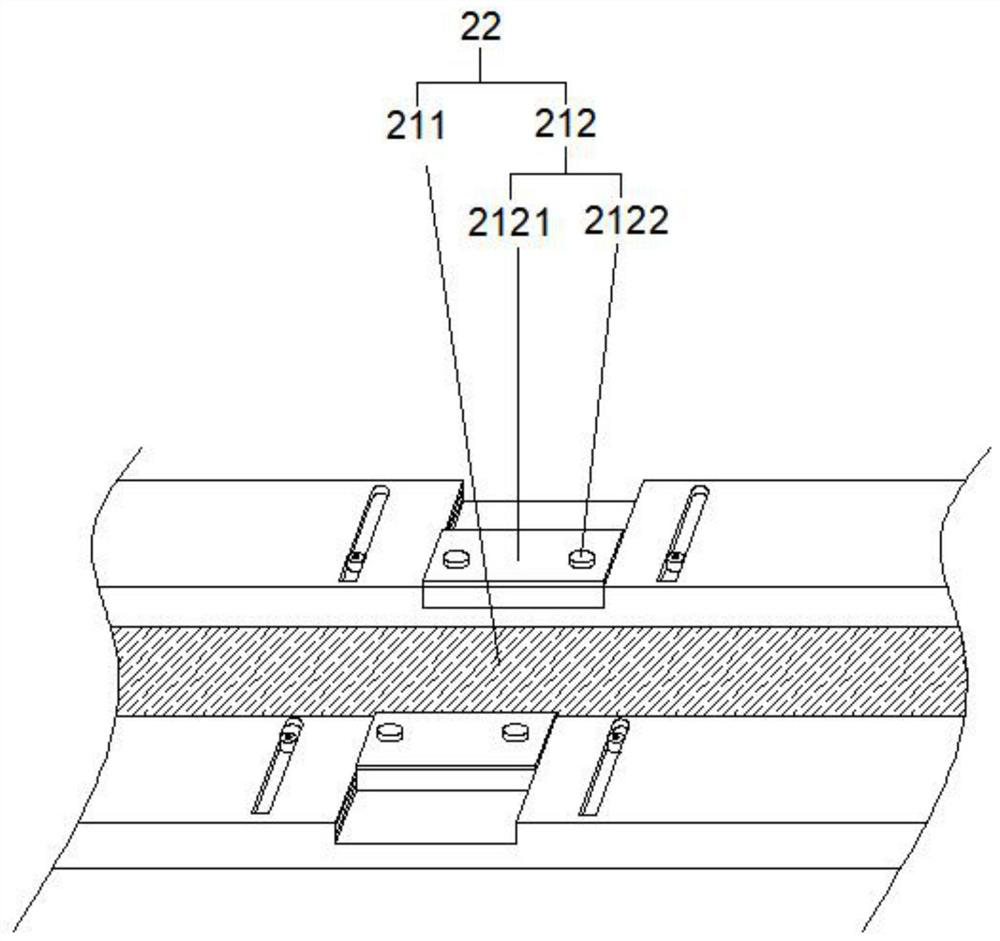

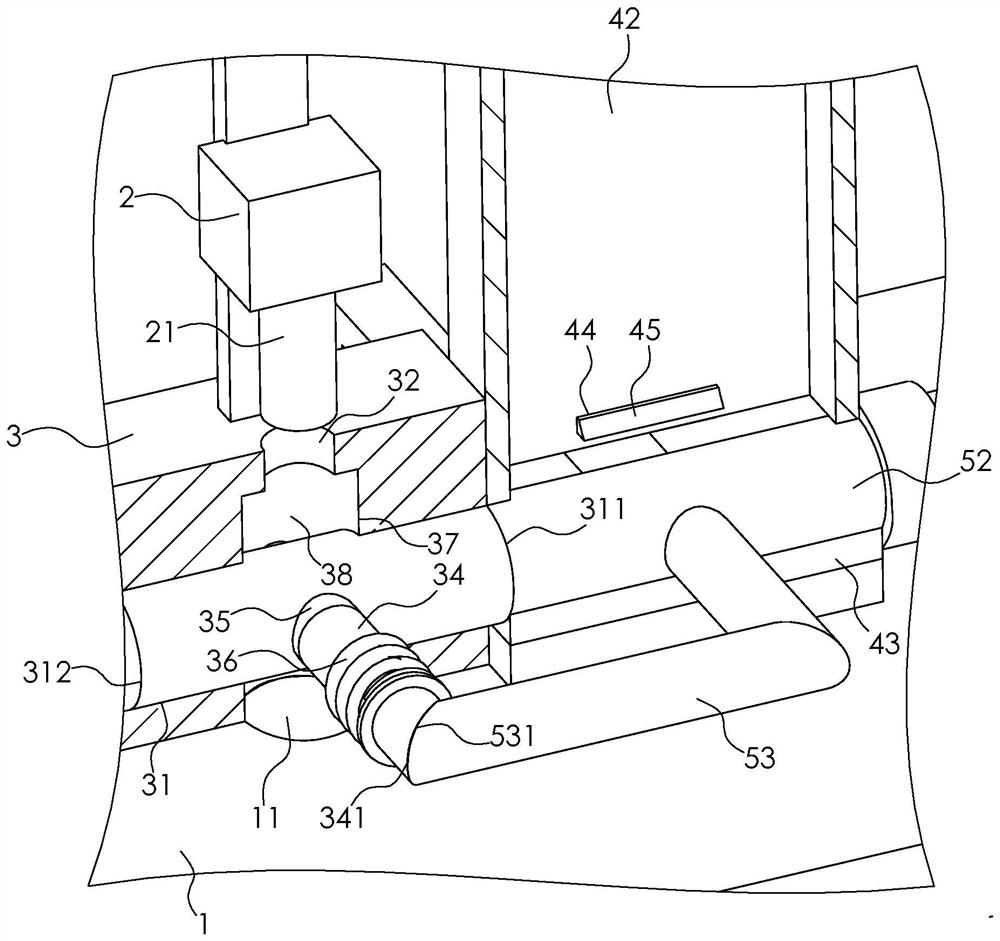

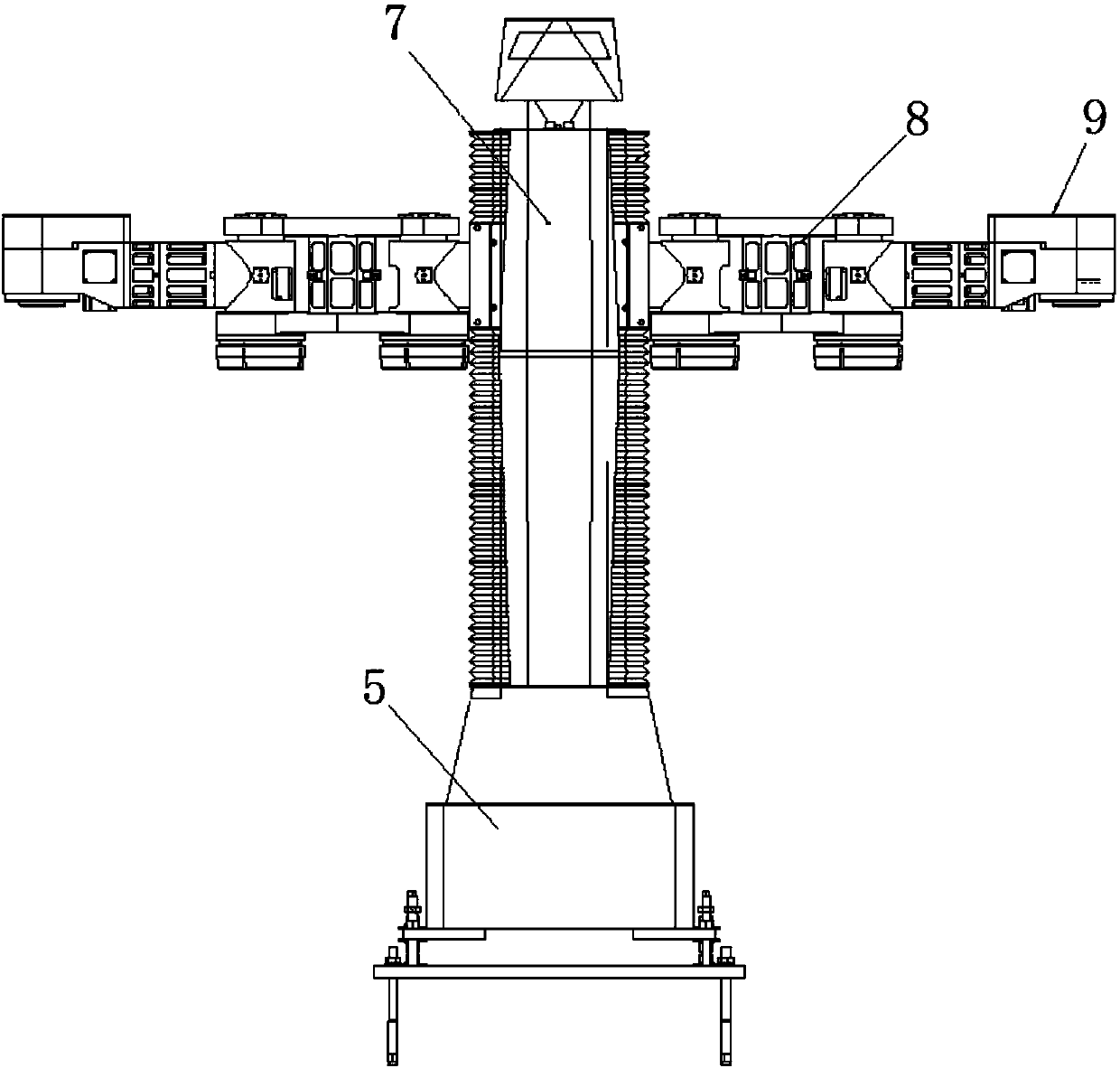

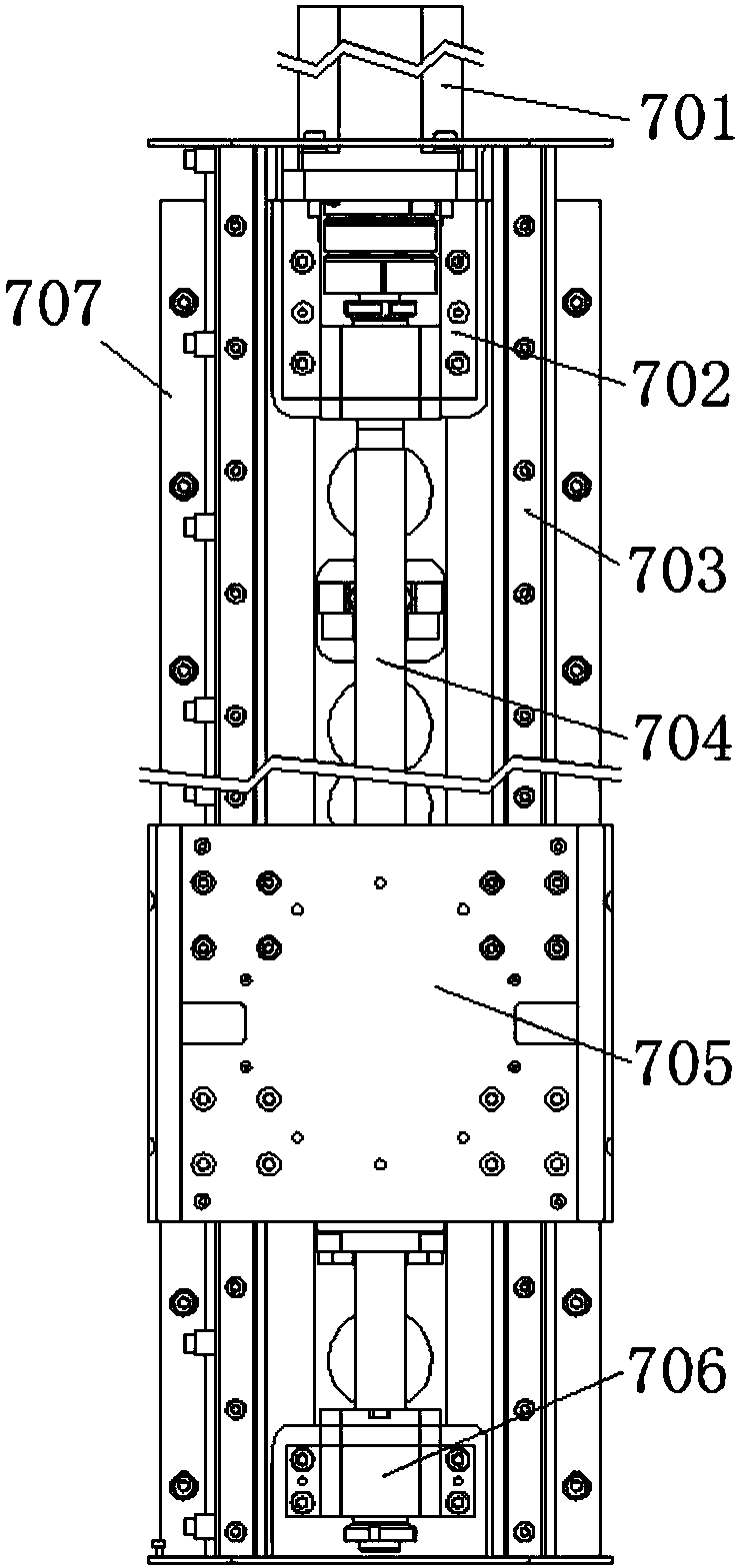

Welding method and special fixture for heavy-duty axle reinforcement ring

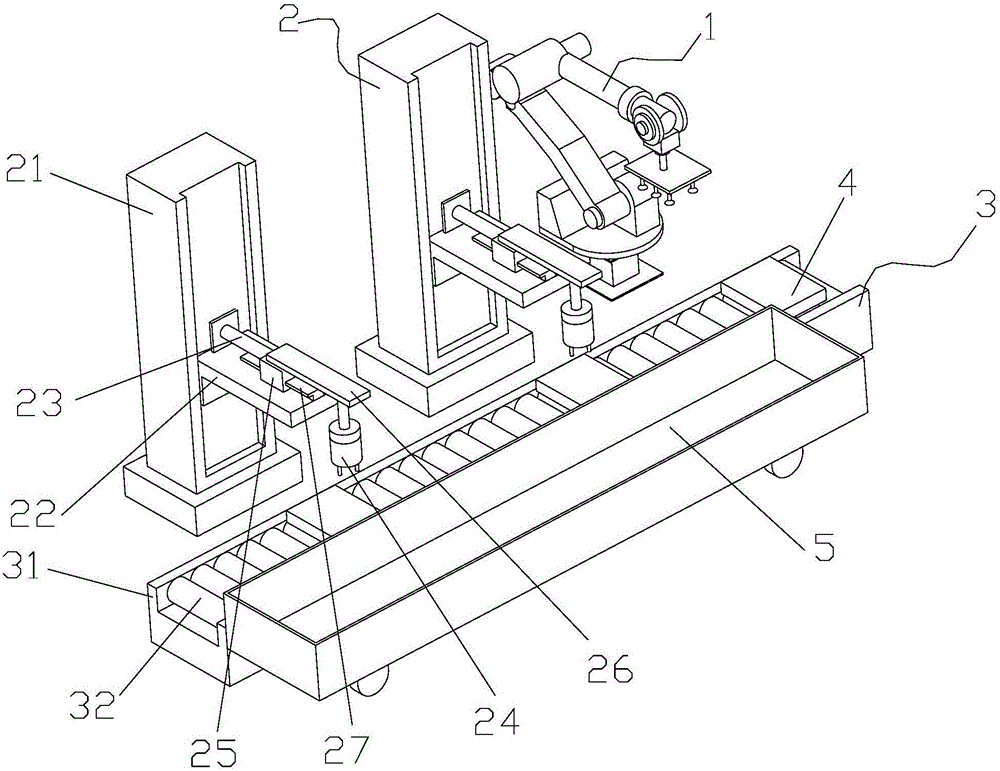

ActiveCN106216868BReasonable design structureAchieve positioningWelding/cutting auxillary devicesAuxillary welding devicesOil distributionSpot welding

The invention relates to a welding method and a special fixture for a heavy-duty axle reinforcement ring, which is suitable for welding between a heavy-duty axle reinforcement ring and the middle section of an axle housing, and belongs to the technical field of automatic assembly and welding for automobile production. The technical solution is: including the inner ring positioning mechanism of the workpiece, the centering clamping mechanism (5) at both ends, the reinforcing ring pressing mechanism and the fixture displacement welding mechanism, and through the cooperation of the oil distribution mechanism, the gas distribution mechanism and the power distribution mechanism, the alignment is completed. Positioning, pressing and welding of the workpiece (9). The invention has a reasonable design and structure, and can directly carry out continuous welding without spot welding after the reinforcing ring and the middle section of the axle housing are positioned. It can be used in conjunction with a welding robot, which can meet the change of the welding process angle and improve the welding quality; Positioning and clamping, pressing the reinforcing ring on the middle section of the axle housing, using a set of tooling with the handling robot and welding robot, to realize automatic loading and unloading, positioning, pressing and welding, improving efficiency and ensuring product quality.

