Turret punch press system based on two-arm robot

A technology of turret punch presses and robots, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems affecting processing efficiency, affecting production capacity, and lack of flexibility, so as to ensure operation safety and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

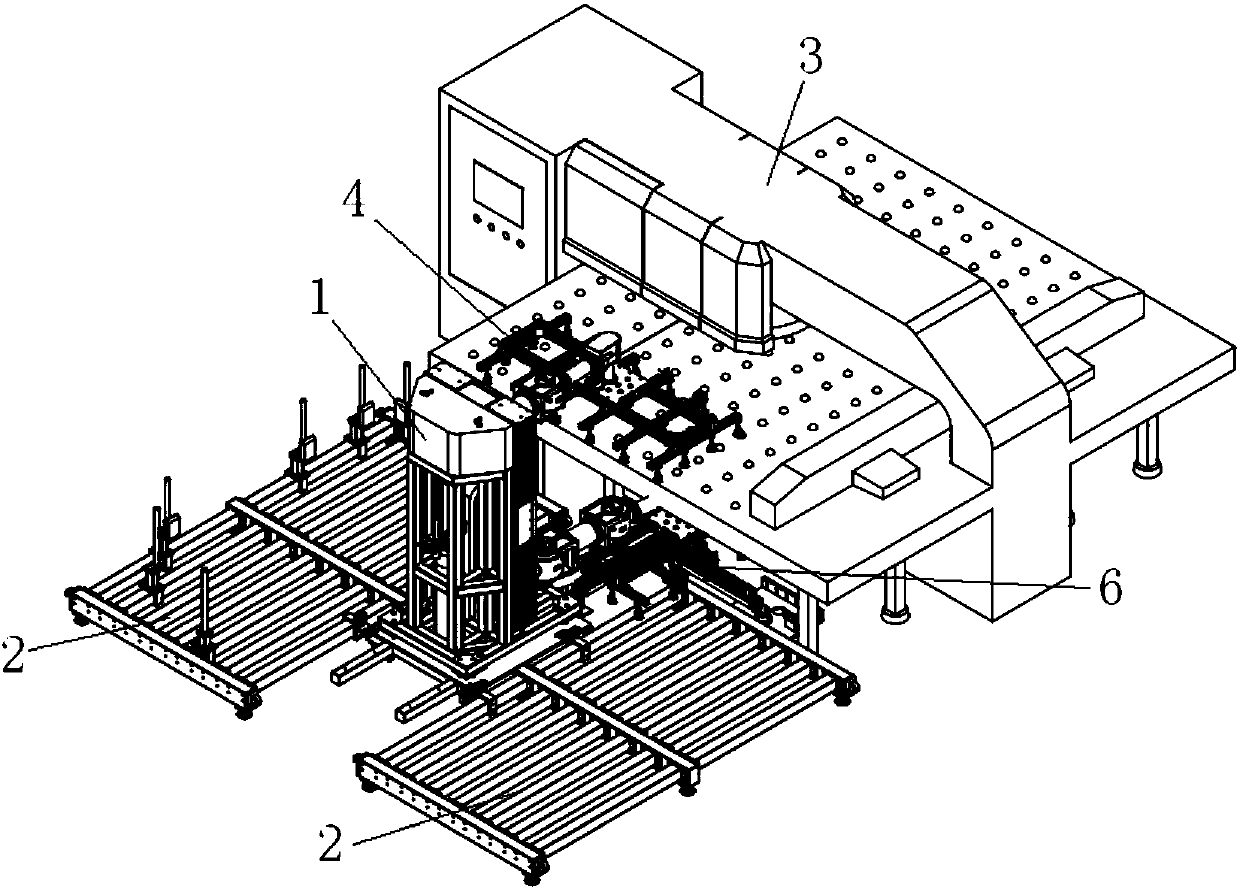

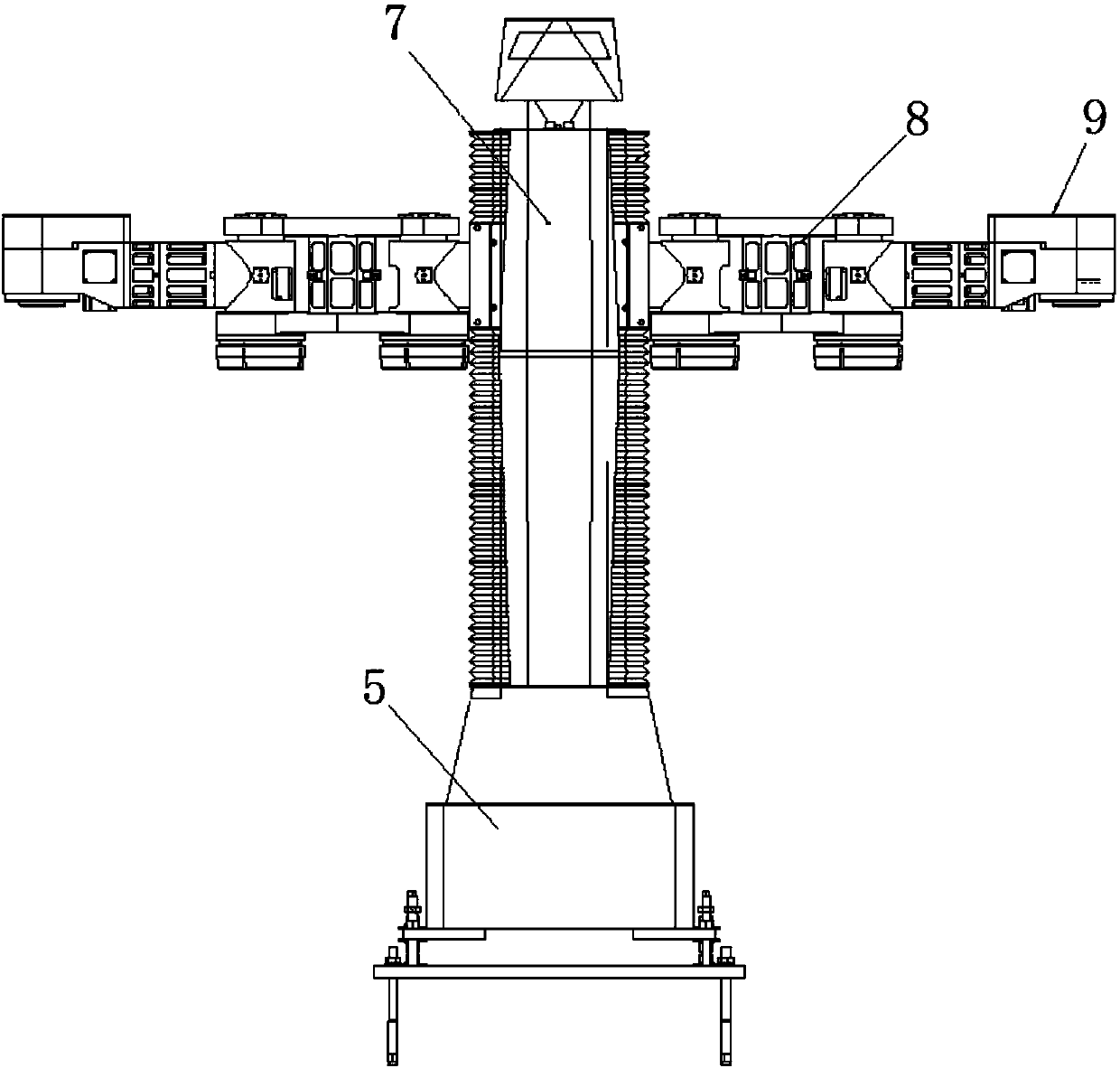

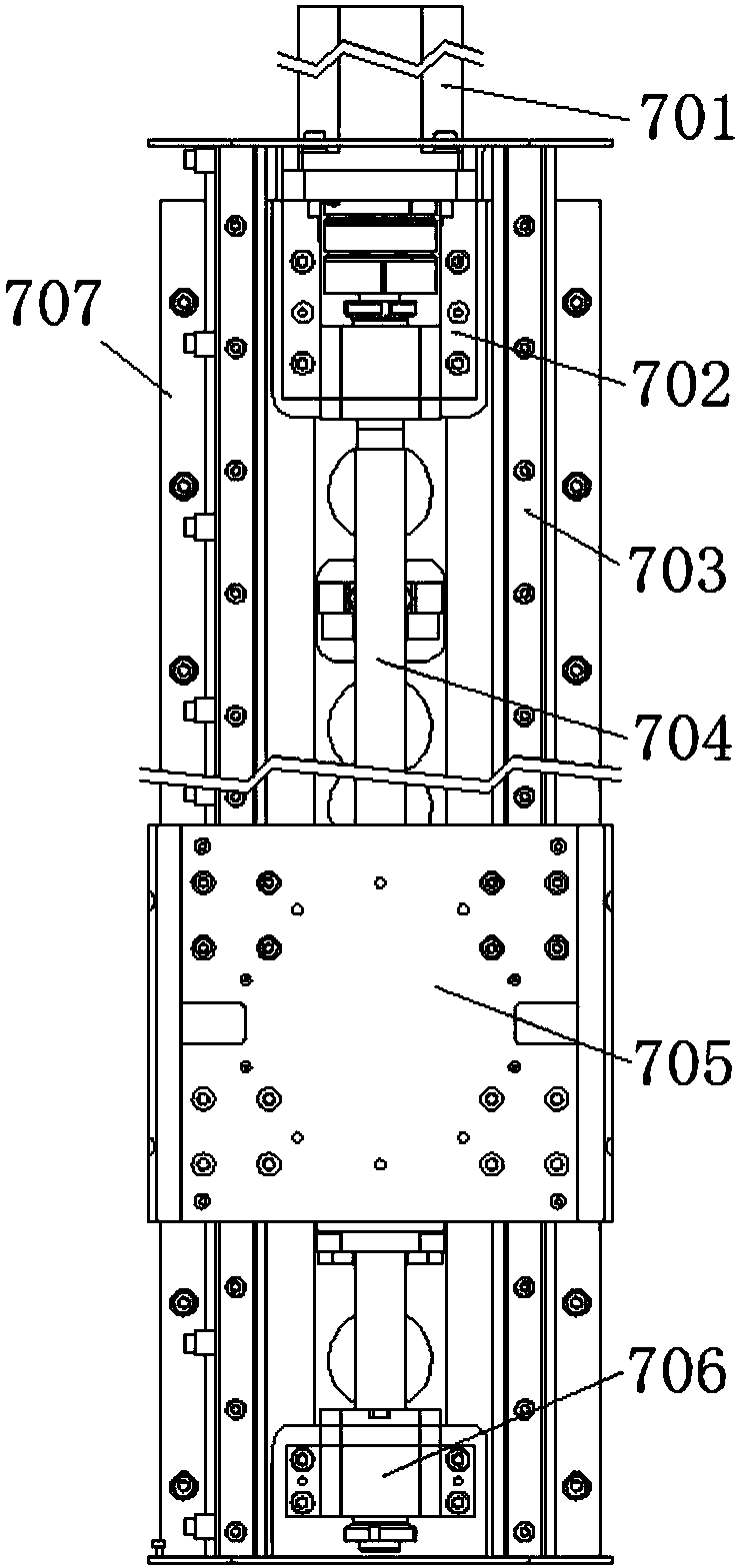

[0028] Such as Figure 1-10 As shown, the present invention includes a dual-arm robot 1, a turret CNC punch press 3, a material platform 2 and a robot rotation positioning mechanism 6, wherein the dual-arm robot 1, the material platform 2 and the robot rotation positioning mechanism 6 are all arranged on the turret CNC punch press 3 on the input side of the plate, and the material table 2 is separately arranged on both sides of the dual-arm robot 1, and the free ends of the mechanical arms on both sides of the dual-arm robot 1 are provided with end pickers 4 for moving the plate, and the dual-arm robot 1. According to the requirements of production and shearing, the rotary positioning mechanism 6 of the robot is used to drive the rotary positioning. When the present invention works, one mechanical arm of the dual-arm robot 1 takes material from one side mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com