Material diameter reducing machine

A shrinking machine and material technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of slow manual operation, single operation, and low productivity, and achieve high work efficiency, simple operation, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

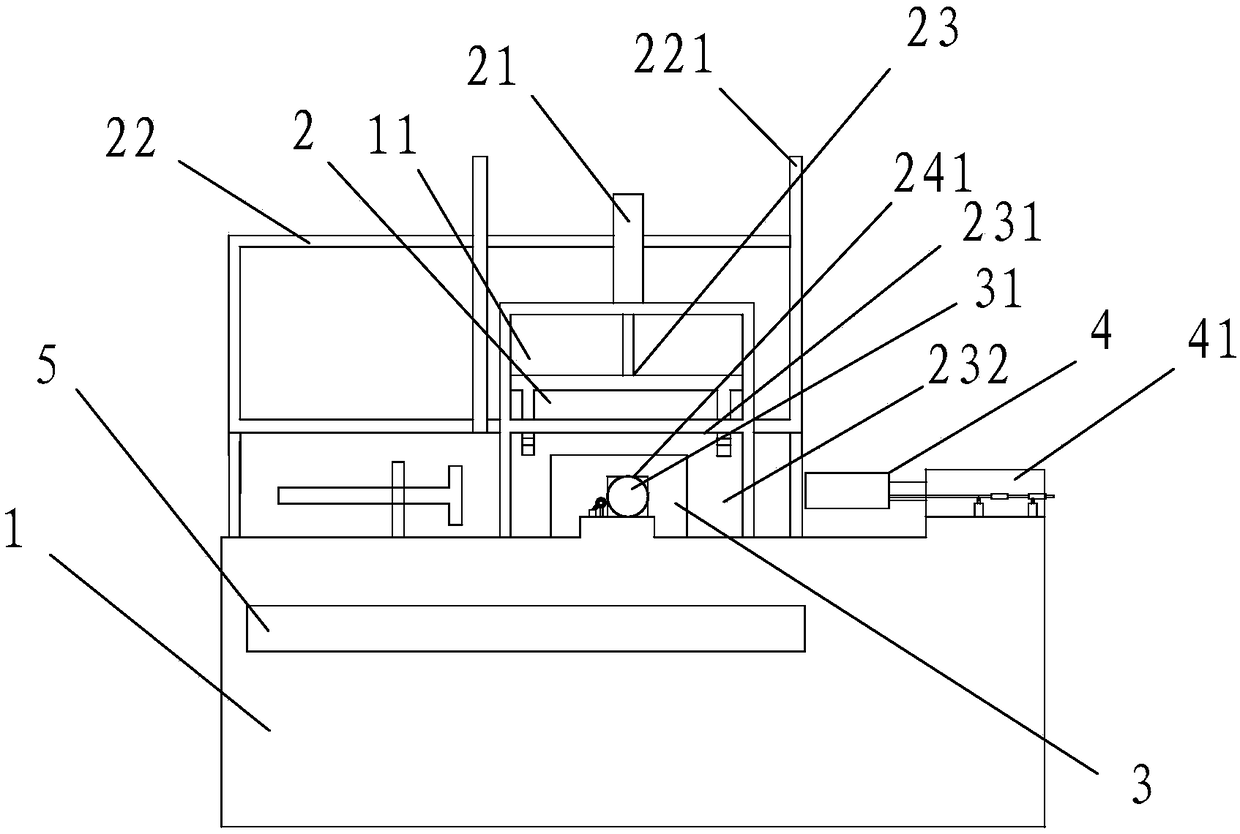

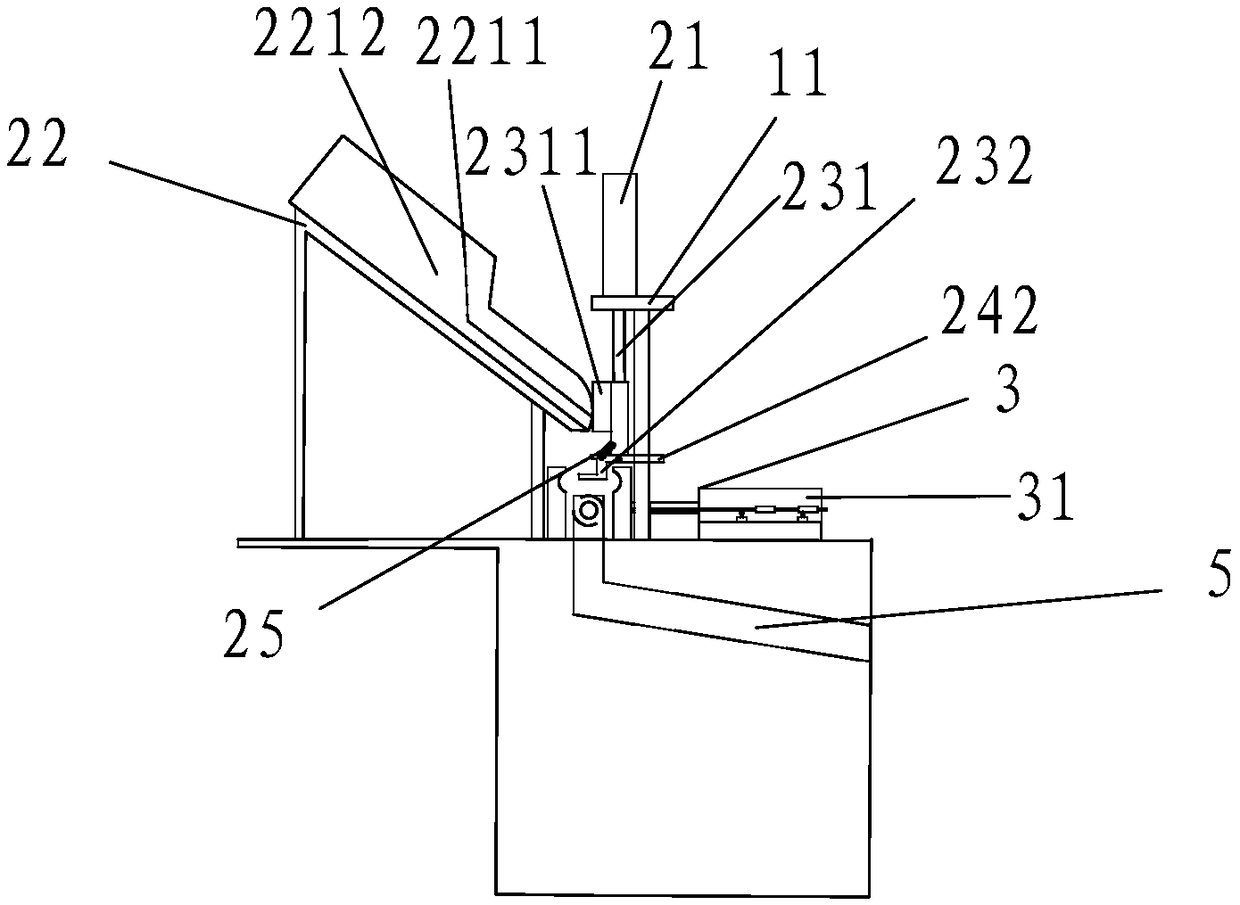

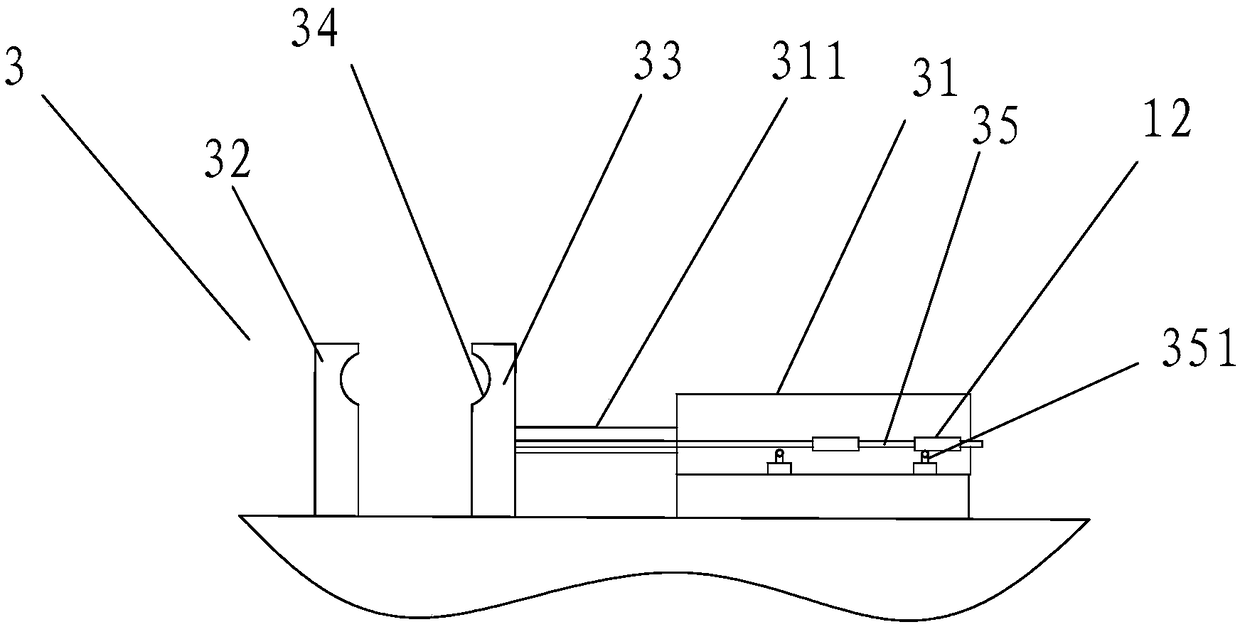

[0019] refer to Figure 1 to Figure 4 , what the embodiment of the present invention discloses is a material shrinking machine, comprising a frame 1, a blanking device 2, a clamping device 3, a shrinking device 4, and a receiving trough 5, and the blanking device 2 includes a rack 22, Retrieving device 23, described storage rack 22 is fixedly arranged on described rack 1, and described storage rack 22 is provided with two baffle plates 221, and described baffle plate 221 is arranged on the described storage rack by screw connection, so The baffles can adjust the distance between the baffles 221 by fastening screws according to the length of the material. The inner wall of the baffles 221 is provided with a guide rod 2211, and the guide rod 2211 and the bottom of the rack 22 form a supply sheet. The feed channel 2212 through which the layer-by-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com