Full-automatic ultrasonic washing device aiming at tandem pump body shells and pump covers

An ultrasonic cleaning and series pump technology, applied in the field of ultrasonic cleaning, can solve the problems of low equipment efficiency, high cost and high labor cost, and achieve the effect of improving work efficiency, ensuring cleaning effect and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

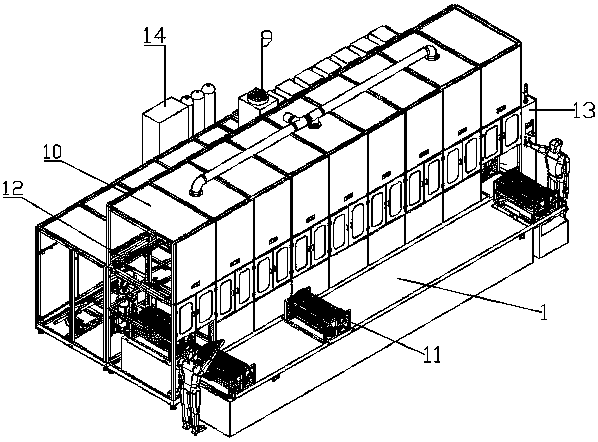

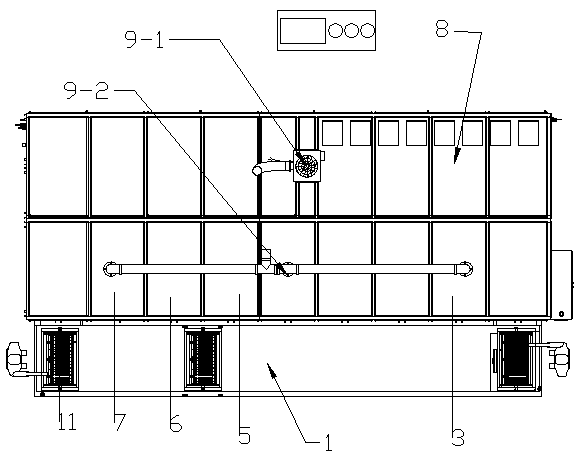

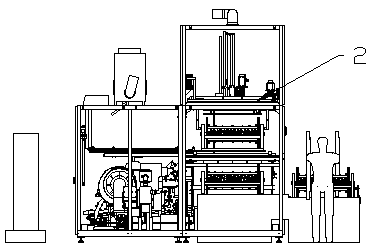

[0040] The accompanying drawing is a specific embodiment of the present invention for a fully automatic ultrasonic cleaning device for series pump casings and pump covers. This embodiment includes a tooling basket 11, a manipulator 2 installed on the top of the frame 10, and a functional mechanism installed on the bottom of the frame 10, wherein the functional mechanism includes several ultrasonic cleaning mechanisms 3, wind shearing mechanisms 5, and drying mechanisms 6 arranged in sequence. And the vacuum drying mechanism 7, the ultrasonic cleaning mechanism 3, the wind cutting mechanism 5 and the drying mechanism 6 are all equipped with a roller basket rotating mechanism 4, a return basket wire conveying mechanism 1 is installed on one side of the frame 10, and a row is installed above the frame 10. wind system9.

[0041] In this embodiment, the manipulator 2 includes a vertical motor 2-2 and a traversing motor 2-1 installed on the mounting plate 2-4, and both sides in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com