A fully automatic marking production line for diamond saw blades

A diamond saw blade, fully automatic technology, applied in typewriters, printing, etc., can solve problems such as low degree of automation, low generalization of equipment, uncertain marking position, etc., to achieve improved efficiency, easy operation, and high versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

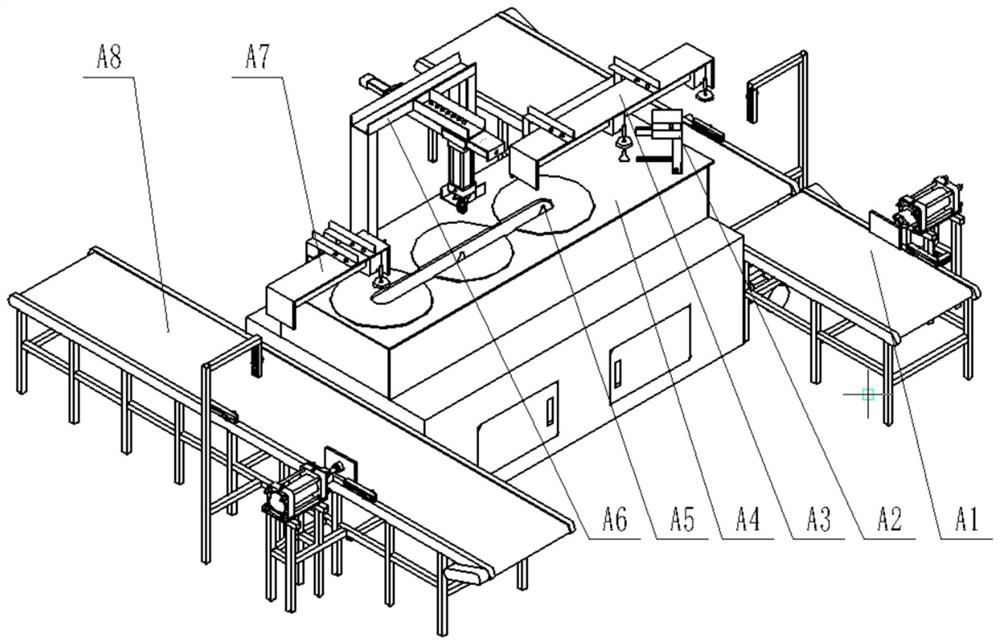

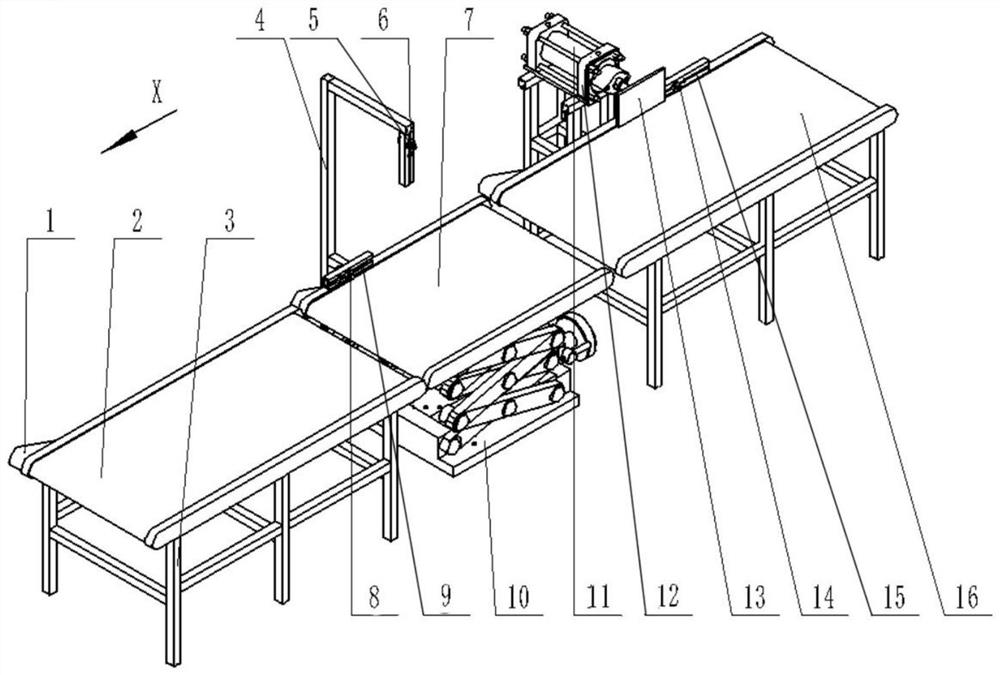

[0039] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0040] see Figure 1-10 .

