Lightweight backsheet for photovoltaic module, and photovoltaic module therefor and preparation method thereof

A photovoltaic module, lightweight technology, applied in chemical instruments and methods, photovoltaic power generation, electrical components, etc., can solve problems such as bubbling, deformation creep, degumming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

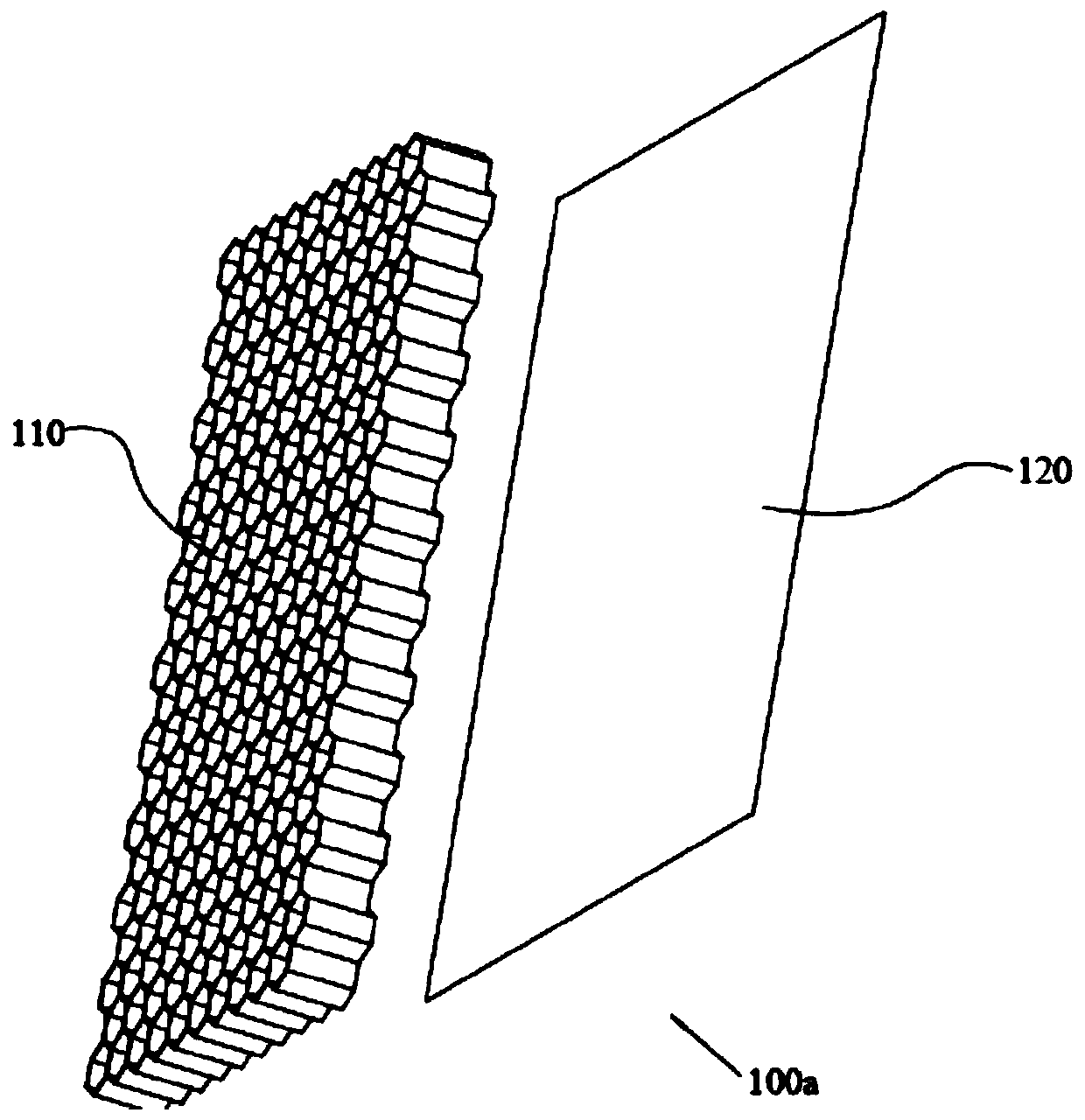

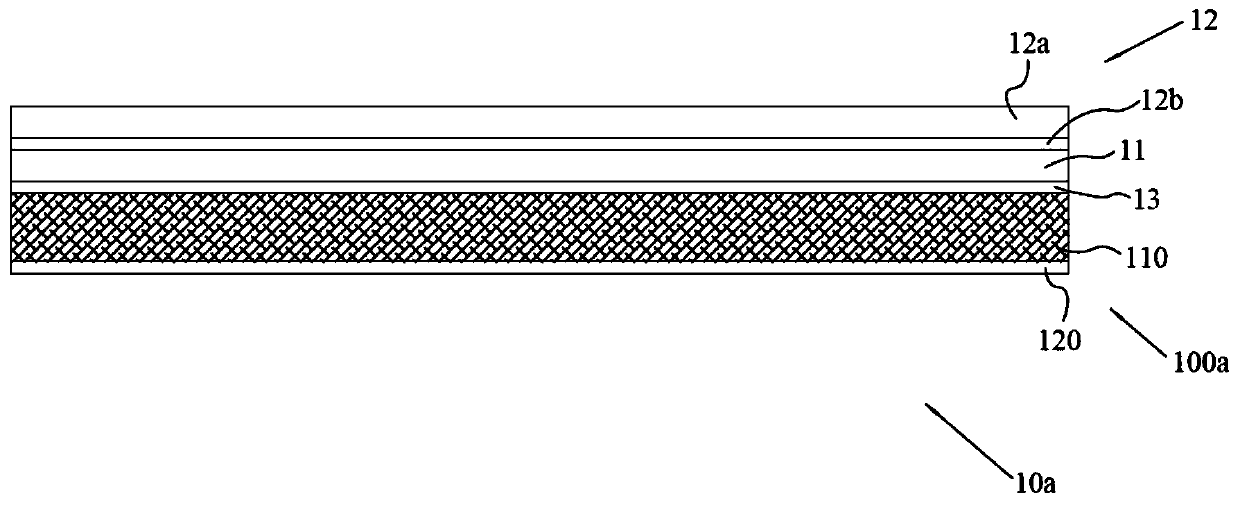

[0053] See figure 1 and figure 2 Shown is a lightweight backsheet 100a for a photovoltaic module. The lightweight backsheet 100a includes a thermoplastic core layer 110 and a first thermoplastic substrate layer 120 that are combined by hot-melt pressure. The thermoplastic core layer 110 and photovoltaic The adhesive film layer on the back side of the component is directly contacted and connected; wherein, the matrix material of the thermoplastic core layer 110 is a core layer thermoplastic polymer, the matrix material of the first thermoplastic substrate layer 120 is a substrate layer thermoplastic polymer, and the core layer thermoplastic polymer and The material of the thermoplastic polymer of the substrate layer is the same; in this embodiment, the thermoplastic core layer 110 is in the shape of a polygonal honeycomb with a thickness ranging from 5 to 25 mm, and is formed by hot-melt extrusion technology or other existing composite materials. Known molding process, the pr...

Embodiment 2

[0061] Embodiment 2: the rest of the technical solutions of this embodiment 2 are the same as those of embodiment 1, the only difference is: please refer to Figure 4 , Figure 5 and Figure 6 As shown, this embodiment 2 proposes a photovoltaic module 10b, including a lightweight backsheet 100b, the thermoplastic core layer 110b of the lightweight backsheet 100b is in the shape of porous foam, and is formed by a foaming process.

Embodiment 3

[0062] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, the only difference is: please refer to Figure 7 , Figure 8 and Figure 9As shown, this embodiment 3 proposes a photovoltaic module 10c, including a lightweight backsheet 100c, the other side of the thermoplastic core layer 110 of the lightweight backsheet 100c is compounded with a second thermoplastic substrate layer 130, and the second thermoplastic The plastic substrate layer 130 is in direct contact with the back adhesive film layer 13 of the photovoltaic module 10c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com