Automatic assembly line and process of low pressure heat and dry treatment of wet sludge

A dry treatment and fully automatic technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of complicated feeding process, low drying efficiency and inconvenience of wet sludge, and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

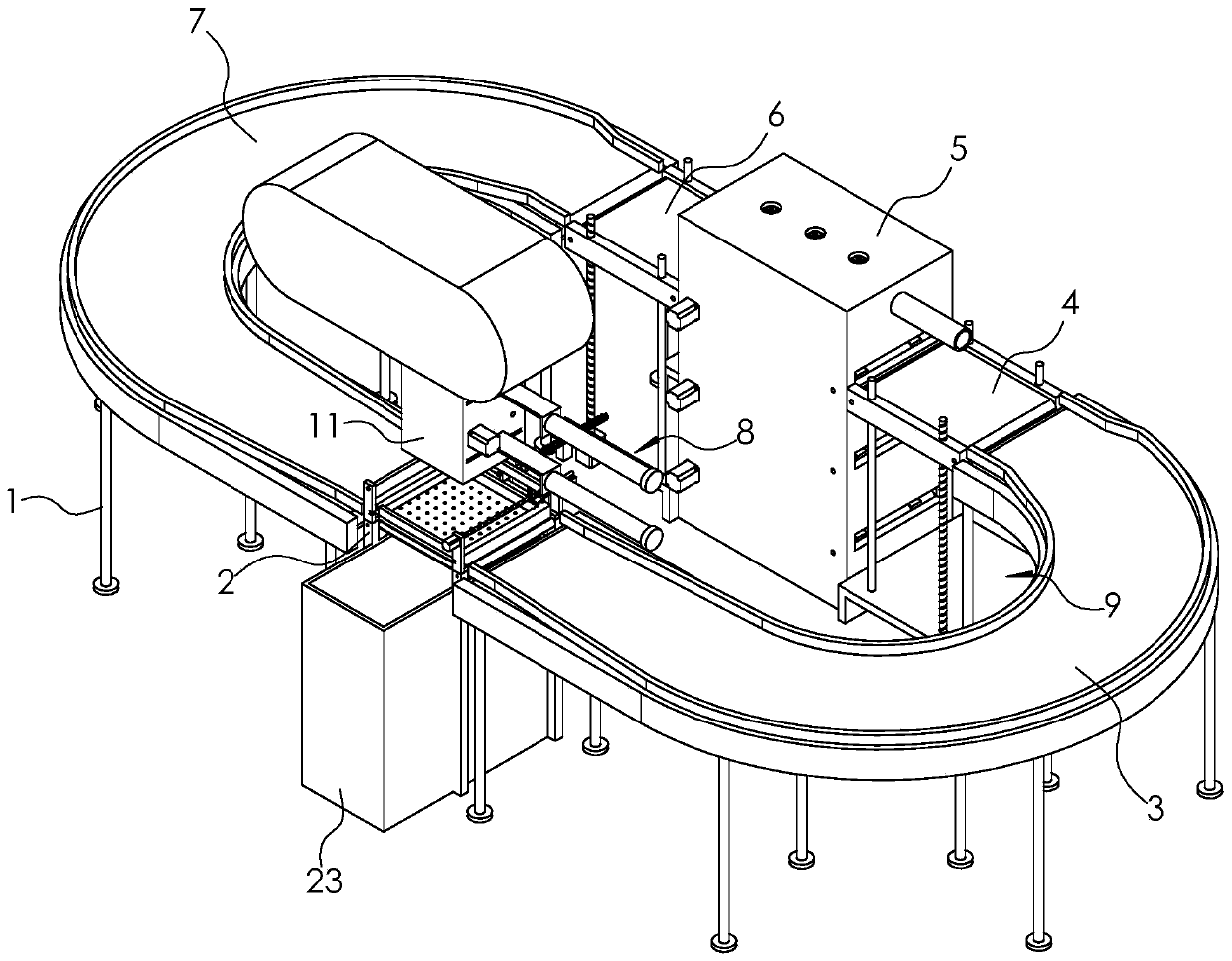

[0055] Embodiment one: if figure 1 As shown, a fully automatic assembly line for wet sludge low-pressure heat-drying treatment, including a frame 1 and a plurality of trays 51, the trays 51 are arranged in a net shape; U-shaped conveying device 3 , second conveying device 4 , drying room 5 , first conveying device 6 and first U-shaped conveying device 7 . The transfer device 2 is located directly below the cake unloading port 11. The transfer device 2, the second conveying device 4 and the first conveying device 6 are all straight conveyor belts, and the first U-shaped conveying device 7 and the second U-shaped conveying device 3 are all U-shaped conveying devices. Shaped conveyor belt, U-shaped conveyor belt are prior art, so do not repeat them here.