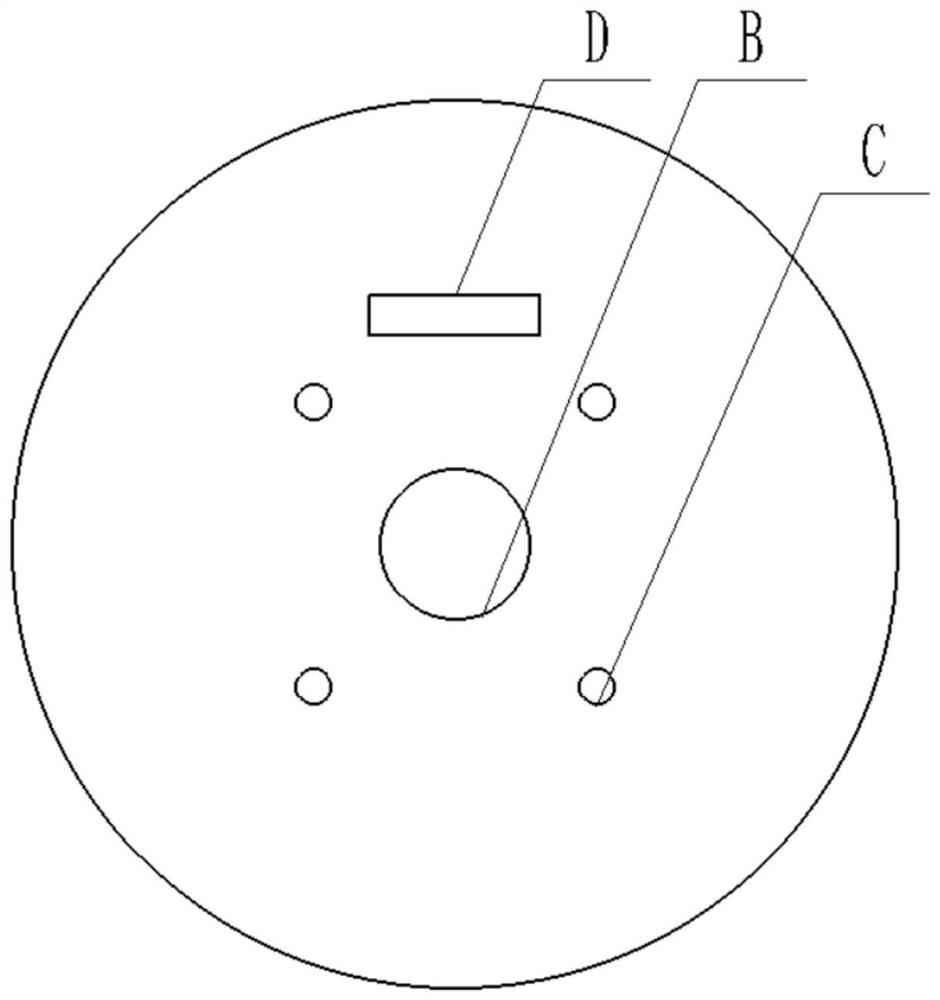

[0041] The invention relates to a fully automatic marking equipment for diamond saw blades, comprising a batch saw blade feeding device A1, a saw blade positioning part A2, a saw blade feeding part A3, a marking workbench A4; a saw blade indexing part A5, a saw blade The marking part A6, the saw blade blanking part A7 and the batch blanking part A8, the batch saw blade loading device A1 is located at the far right end of the equipment, the saw blade positioning part A2 is located at the lower left of the batch saw blade loading device A1 The saw blade feeding part A3 is located on the left side of the saw blade positioning part A2, and the marking table A4 is located in the middle of the production line. The saw blade indexing part A5 is located at the lower left of the saw blade loading part A3, the saw blade marki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com