Warehouse goods storage device

A cargo storage and warehouse technology, applied in storage devices, transportation and packaging, skidways, etc., can solve problems such as difficult cargo transportation to shelves, increase the labor intensity of staff, and affect the efficiency of cargo loading and unloading, so as to save labor costs , Reduce labor intensity, improve loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

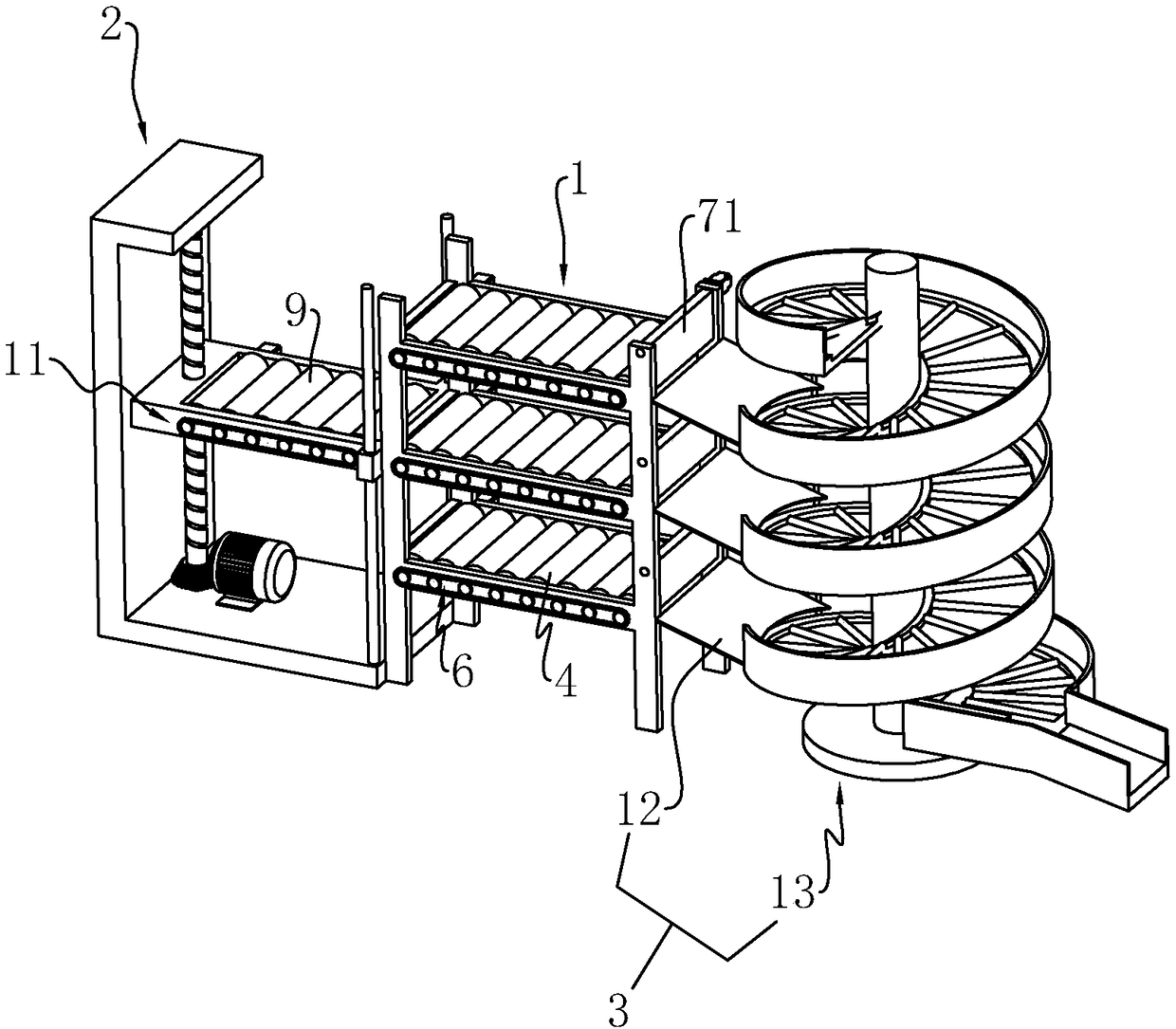