Owner:TANGSHAN KAIYUAN AUTOWELDING SYST

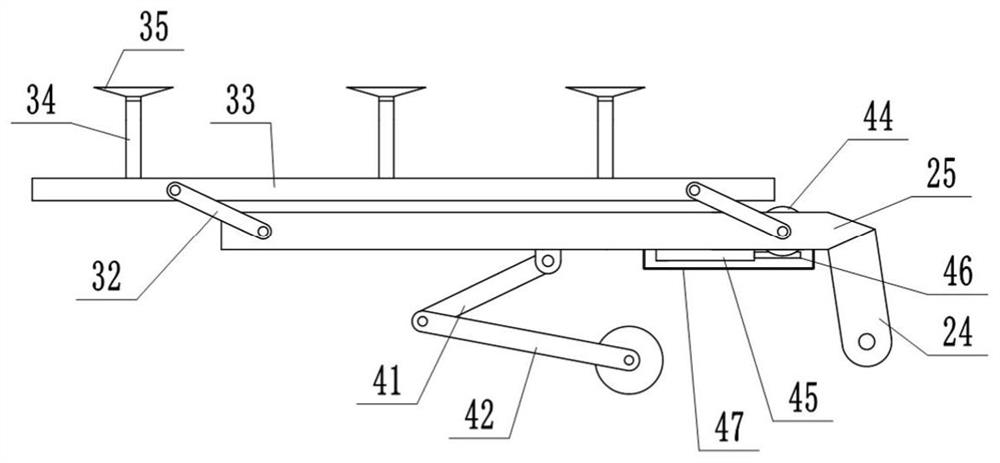

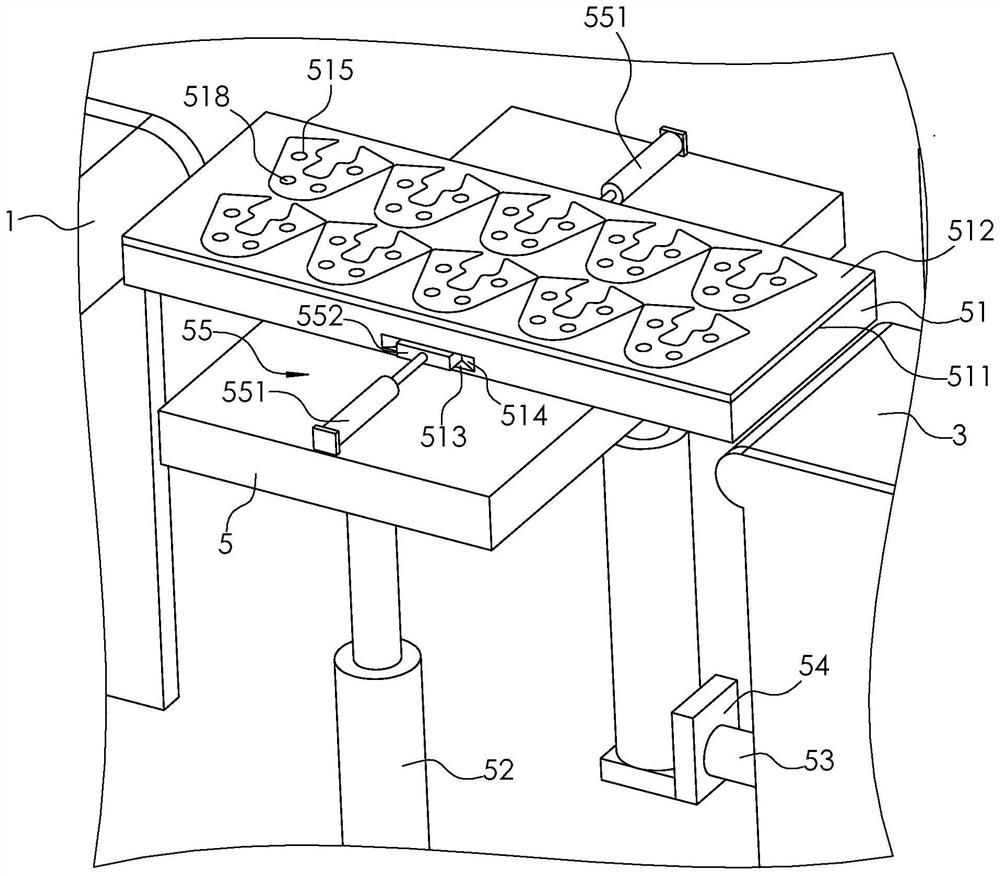

Automatic feeding and discharging device for shoe blank cold and hot die treatment

PendingCN108851354ASo as not to damageSimple structureShoemaking devicesInsolesEngineeringMechanical engineering

The invention relates to an automatic feeding and discharging device for shoe blank cold and hot die treatment. The automatic feeding and discharging device comprises a rotating device, a rack, a feeding device, a discharging device and a controller, the feeding device and the discharging device are mounted on the rack which is mounted on a rotating shaft of the rotating device, the controller isused for controlling the feeding device to clamp a shoe blank and putting the same into a die of a cold and hot die treatment device, the feeding device comprises a left-foot shoe blank clamping mechanism, a right-foot shoe blank clamping mechanism and a first pushing mechanism, the controller is used for controlling the discharging device to take out the treated shoe blank from the cold and hot die treatment device, and the discharging device comprises a hooking mechanism and a clamping mechanism. The automatic feeding and discharging device can automatically clamp the shoe blank and accurately mount the same into the cold and hot die treatment device, can respectively clamp the left-foot shoe blank and the right-foot shoe blank and can automatically take out the shoe blank after being treated from the cold and hot die treatment device completely through cooperation of a hooking mechanism and a clamping mechanism without causing damage to the shoe blank.

