Single drilling device and method for high portion of building wall

A technology for drilling devices and buildings, applied in drilling/drilling equipment, portable drilling rigs, workbenches, etc., can solve problems such as inconvenience, and achieve the effect of ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

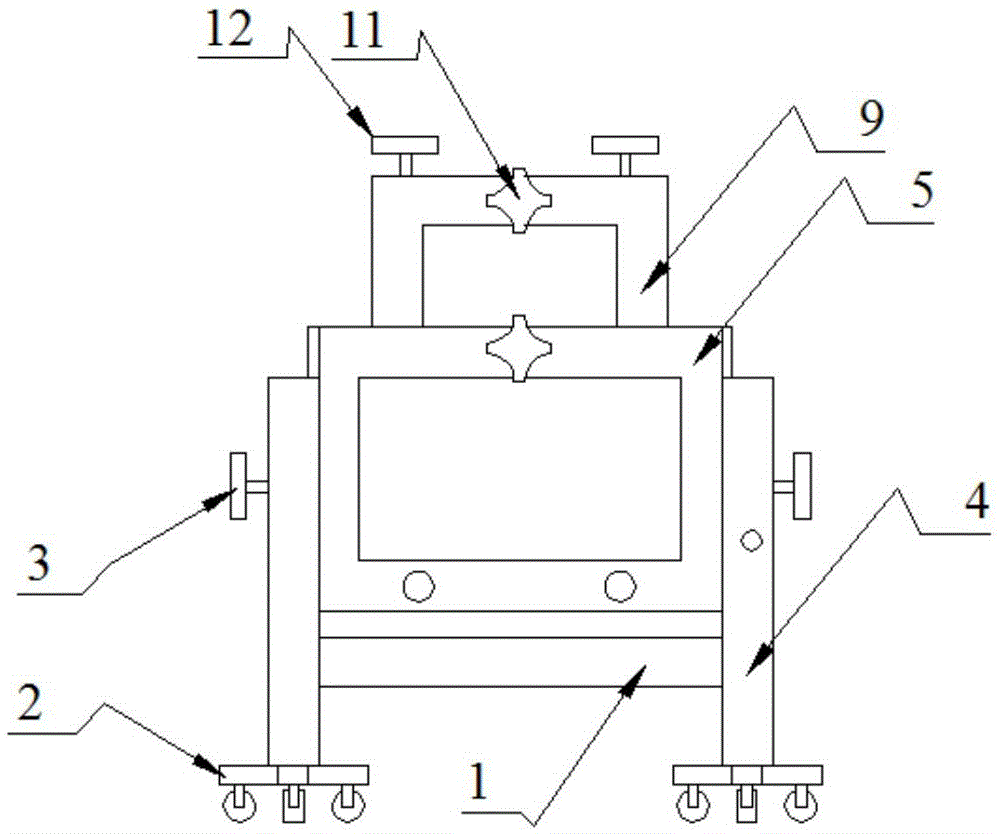

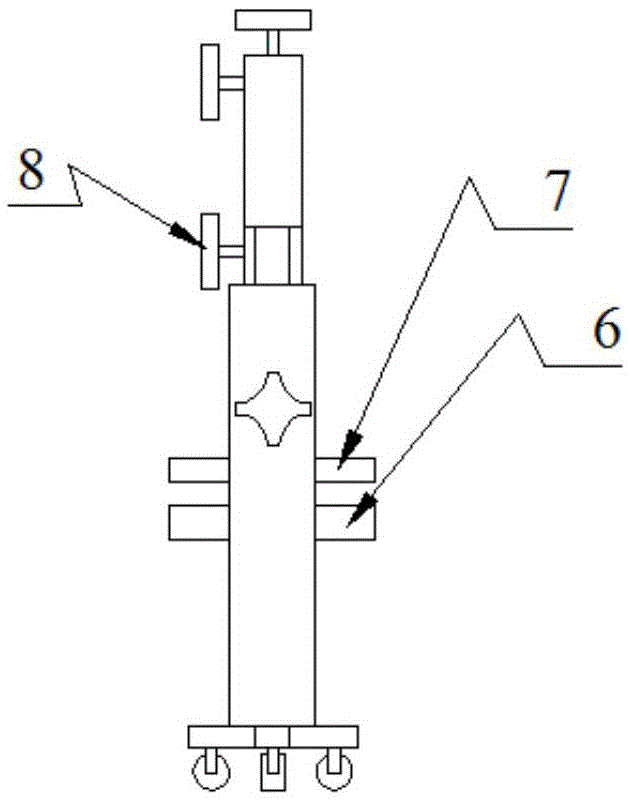

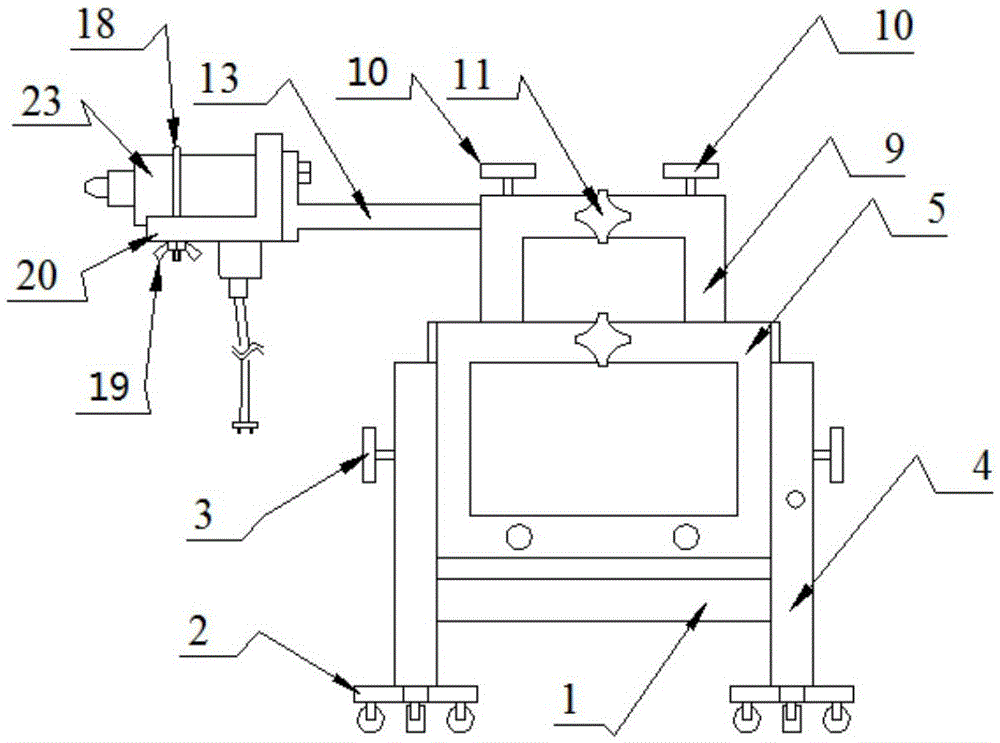

[0034] see Figure 1-Figure 16 , a single-person drilling device for high places on building walls, including three parts: a mobile bracket, a vertical support, and a horizontal support; both the horizontal support and the vertical support are installed on the U-shaped bracket of the mobile bracket, and according to the horizontal hole Adjust the height of the sliding frame, then use the fastening screws on the two columns to fix the sliding frame, and operate the operating handle on the column to realize the drilling of the horizontal hole; according to the position of the vertical hole, adjust the drilling device and align the drilling device with the moving wheel Use the self-locking mechanism on the wheel to lock the wheel, and operate the operating handle on the sliding frame to realize the drilling of vertical holes;

[0035] The mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com