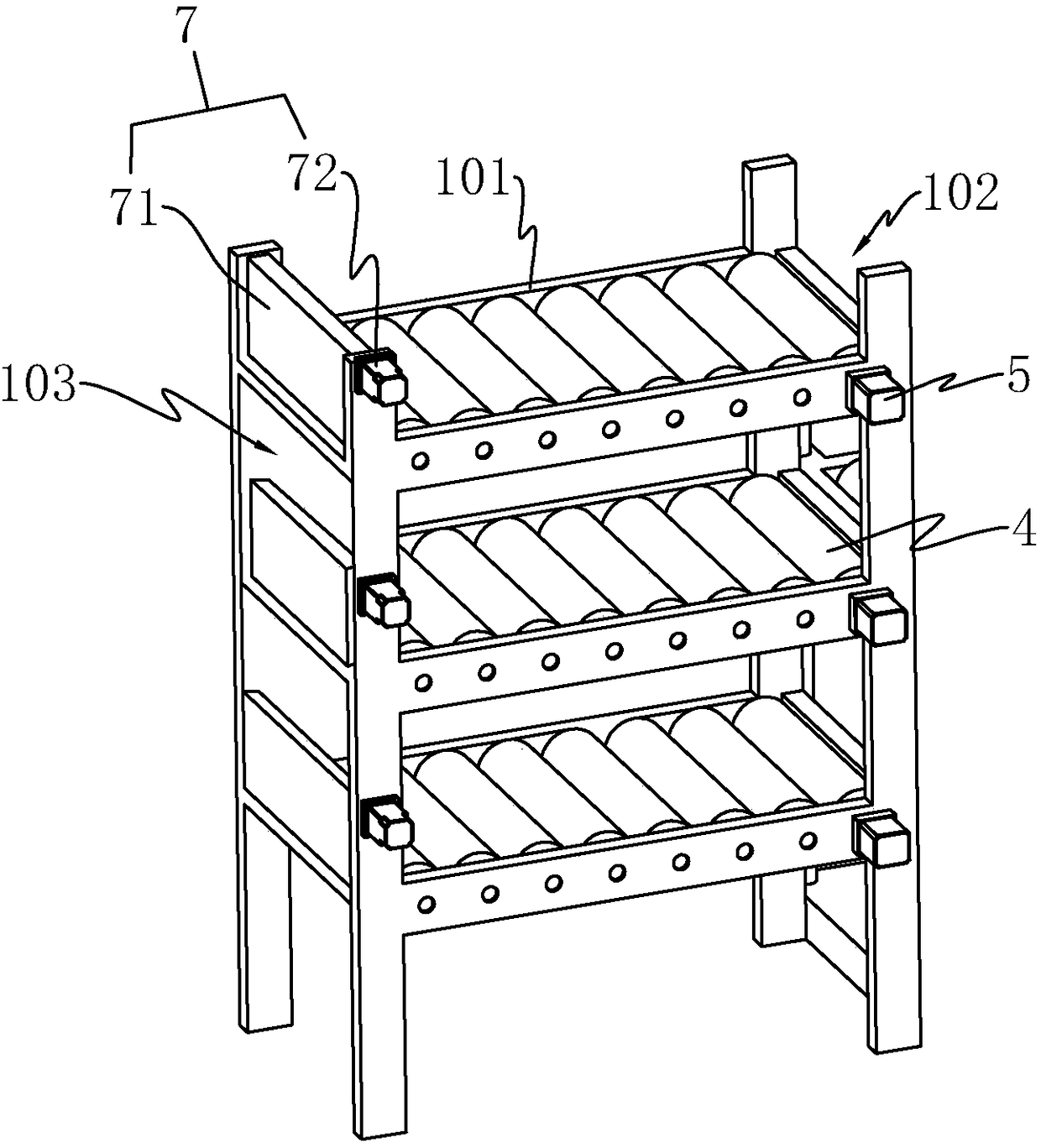

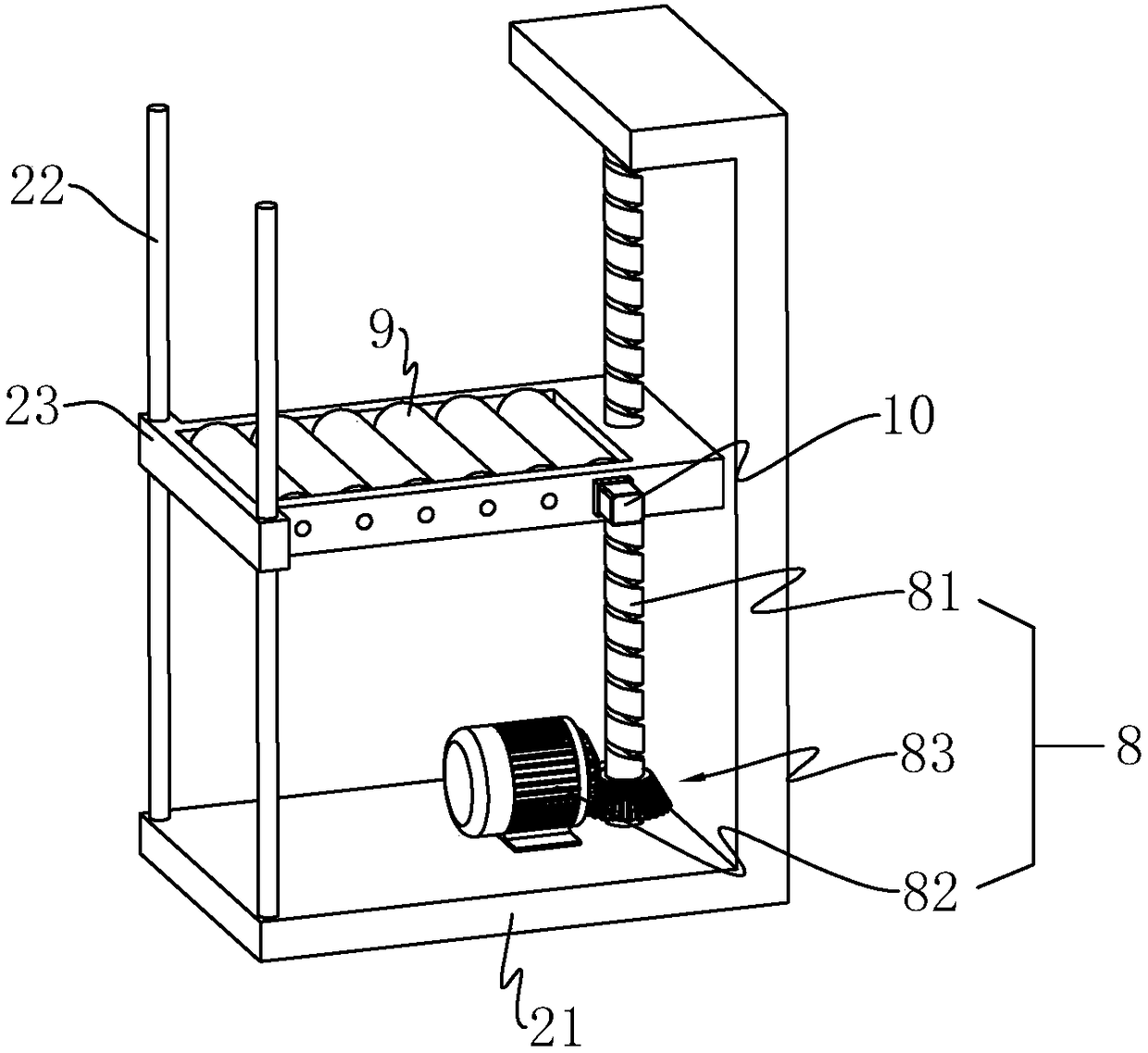

[0039] See attached figure 1 , a storage device for goods in a warehouse, comprising a shelf main body 1, the shelf main body 1 includes three sets of placement layers 101 for stacking goods from bottom to top, and the two sides of the placement layer 101 in the length direction are respectively provided with an inlet port 102 and an outlet port 103 At the same time, the shelf body 1 is provided with a cargo loading mechanism 2 on its side close to the cargo inlet 102, and a cargo unloading mechanism 3 is correspondingly provided on its side close to the cargo outlet 103.

[0040]In actual work, when the staff puts the goods on the goods racking mechanism 2, the goods racking mechanism 2 can automatically lift the goods to the height of the corresponding placement layer 101, and automatically push the goods into the corresponding placement layer 101; when unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com