Full-automatic welding system

A fully automatic welding and pipe fitting welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of safety accidents, low welding quality reproducibility, low welding efficiency, etc., to improve efficiency and avoid labor Over-participating, highly reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

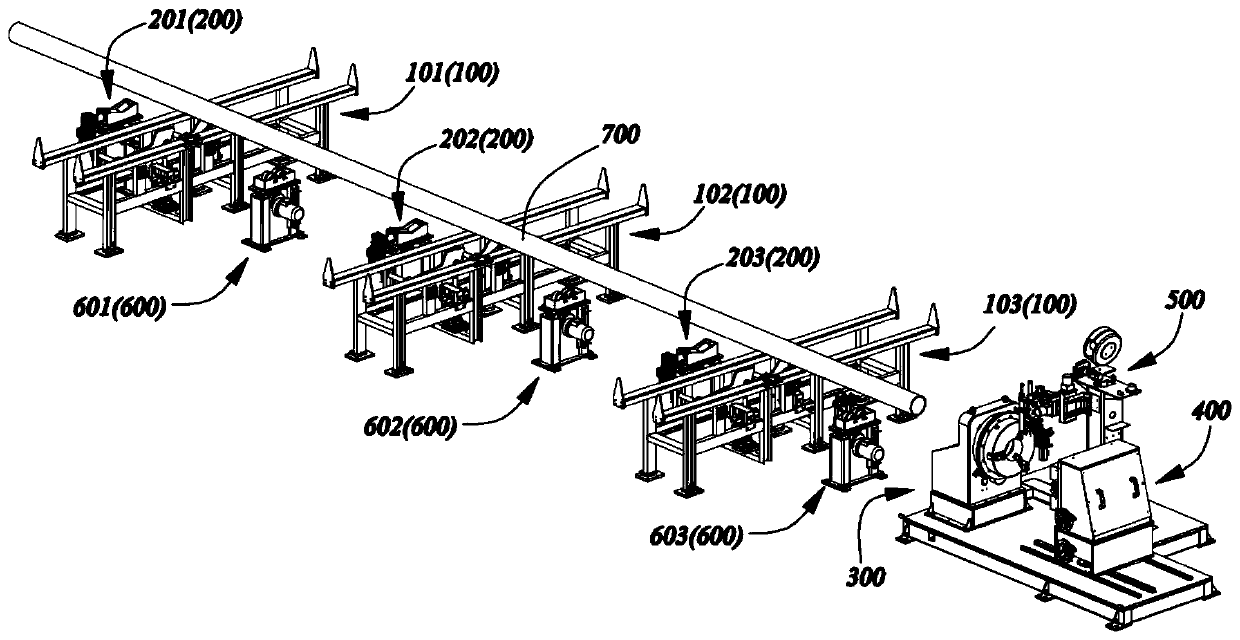

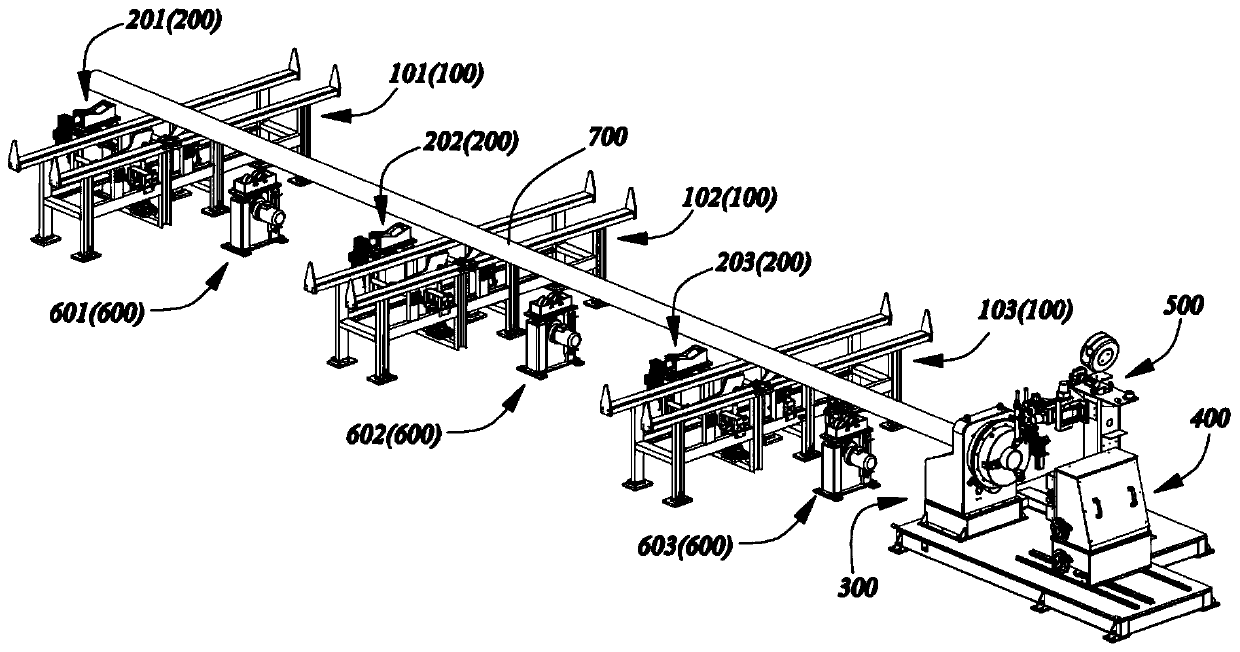

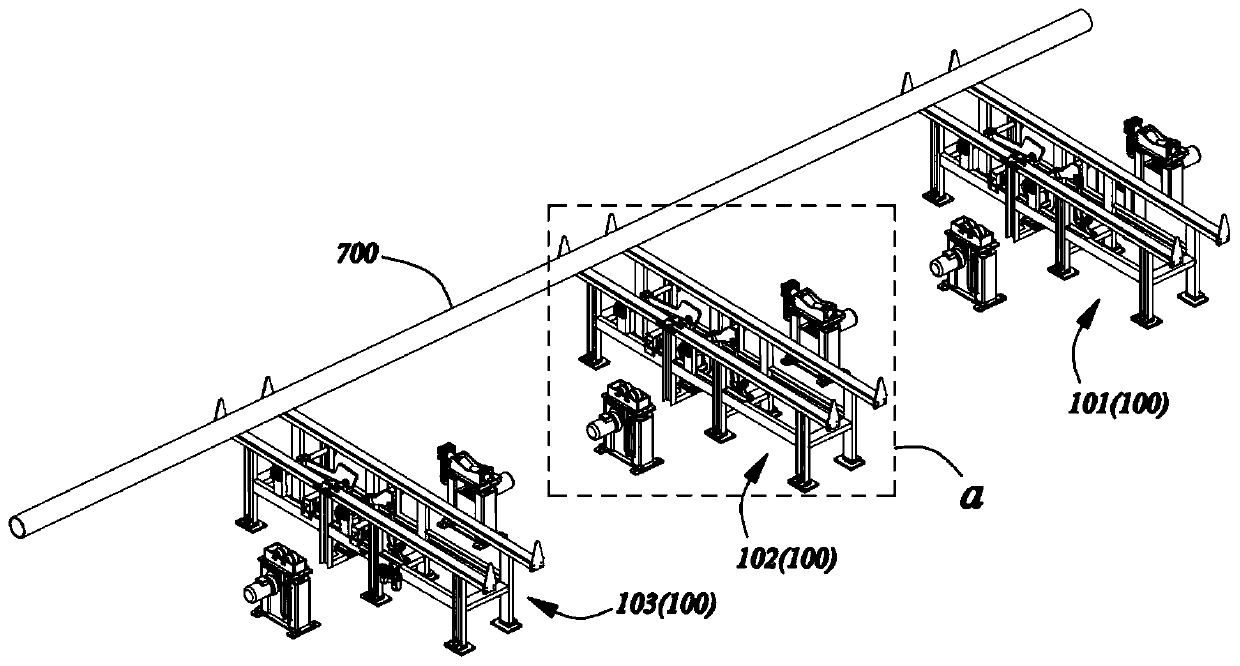

[0036] The present invention will be described in detail below in conjunction with each implementation structure shown in the accompanying drawings, please refer to Figure 1 to Figure 20 As shown, it is some preferred implementation structures of the present invention.

[0037] The fully automatic welding system involved in the present invention is used to weld the pipe fitting 800 to one end of the pipeline 700, combining Figure 18 , Figure 19 , Figure 20 As shown, the pipe fittings involved may be small and small heads 801, extended short pipes 802, embedded short pipes 803 or other types of parts that need to be welded to the end of the pipeline 700 to adapt to specific purposes, and details will not be described here. One unfolds. In the specific welding process, the weld B involved is usually a circular seam, and the circular seam can be Figure 18 Butt seams shown in, Figure 19 outside corner seams shown in, Figure 20 The inner corner seam shown in , can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com