Bookbinding punching device

A technology of punching device and stapler, which is applied in binding, metal processing, etc., can solve the problems of high cost of binding equipment, consumption of staff's physical strength, and complicated operation of binding equipment, so as to improve service life, improve work efficiency, Convenient fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

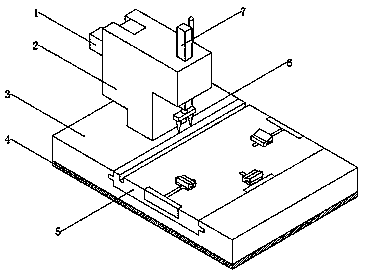

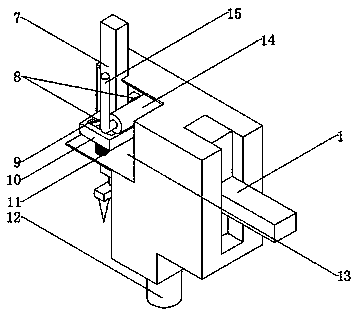

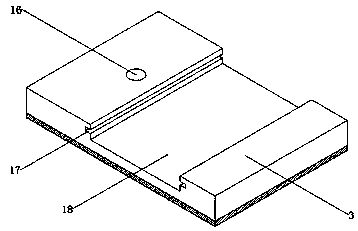

[0013] A binding and punching device, including a stapler 1, a box body 2, a base 3, a rubber pad 4, a slide plate 5, a staple 6, a column 7, a linkage rod 8, a chute 9, an extruding plate 10, and a spring 11. Rotating column 12, transmission compartment 13, rotating shaft 14, control rod 15, rotating groove 16, sliding groove 17, sliding groove 18, fixed pin 19, staple groove 20, sliding convex contact 21, fixed clip convex contact 22. Fixing clip slideway 23, fixing pin groove 24 and fixing clip 25, a stapler 1 is arranged at one end of the top of the box body 2, a transmission cabin 13 is arranged inside the other end of the top of the box body 2, and the column 7 runs through the transmission cabin 13, and the column Staples 6 are installed at the bottom of 7, and extruding plate 10 is arranged at the bottom of column 7 in transmission com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com