Automatic feeding and discharging device for hot galvanizing and using method

A technology of automatic loading and unloading, hot-dip galvanizing, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of many risk factors of bumping feet, high risk of workers' operation, high labor intensity, etc. , to avoid risks, reduce the discharge of waste acid, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

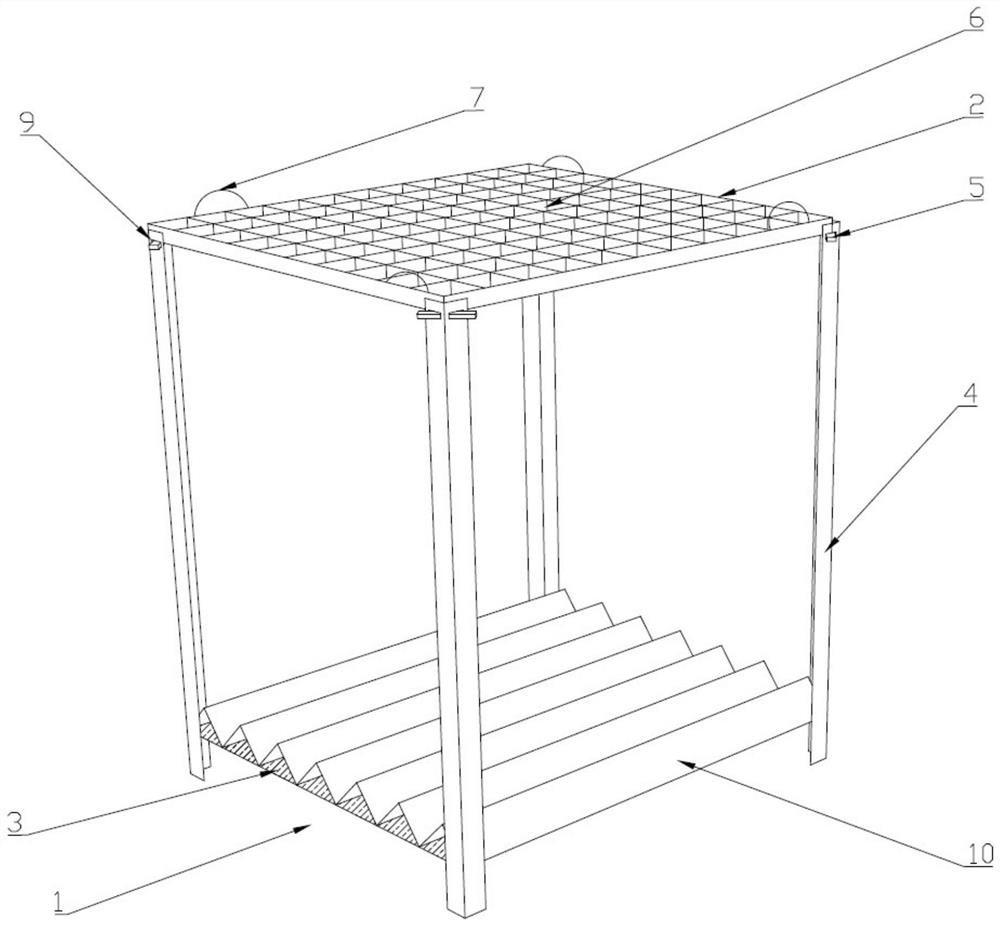

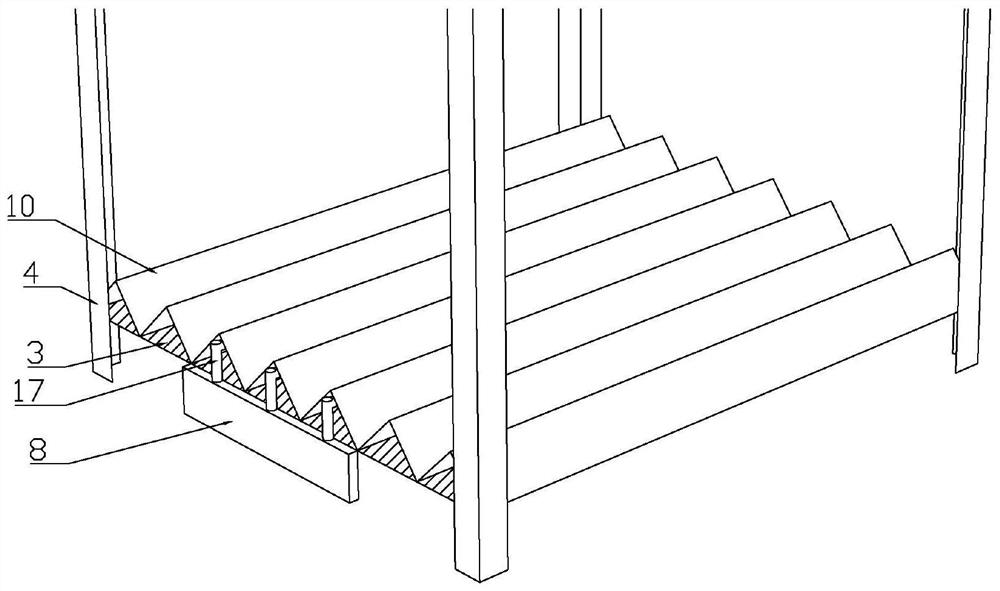

[0042] Such as image 3 with 5As shown, the hydraulic press 8 is placed around the base 1 according to the length of the buckle-type scaffold cross bar 13, and the position of the corrugated plate 10 is adjusted and supported by the lifting of the hydraulic strut 17. During the production process, the pickling hanger 11 is first fixed between the support rods 4 of the base 1, and the robot arm inserts the welded buckle-type scaffold cross bar 13 on the conveyor belt into the pickling hanger 11, and the pickling hanger 11 is worn After it is full, put the flat steel 15 through the plate pin hole 14 on the top of the buckle-type scaffolding cross bar 13 according to the row, and transfer the full pickling hanger 11 to the transfer car by driving the car, and then transfer it to the pickling