Patents

Literature

32 results about "Corner tube boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cornertube boiler is a type of natural circulation water-tube boiler which differentiates itself from other water tube boilers by its characteristic water-steam cycle and a pre-separation of heated steam from the steam-water mixture occurs outside the drum and the unheated downcomers.

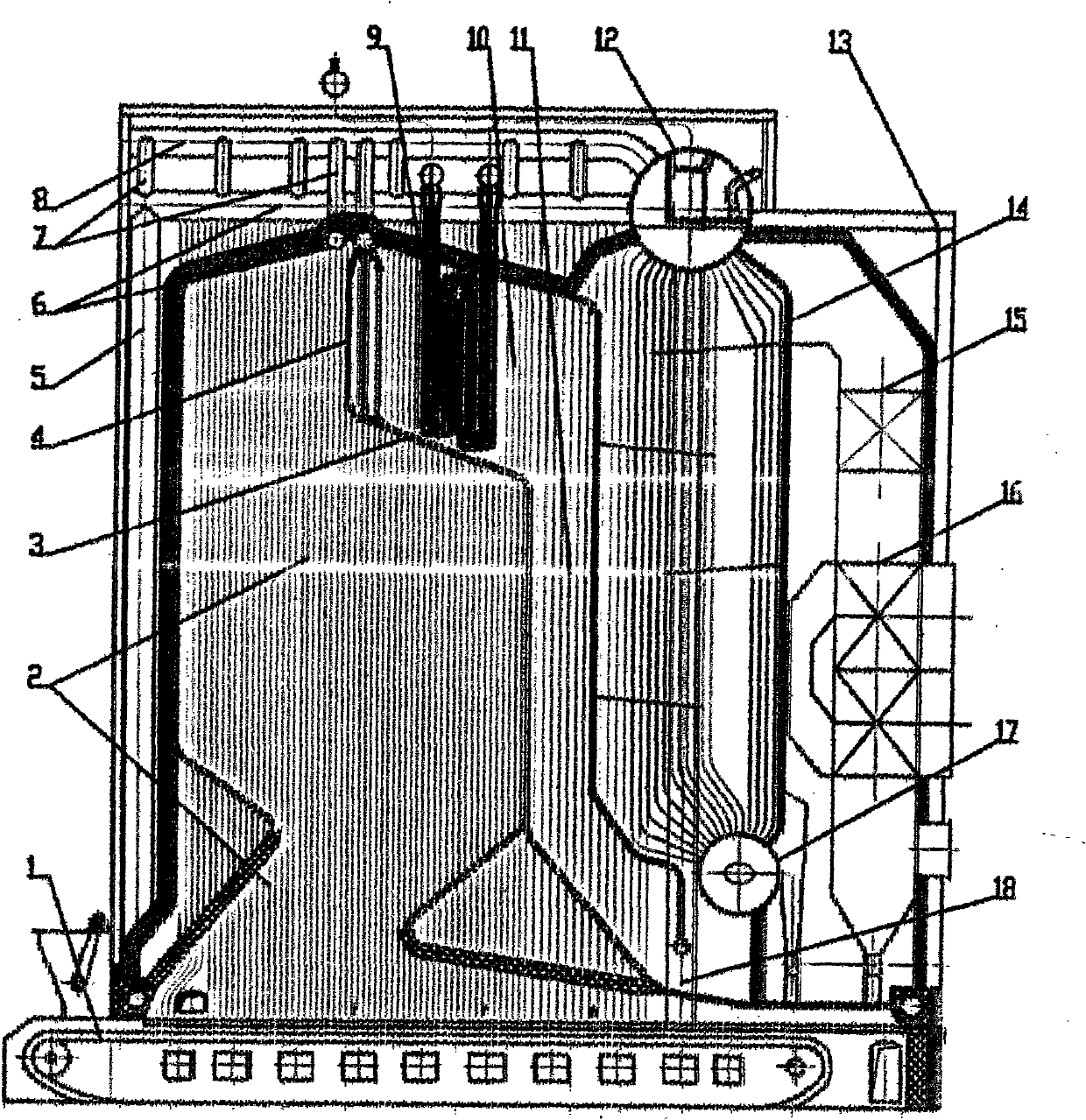

