3d printer printing platform

A 3D printer and printing platform technology, used in manufacturing auxiliary devices, processing material handling, additive processing, etc., can solve the problems of workpiece forming plate shaking, easy damage, loose screws, etc., to facilitate installation, improve service life, Improve the effect of locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

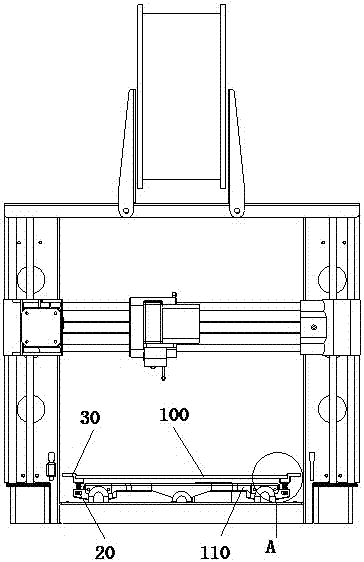

[0037] Such as Figure 1-7 As shown, in this example, figure 1 It is a diagram illustrating the complete assembly of the workpiece forming board 100 of the overall 3D printer. In the figure, the workpiece forming board 100 is placed on the moving table 110, and the moving table 110 moves axially along the guide rail 120;

[0038] In this embodiment, a support seat 20 is provided below the mobile table 110 , the upper surface of the support seat 20 exceeds both sides of the mobile table 110 , and the support seat 20 is fixedly connected with the mobile table 110 .

[0039] In this embodiment, the middle part of the support base 20 is provided with a through hole 210 for being sleeved on the slide rail 120. Sides (111, 112), the front or rear side of the support seat 20 is provided with a convex hull 220, and the corner 111 at the front or rear of the mobile table is provided with a slot that matches the convex hull 220 .

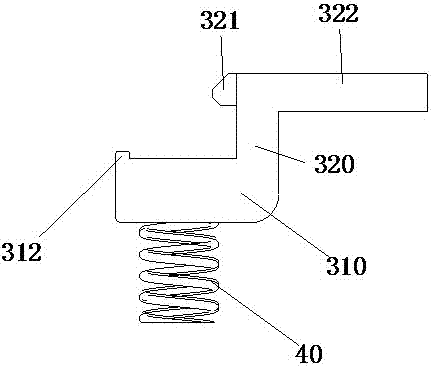

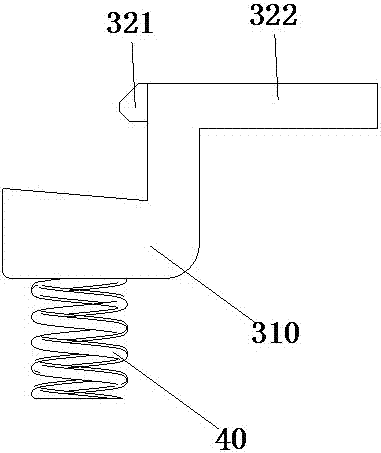

[0040] The corner edge 112 on the side of the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com