car. At the hanging beam, the pickling hanger 11 full of materials is hung by the hanging beam to carry out pickling, water washing, and plating help operations. After the plating help is co...

Embodiment 2

[0044] Such as Figure 5 Shown:

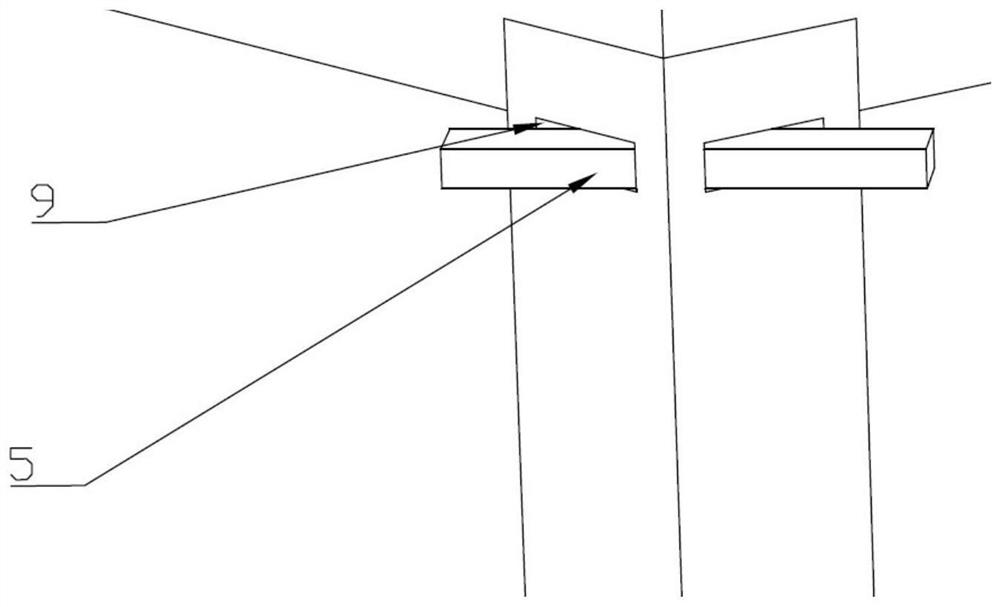

[0045] (1) The machine arm lifts the pickling hanger 11 and places it on the support plate 5 so that the pickling hanger 11 is fixed between the support rods 4 .

[0046] (2) The robot arm will weld the buckle-type scaffold cross bar 13 on the conveyor chain and insert it vertically into the grid 6 of the pickling hanger 11, so that the bottom of the buckle-type scaffold cross bar 13 and the concave surface of the zigzag corrugated plate 10 Groove contact; Make the plate pin hole 14 of the same column buckle type scaffold cross bar 13 be positioned on the same straight line, the plate pin hole 14 of the plate buckle type scaffold cross bar 13 top is worn by flat steel 15 by column.

[0047] (3) Through the hanging point hook 7 on the pickling hanger 11, the full pickling hanger 11 is transferred to the transfer truck by driving, and then transferred from the transfer truck to the pickling hanging beam, where it is hung by the hanging beam Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com