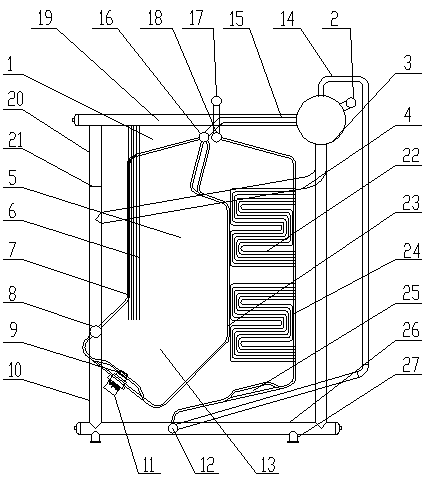

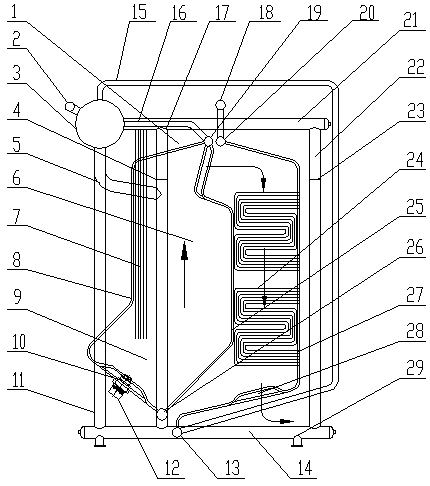

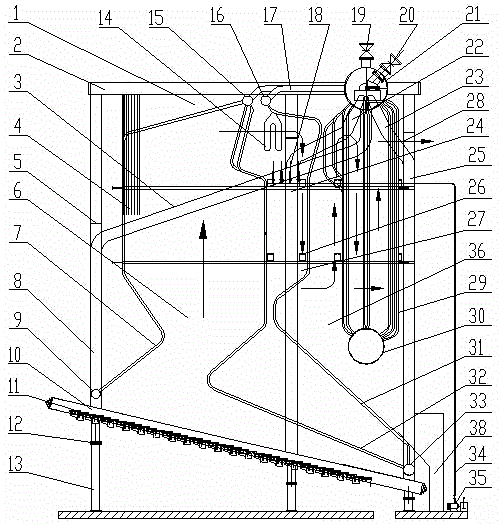

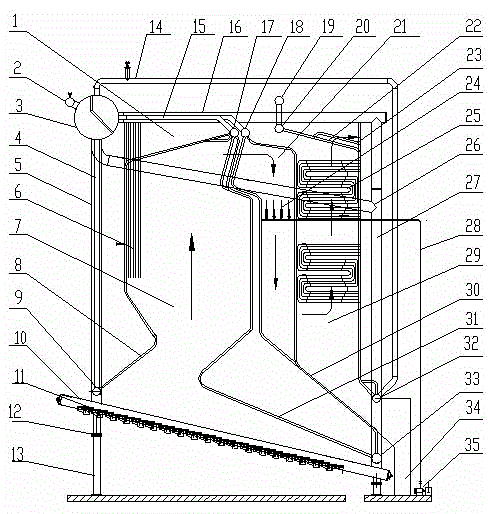

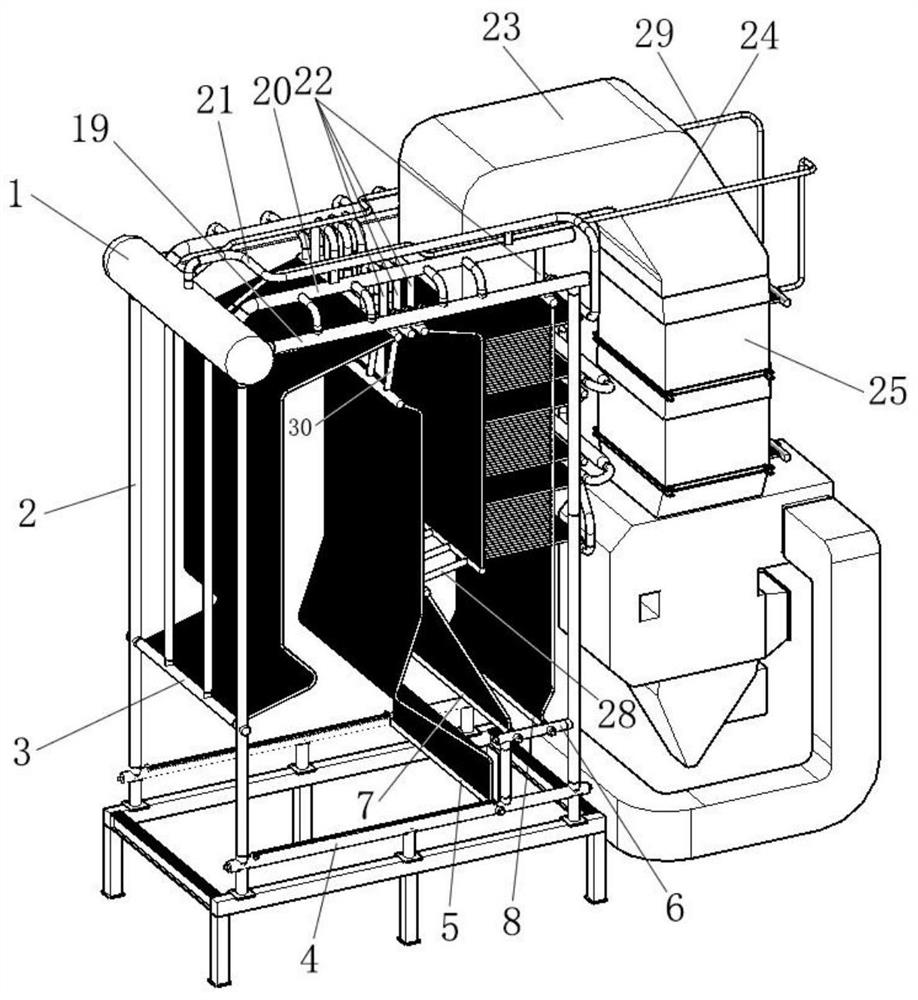

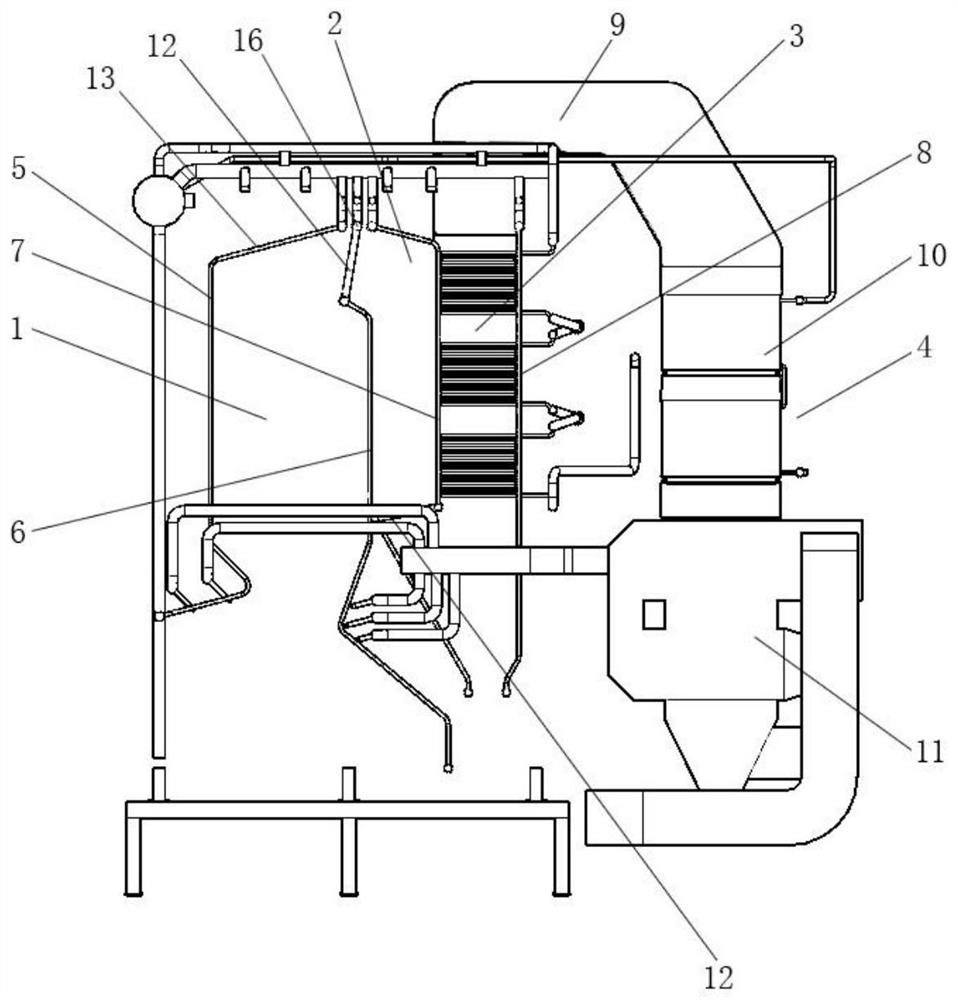

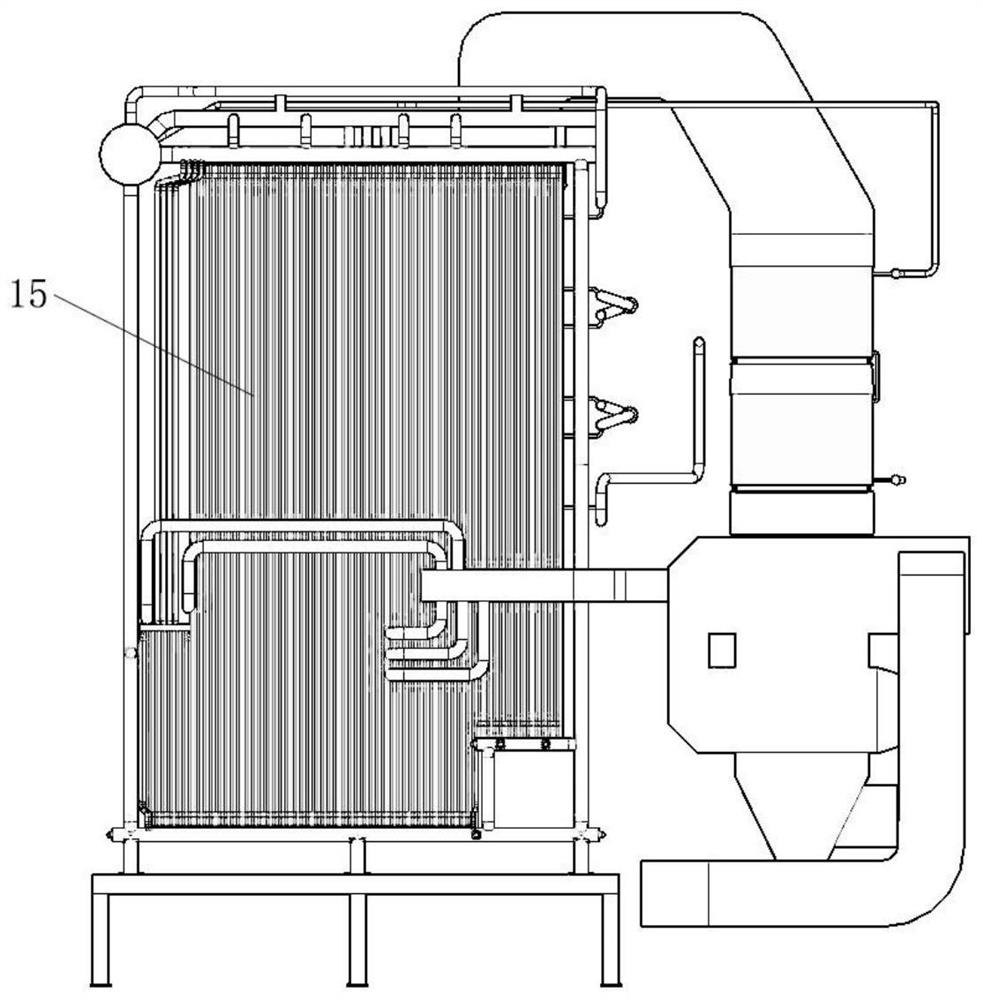

Vertical coal dust corner tube boiler

InactiveCN102644911ACompact structureStructure, compact arrangement of four cornersSteam boilersAir preheaterCoal dust

