Automatic conveying and classifying mechanism for balsa wood of wind power blade and application of automatic conveying and classifying mechanism

A technology of automatic transportation and wind power blades, which is applied in the direction of conveyor objects, conveyor control devices, wind power generation, etc., can solve the problems of manpower consumption, management confusion, low efficiency, etc., achieve convenient operation, improve production efficiency, and improve the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

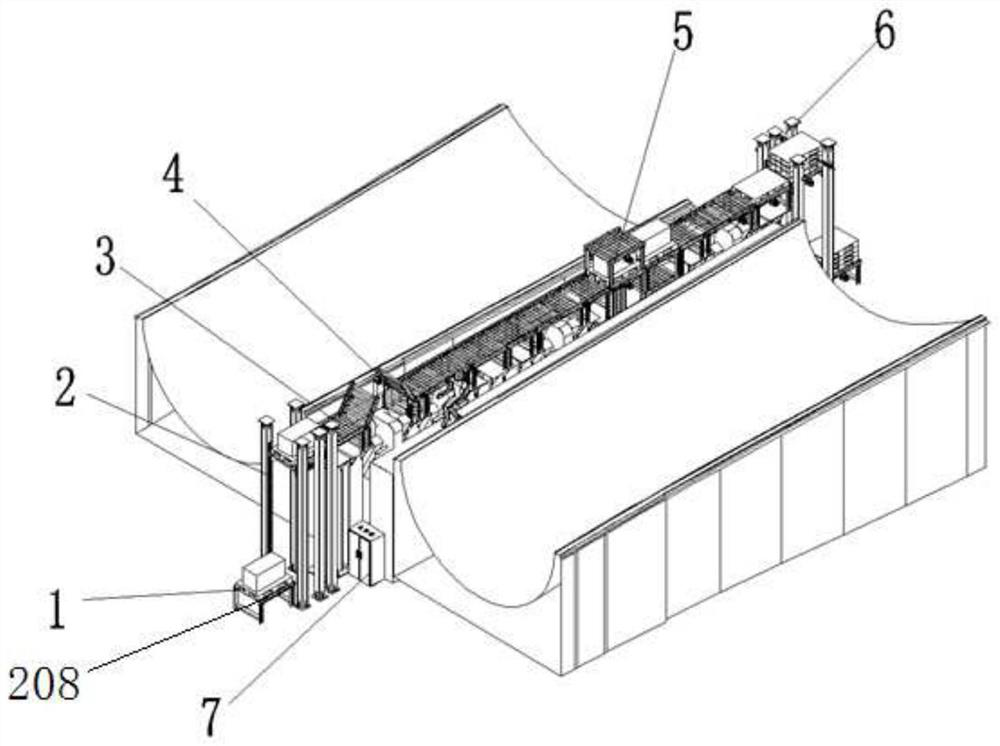

[0053] Step 1: When the mold of the wind power blade is in the open state, the material is transported to the automatic feeding mechanism 2 by a forklift. At this time, the code recognizer 1 performs serial number identification on the balsa wood placed on the automatic feeding mechanism 2, Read the final position of the dispatched balsa wood;

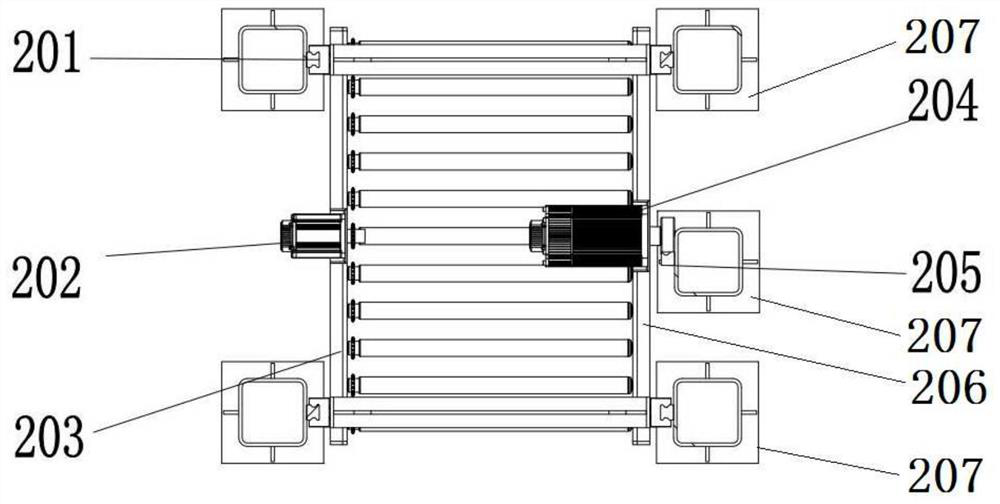

[0054] like image 3 As shown, when the code recognizer 1 located below the conveyor roller 208 waiting to be loaded carries out serial number recognition to the balsa wood placed on the conveyor roller 208 waiting to be loaded, the control system 7 will control the conveyor roller 208 waiting to be loaded. The rotating feeding conveyor motor 202 is energized, so that the balsa wood placed on the waiting feeding conveyor roller 208 is transferred to the feeding conveyor roller 203, and the position sensor on the feeding frame 206 senses the feeding conveyor roller After the material tray 602 of balsa wood is placed on the 203, the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com