Waste incineration boiler

A waste incineration and boiler technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of short continuous operation time, high operation and maintenance costs, easy ash accumulation, etc., to achieve less leakage, lower maintenance costs, and dust accumulation little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

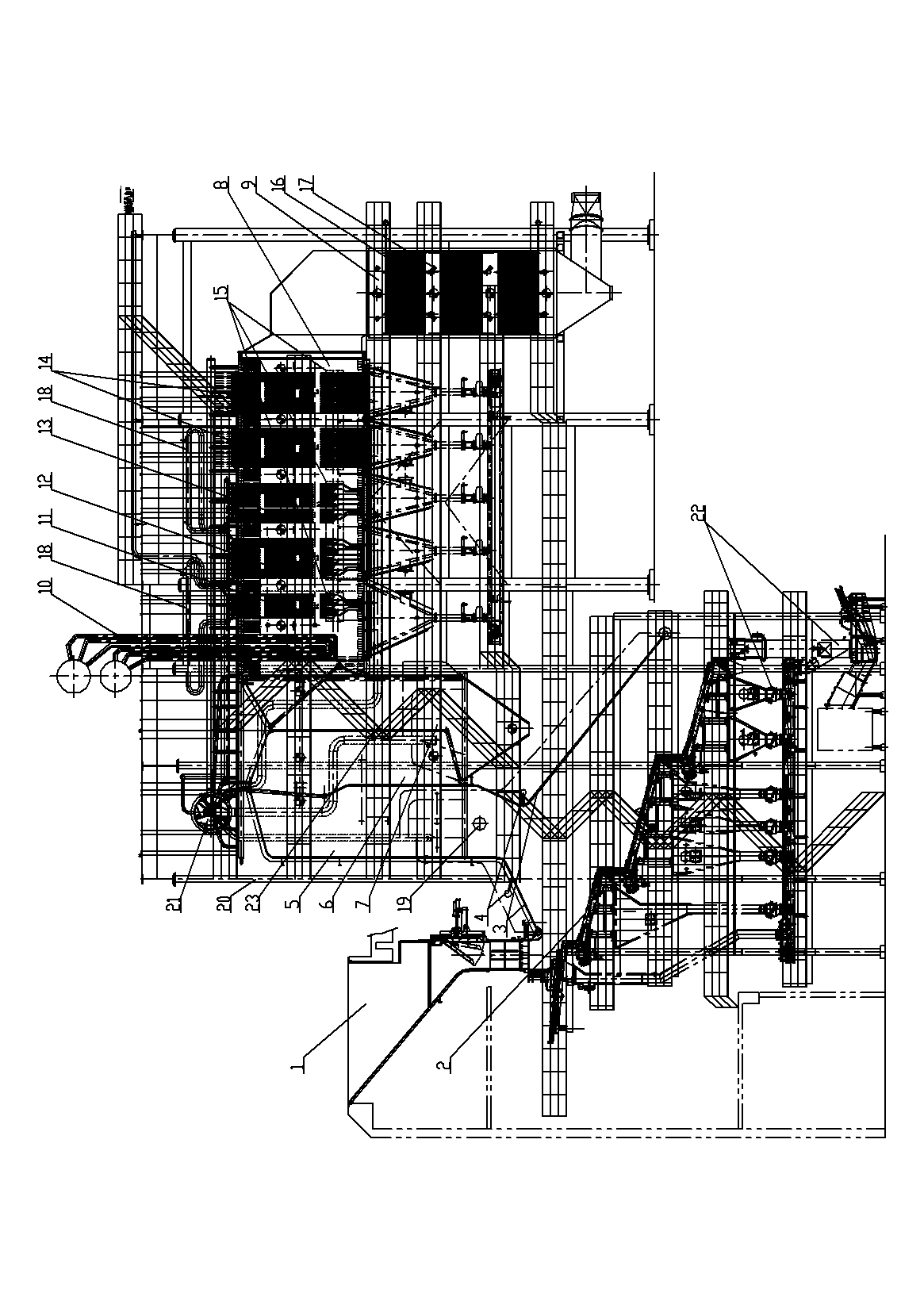

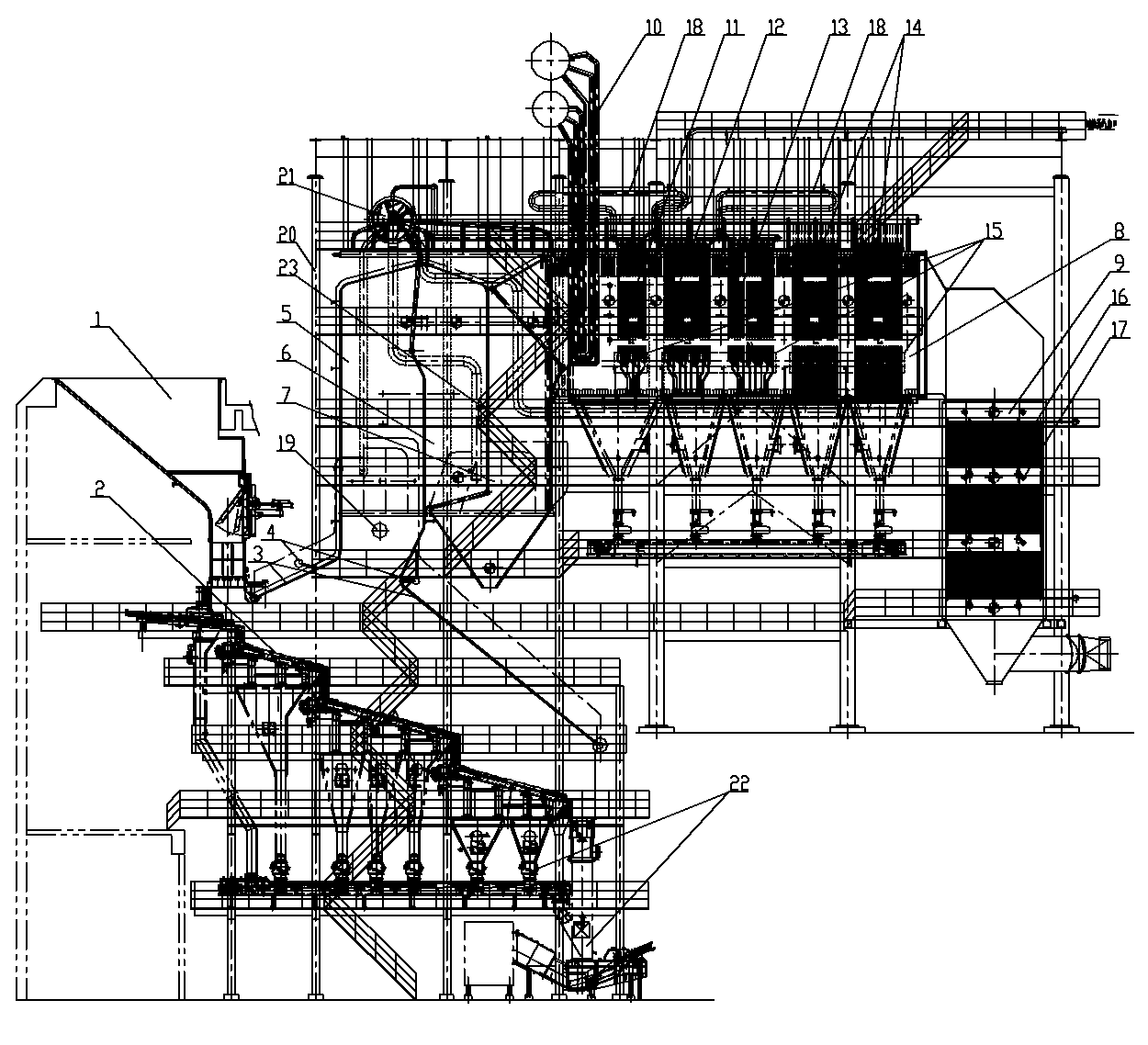

[0010] See figure 1 , which includes a furnace 5, a fire grate 2, and a horizontal flue 8. A garbage hopper 1 is installed on the front wall of the lower part of the furnace 5, and an auxiliary burner 19 is installed on the side wall of the lower part of the furnace 5. The furnace 5 is located in the Above the fire grate 2, a drum 21 is arranged above the furnace 5, and a front and rear arch 3 is arranged at the bottom of the furnace 5, and a secondary air 4 is arranged on the front and rear arch 3, and the secondary air 4 is directed toward the The fire grate 2, the horizontal flue 8 is arranged with an air preheater 10, a superheater, and an evaporator 14, and the furnace 5 is connected to the vertical combustion chamber 6, the vertical three flues 7, the horizontal flue 8 and the tail A vertical flue 9, an economizer 16 is arranged in the tail vertical flue 9, and a shock wave or steam sootblower 17 is arranged in the tail vertical flue 9. The superheater in the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com