Owner:武汉理惠诚机器人科技有限公司

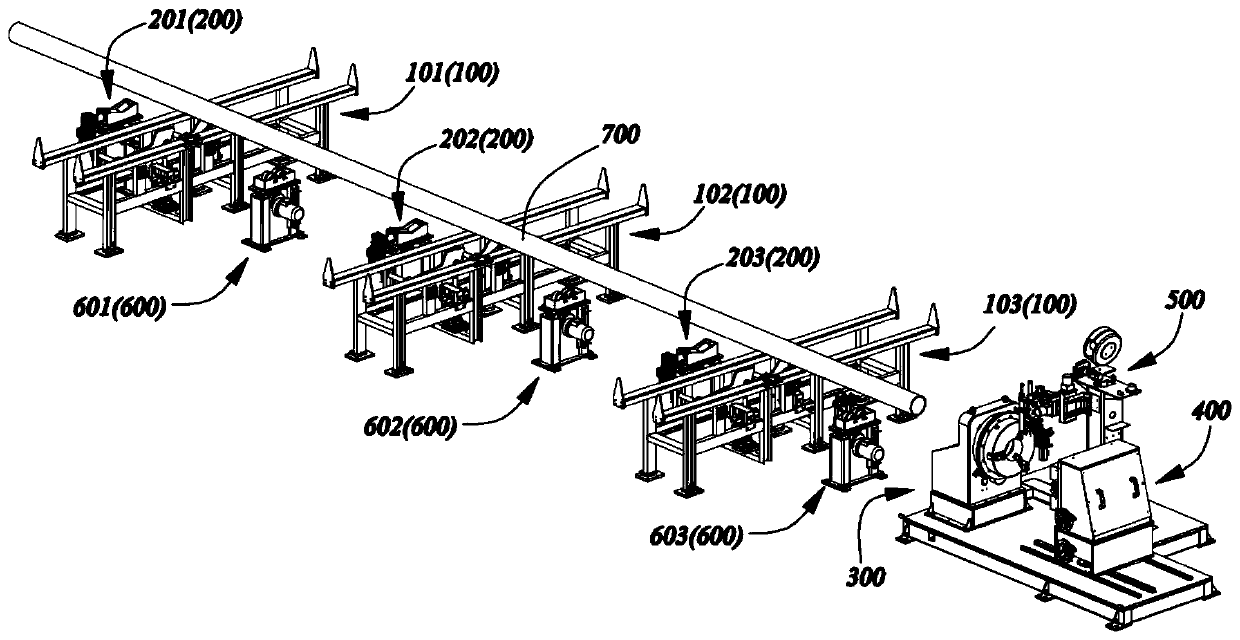

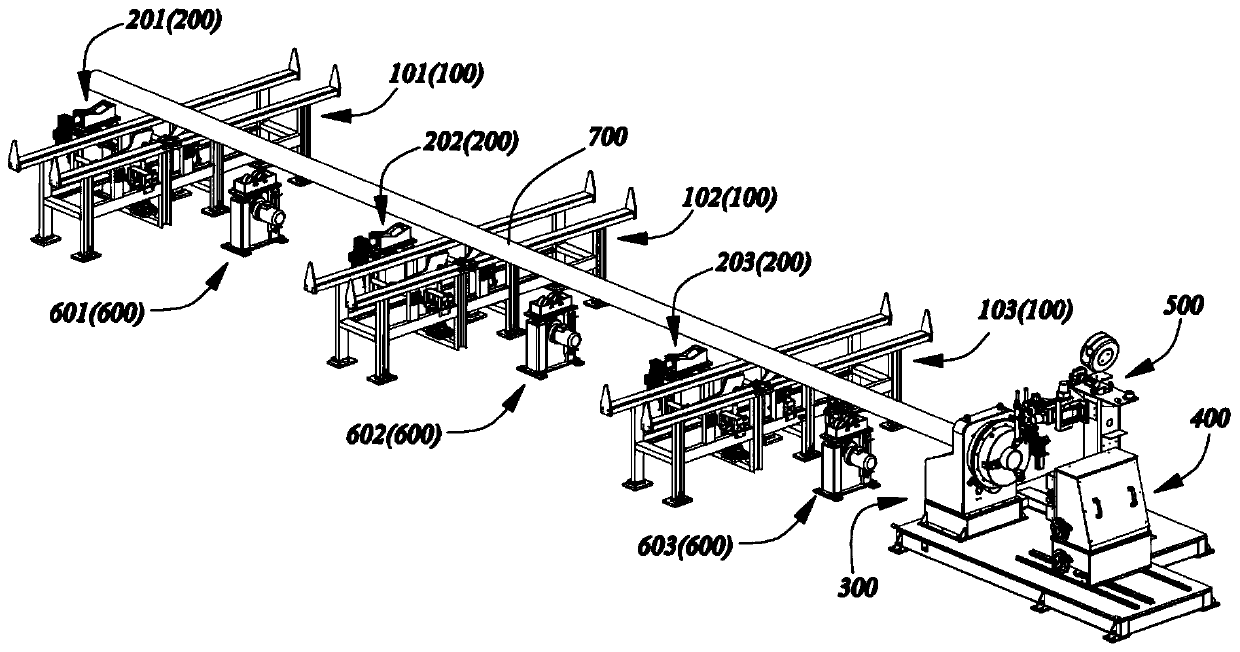

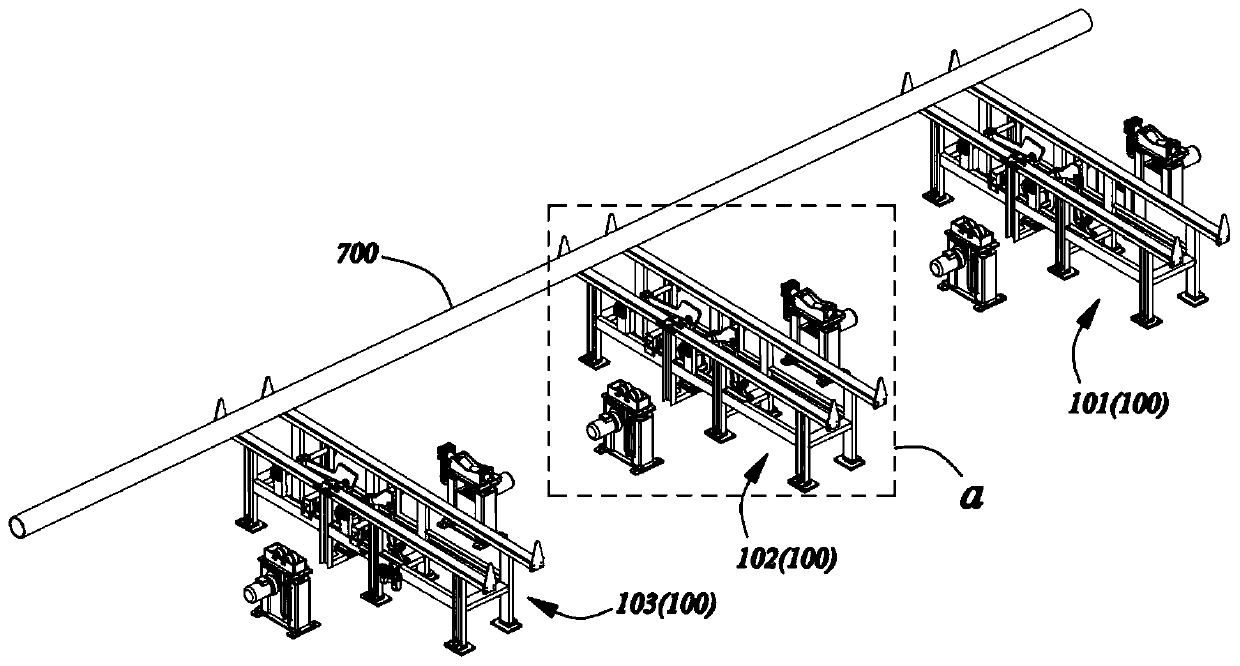

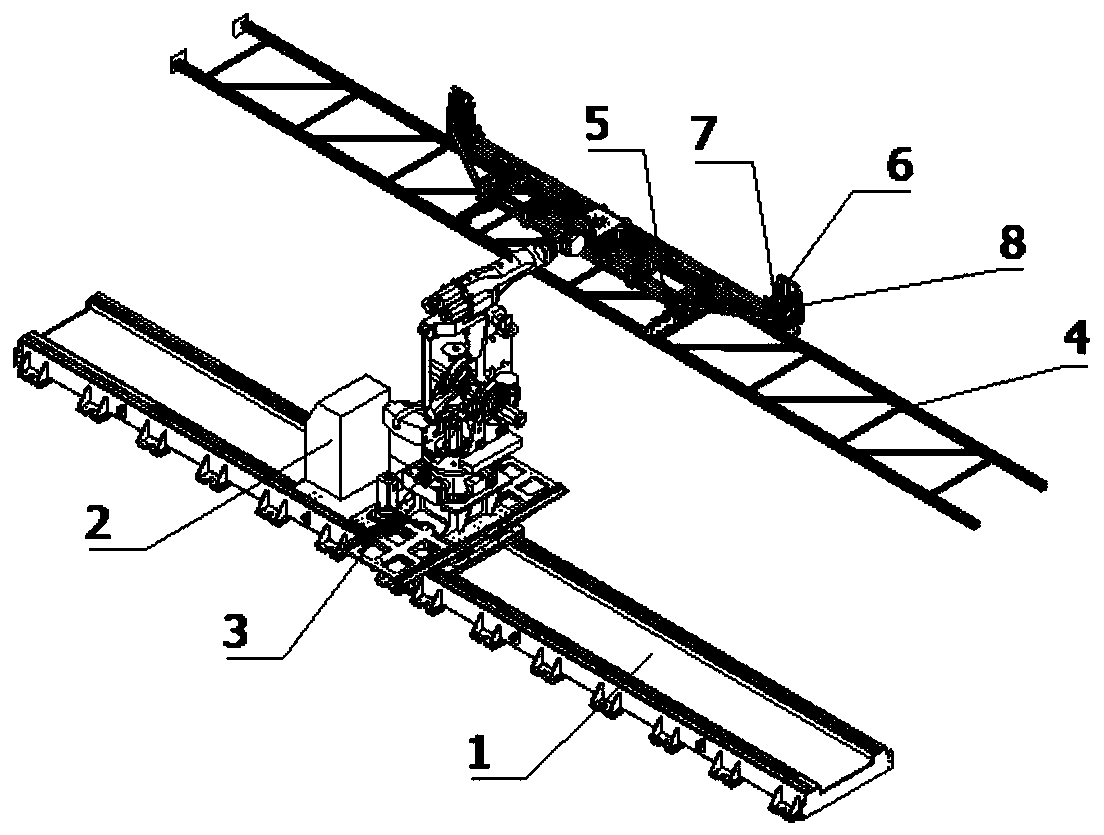

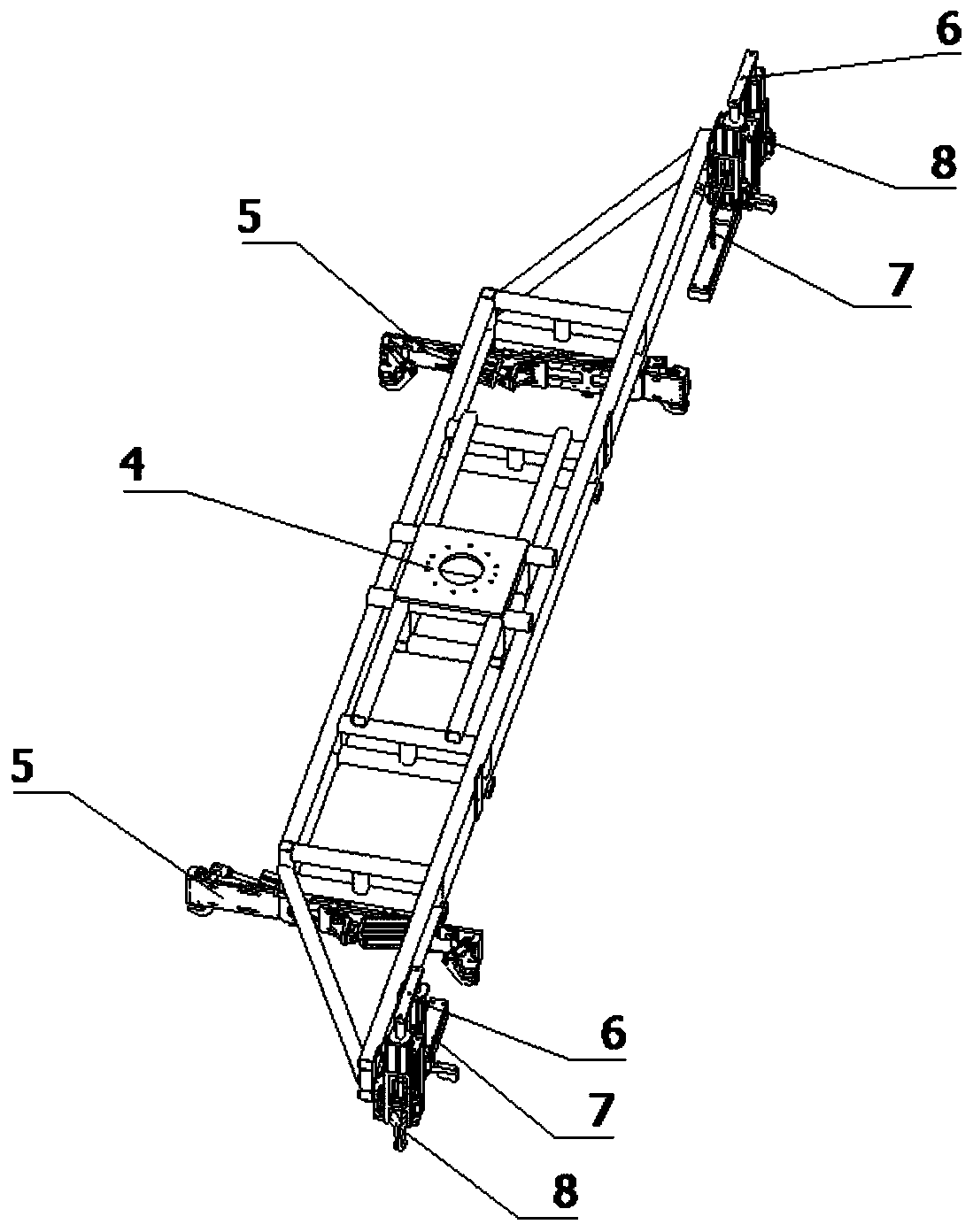

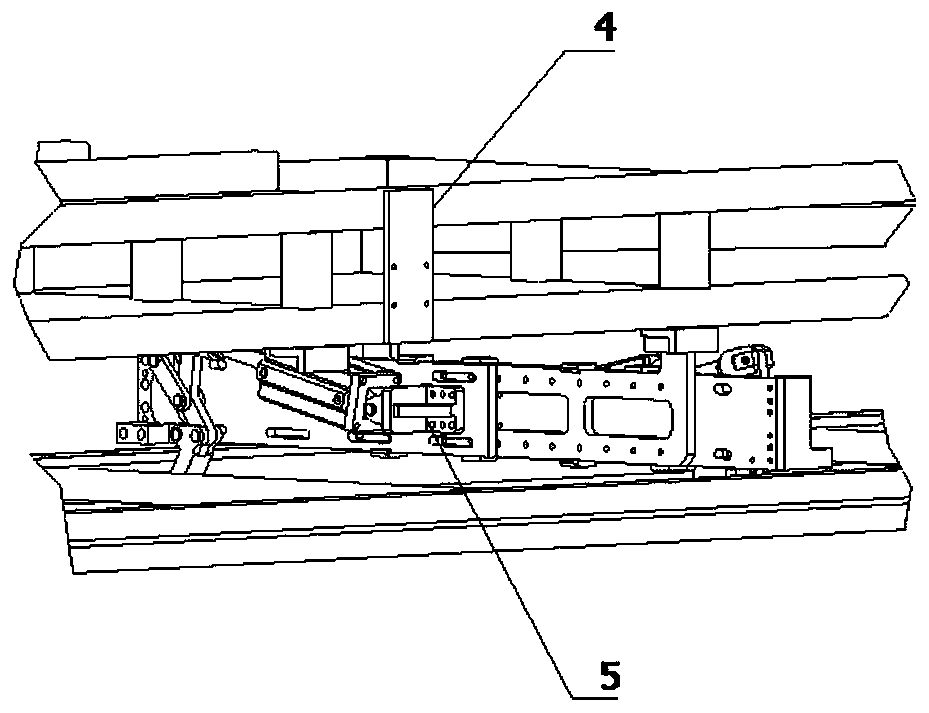

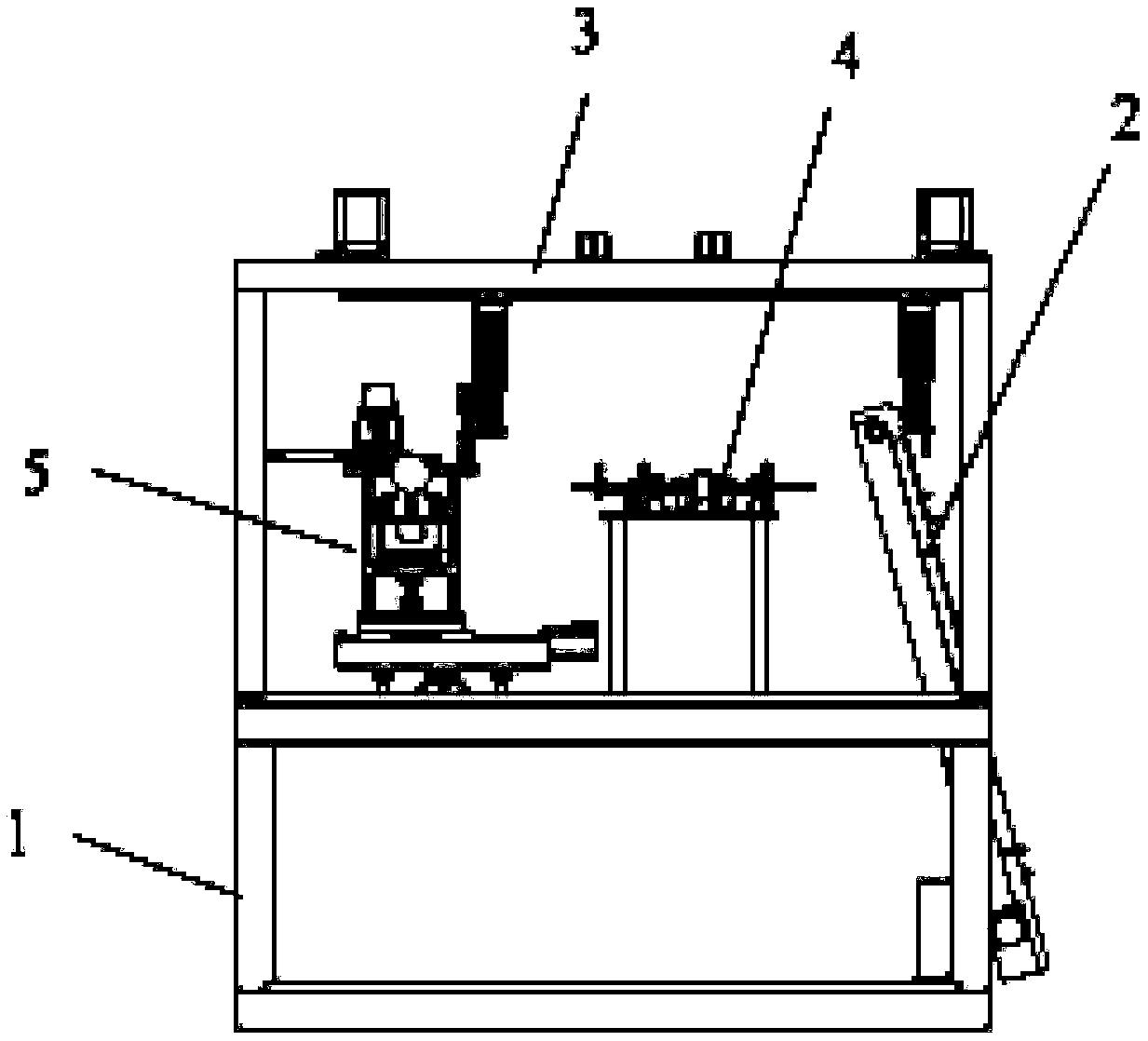

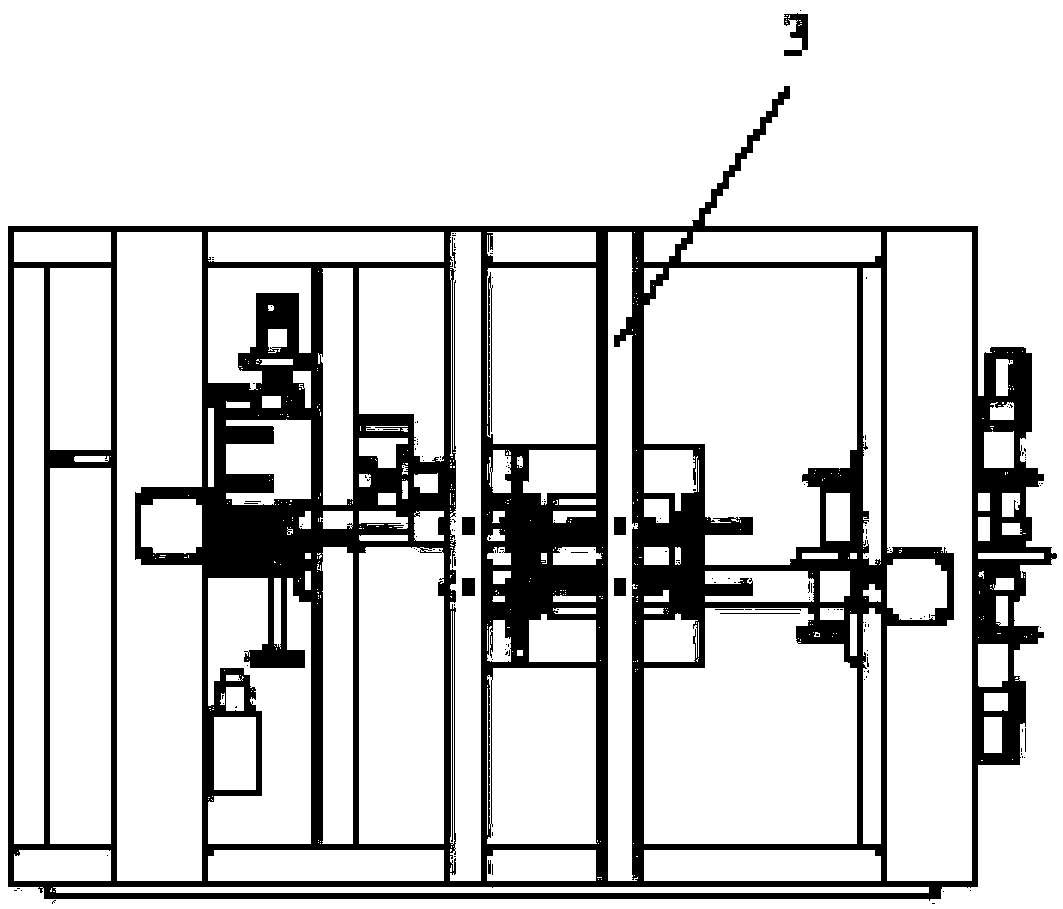

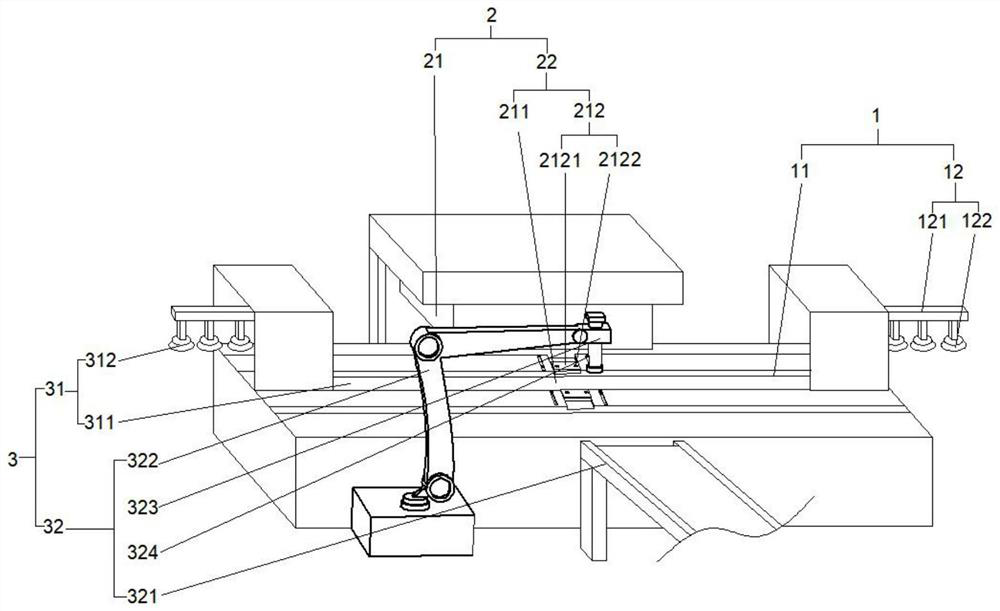

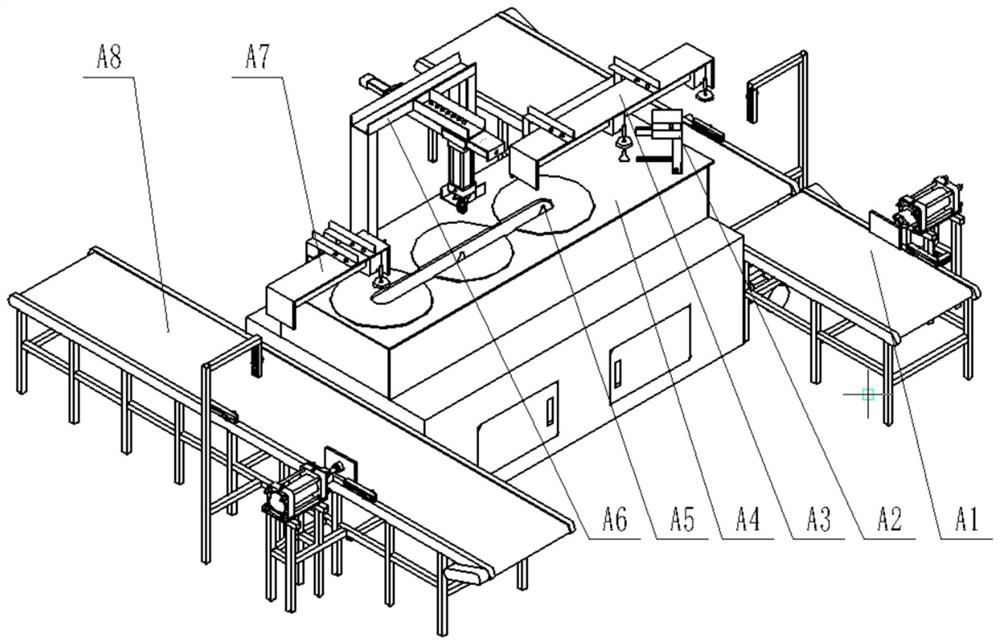

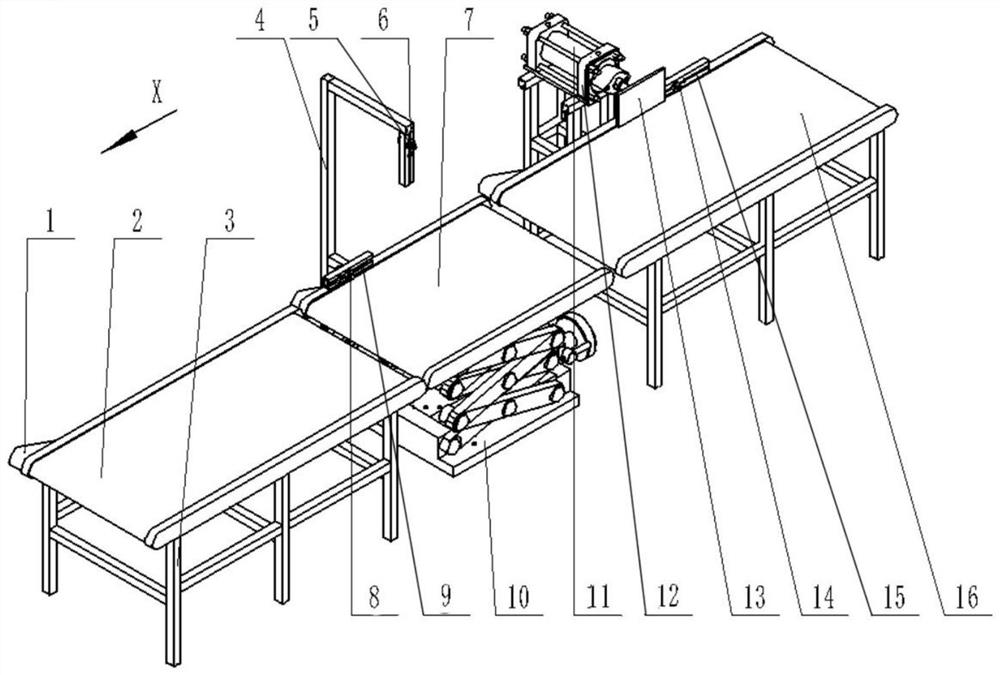

Full-automatic welding system

PendingCN109746585ARealize fully automatic loading and unloadingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe fitting

The invention discloses a full-automatic welding system. The full-automatic welding system is used for welding pipe fitting to one end of a pipeline. Based on the full-automatic welding system, in theprocess that the pipeline is welded to other pipe fitting, procedures of full-automatic feeding and discharging, clamping and welding of the pipeline can be realized, too much manual participation can be avoided, the efficiency of pipeline welding is effectively improved, the full-automatic welding system is suitable to basic requirement of the efficient production of a present enterprise, and standardized welding processes can also ensure that the welding quality has high reproducibility.

Owner:HUAHENG WELDING +2

Automatic feeding and discharging device for hot galvanizing and using method

PendingCN113249671AAvoid dangerRealize fully automatic loading and unloadingHot-dipping/immersion processesStructural engineeringMechanical engineering

The invention discloses an automatic feeding and discharging device for hot galvanizing and a using method thereof. The device comprises a base and a hanging tool movably connected with the base, wherein the base comprises a fixed bottom plate, a plurality of supporting rods are longitudinally arranged on the periphery of the fixed bottom plate, and a supporting plate for supporting the hanging tool is arranged on the upper portions of the supporting rods; and a grid is arranged inside the hanging tool, and a plurality of hanging point hooks which are evenly distributed are arranged on the periphery of the hanging tool. The invention further discloses a method for carrying out automatic feeding and discharging through the device during hot galvanizing of a ring lock type scaffold cross rod. The method comprises the steps that the hanging tool is fixed between the supporting rods, the cross rod penetrates through the hanging tool, a metal wire penetrates through a plate pin hole, and then the hanging tool is hoisted for acid pickling and galvanizing. According to the device, manual operation is not needed, and automatic feeding and discharging can be achieved by setting equipment parameters; and the cost is saved, and risks possibly generated by manual operation are reduced.

Owner:郅西敬

Automatic assembly line and process of low pressure heat and dry treatment of wet sludge

ActiveCN110981153ARealize fully automatic loading and unloadingImprove drying efficiencySludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The invention relates to an automatic assembly line and process of low pressure heat and dry treatment of wet sludge, wherein the automatic assembly line comprises a rack, a cake discharging opening and a drying room; a first gate and a second gate are arranged in the cake discharging opening, and a plurality of supports, a plurality of trays, a plurality of feeding openings, a plurality of discharging openings, a plurality of sealing doors and a plurality of conveying devices are arranged in the drying room; a first U-shaped conveying device, a first conveying device, a first lifting device,a second U-shaped conveying device, a second conveying device, a second lifting device and a transferring device are arranged on the rack; a collecting box is arranged obliquely below the transferringdevice, and a scraping device is arranged on the transferring device. Full-automatic feeding and discharging of mud cake fragments are achieved; and compared with feeding modes of workers and forklifts, the drying efficiency of the wet sludge is greatly improved. The drying efficiency of the wet sludge is greatly improved.