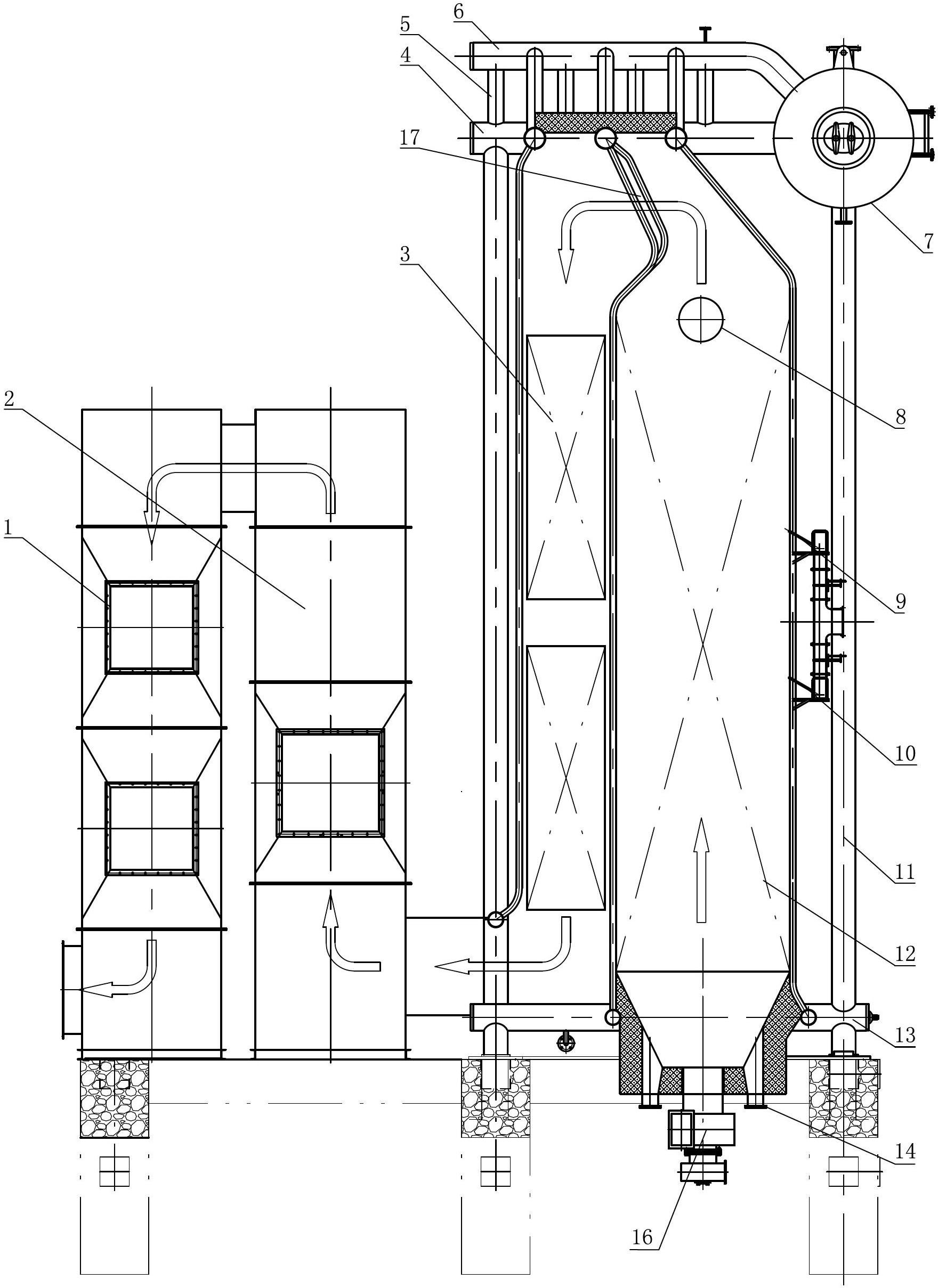

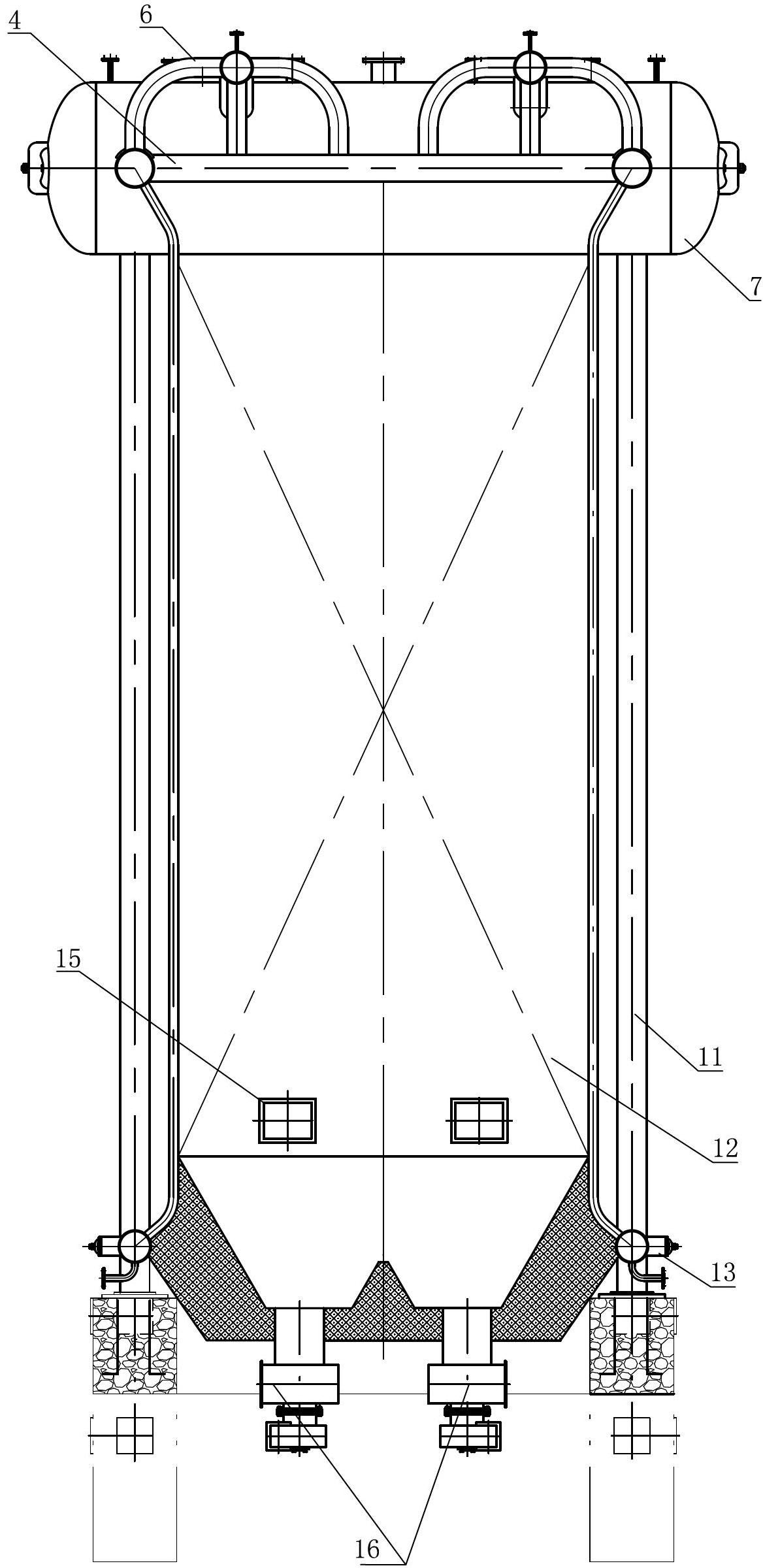

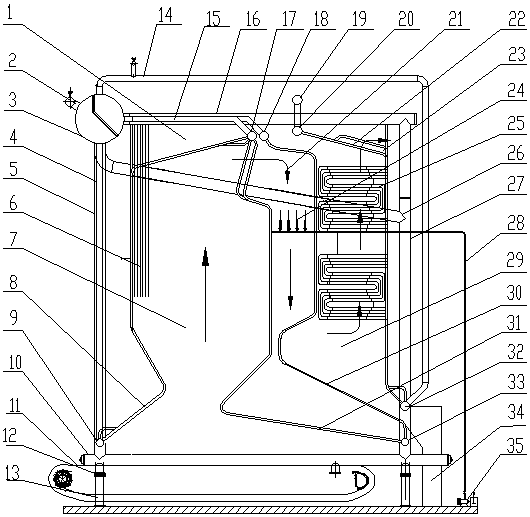

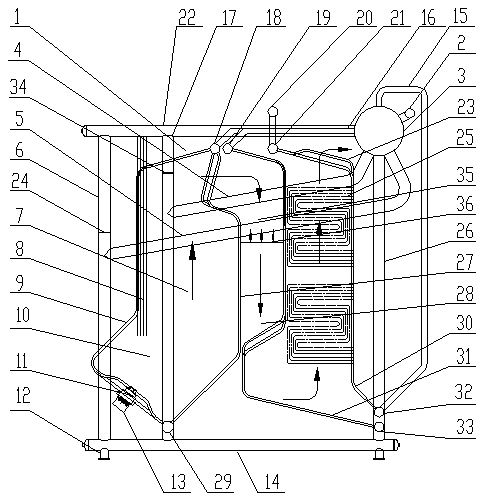

The invention discloses a vertical coal dust corner tube boiler, which comprises a burner, a boiler body, an air preheating device, a waste heat water tank, a convection bank, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of the boiler body, and the upper collecting box and the top collecting box are arranged on top of the boiler body and communicated through a steam communicating pipe. The vertical coal dust corner tube boiler is characterized in that the burner is arranged at the bottom of the boiler body which adopts a vertical film type water cooling wall structure, four lowering pipes are arranged at four corners, and two ends of the lowering pipe and the film type water cooling wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged outside the film type water cooling wall, the top of the convection tube bundle is communicated with a boiler chamber smoke outlet, and the bottom of the convection tube bundle is communicated with the waste heat water tank. The vertical coal dust corner tube boiler has the advantages of being compact in integral structure, simple in appearance display, small in covered area, low in steel consumption, big in boiler water circulation pressure difference and safe and reliable in water circulation and the like.

Owner:HANGZHOU JUNENG BOILER

Novel layer burning boiler

InactiveCN101949531AImprove efficiencyReduce raw emission concentrationSteam boilersAir preheaterEngineering

The invention provides a novel layer burning boiler. A hearth smoke outlet is arranged above the middle part of a hearth; the hearth of the boiler adopts the hearth structure of a corner tube boiler; and the main convection heating surface of the boiler adopts the boiler convection tube bank structure of an SHL boiler. A large amount of heating surface tubes such as boiler tube banks are connected with upper and lower boiler barrels directly, and the boiler adopts a water cooled communicating tube supporting and steel frame supporting combined supporting mode. The novel layer burning boiler has the characteristics that: the smoke in the hearth is fully mixed; the dust content of the smoke is low; the temperature of the effluent of an economizer is low; the large amount of boiler banks are convenient to check and maintain; the economizer and an air preheater can be arranged flexibly and conveniently; and the like. The novel layer burning boiler is mainly used in the fields requiring traveling grate boilers and reciprocating grate boilers.