[0056] Such as figure 1As shown, the first conveying device 6, the second conveying device 4, the first U-shaped conveying device 7 and the second U-shaped conveying device 3 are equipped with a protective plate 31 to ensure ...

Embodiment 2

[0101] Embodiment 2: A process for fully automatic assembly line of wet sludge low-pressure heat-drying treatment, comprising the following steps:

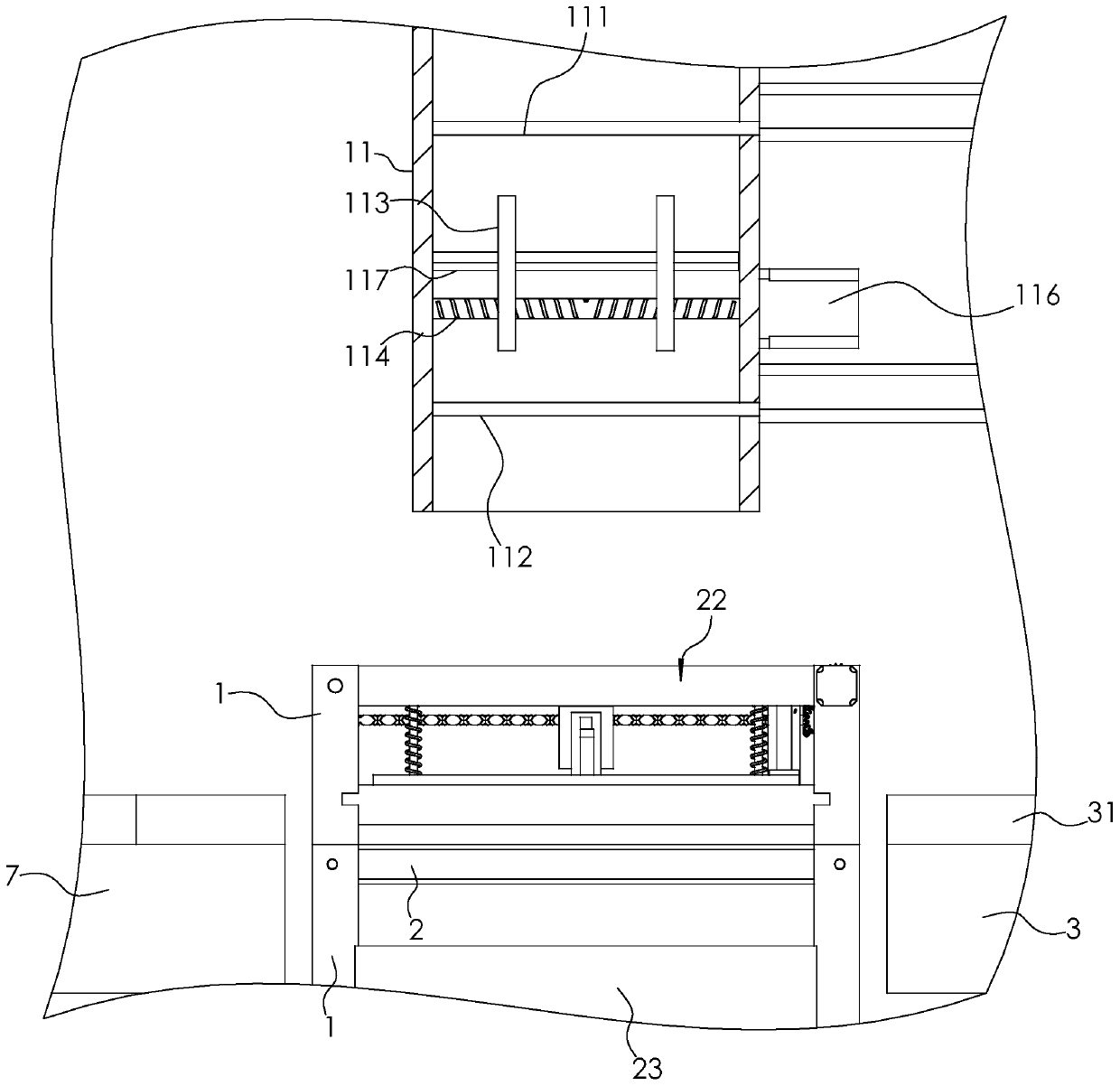

[0102] S1. Open the first gate 111 to make the mud cake fall onto the second gate 112, and then drive two sets of third scrapers 113 to flatten the mud cake fragments through the first servo motor 116 and bidirectional screw 114, and then open The second gate 112 makes the mud cake fragments drop into the tray 51 more evenly;

