Flexible package lithium battery formation loading and unloading device

A soft-pack lithium battery and battery technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of low loading and unloading efficiency, unfavorable production efficiency, and the overall structure is not compact enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

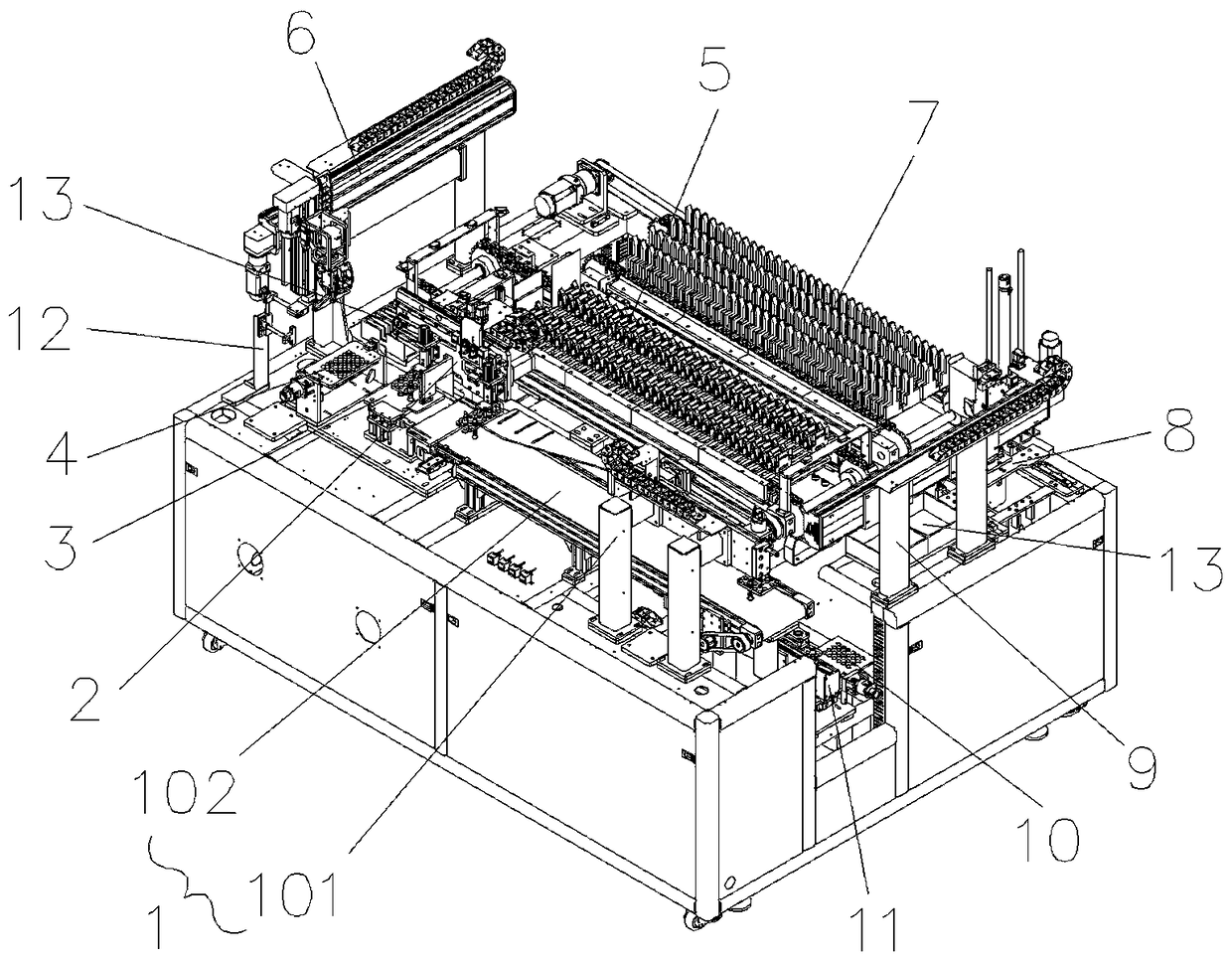

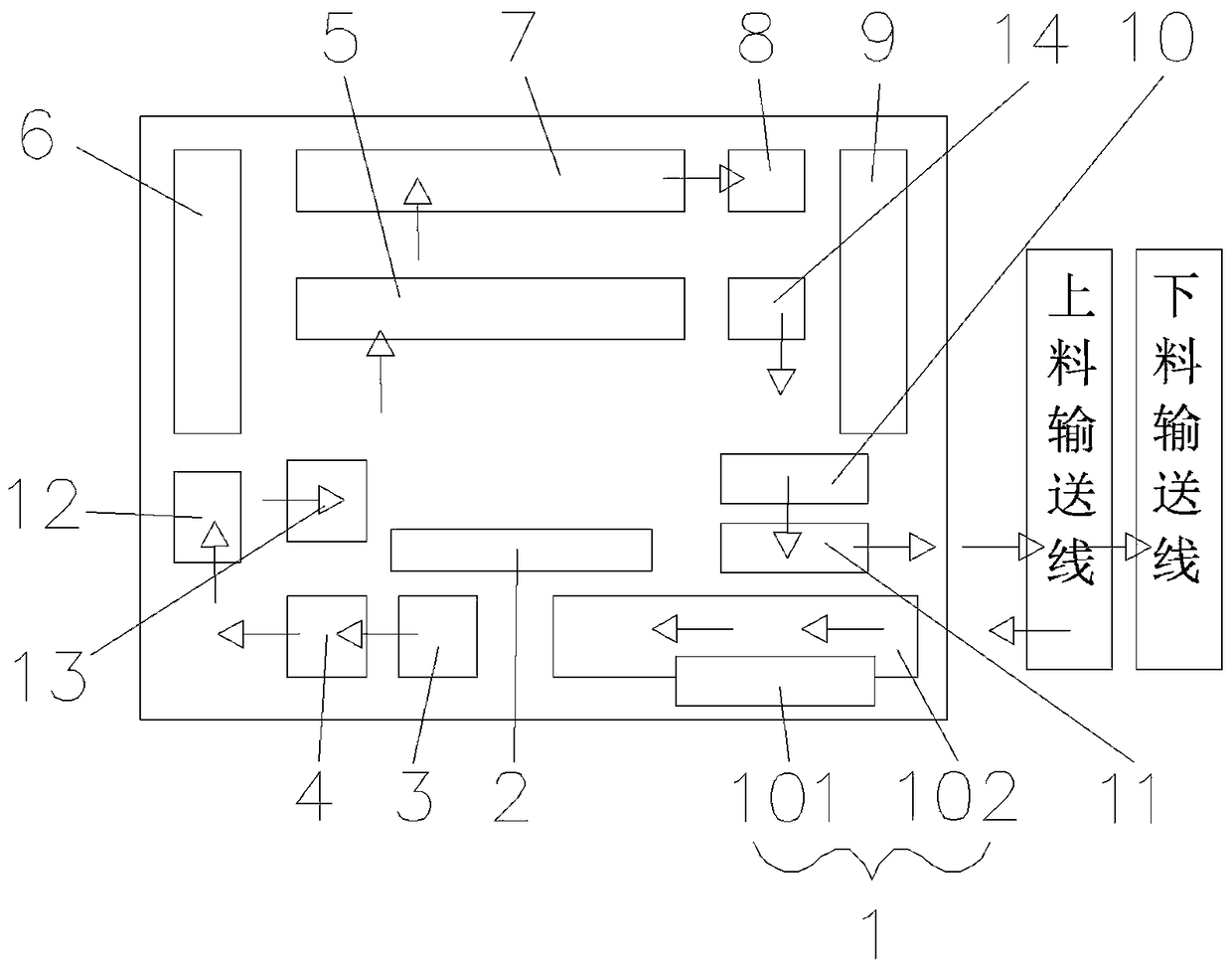

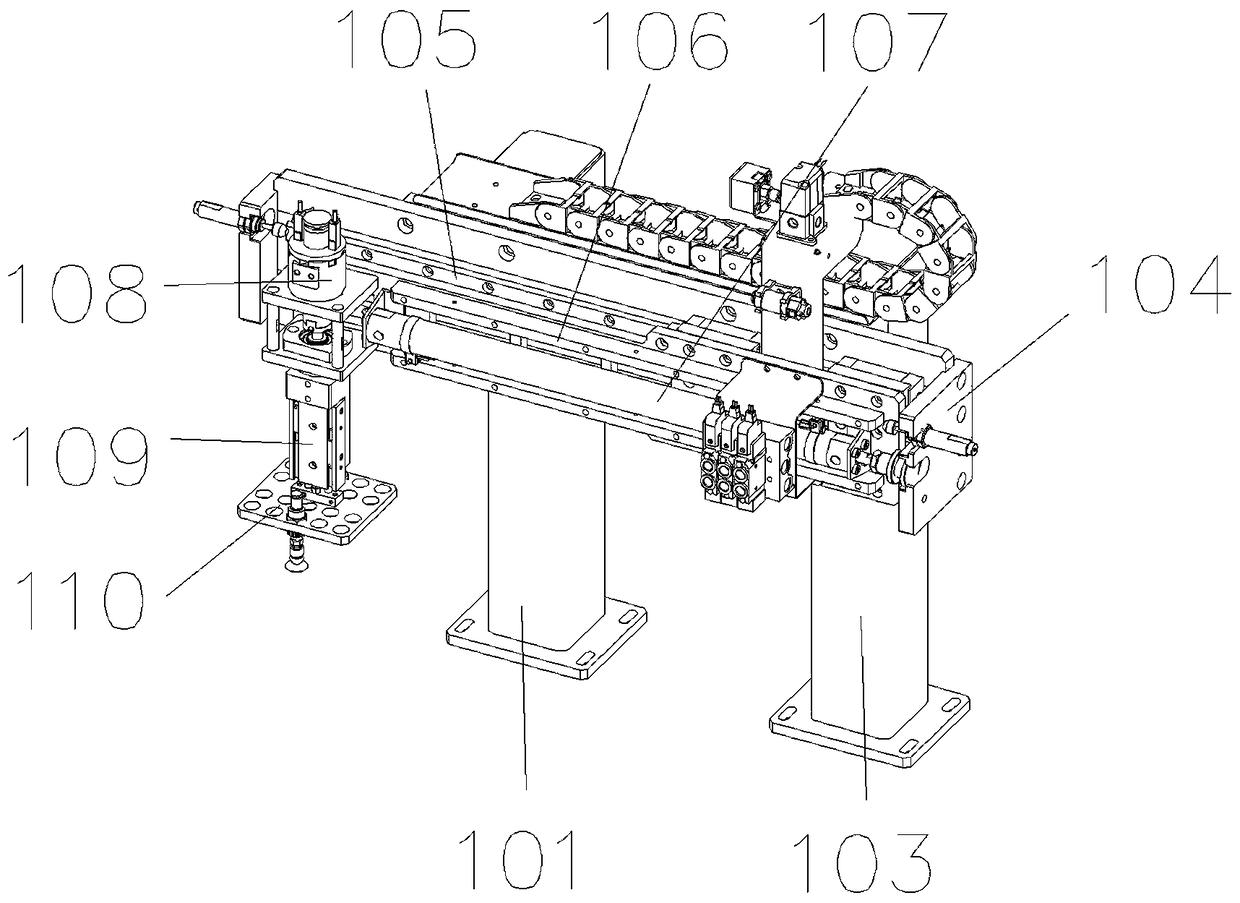

[0027] Such as Figure 1 to Figure 2As shown, in this embodiment, the present invention includes a retrieving and transporting module 1, a double manipulator 2, a lug shaping mechanism 3, a feeding turning mechanism 4, a feeding water truck 5, a feeding manipulator 6, and a feeding water truck 7. The unloading traverse mechanism 8 and the unloading manipulator 9, the unloading water wheel 7, the loading water wheel 5 and the double manipulator 2 are arranged in the X direction and front and back sequentially, and the feeding water wheel The overturning mechanism 4 and the tab shaping mechanism 3 are all located behind the duplex manipulator 2, the tab shaping mechanism 3 is located on the right side of the feeding turning mechanism 4, and the retrieving and transporting module 1 is in the shape of an X To and arranged on the right side of the lug shaping mechanism 3, the feeding manipulator 6 is in the Y direction and is arranged at one end of the feeding water wheel 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com