Owner:TIANJIN BAOCHENG MACHINERY MFG

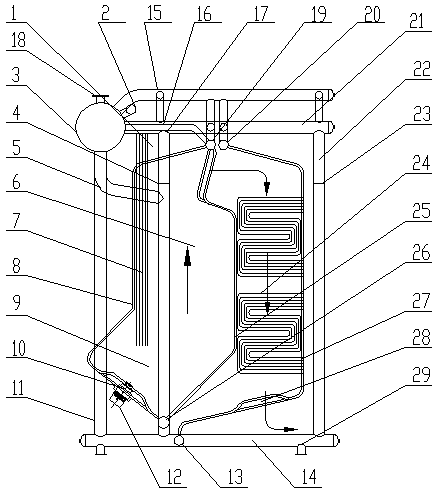

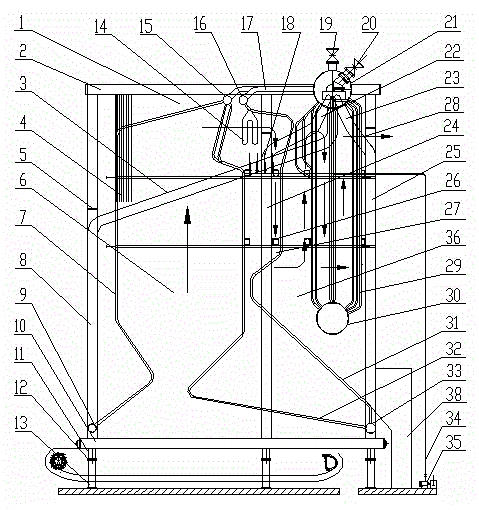

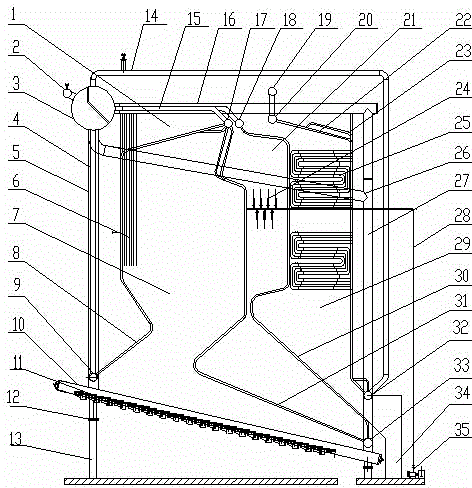

Vertical type coal dust corner tube boiler

InactiveCN103062747AFull reaction combustionImprove sealingSteam boilersAir preheaterDifferential pressure

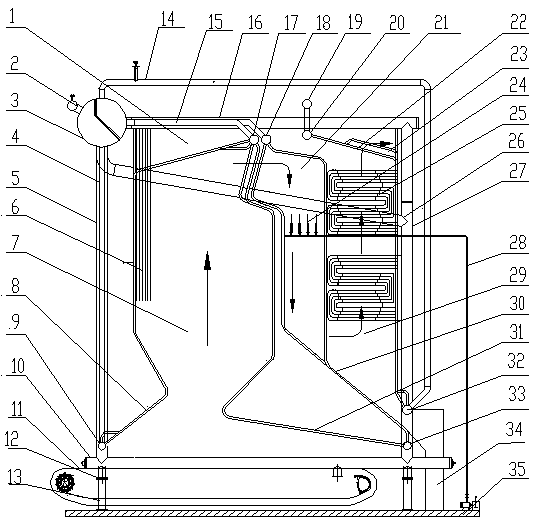

The invention discloses a vertical type coal dust corner tube boiler which comprises a burner, a boiler furnace, a high temperature air preheater, a coal economizer, a low temperature air preheater convection tube bundle, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of a boiler body, and the upper collecting box and the top collecting box are arranged at the top of the boiler body and are communicated through a vapor communicating pipe. The vertical type coal dust corner tube boiler is characterized in that the burner is arranged in the front of the boiler body, the boiler body is of a vertical type tubular membrane type water-cooled wall structure, four down pipes are arranged at four corners, and the down pipes and two ends of the membrane type water-cooled wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged on the outer side of the membrane type water-cooled wall, the top of the convection tube bundle is communicated with a hearth smoke outlet, and the bottom of the convection tube bundle is communicated with the high temperature air preheater. The vertical type coal dust corner tube boiler has the advantages that an integral structure is compact, the appearance is arranged simply, an occupied area is small, steel consumption is small, water circulating differential pressure of the boiler is large, and water circulation is safe and reliable, and the like.

