UV laser drilling method for preparing blind holes controllable in taper

A laser drilling and taper technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of blind hole taper and difficult quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] as the picture shows:

[0010] A method for preparing a blind hole with a controllable taper by UV laser drilling of the present invention comprises the following steps:

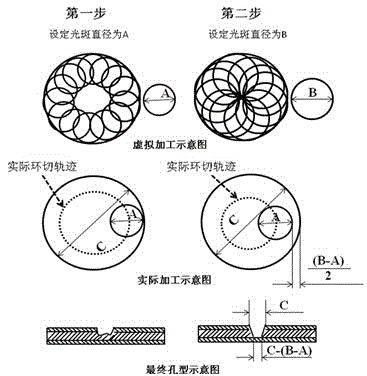

[0011] 1. The laser beam scans along a certain trajectory within the set aperture range. Each micro via hole is formed in two steps. By adjusting the energy, defocus amount and spot size of each step parameter, a blind with controllable taper is prepared. hole.

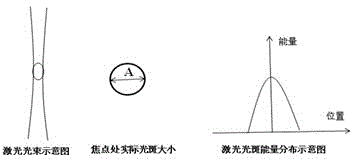

[0012] 2. The energy distribution of the laser beam is Gaussian distribution, the energy at the center of the beam focus is the largest, and the energy at the edge is relatively small.

[0013] 3. The diameter of the formed hole is related to the set aperture and the set value of the light spot. When the set value of the light spot is the actual spot size at the focus of the beam, the set aperture size is consistent with the target apert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com