Automatic gumming machine for packaging carton box

A gluing machine, automatic technology, applied in the direction of packaging, transportation and packaging, papermaking, etc., can solve the problems of glue dripping on the ground or on the operating table, affecting the cleanliness of the ground or operating table, affecting product quality, etc., to achieve saving The effects of manpower, guarantee of pasting quality, and improvement of gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

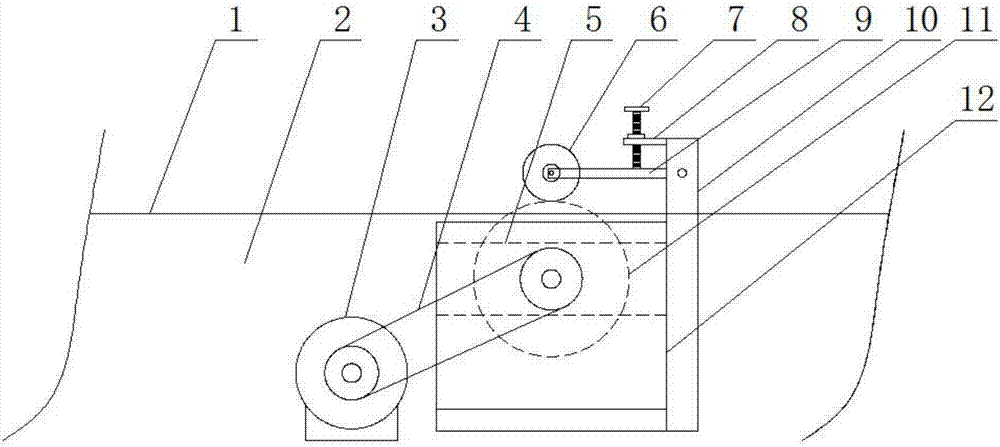

[0018] An automatic gluing machine for packaging cartons, which is innovative in that it includes a frame 2, a conveyor belt 1, a glue tank 12, a heater, a gluing roller 11, a pressing roller 6, an adjustment bracket and a motor 3. A conveyor belt is installed on the frame, and a glue tank with a heater at the bottom is installed on the side of the frame, and a gluing roller driven by a motor chain 4 is installed in the glue tank, and the height of the gluing roller is slightly higher than that of the conveyor belt. Height, a pressing roller is arranged directly above the gluing roller, and the pressing roller is adjusted and installed on an adjusting bracket, and the adjusting bracket is installed on the side of the glue tank.

[0019] Desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com