Owner:HANGZHOU JUNENG BOILER

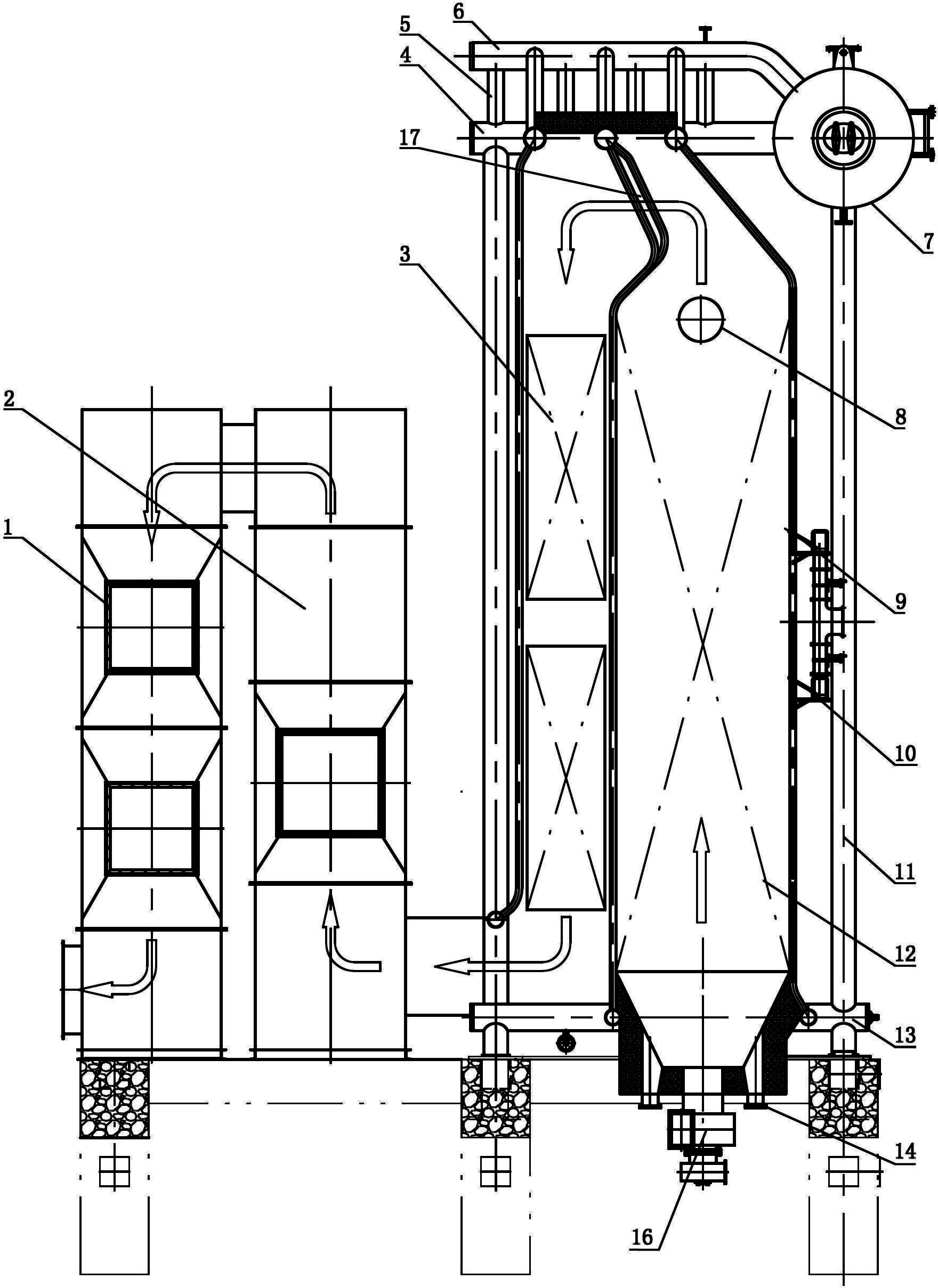

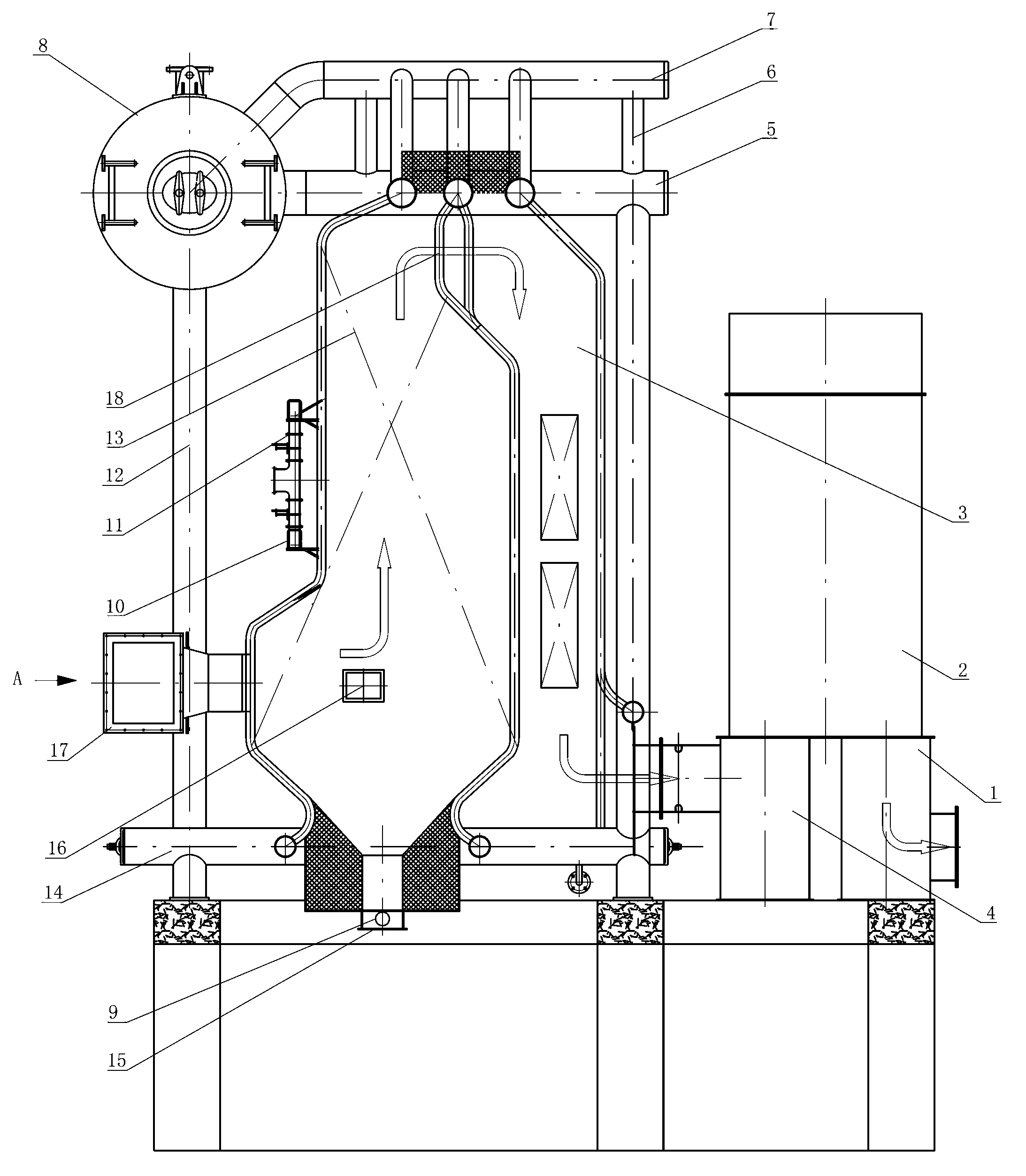

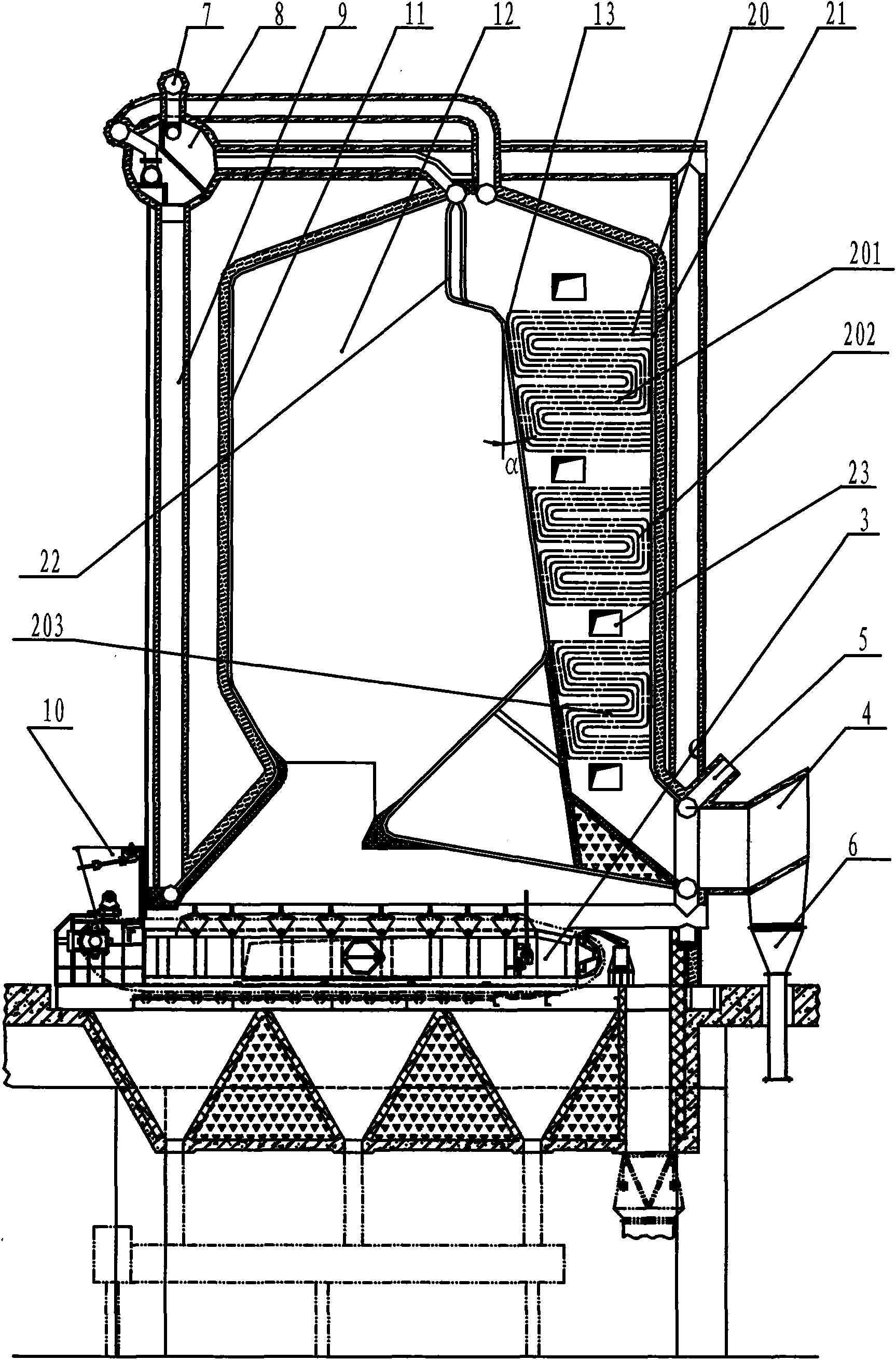

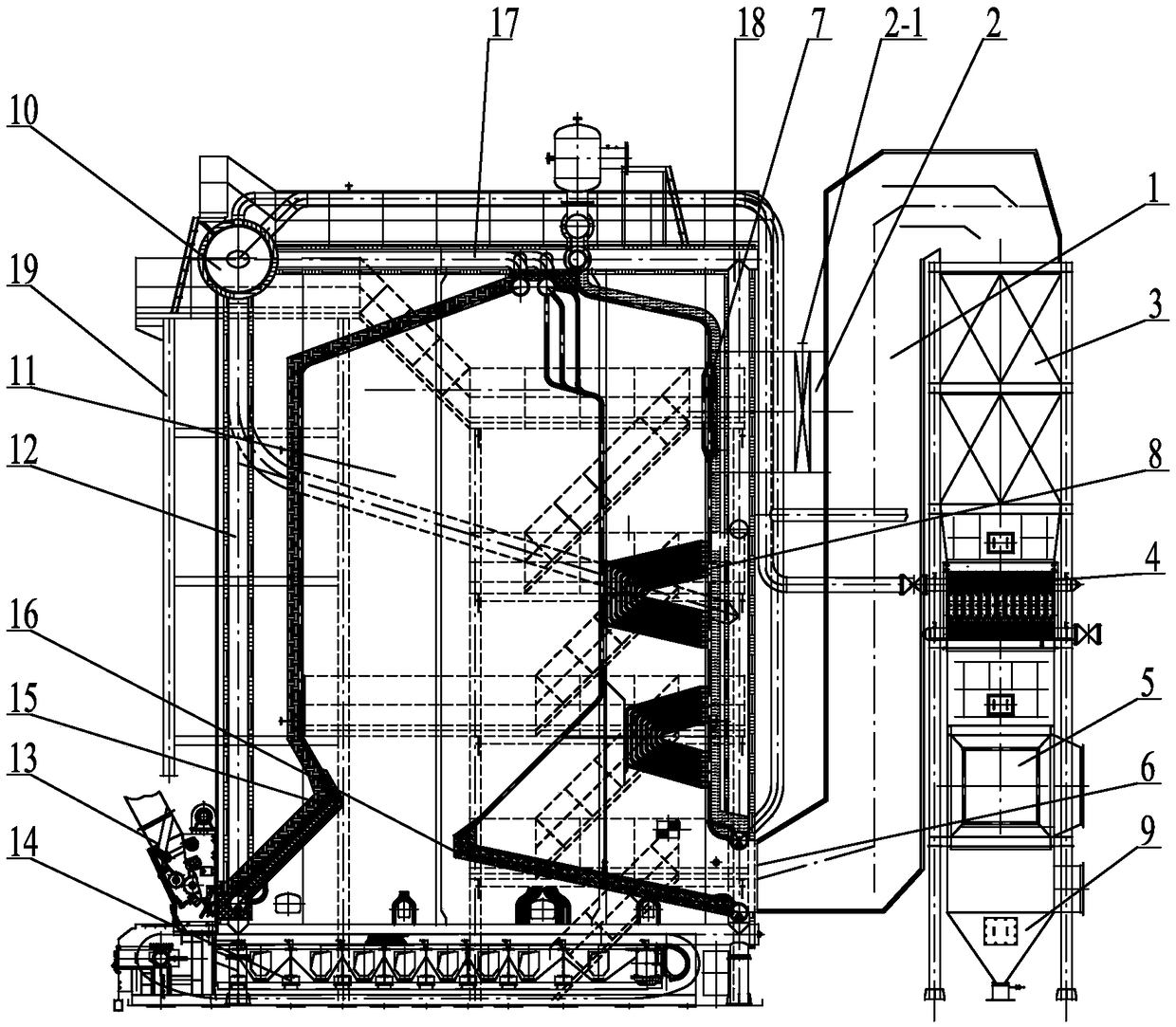

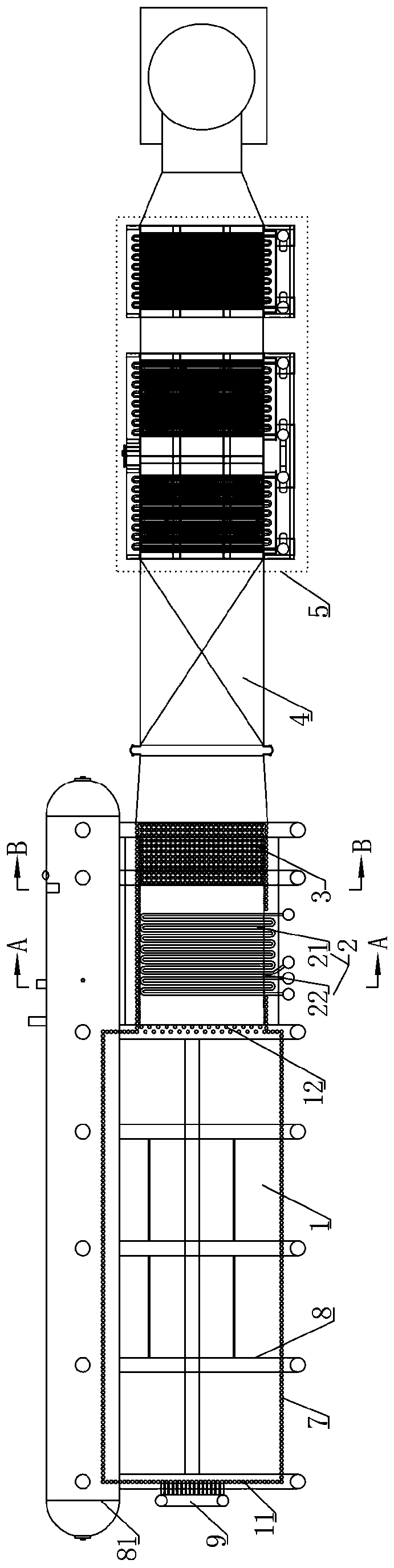

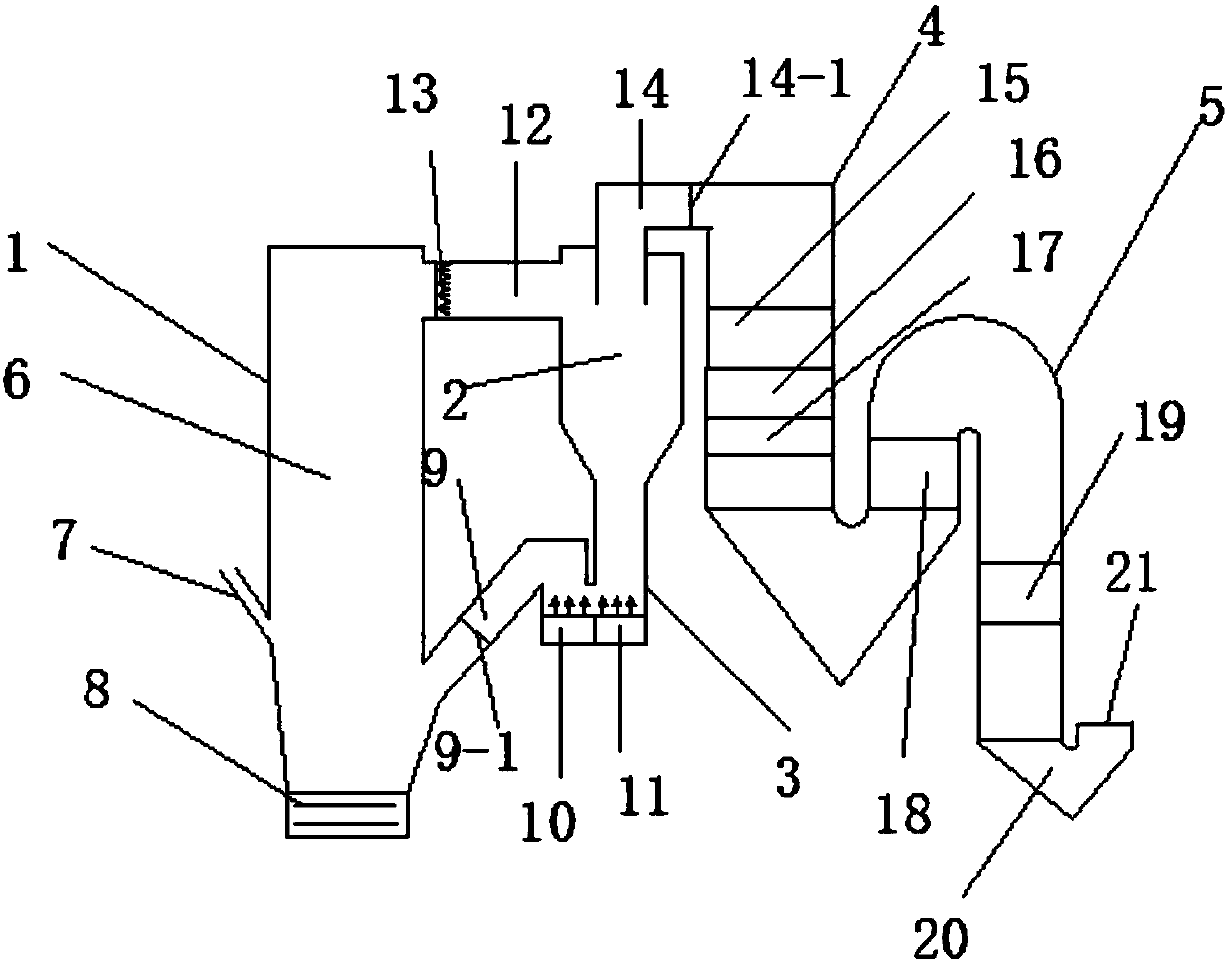

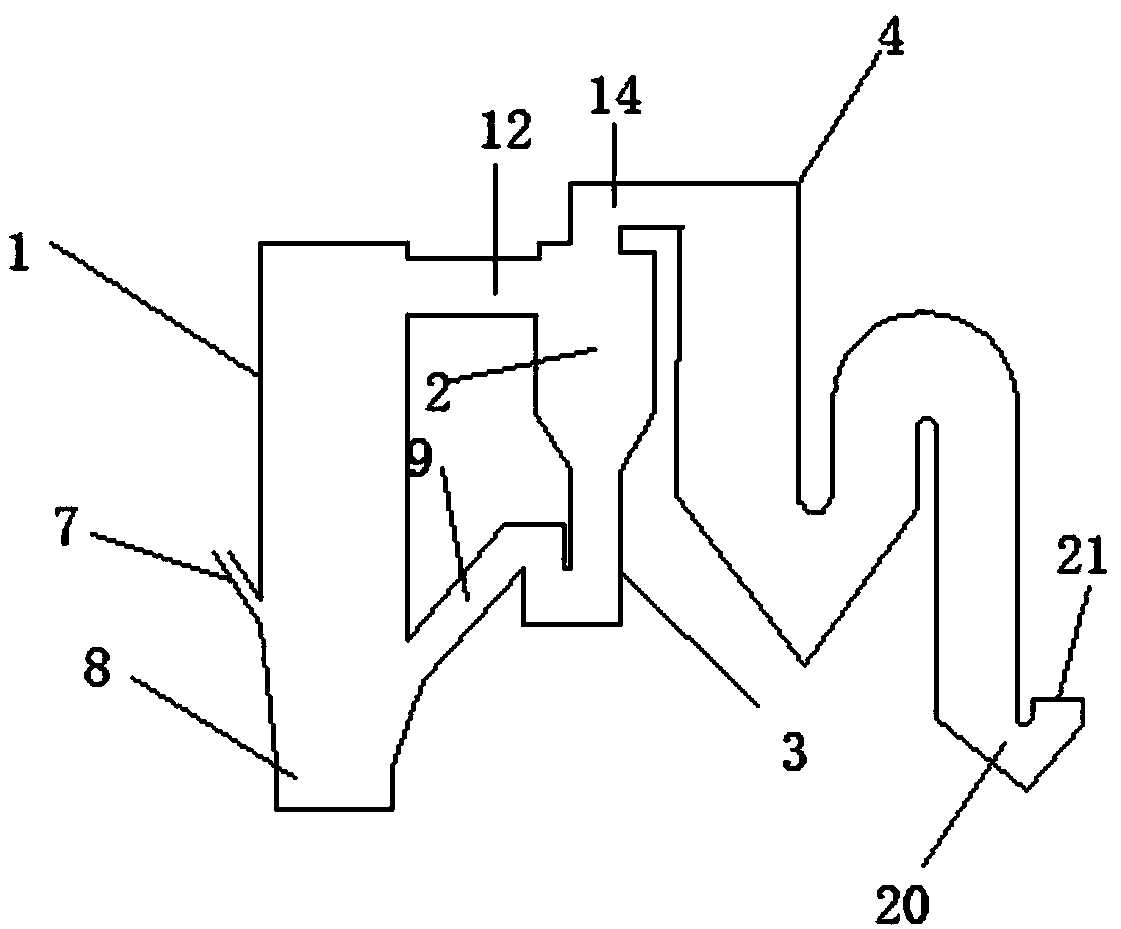

