Hopper automatic charging stick bunching machine

An automatic feeding and stringing machine technology, applied in the field of stringing machines, can solve the problems of poor sanitation, inability to realize automatic production, and high requirements for bamboo sticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

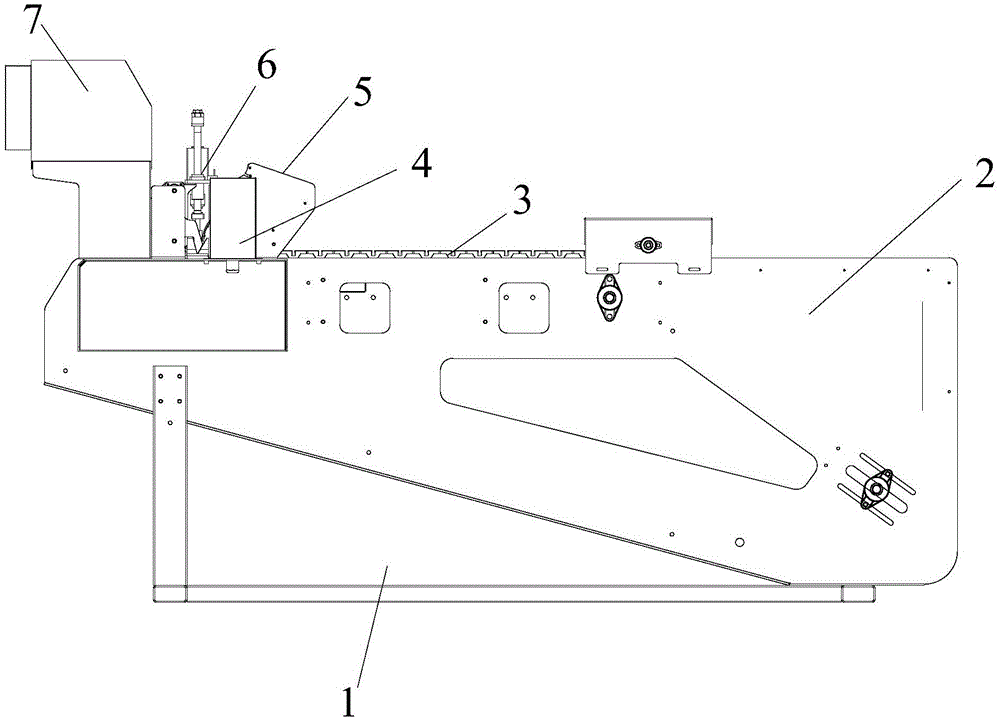

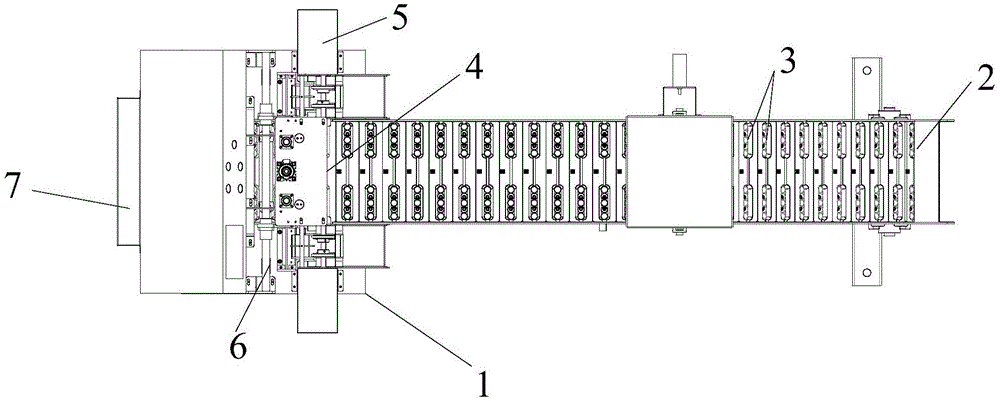

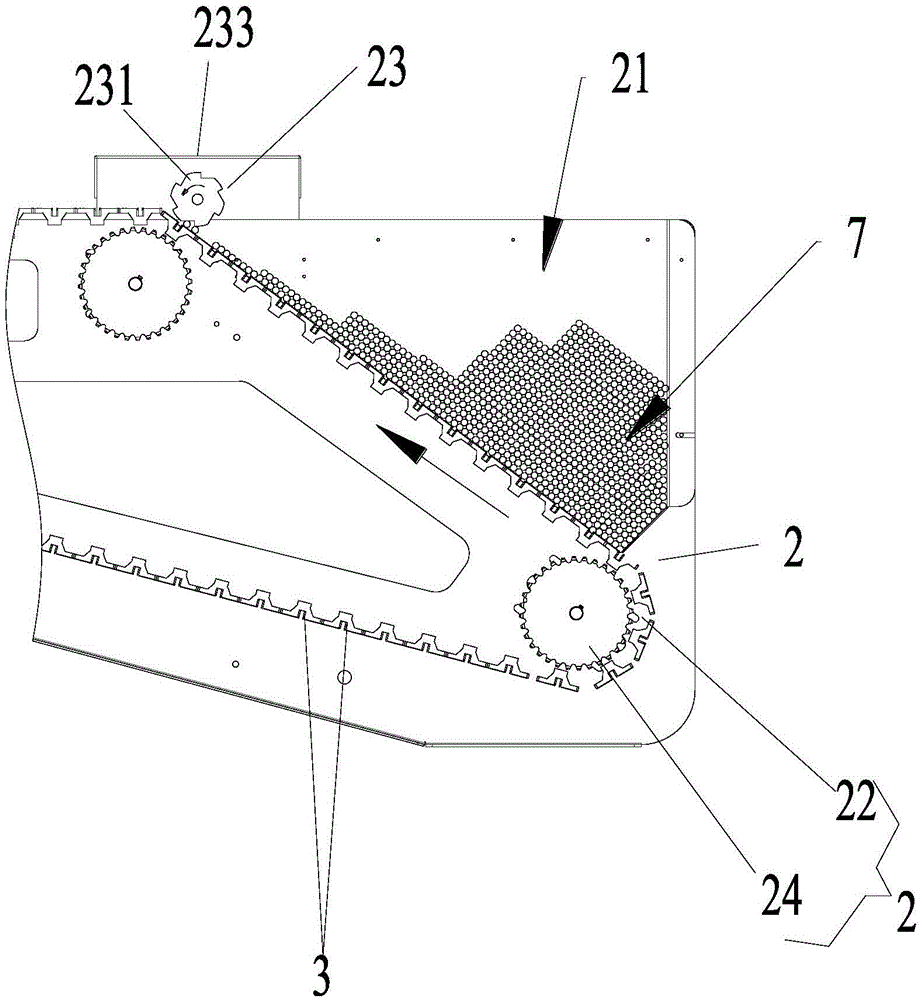

[0031] as attached Figure 1-11 As shown, the bucket-type automatic feeding and threading machine includes a main frame 1, and the main frame 1 is provided with an automatic feeding mechanism 2, a lower mold 3, an upper mold 4, a bamboo stick mechanism 5, a label threading mechanism 6 and an electric Control box 7, the automatic feeding mechanism 2 includes a hopper 21, a conveyor belt 22 and a material shifting mechanism 23, the conveyor belt 22 passes through the hopper 21 obliquely upward, and the conveyor belt 22 is fixed with the lower mold 4, The conveyer belt 22 is driven by a conveying motor 24, and the material shifting mechanism 23 is arranged above the lower mold 3, and the conveying motor drives the conveyer belt to move obliquely upward, and the material 7 is automatically loaded into the lower mold 3, so that The material shifting mechanism 23 pushes away the excess material 7, the material 7 in the lower mold 3 is transported to the bottom of the upper mold 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com