motor actuator

A technology of actuators and motors, which is applied in the direction of electric components, casings/covers/supports, and mechanical energy control, to achieve the effect of simple structure and difficult vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described by way of example based on the drawings. However, materials, shapes, relative arrangements, and the like of components described in this embodiment are not intended to limit the scope of the present invention to these unless otherwise specified.

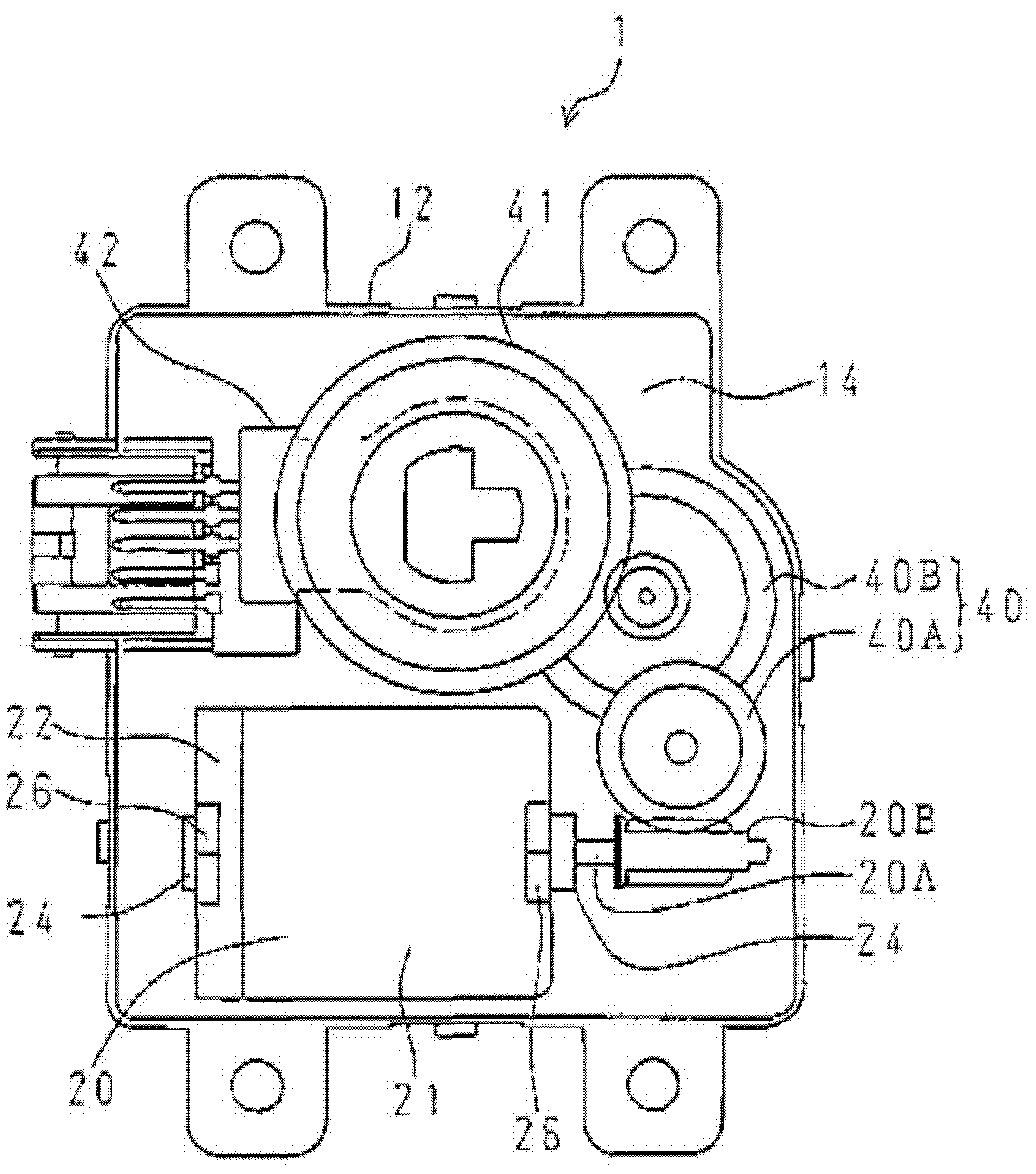

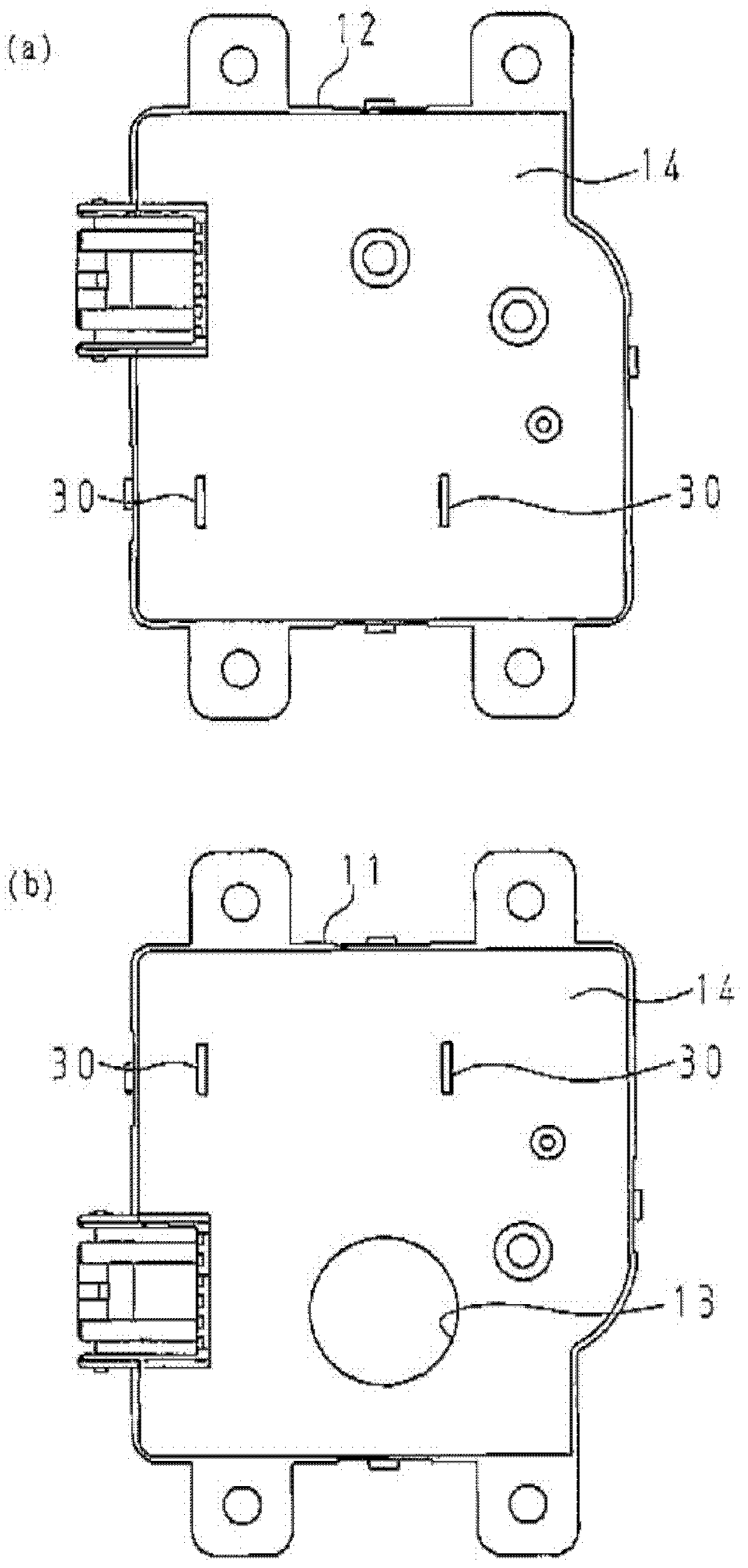

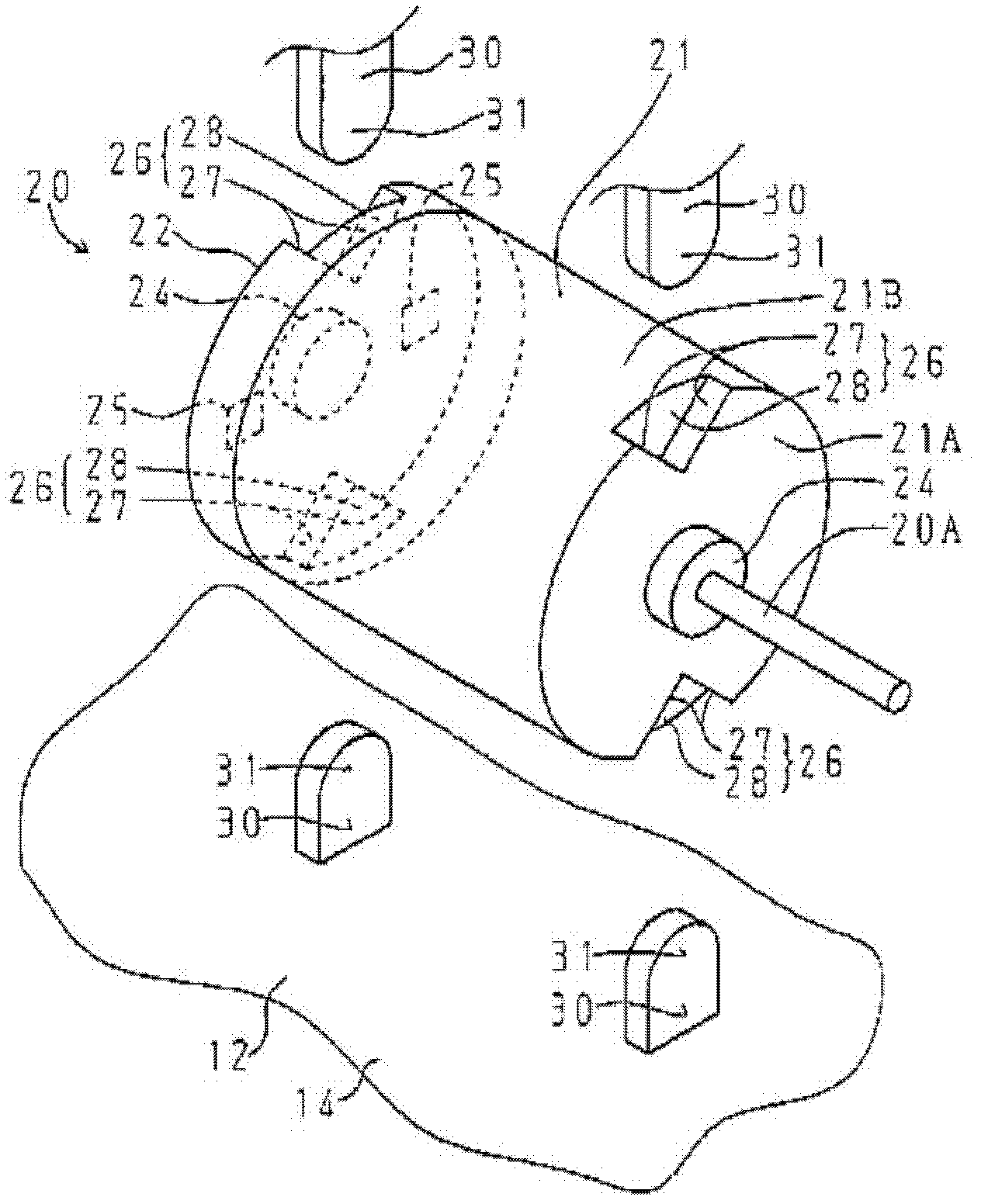

[0019] figure 1 It is a plan view of the motor actuator excluding the upper case according to one embodiment of the present invention. figure 2 (a) is figure 1 A top view of the lower shell, figure 2 (b) is figure 1 A top view of the upper shell. image 3 Yes figure 1 A perspective view of the assembly near the motor. Figure 4 Viewed from the direction of the axis of rotation, the figure 1 A side view of the upper and lower case when the motor is inside. Figure 5 is configured in figure 1 Front view of the motor inside the upper and lower housings.

[0020] like Figure 1 to Figure 5 As shown, the motor actuator 1 of this example is used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com