Owner:杭州嘉澍环境监测有限公司

Automatic system for loading and unloading

InactiveCN105905606APrecise handlingPrecise stackingConveyorsControl devices for conveyorsAutomatic controlEngineering

The invention discloses an automatic system for loading and unloading. The automatic system for loading and unloading comprises a storage yard transporter, a transition yard transporter and a moving chain, wherein the storage yard transporter comprises a standing seat, a big arm, a small arm and a vacuum sucker, the big arm is connected with the standing seat, and the small arm is connected with the vacuum sucker and the big arm; the transition yard transporter comprises a mounting seat, a vertical moving seat, a cylinder, a sucker, a guide rail, a sliding block and a mounting plate, the mounting seat is arranged beside the moving chain, the vertical moving seat moves vertically on the mounting seat, the vertical moving seat is provided with the cylinder arranged in a position close to the mounting seat, the guide rail is mounted on the vertical moving seat, the sliding block moves on the guide rail, the cylinder is connected with a side surface of the sliding block, the mounting plate is mounted at the upper end of the sliding block, and the sucker is mounted at the tail end of the mounting plate; and the moving chain comprises a moving tank, and rollers placed evenly are arranged on the moving tank. According to the automatic system provided by the invention, the transition yard transporter can stack goods into vehicles accurately, or transport the goods out of the vehicles accurately through automatic control according to positions and dimensions of the vehicles, and automatic loading and unloading as well as stacking are realized.

Owner:ANHUI SONGKE INFORMATION TECH CO LTD

Automatic feeding and discharging integrated machine and hot-pressing production line

The invention provides a hot-pressing production line and an automatic feeding and discharging integrated machine. The production line comprises the automatic feeding and discharging integrated machine. The integrated machine comprises a feeding mechanism, a manipulator mechanism, a conveying belt mechanism and a discharging mechanism. The feeding mechanism comprises a feeding groove and a jackingmechanism. The jacking mechanism drives a material to move in the feeding groove. A plurality of first vacuum adsorption pipes are arranged on the manipulator of the manipulator mechanism. The conveying belt mechanism comprises a first conveying belt, and a manipulator driving mechanism drives the manipulator to move to the feeding groove or the first conveying belt. The discharging mechanism comprises a lower material receiving disc and a lower material shifting mechanism. The lower material shifting mechanism is arranged below the conveying belt mechanism. The lower material shifting mechanism is arranged above the lower material receiving disc. A lower material shifting moving driving mechanism of the lower material shifting mechanism drives a lower material shifting sheet to move fromthe conveying belt mechanism to the lower material receiving disc, and the feeding mechanism and the discharging mechanism are located at the same end of a driving belt mechanism; and by the adoptionof the structure, full-automatic material conveying is achieved, efficiency is effectively improved, and the occupied area is reduced.

Owner:珠海市艾森工匠科技有限公司

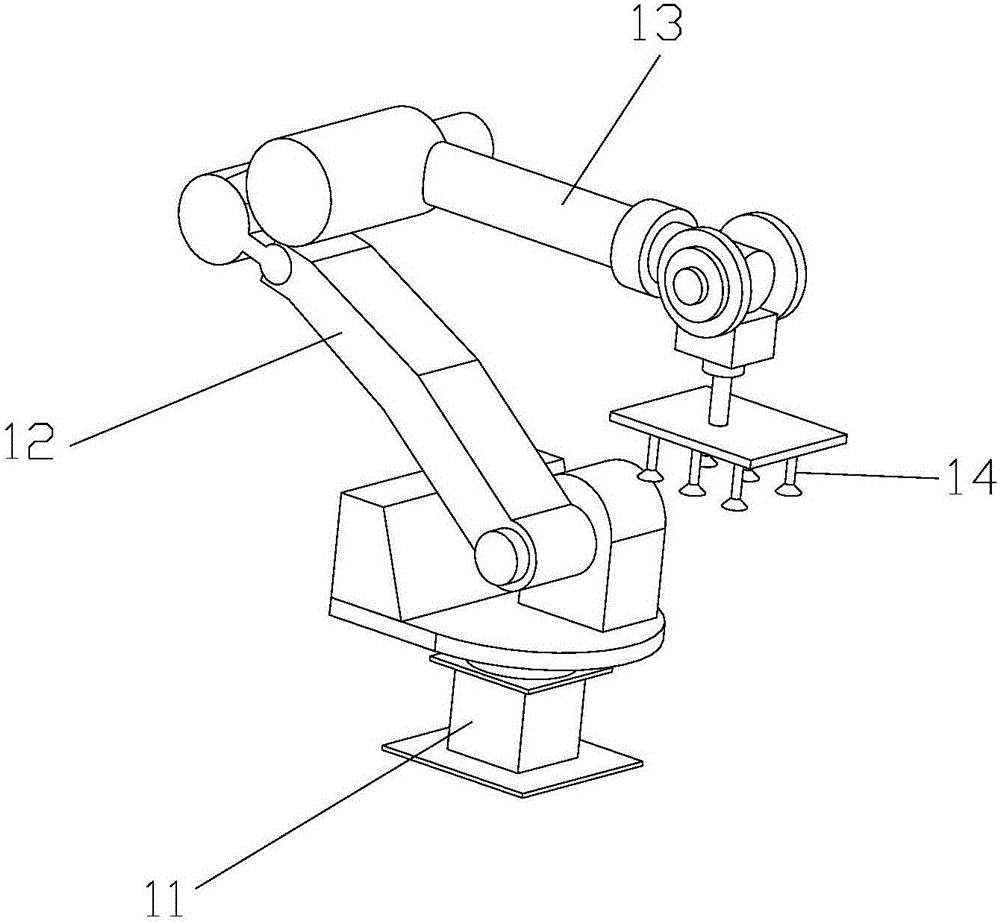

Full-automatic storage shelf feeding and discharging robot

PendingCN110900564ARealize fully automatic loading and unloadingManipulatorControl engineeringIndustrial robotics

The invention relates to the technical field of a robot and particularly to a full-automatic storage shelf feeding and discharging robot. The robot comprises a walking track, an electric appliance control box and an industrial robot, wherein the walking track is horizontally arranged and fixedly installed on the ground, the electric appliance control box and the industrial robot are both fixedly installed on a movable part of the walking track, the walking track and the industrial robot are electrically connected with the electric appliance control box, a multifunctional tool clamp is fixedlymounted at a working end of the industrial robot, the multifunctional tool clamp comprises a clamp installation support, and component tool clamps and lifting sliding tables, the component tool clampsand the lifting sliding tables are symmetrically installed on two sides of the clamp installation support, the working direction of the lifting sliding tables is vertically arranged, a part tool clamp is fixedly installed at the working end of the lifting sliding table and comprises a part external tool clamp body and a part internal tool clamp body. The robot is advantaged in that problems thata storage shelf machining workshop depends on manual feeding and discharging, and labor cost is high are solved.

Owner:浙江摩科机器人科技有限公司

Battery automatic loading and unloading laser welding machine

PendingCN109570788ARealize fully automatic loading and unloadingLaser beam welding apparatusLaserWelding process

The invention discloses a battery automatic loading and unloading laser welding machine which comprises a machine table base, a loading / receiving mechanism, a battery core transporting mechanism, a battery core pre-positioning mechanism and a battery core positioning clamping mechanism. The machine table base is used for installing the loading / receiving mechanism, the battery core transporting mechanism, the battery core pre-positioning mechanism and the battery core positioning clamping mechanism. The battery automatic loading and unloading laser welding machine mainly comprises the machine table base, the loading / receiving mechanism, the battery core transporting mechanism, the battery core pre-positioning mechanism and the battery core positioning clamping mechanism, full-automatic loading and unloading can be achieved, and the function of being changed into circumferential weld at one time is achieved. The battery automatic loading and unloading laser welding machine can solve theproblems that in the battery core welding process, the battery core manual placement efficiency is low and manual work is wasted, solves the problem that the battery core manual overturning efficiencyis low, and solves the problem that the distance between a laser head at the square battery core circumferential weld circular bead position and a welding point is changed.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

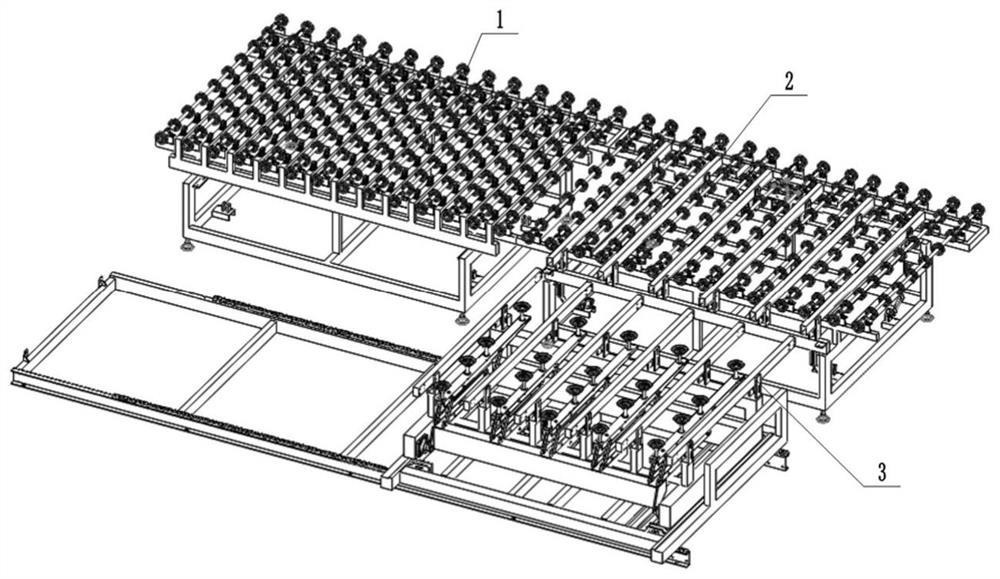

Full-automatic sheet loading and unloading device of toughening furnace

PendingCN113320983ARealize fully automatic loading and unloadingSimple structureCharge manipulationConveyor partsMechanical engineeringMaterials science

The invention relates to a full-automatic sheet feeding and discharging device of a toughening furnace and belongs to the technical field of glass conveying equipment. The full-automatic sheet feeding and discharging device specifically comprises a roller conveying line mounted at the outlet end of the toughening furnace; an automatic sheet lifting and conveying mechanism is mounted on the roller conveying line; the height of the automatic sheet lifting and conveying mechanism is lower than that of the roller conveying line; a sheet turning and falling mechanism is mounted on one side of an automatic raw sheet conveying mechanism; the roller conveying line is used for conveying glass to the automatic sheet lifting and conveying mechanism; the automatic sheet lifting and conveying mechanism is used for conveying the glass to the sheet turning and falling mechanism; and the sheet turning and falling mechanism is used for vertically placing the glass on a glass frame. The full-automatic sheet loading and unloading device of the toughening furnace is compact in structure and small in occupied space, and is capable of greatly improving the feeding and discharging efficiency of the toughening furnace.

Owner:山西绿建智造幕墙科技有限公司

Automatic feeding and discharging aluminum plate profile punching machine

PendingCN113182417ARealize fully automatic loading and unloadingImprove processing efficiencyMetal-working feeding devicesPositioning devicesProcess engineeringMachining process

The invention discloses an automatic feeding and discharging aluminum plate profile punching machine. The machine comprises a feeding part, an operation part and a discharging part, the discharging part comprises a finished product discharging part and a waste discharging part, the operation part comprises a machining face and a punching tool bit set arranged over the machining face, the feeding part comprises a feeding rail and a feeding suction cup matched with the feeding rail, the waste discharging part comprises a waste discharging rail and a waste discharging suction cup matched with the waste discharging rail, and the feeding rail, the machining face and the waste discharging rail are coaxially and horizontally arranged and sequentially connected; the finished product discharging part comprises a finished product discharging sliding way and a mechanical grabbing arm matched with the finished product discharging sliding way; and the feeding suction cup comprises a four-way electric control suspension rail and a plurality of negative pressure suction cups installed on the suspension rail, and the waste discharging suction cup and the feeding suction cup are the same in mechanical structure. The machine has the advantages that full-automatic feeding and discharging in the aluminum plate profile stamping machining process are achieved, and manual interference is completely not needed in the machining process.

Owner:昆山利欣尔精密模具有限公司

Material diameter reducing machine

The invention provides a material diameter reducing machine which is reasonable in structural design and simple to operate. The material diameter reducing machine comprises a machine frame, and is characterized in that a material feeding device, a clamping device and a diameter reducing device are arranged on the machine frame, wherein the material feeding device comprises a material placement frame and a material taking device, a material outlet is formed in the side, located on the material taking device, of the material placement frame, the material taking device comprises an ascending anddescending table and at least two material taking claws, the ascending and descending table is arranged above the clamping device in an ascending and descending mode, the material taking claws are arranged on the ascending and descending table in a rotatable mode, a control device for controlling the material taking claws to turn over is arranged between the material taking claws and the machine frame, and a first driving device for driving the ascending and descending table to ascend and descend is arranged on the machine frame.

