Double-station polishing machine and operating method thereof

A polishing machine, dual-station technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of unfavorable fully automatic loading and unloading, high labor intensity, low work efficiency, etc. The effect of automatic loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

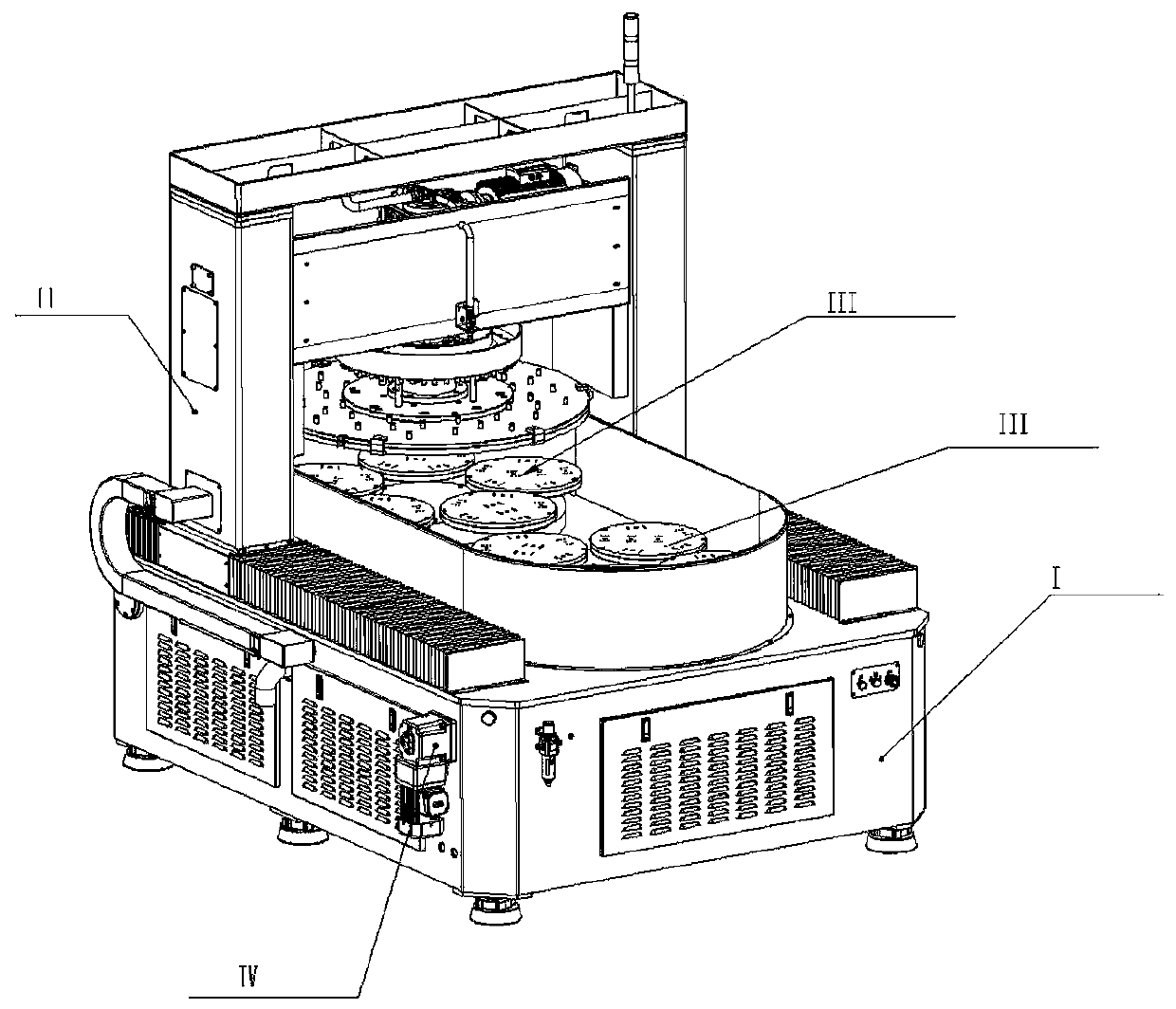

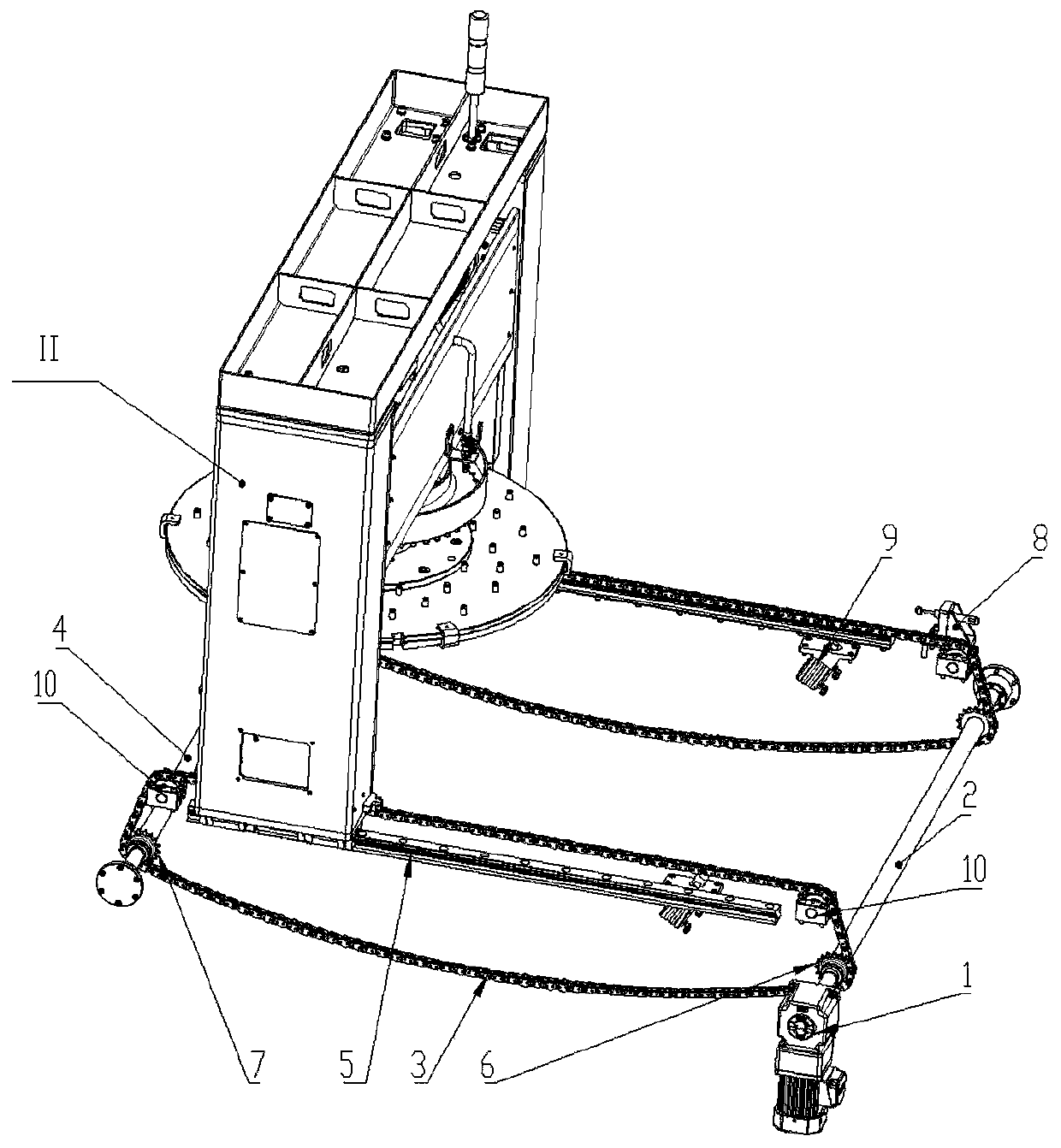

[0016] Such as figure 1 , 2 As shown, this double-station polishing machine includes a box body part I, an upper disk device II, and a main transmission system III. The transmission system is inside the box body. The double-station polishing machine also includes a reciprocating drive system IV. The main transmission system includes a first station and a second station. Each station has a workpiece disc, and the workpiece disc drives the workpiece to rotate. and revolution, the reciprocating drive system drives the upper disk device to reciprocate between the first station and the second station.

[0017] The invention realizes the cyclic transformation of the upper plate device between the first station and the second station through the reciprocating drive system, and one upper plate device can polish the workpieces on the two main transmission systems, and the worker can perform polishing at one station. At the same time of polishing, another station is used to swing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com