Production process of enamel steel plate

A production process and technology of steel plates, applied in the field of production technology of enamel steel plates, can solve the problems of poor impact resistance and elasticity, short service life, cumbersome process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

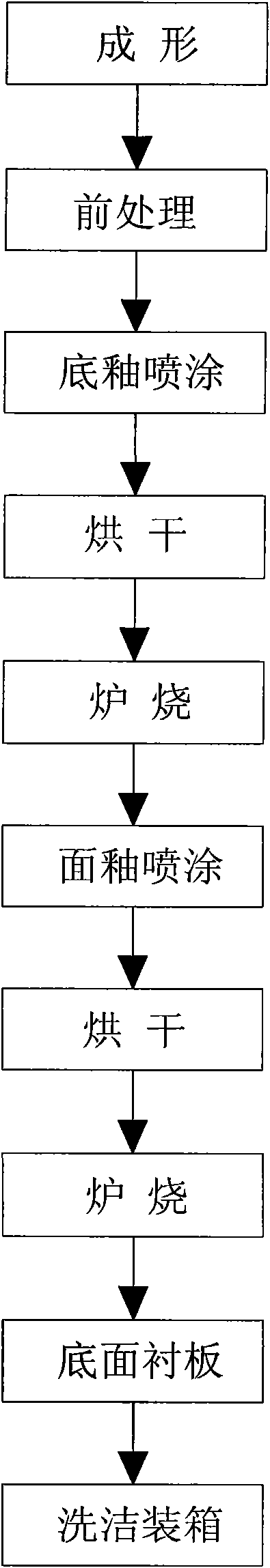

[0030] Such as figure 1 Shown, a kind of production technique of enamelled steel plate of the present embodiment comprises the following steps:

[0031] Step 1. Forming: Cut the steel plate substrate to be processed into the desired shape; the steel plate substrate is first drawn by computer, and then cut into the desired shape by the laser cutting machine according to the digital data of the design drawing input by the computer , and then through the bending machine to make surface features such as face angles, side angles or arcs.

[0032] Step 2. Pretreatment: Chemically treat the formed steel plate substrate to remove pollutants and derust at the same time;

[0033] Step 3, bottom glaze spraying: spray bottom glaze on the steel plate substrate;

[0034] Step 4, drying: drying the base glaze on the steel plate base material sprayed with the primer at 100°C to 250°C to form a biscuit state;

[0035] Step 5. Furnace firing: Preheat the steel plate base material to 400°C, p...

Embodiment 2

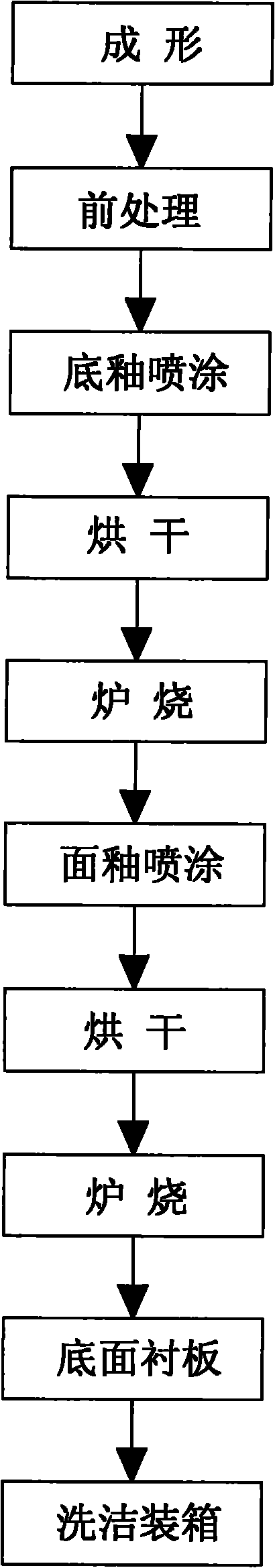

[0047] A kind of production technology of enamelled steel plate of the present embodiment, comprises the following steps:

[0048] Step 1. Forming: cutting the steel plate substrate to be processed into the desired shape;

[0049] Step 2. Pretreatment: Chemically treat the formed steel plate substrate to remove pollutants and derust at the same time;

[0050] Step 3, bottom glaze spraying: spray bottom glaze on the steel plate substrate;

[0051] Step 4, drying: drying the base glaze on the steel plate base material sprayed with the primer at 100°C to 250°C to form a biscuit state;

[0052] Step 5. Furnace firing: Preheat the steel plate base material to 400°C, put it into an enamel firing electric furnace and heat it to 800°C, and fuse the enamel bottom glaze with the surface layer of the steel plate base material;

[0053] Step 6, surface glaze spraying: spray a layer of surface glaze on the steel plate substrate according to the required color;

[0054] Step 7, drying: d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com