Owner:东山欧凯金属塑料制品有限公司

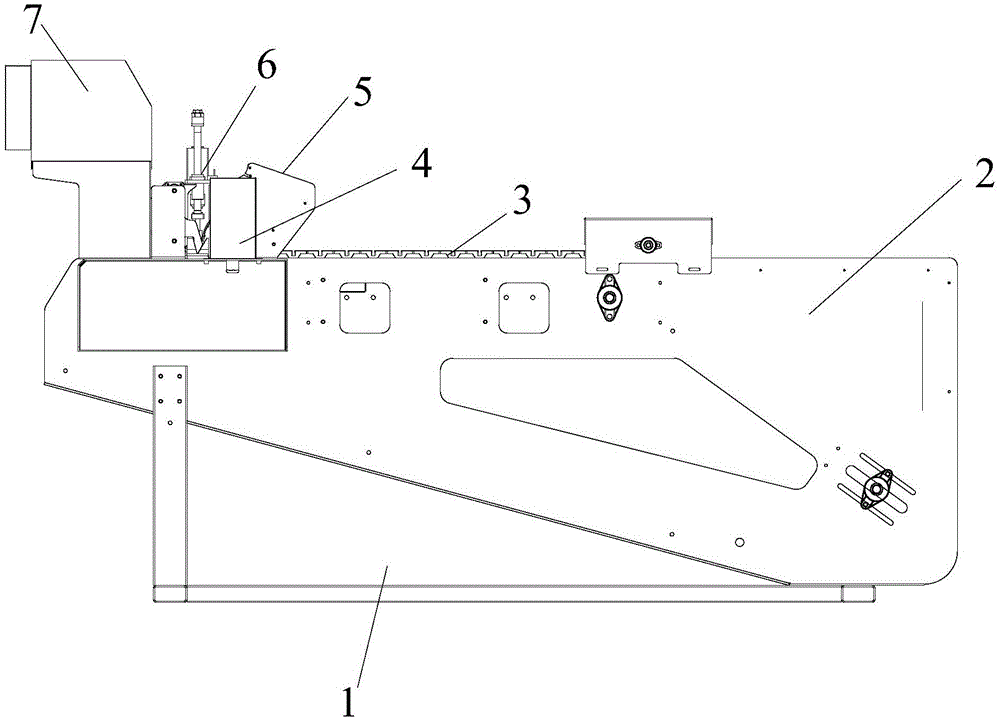

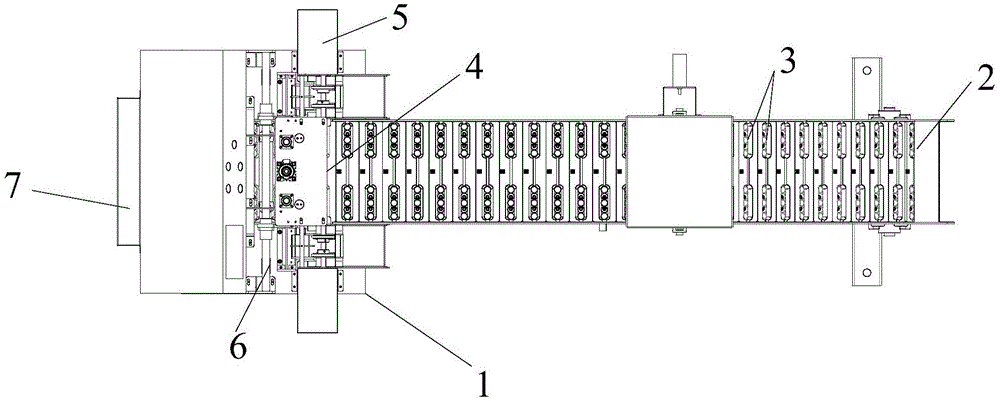

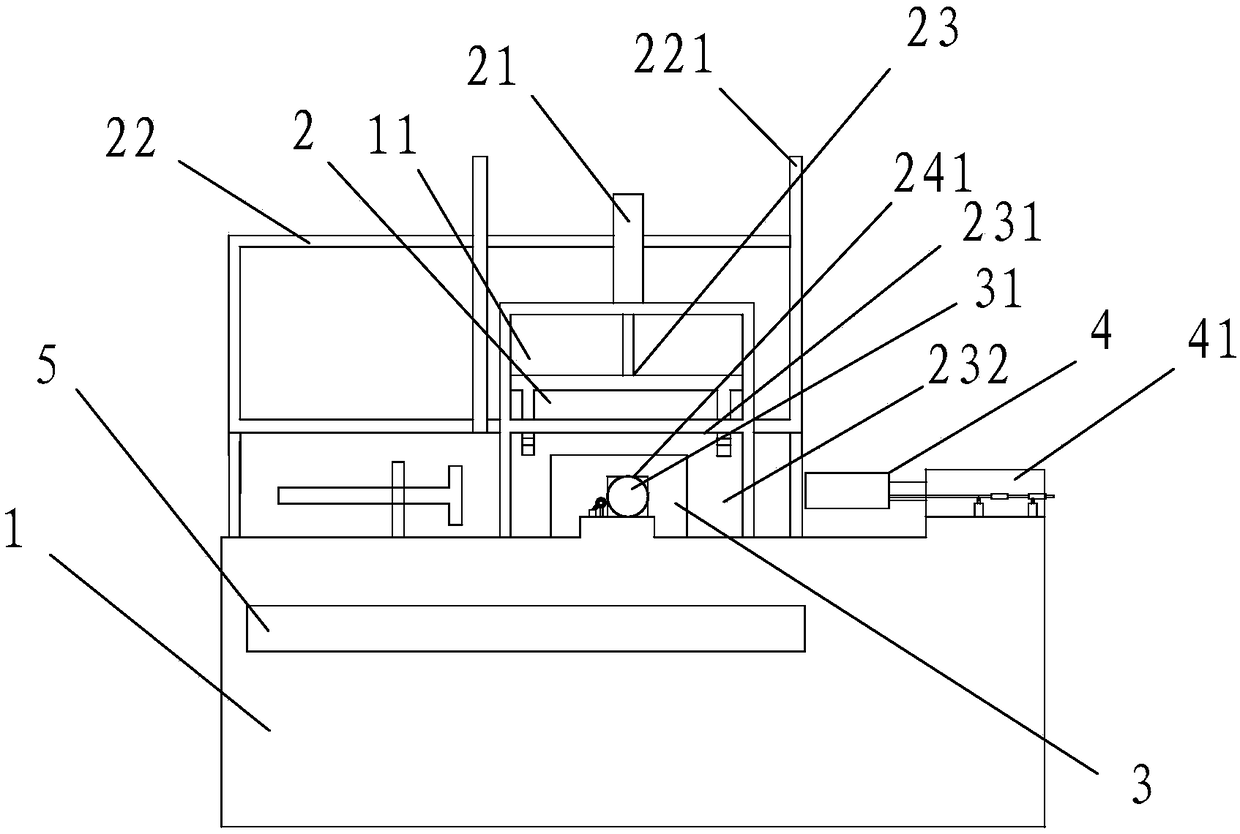

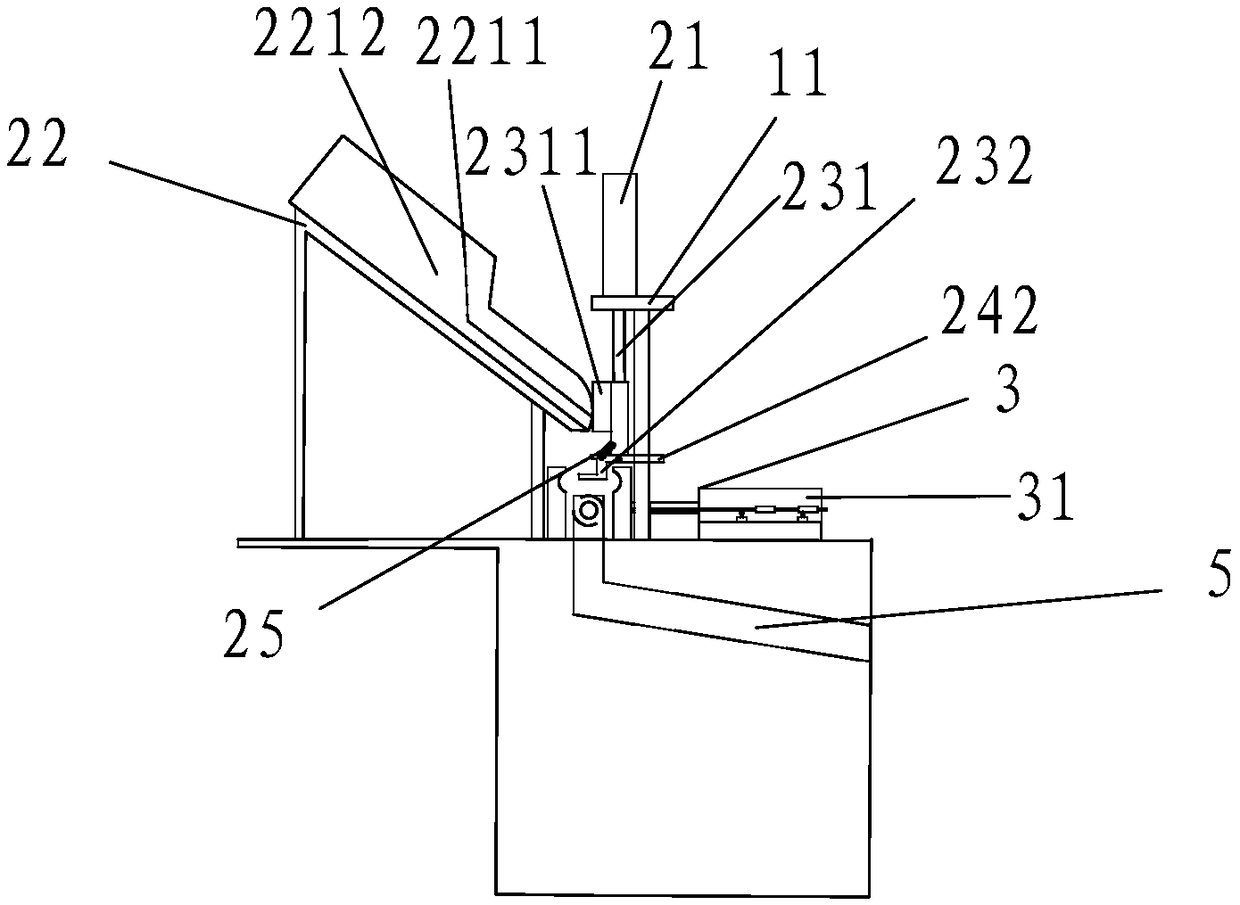

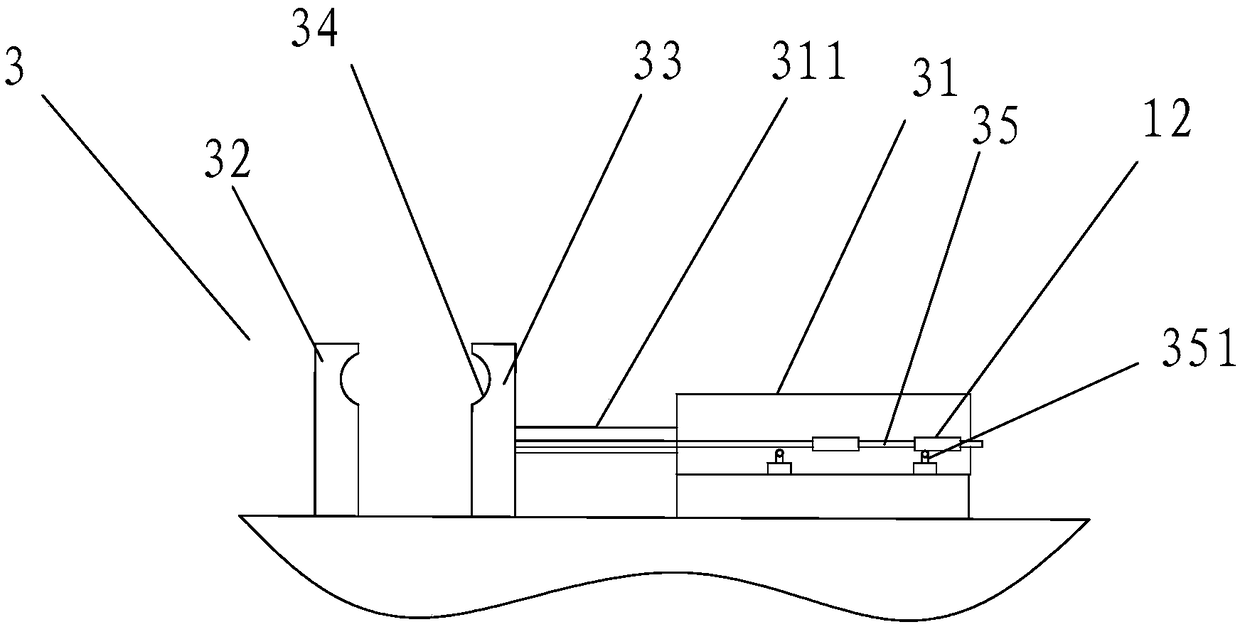

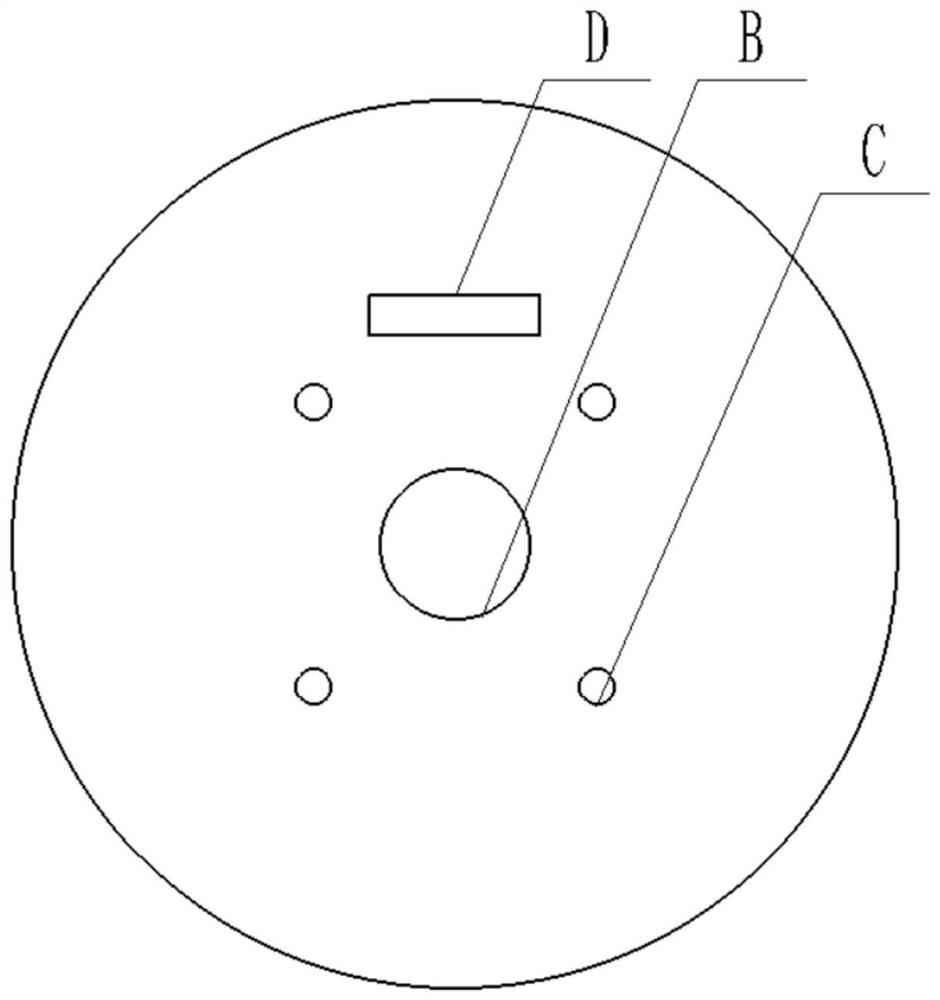

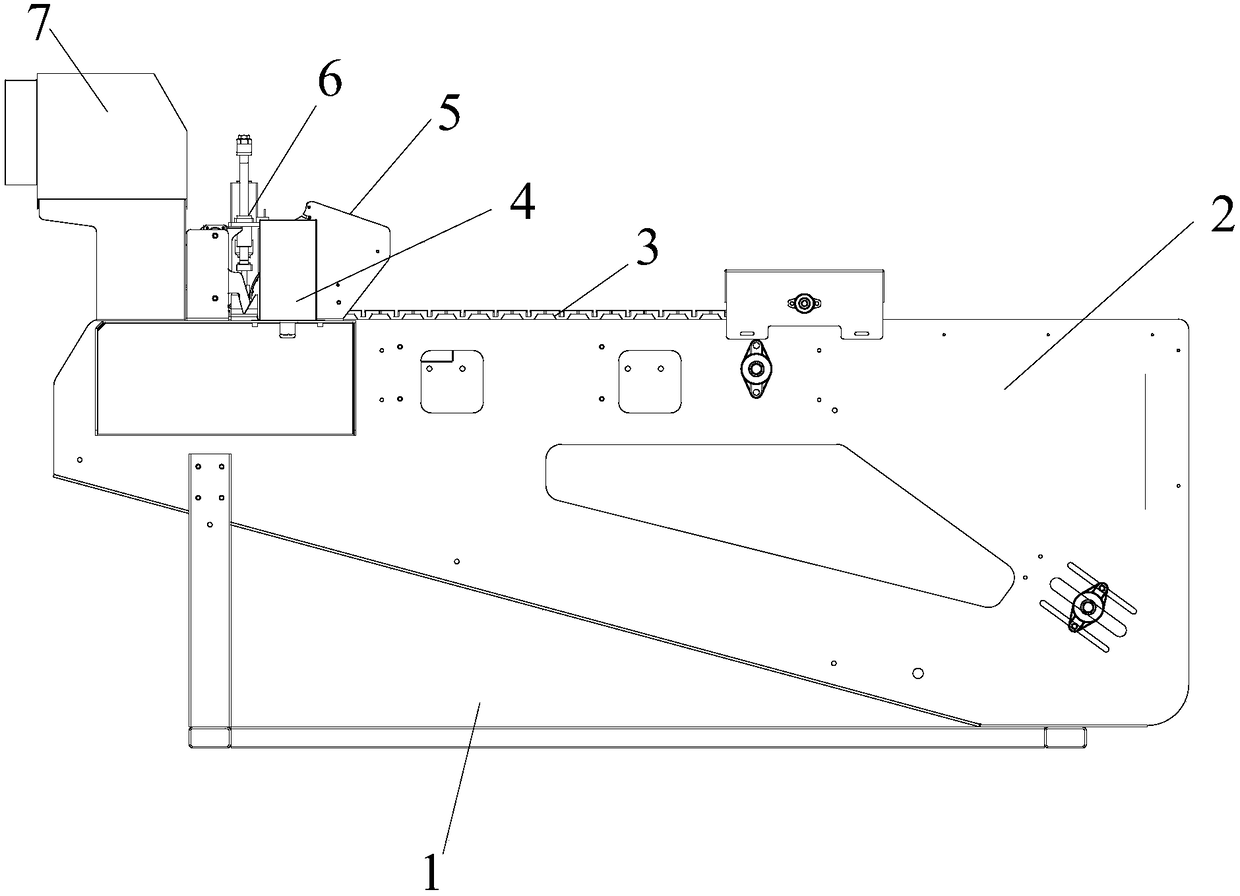

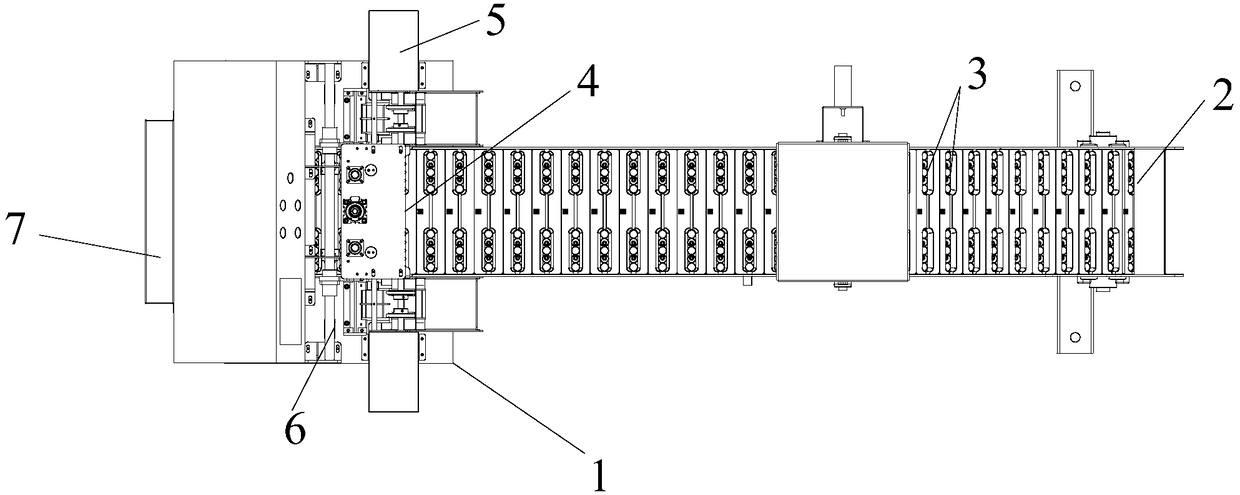

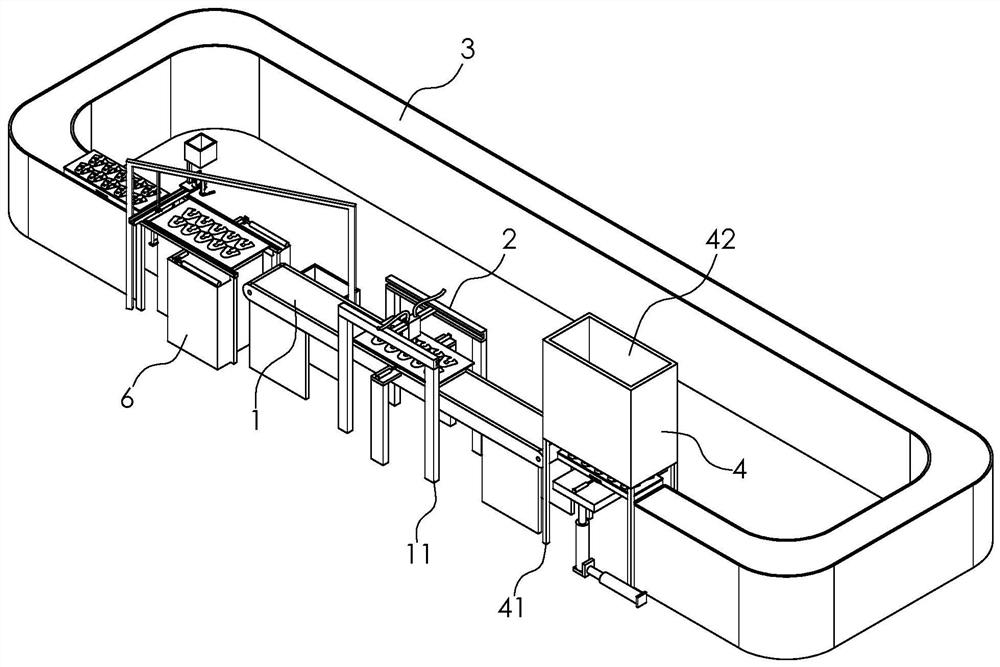

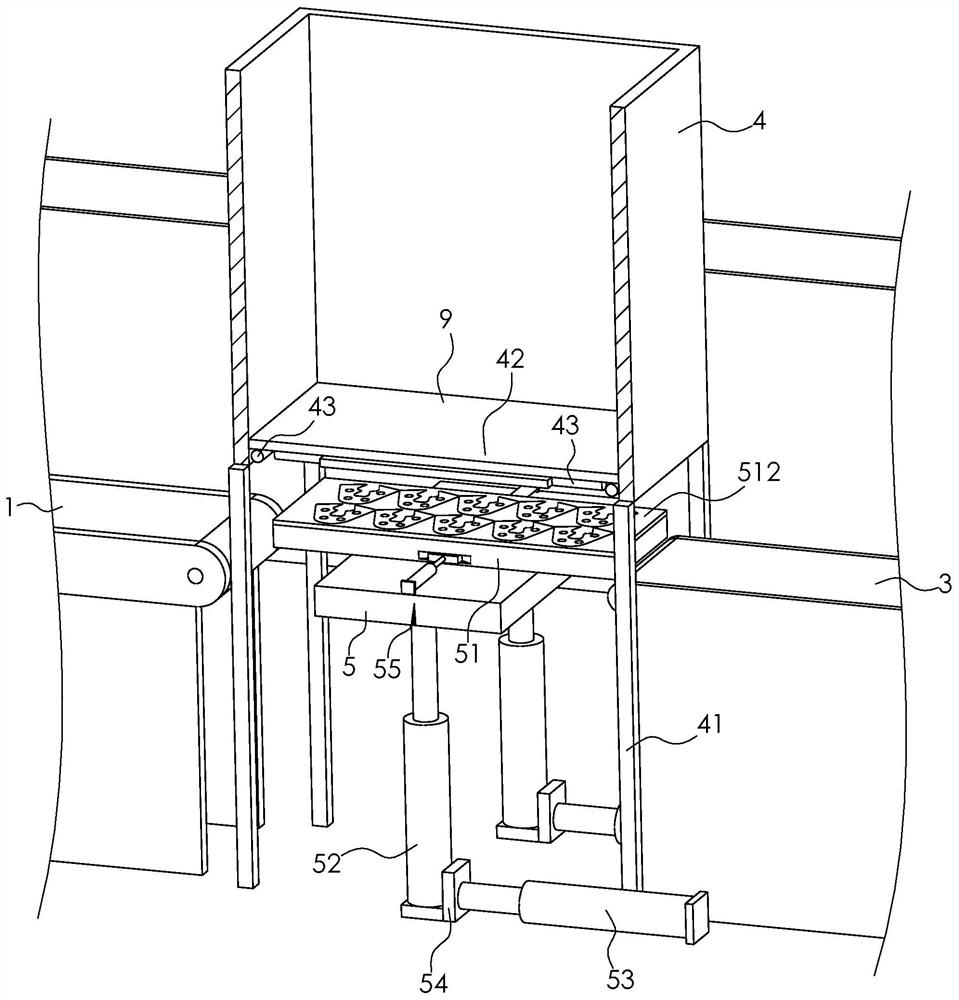

A fully automatic marking production line for diamond saw blades

InactiveCN110039908BRealize fully automatic loading and unloadingImplement automatic connectionTypewritersManufacturing lineIndustrial engineering

