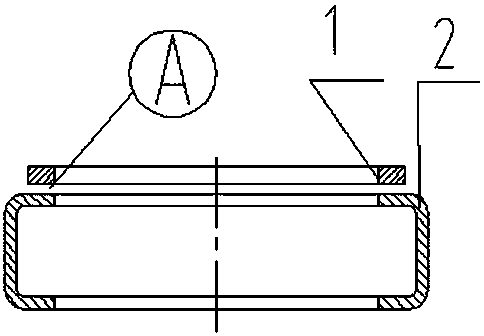

Welding method and special fixture for heavy-duty axle reinforcement ring

A special fixture and reinforcing ring technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the processing of the outer welding threaded hole, uneven surface flatness, reducing the overall performance of the axle housing, etc. The effect of improving welding quality, ensuring product quality, and designing reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

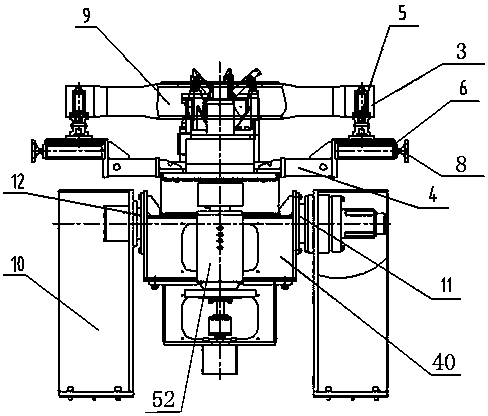

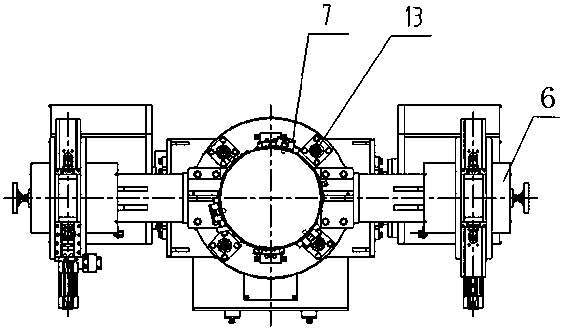

[0069] The present invention satisfies the changing requirements of the welding angle through the displacement of the displacement shaft, and satisfies the requirements of continuous welding of the circular seam of the reinforcement ring through the rotation of the hollow drive shaft 48. The claws of the workpiece inner ring positioning mechanism tighten the inner hole of the middle section of the axle housing and the reinforcement ring, and the reinforcement ring pressing mechanism presses the top of the reinforcement ring through the pressure head; the known public power distribution, oil distribution, and gas distribution mechanisms provide necessary Power and feedback signals ensure automatic completion of workpiece positioning and welding process. Signal detection is provided after each action is in place, making the whole system intelligent, safe and reliable.

[0070]The centering clamping mechanism 5 at both ends clamps the round tubes at both ends of the middle section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com