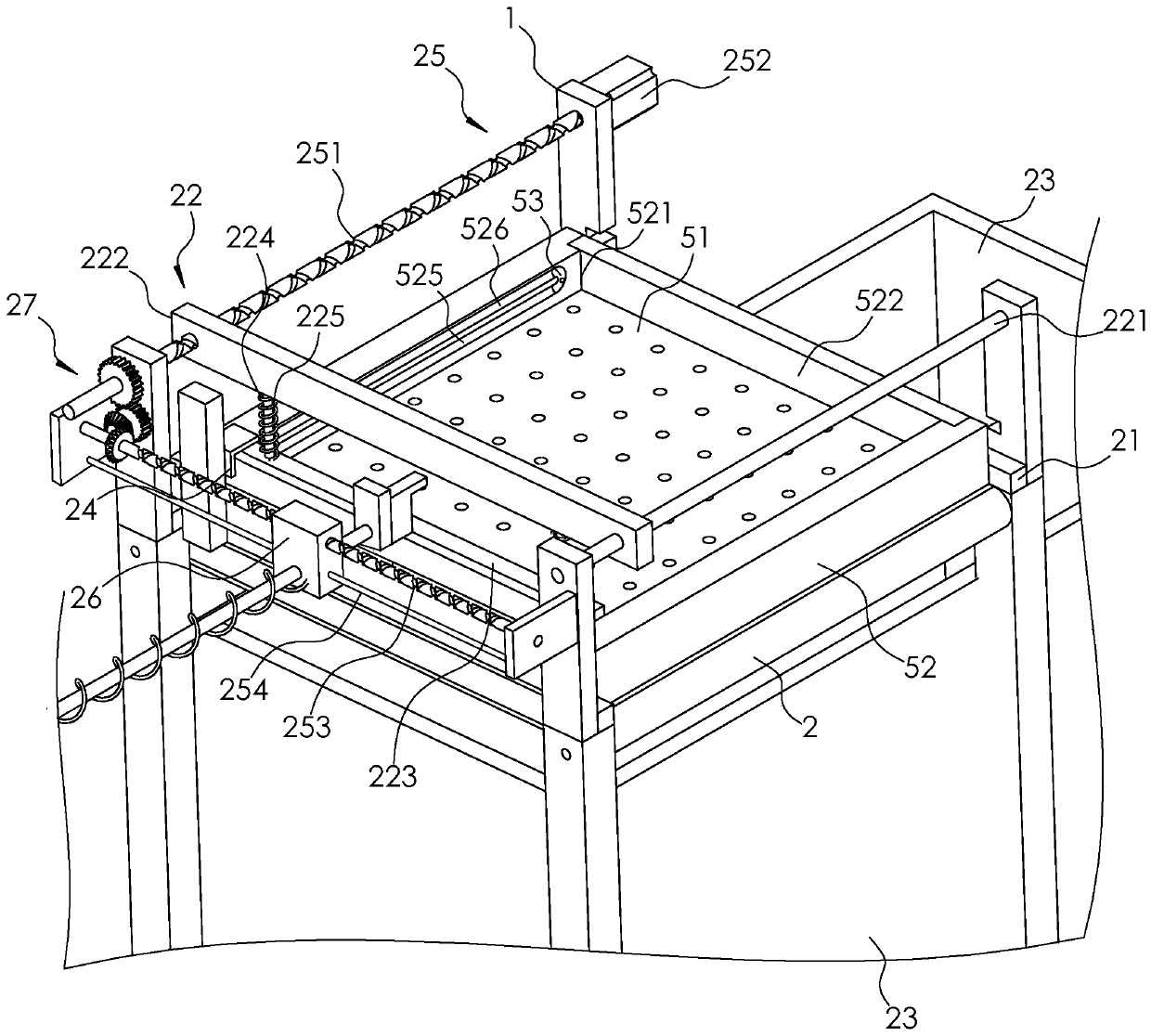

[0103] S2. Drive the mounting plate 222 to slide through the driving motor 252 and the first reciprocating screw rod 251, and drive the second reciprocating screw rod 253 to rotate through the linkage assembly 27. The second reciprocating screw rod 253 will drive the slider 26 to slide, and the third spring 264 It will drive the second scraper 263 against the first scraper 223, the second scraper 263 will make a circular serpentine movement and flatten the mud cake fragments in the tray 51, and the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com