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Bucket type automatic feeding threading machine

ActiveCN105559123BGood effectRealize fully automatic loading and unloadingFood shapingMotor driveEngineering

The invention relates to the technical field of stick bunching machines, in particular to a hopper automatic charging stick bunching machine, comprising a main rack; an automatic charging mechanism, a lower die, an upper die, a bamboo stick mechanism, a stick bunching mechanism and an electric control box are arranged on the main rack; the automatic charging mechanism comprises a hopper, a conveyor belt and a material poking mechanism; the conveyor belt obliquely upwards penetrates through the hopper, is fixedly provided with the lower die, and driven by a conveying motor; the material poking mechanism is arranged above the lower die; the conveying motor drives the conveyor belt to obliquely upwards move; materials are automatically charged into the lower die; the material poking mechanism pokes excessive materials; the materials in the lower die are conveyed to be below the upper die; the bamboo stick mechanism takes a bamboo stick out and places in a V-shaped slot of the stick bunching mechanism for preparing for stick bunching; the upper die presses the materials down to gather and press the materials; the stick bunching mechanism bunches the bamboo stick into the materials, then the upper die is released, the conveyor belt continues to move forward, and the bunched materials are automatically discharged. Full automatic charging and discharging are realized; the effect is good; the stability is high and the efficiency is high.

Owner:CLOUDFOCUS DONGGUAN AUTOMATION EQUIP CO LTD

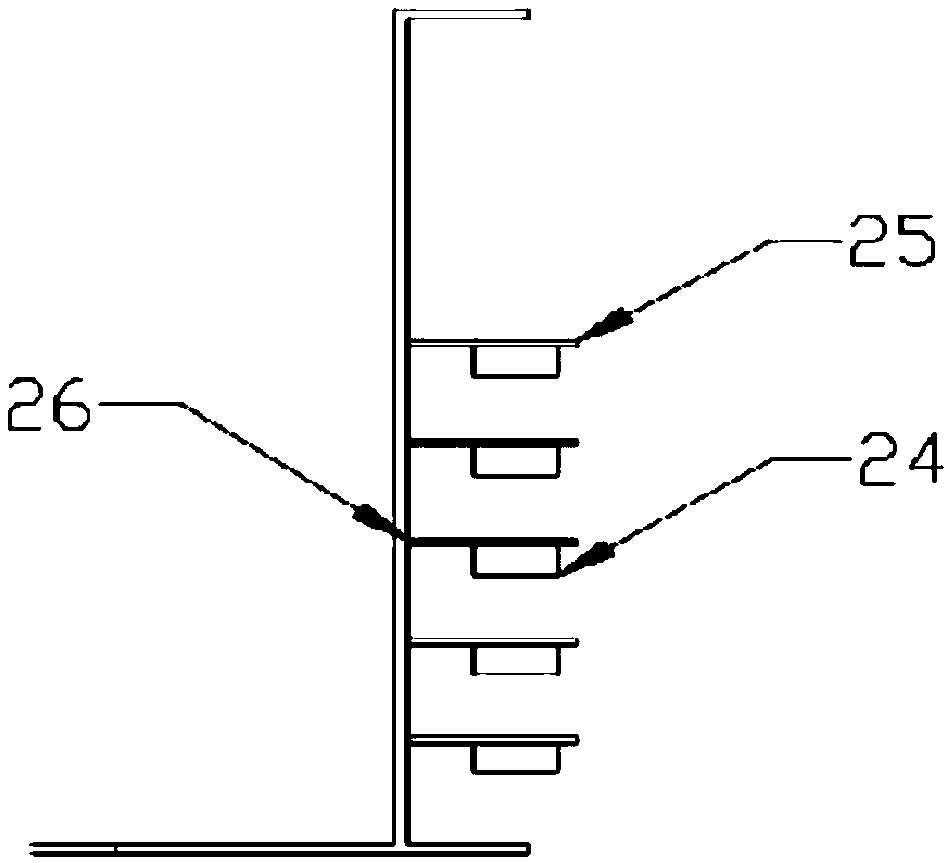

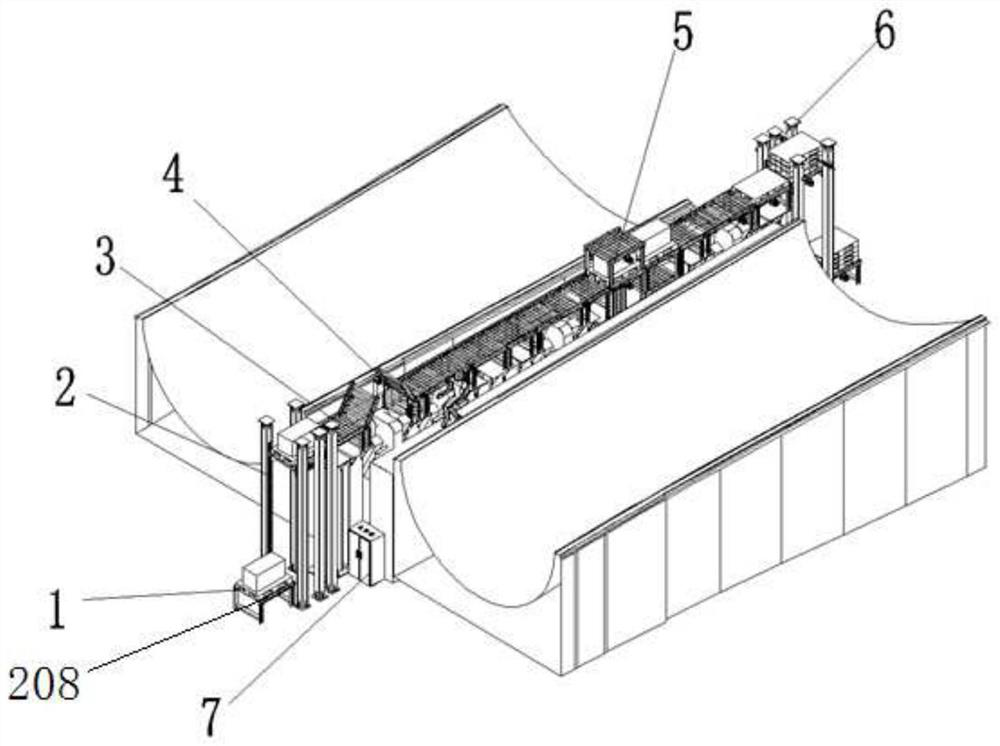

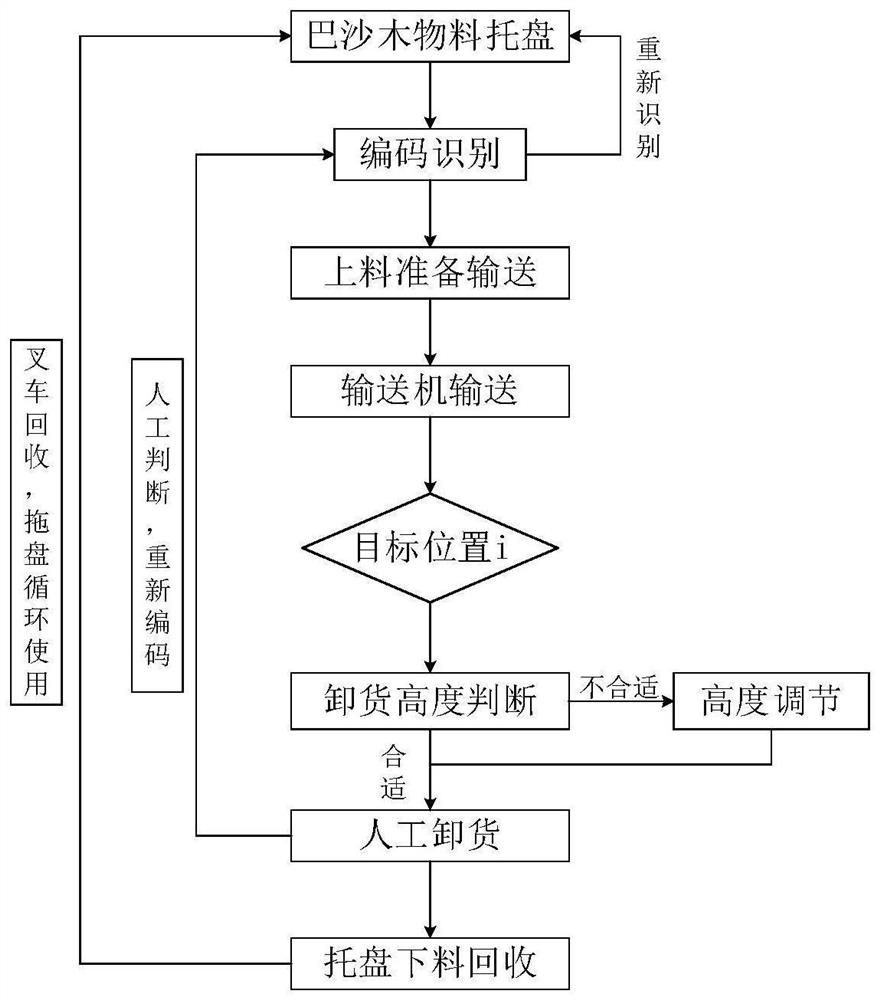

Automatic conveying and sorting mechanism of wind power blade balsa wood and its application

