AGV trolley used to carry flower baskets in the production process of solar cells

A technology of solar cells and production process, which is applied in the direction of circuits, electrical components, transportation and packaging, etc. It can solve the problems of affecting the layout of the workshop and the flow of people and logistics, occupying a large space, and poor flexibility, so as to improve work efficiency and product quality. , solve the effect of poor flexibility and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

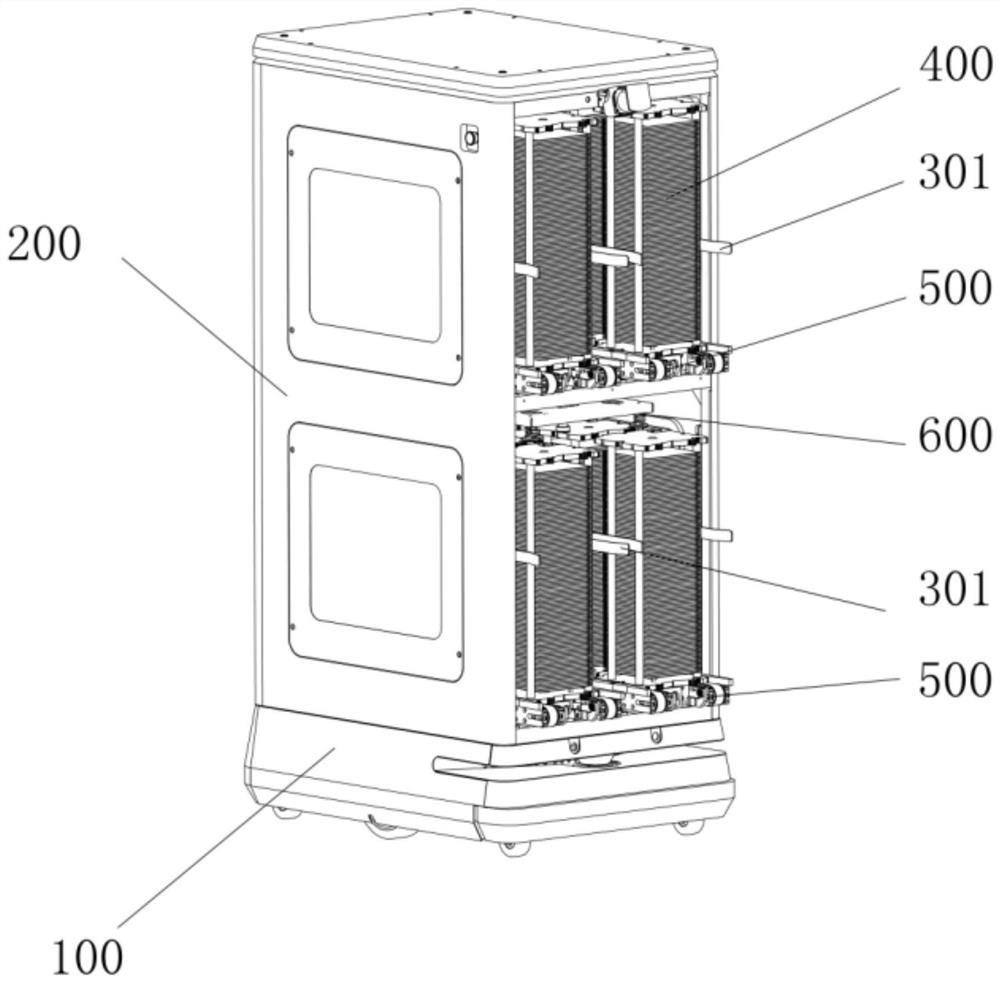

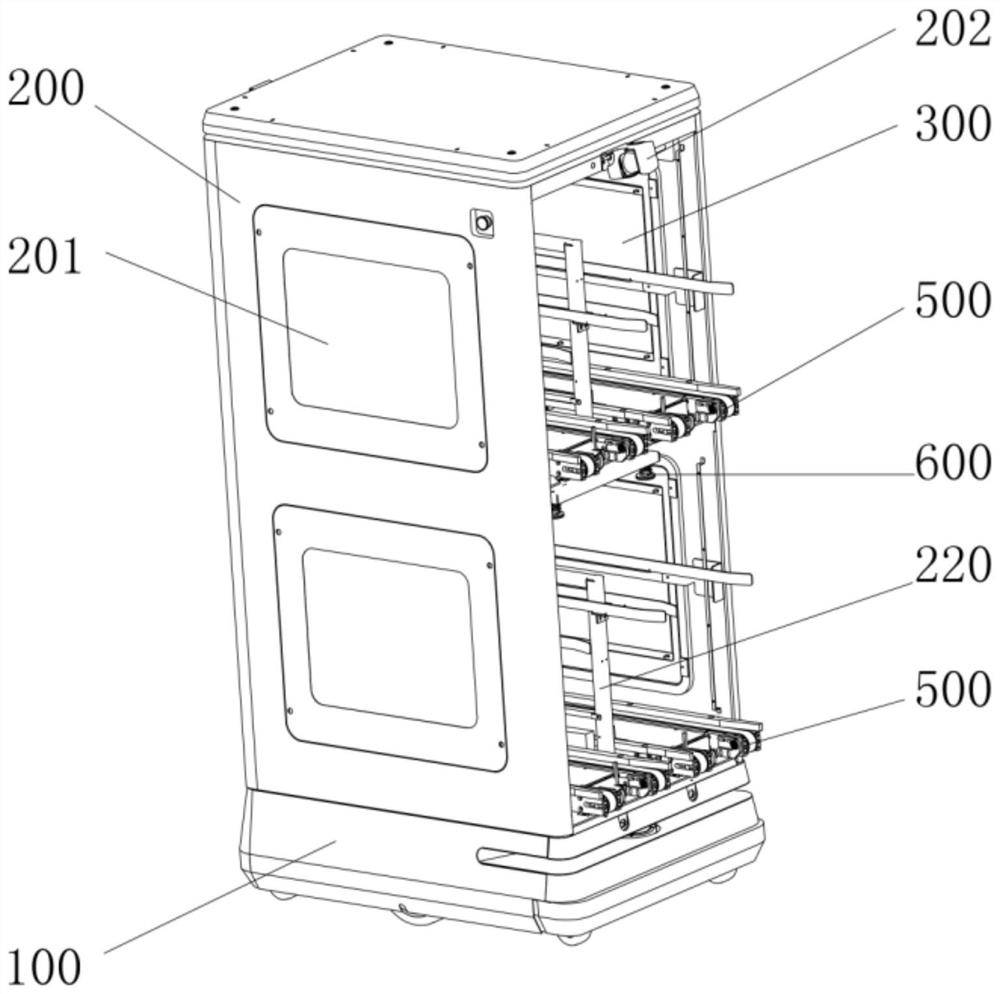

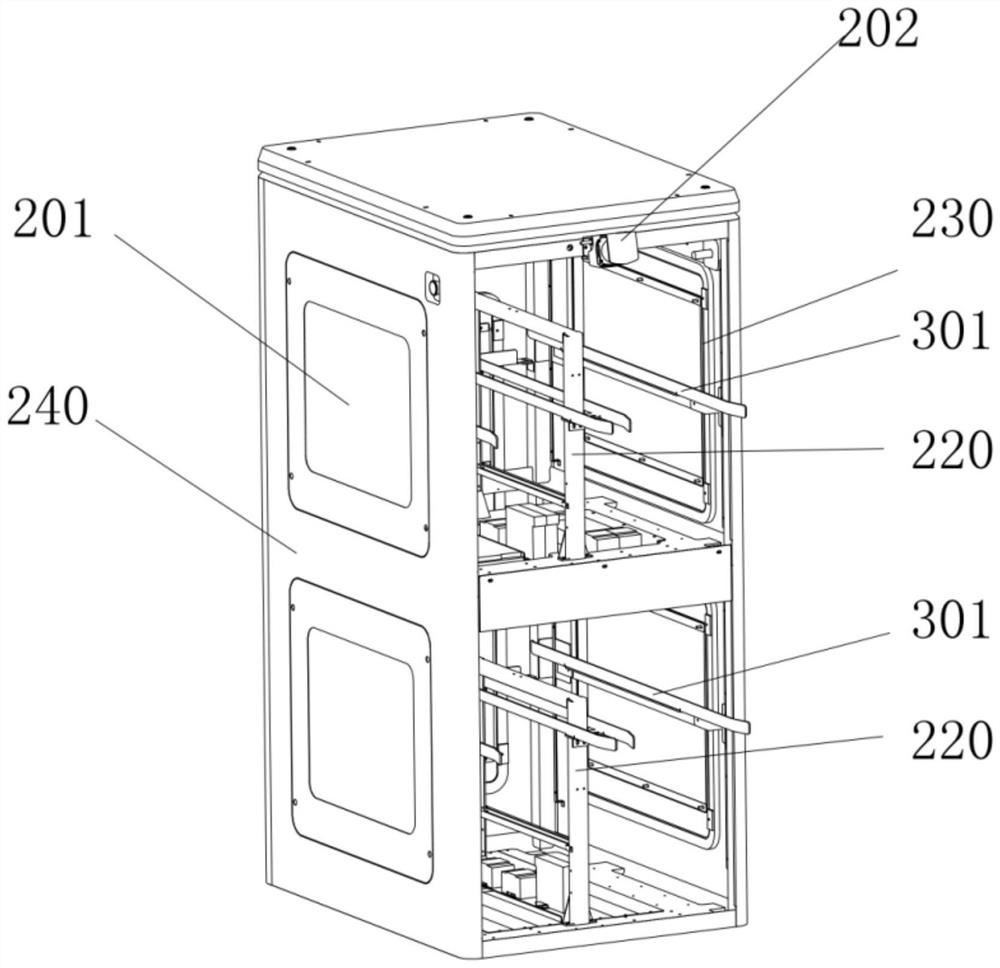

[0030] like Figure 1 to Figure 8 As shown, the AGV trolley used to carry flower baskets in the solar cell production process of this embodiment includes an AGV chassis 100 with a laser navigation function and a main carriage 200 located on the AGV chassis 100. The interior of the main carriage 200 is divided into upper and lower parts. Two floors, each floor is provided with two storage areas 300 side by side, each storage area 300 can store four flower basket boxes 400, the bottom of the storage area 300 is provided with a transmission mechanism 500 for transmitting flower basket boxes 400, and the main carriage 200 has a side It is open, and the entrances of each storage area 300 are located at the open side of the main carriage 200 . The AGV chassis 100 adopts laser navigation, is responsible for walking, and has the function of autonomously selecting routes. The main carriage 200 is provided with a signal transceiver unit 210, specifically a transceiver antenna, installed...

Embodiment 2

[0042] In this embodiment, the main carriage 200 has two opposite sides that are open, one of which is the inlet and the other is the outlet. One side feeds and the other side discharges. The rest are the same as those in Embodiment 1, and will not be repeated here.

[0043] In addition to the above embodiment 1 and embodiment 2, each storage area 300 can also store one or two or three or more than four flower basket boxes 400 .

[0044] Except for the first and second embodiments above, the pressing device 600 only includes a pressing plate 610 , an electric push rod 620 and an electric push rod fixing seat 630 . The electric push rod 620 drives the pressing plate 610 up and down to compress the flower basket box 400 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com