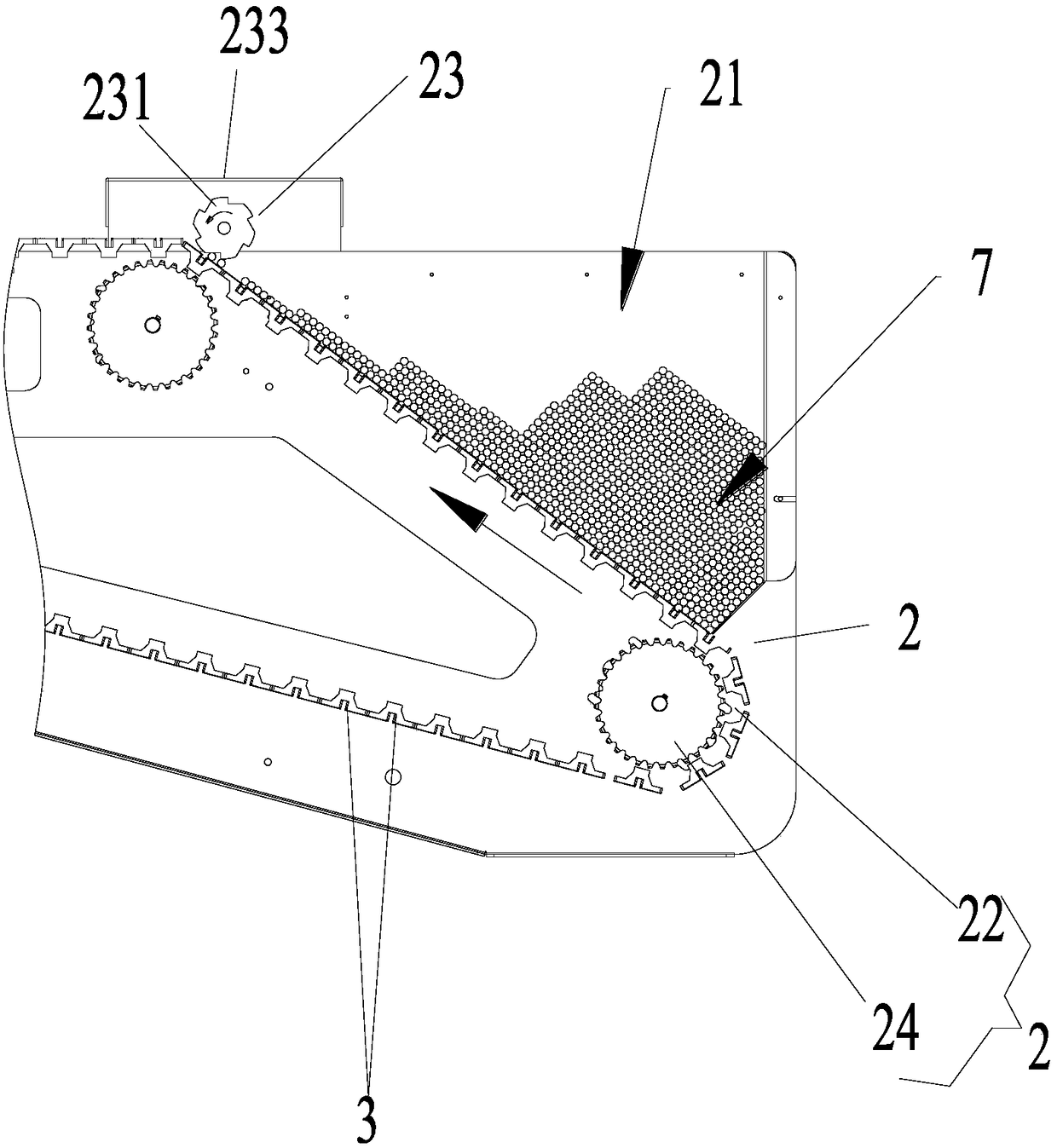

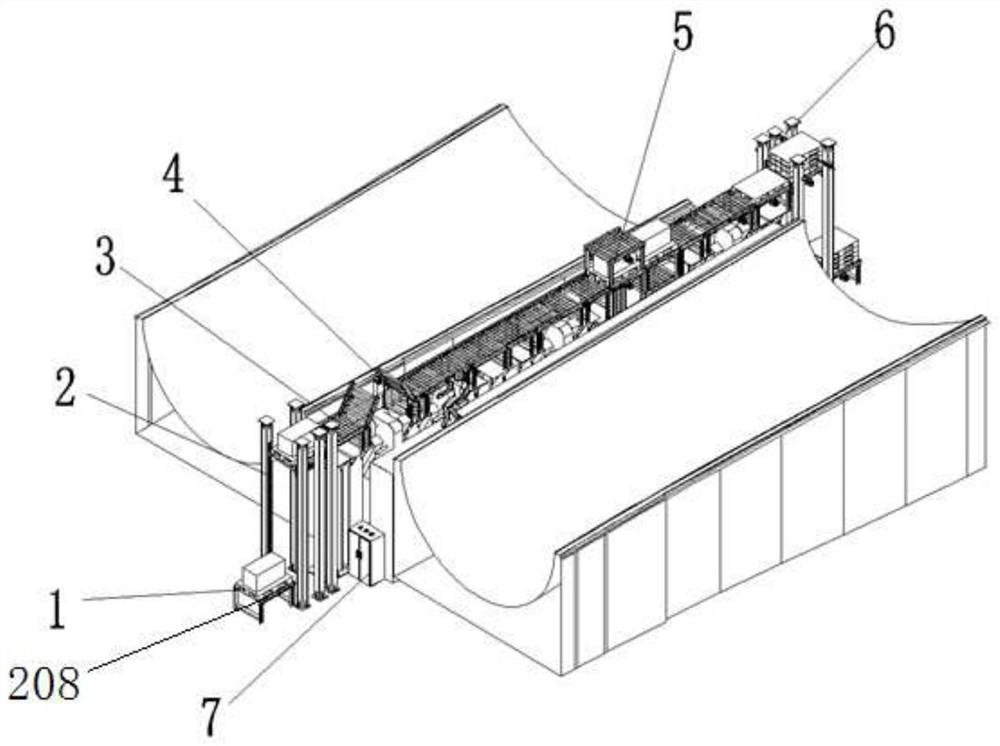

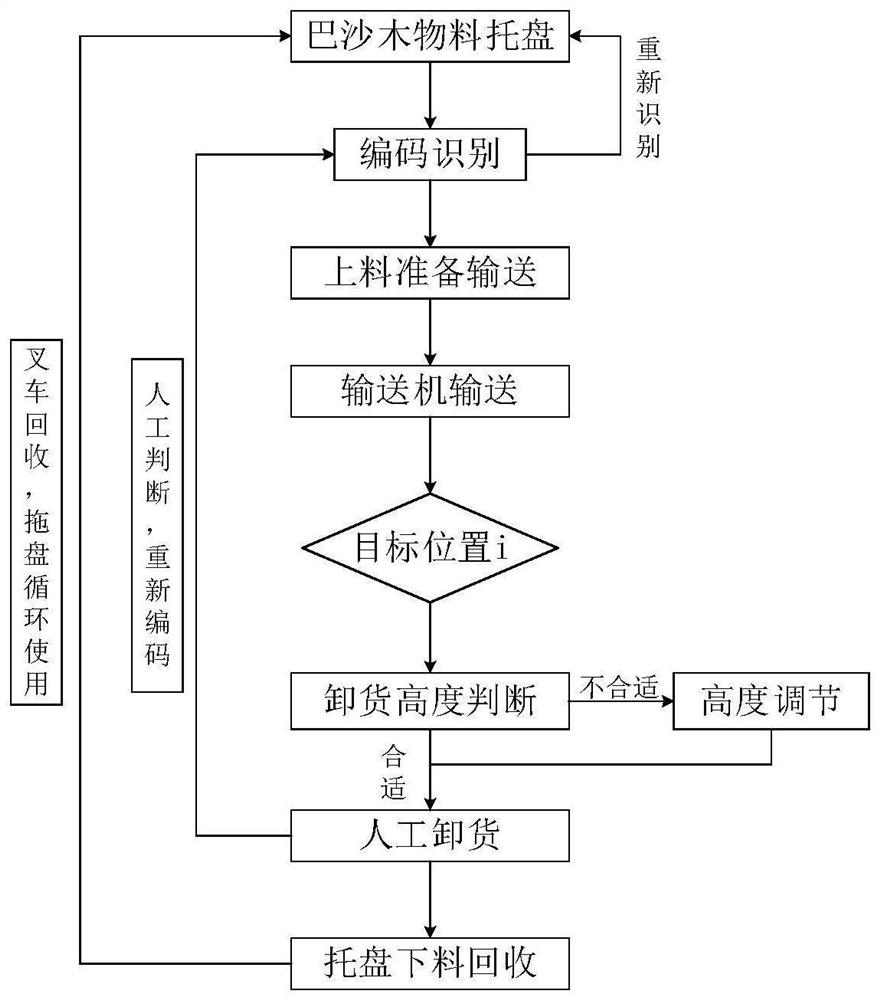

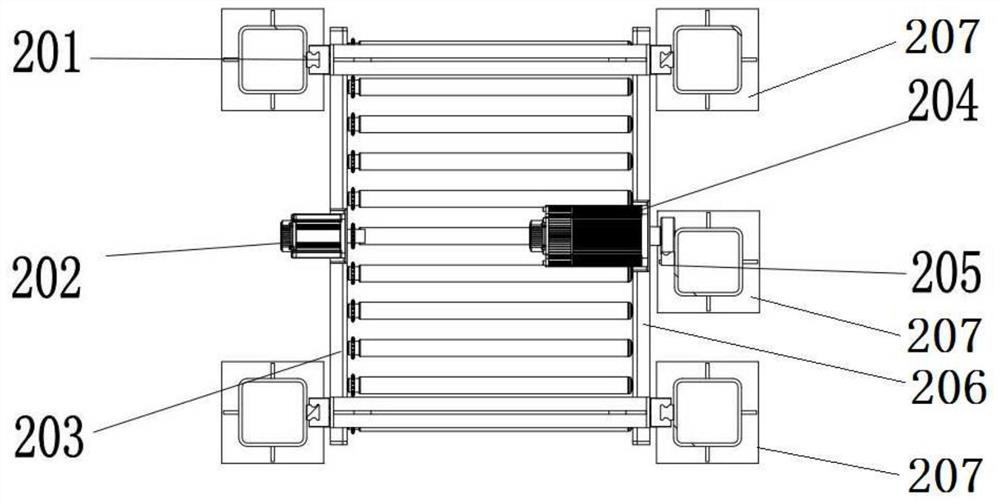

ActiveCN112938443BRealize fully automatic loading and unloadingImprove the working environment on siteEnergy industryControl devices for conveyorsProcess engineeringMechanical engineering

The invention discloses an automatic conveying and sorting mechanism for wind power blade balsa wood and its application. The mechanism comprises an automatic spreading and avoiding device, a conveyor unit and an automatic conveyor lifting unit connected in sequence, and the automatic conveyor lifting unit is connected in sequence. It is connected with the automatic unloading mechanism, and the automatic support and avoidance device is connected with the automatic feeding mechanism. The automatic feeding mechanism is provided with a code identifier. This device not only solves the automatic loading and unloading process of balsa wood at the head and tail ends of the mold and the mold turning process. The problem of mechanical interference in the blade production process is realized, and the fully automatic conveying and sorting of balsa wood in the blade production process is realized. The whole process does not require human intervention, which solves the problems of labor consumption, low efficiency and chaotic management in the process of balsa transportation, and greatly improves the transportation and distribution efficiency of balsa in the blade production process.

Owner:GURIT TOOLING (TAICANG) CO LTD

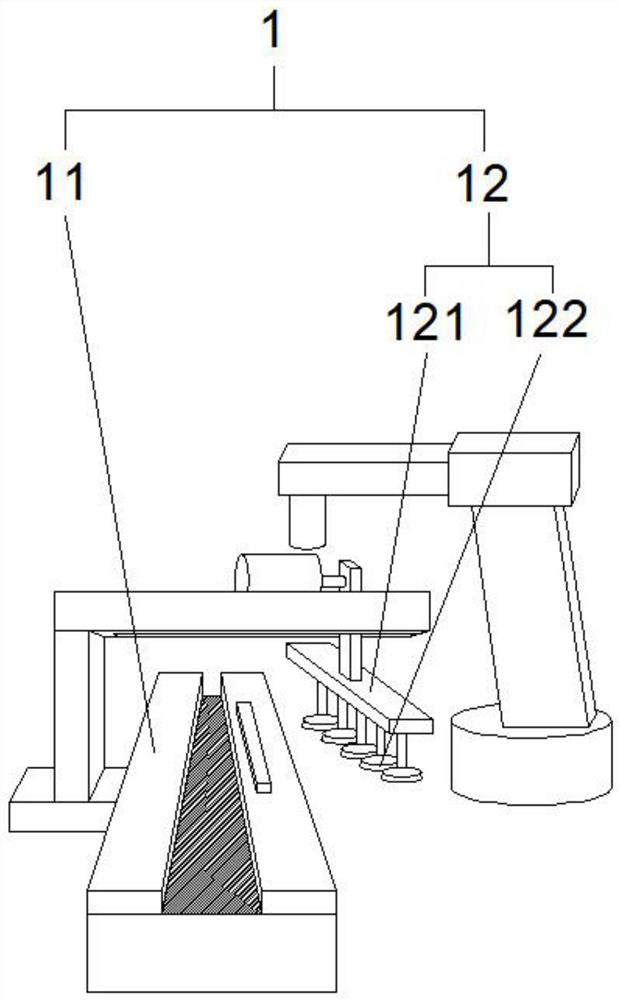

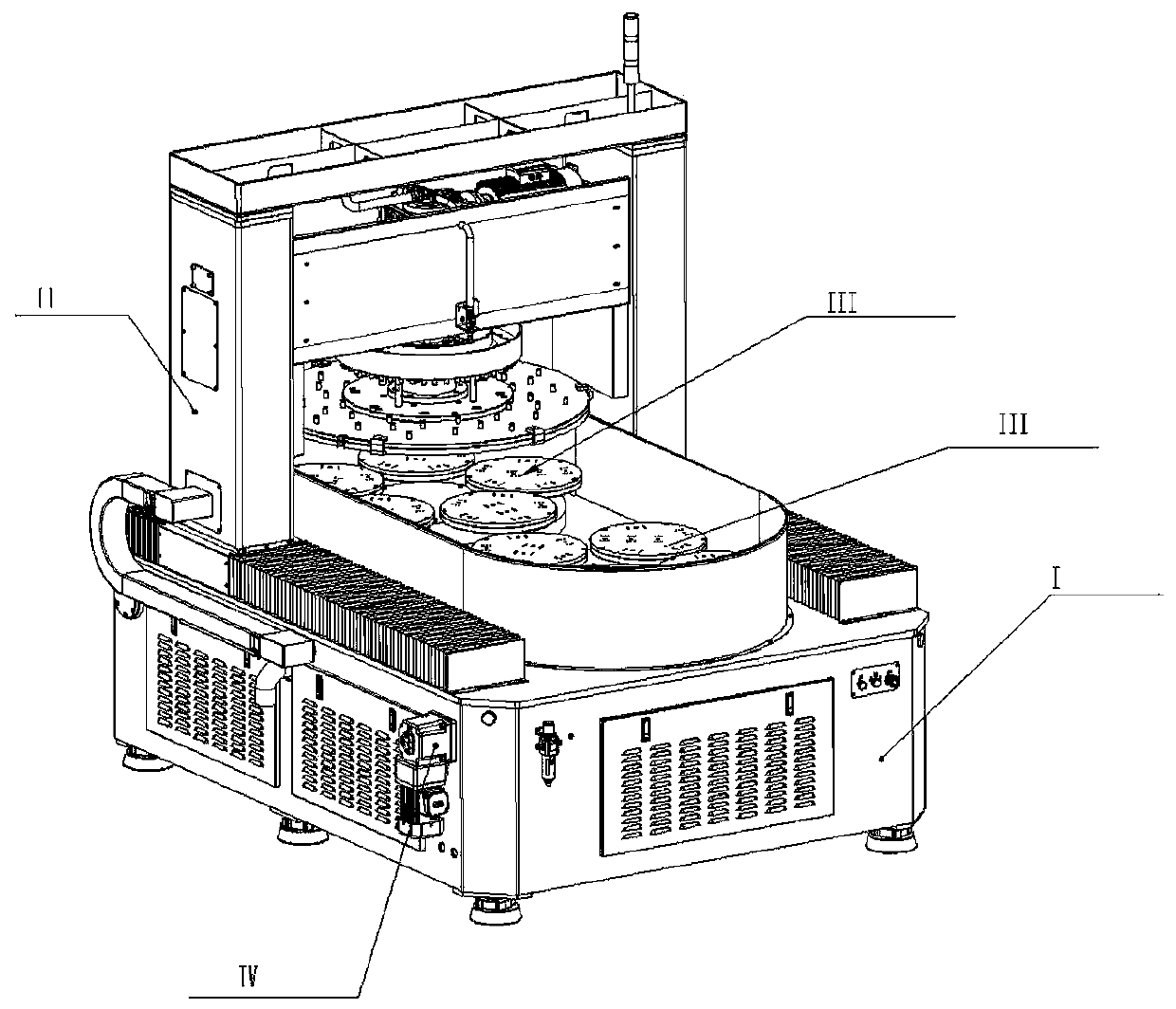

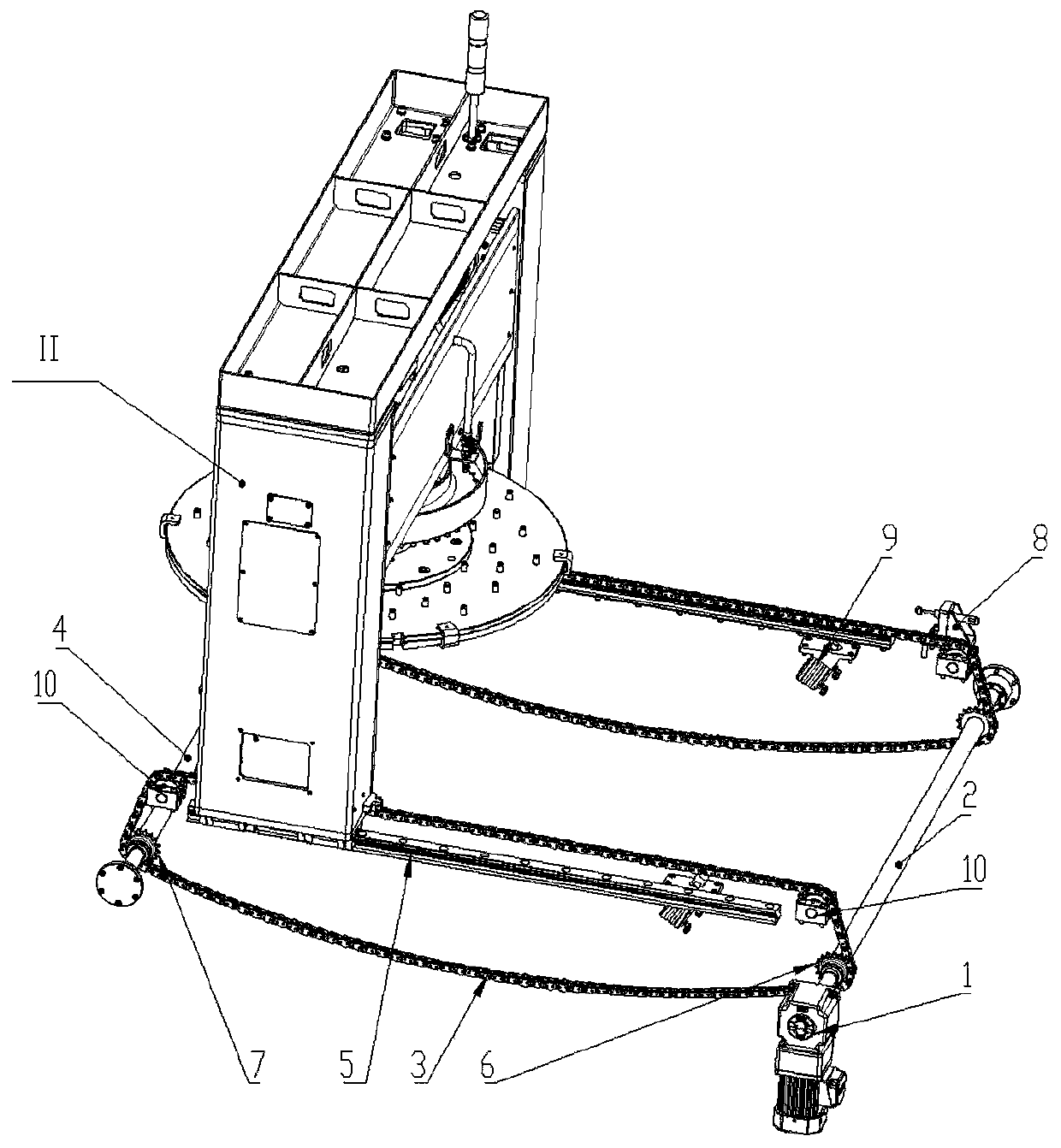

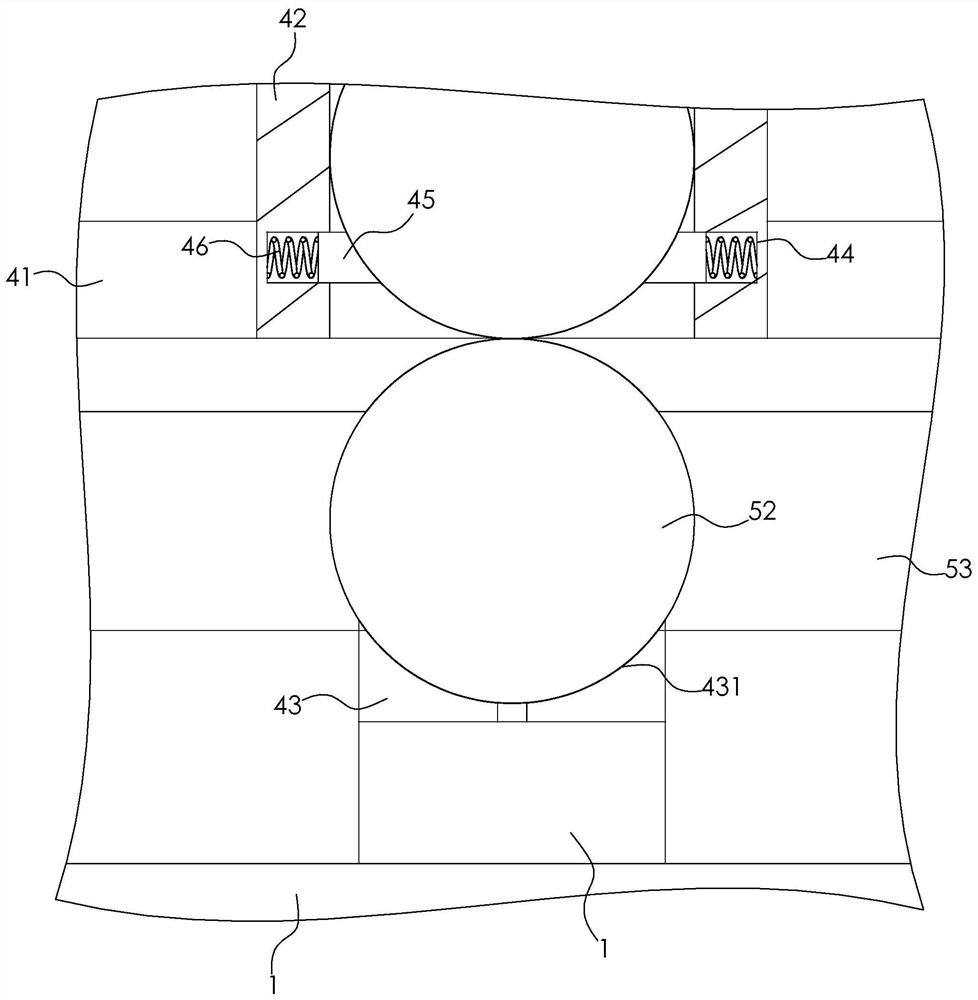

Double-station polishing machine and operating method thereof

PendingCN110814994ARealize fully automatic loading and unloadingPolishing machinesGrinding drivesElectric machineReciprocating motion

The invention discloses a double-station polishing machine and an operating method thereof. When polishing is performed at one station, sheet arrangement can be performed at the other station, so thatcontinuous polishing operation without shutdown is realized, and additionally, full-automatic feed and discharge are realized. The double-station polishing machine comprises a box body component (I),a hanging wall device (II), a main driving system (III) and a reciprocating driving system (IV), wherein a hanging wall of the hanging wall device is driven to rotate by a motor and is lifted and pressurized by virtue of an air cylinder, the main driving system is arranged in the box body component, the main driving system comprises a first station and a second station, workpiece trays are respectively arranged at each station, workpieces are driven to rotate and revolute by the workpiece trays, and the hanging wall device is driven to reciprocate between the first station and the second station by the reciprocating driving system.

Owner:湖南金岭机床科技集团有限公司

A high-precision and high-efficiency automatic cutting mechanism

ActiveCN111268462BRealize automatic feeding processRealize automatic material preparationConveyorsSevering textilesEngineeringStructural engineering

The invention relates to a high-precision and high-efficiency automatic cutting mechanism, which includes a first conveyor belt and a cutting device. The input end of the first conveyor belt is provided with a material box fixed on the ground through a column, a mounting frame, a lifting piece and a driving piece. The bottom of the material box is provided with a first opening and a plurality of first blocking rods, an adhesive plate and a first locking assembly are arranged on the mounting frame, a first adhesive layer is provided on the upper surface of the adhesive plate; There is a platform, a second locking assembly, a first separation device, a waste bin, a second separation device and a collection bin. During the processing of the shoe upper, the pasting board pastes the fabrics in the material box, and then the first conveyor belt will transport the pasting board to the cutting device. After the material cutting is completed, the pasting board will be transported to the platform, the first separation device will make the waste fall into the waste box, and the second separation device will make the upper fall into the collection box. The invention improves the processing efficiency and cutting precision of the vamp.

Owner:HANGZHOU AFU CHILDREN ARTICLES

A high-efficiency drilling device

ActiveCN111299637BImprove drilling efficiencyRealize fully automatic loading and unloadingPositioning apparatusMetal working apparatusEngineeringWorkbench

Owner:杭州顺钢机械有限公司

Turret punch press system based on two-arm robot

InactiveCN109865758ARealize fully automatic loading and unloadingGuaranteed continuous operationMetal-working feeding devicesPositioning devicesEngineeringMetal sheet

The invention relates to the field of metal sheet machining, in particular to a turret punch press system based on a two-arm robot. The turret punch press system comprises the two-arm robot, a turretnumerical-control punch press, material tables and a robot rotating and locating mechanism, wherein the two-arm robot, the material tables and the robot rotating and locating mechanism are arranged onthe sheet input side of the turret numerical-control punch press; the material tables are correspondingly arranged on the two sides of the two-arm robot; end picking devices are arranged at the mechanical arm free ends of the two sides of the two-arm robot; and the two-arm robot drives, rotates and locates through the robot rotating and locating mechanism. Full-automatic feeding and blanking of the turret numerical-control punch press are achieved by utilizing the two-arm robot, and continuous operation is ensured, so that the production efficiency is improved substantially.

Owner:沈阳自动化研究所(昆山)智能装备研究院 +1

An intelligent triple geotechnical triaxial instrument for constant load loading or unloading

ActiveCN106644745BSolve Load FluctuationsSimple structureMaterial strength using tensile/compressive forcesElectricityAxial pressure

The invention discloses a constant load loading or unloading intelligent triplex geotechnical triaxial apparatus. The constant load loading or unloading intelligent triplex geotechnical triaxial apparatus comprises an axial loading system, a feedback automatic confining pressure control system, and an automatic mobile and control system of an industrial camera for measuring deformation of a soil sample, and is suitable for a triaxial pressure chamber for measuring deformation digital image of the soil sample. The triaxial apparatus uses a counterweight for gradually applying constant vertical load, triaxial tests of three soil samples can be carried out simultaneously, triaxial tests of same confining pressure and different axial pressures / different confining pressures and same axial pressure / different confining pressures and different axial pressures can be completed at one time, counterweight loading enables automation, the automatic confining pressure control system and the soil sample deformation digital image measurement system are integrated. The axial loading employs the counterweight and a lever for loading, which solves the problems of load fluctuation generated due to motor loading and reduced service life due to continuous positive and negative rotation of the motor. a RC circuit is employed for control of switching on or off electricity on an electromagnet, and automatic loading and unloading of the counterweight can be realized.

Owner:DALIAN UNIV OF TECH

Automatic conveying and classifying mechanism for balsa wood of wind power blade and application of automatic conveying and classifying mechanism

ActiveCN112938443ARealize fully automatic loading and unloadingImprove the working environment on siteEnergy industryControl devices for conveyorsProcess engineeringMechanical engineering

The invention discloses an automatic conveying and classifying mechanism for balsa wood of a wind power blade and application of the automatic conveying and classifying mechanism. The mechanism comprises an automatic opening and avoiding device, a conveyor unit and a conveyor automatic lifting unit, all of which are connected in sequence. The conveyor conveyor lifting unit is connected with an automatic discharging mechanism, the automatic opening and avoiding device is connected with an automatic feeding mechanism, and a code recognizer is arranged on the automatic feeding mechanism. The mechanism not only solves the problem of mechanical interference in the processes of automatic feeding and discharging of the balsa wood at the head end and the tail end of a die and overturning of the die, but also realizes full-automatic conveying and classification of the balsa wood in the blade production process. The whole process does not need human intervention, the problems of manpower consumption, low efficiency and disordered management in the balsa wood conveying process are solved, and the conveying and distributing efficiency of the balsa wood in the blade production process is greatly improved.

Owner:GURIT TOOLING (TAICANG) CO LTD

AGV trolley used to carry flower baskets in the production process of solar cells

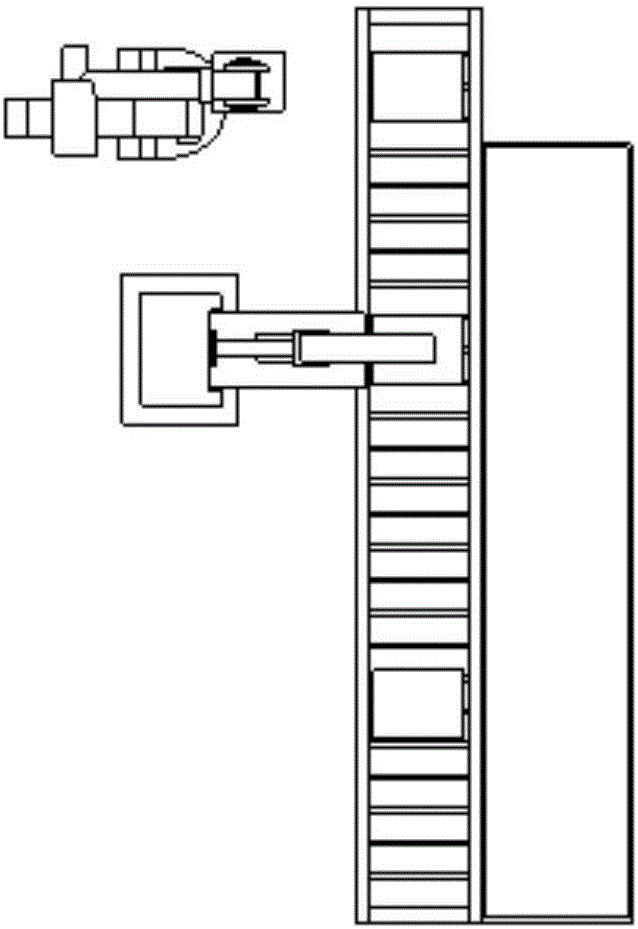

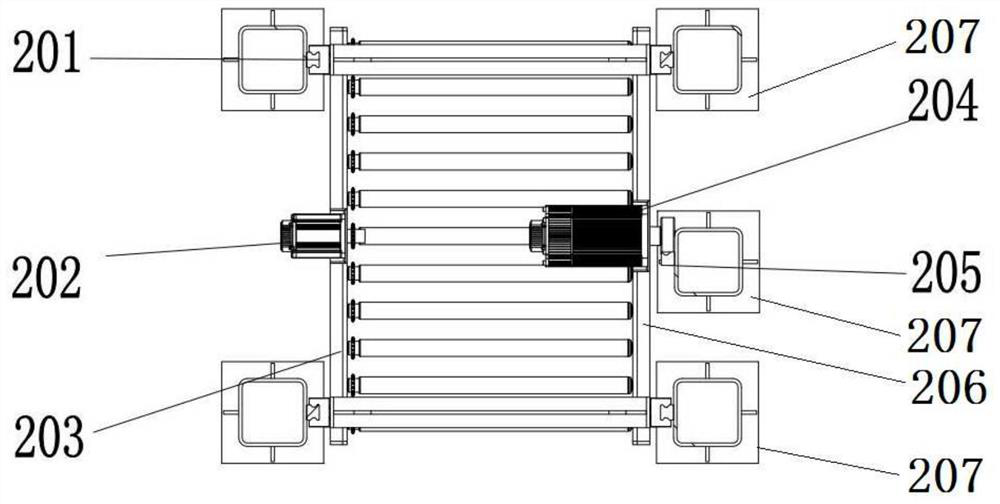

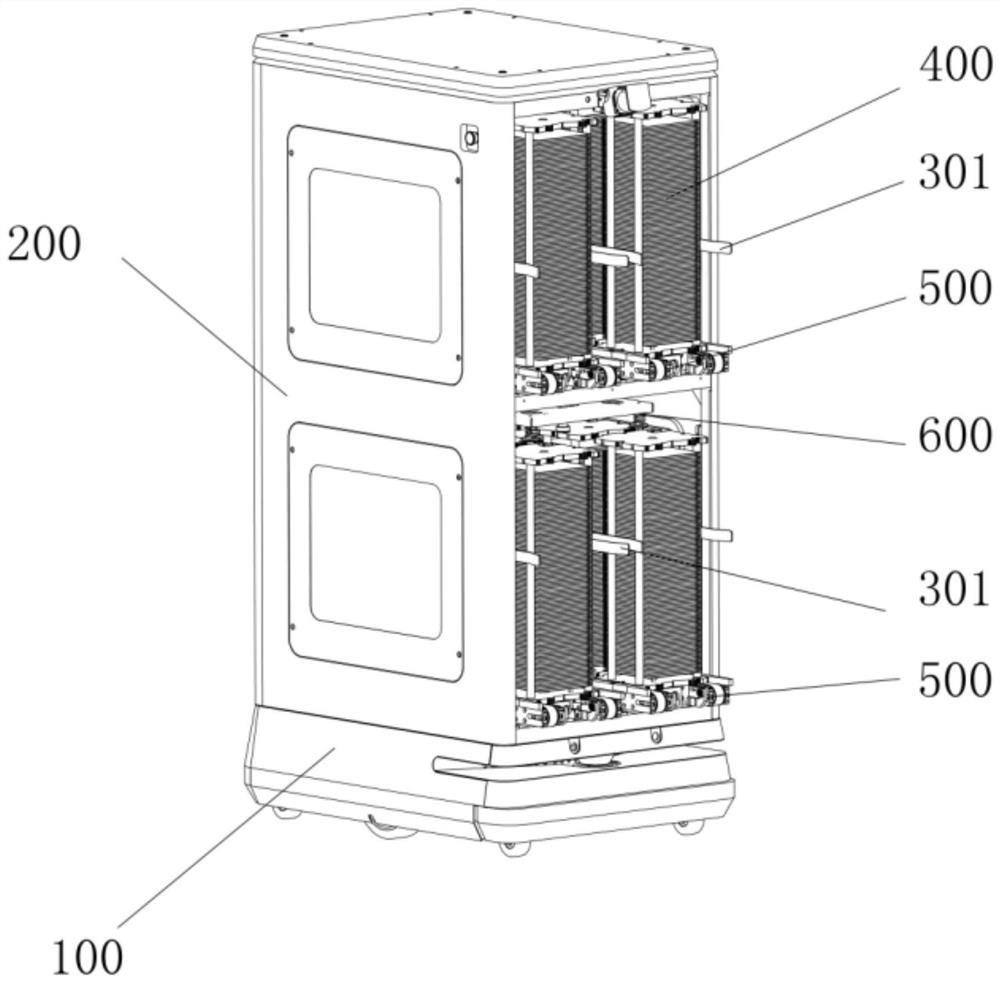

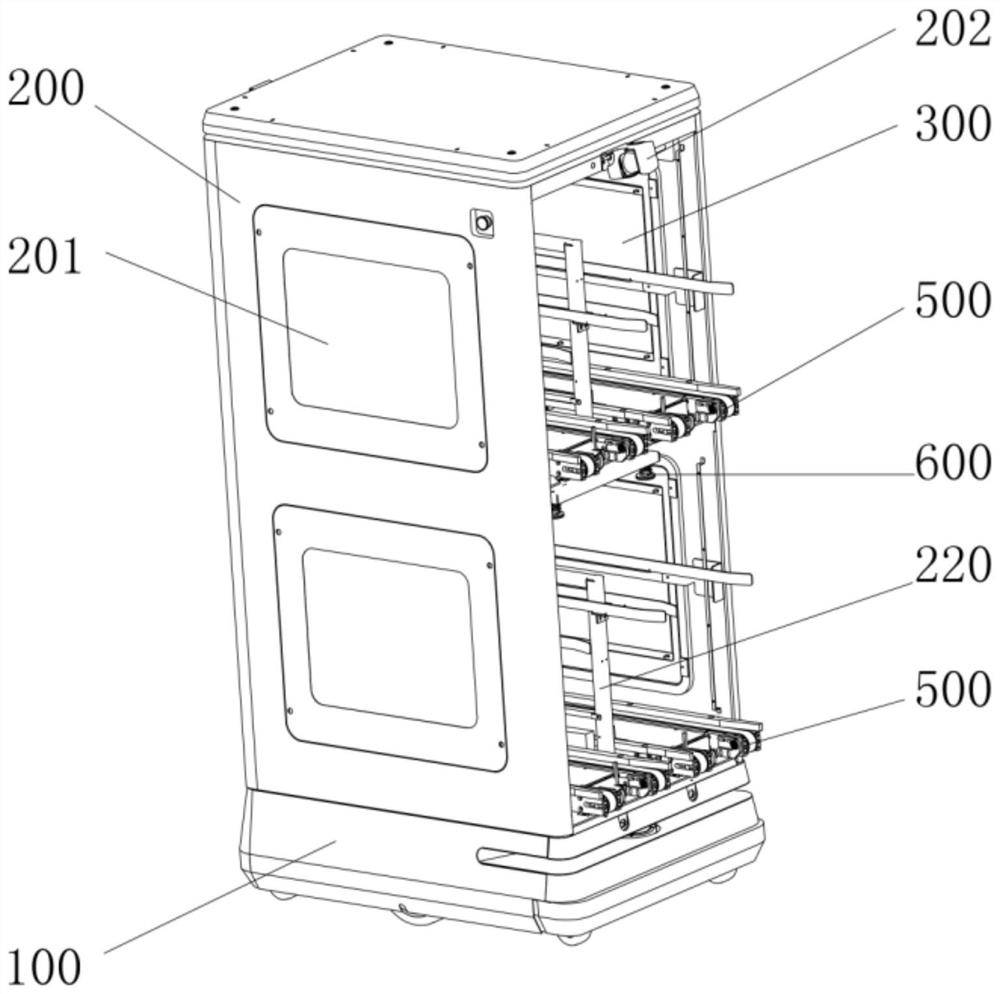

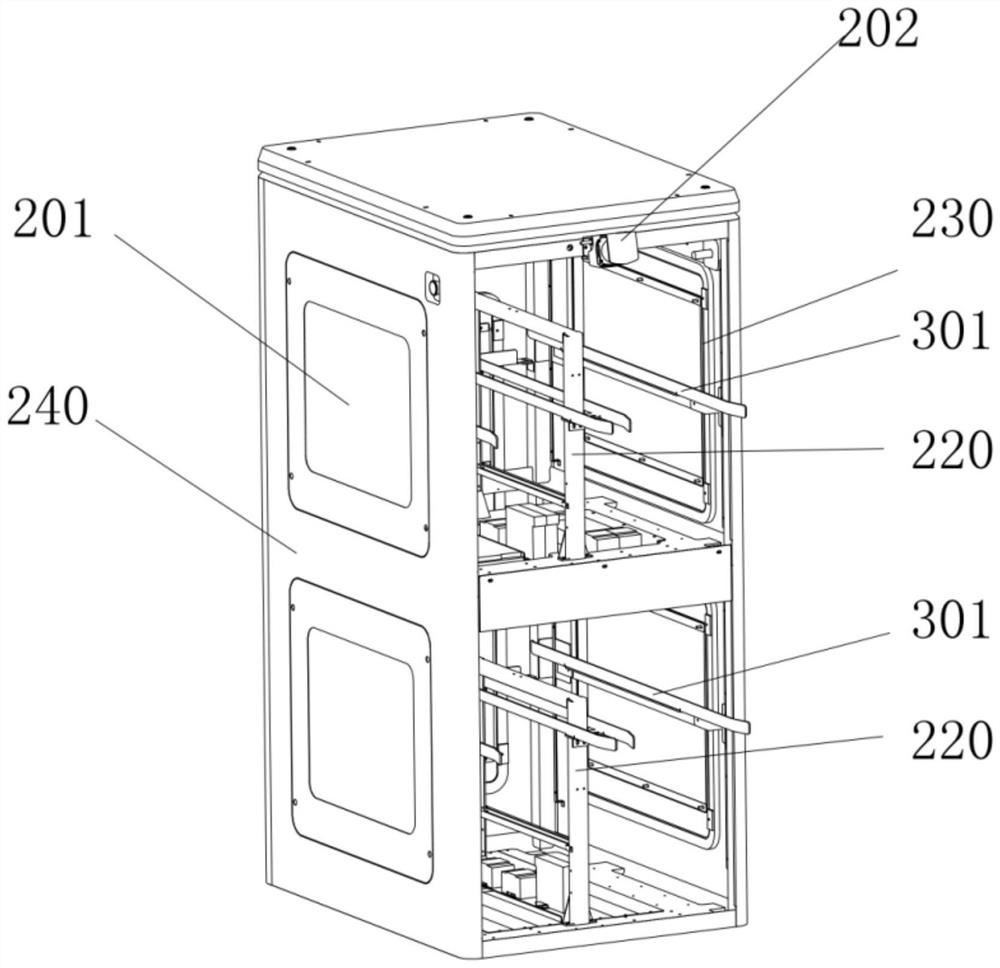

ActiveCN109524340BRealize fully automatic loading and unloadingAffect production capacityFinal product manufactureSemiconductor/solid-state device manufacturingProduction lineSolar battery

The invention discloses an AGV for carrying flower basket boxes in a solar cell piece production process. The AGV comprises an AGV chassis with a laser navigation function and a main vehicle compartment arranged on the AGV chassis. The interior of the main vehicle compartment is divided into upper and lower layers. Each layer is provided with two storage areas side by side. Each storage area can store at least one flower basket box. The bottom of the storage area is provided with a conveying mechanism for conveying the flower basket box. At least one side of the main vehicle compartment is open. The entrance of each storage area is located at the open side of the main vehicle compartment. The main vehicle compartment is equipped with a signal transceiver unit. The AGV of the invention canautomatically load, unload and transfer the flower basket box, solves the problem that manual flower basket conveyance is high in labor intensity, low in production efficiency, high in fragmentation rate and likely to cause silicon wafer pollution, can realize complete automatic production of a solar cell production line, greatly improves work efficiency and product quality, reduces production cost to a great extent and improves economic efficiency.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com