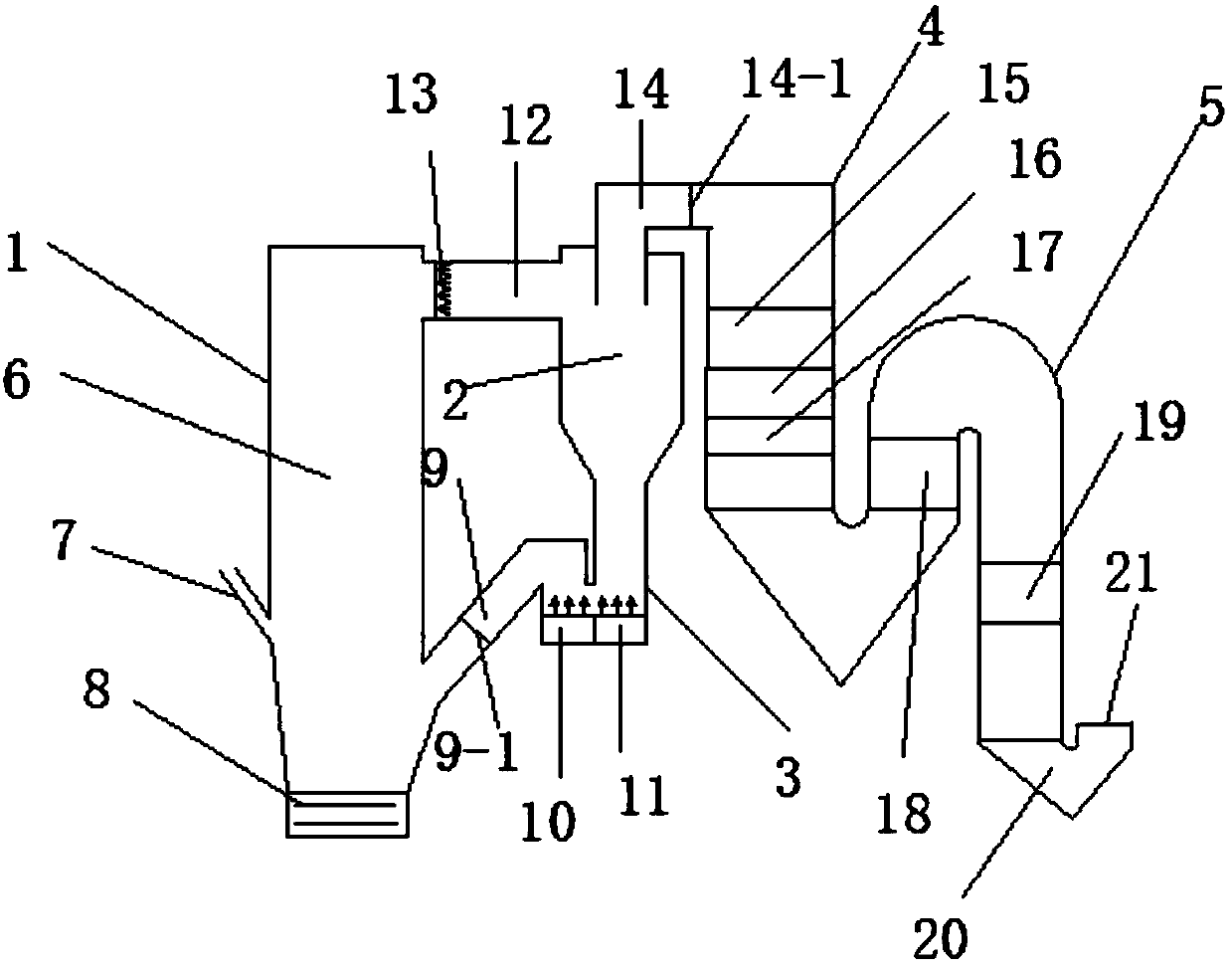

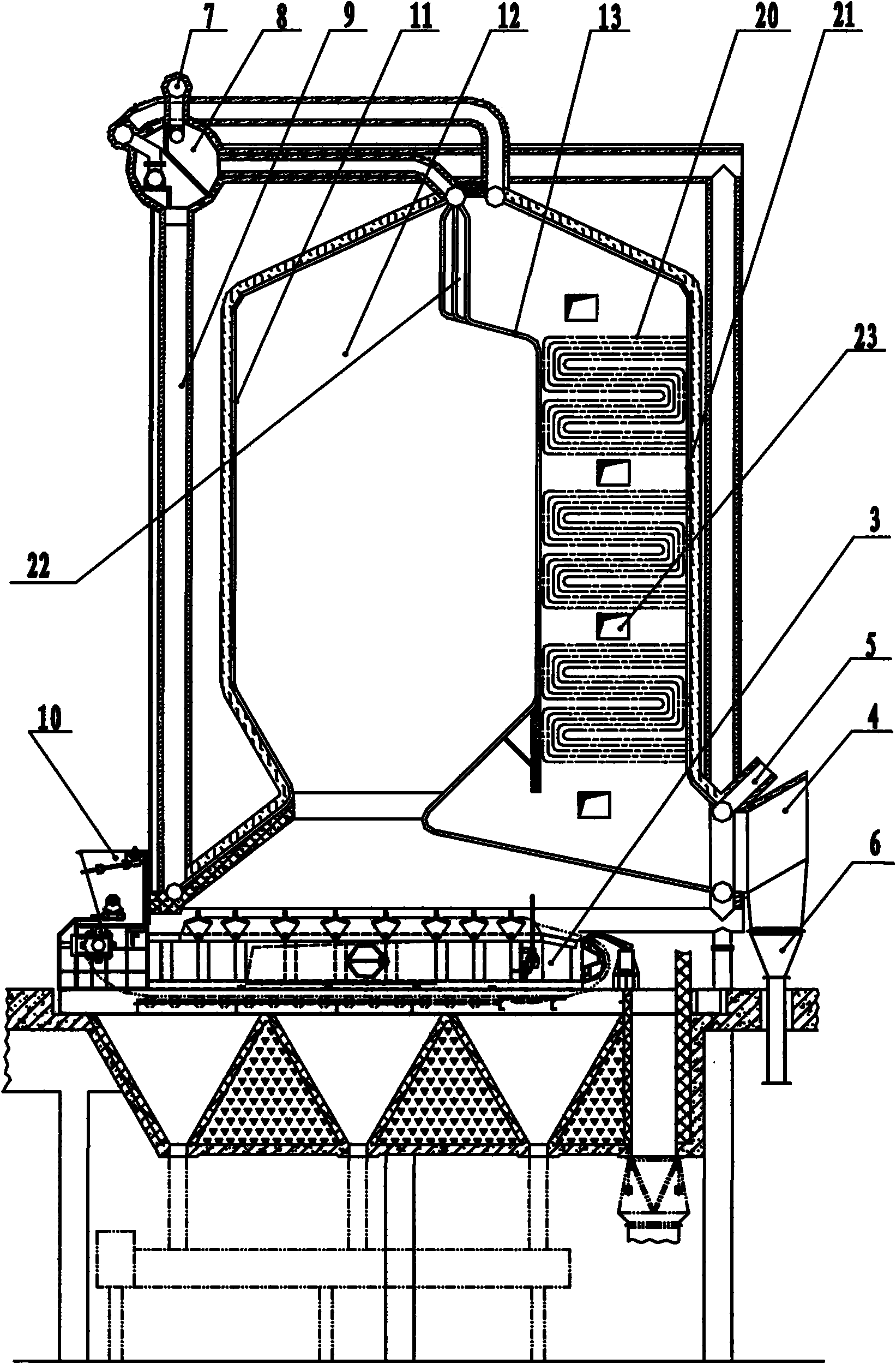

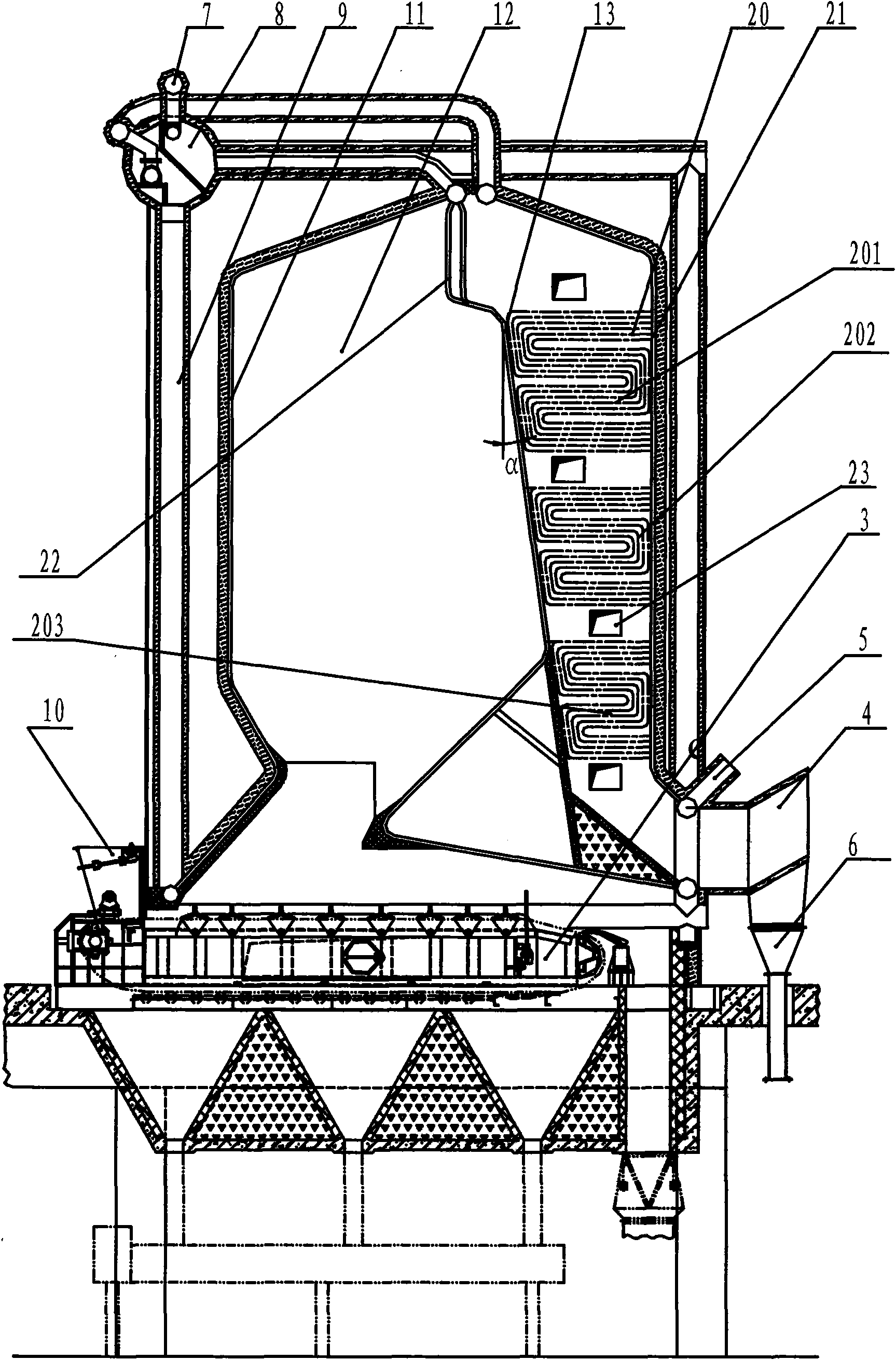

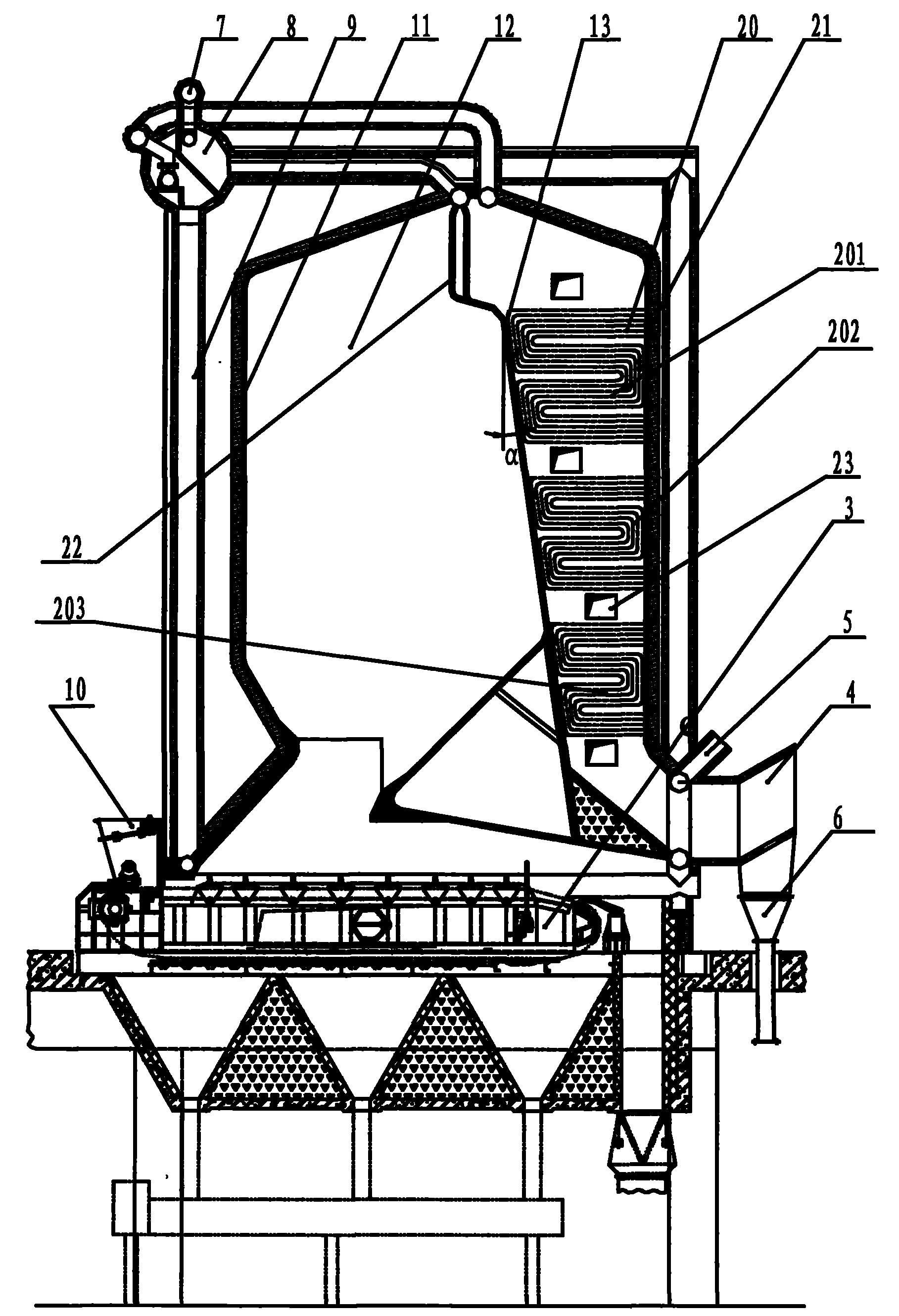

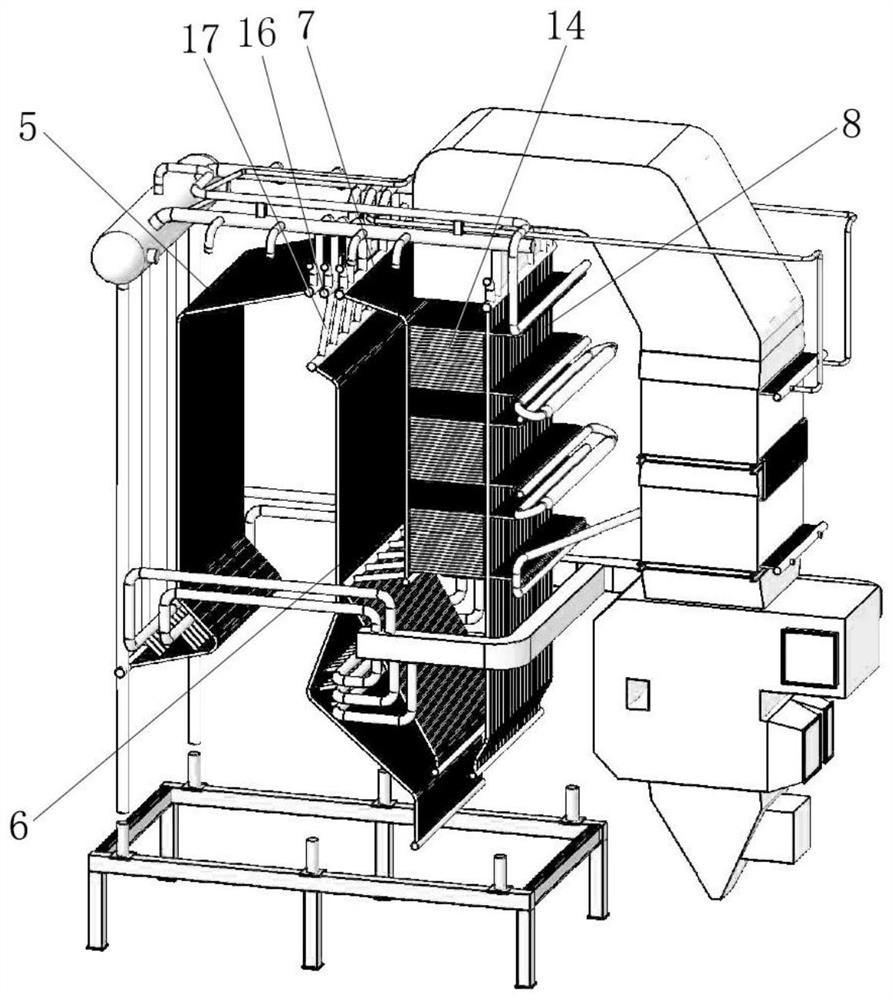

Corner tube boiler adopting uniform scouring convection tube bundle

The invention discloses a corner tube boiler adopting a uniform scouring convection tube bundle. The whole of the corner tube boiler has an n-shaped structure, wherein, the left side is a hearth, the right side is a tail flue, and the hearth back wall positioned in the middle is used as an interface of the hearth and the tail flue; the hearth front wall, the side wall and the hearth back wall form the hearth; the hearth back wall, the side wall and the flue back wall form the tail flue; the hearth front wall of the hearth is arranged vertically to the ground of the flue back wall; the hearth back wall is obliquely arranged towards the right from top to bottom so that the cross section of the hearth is gradually widened from top to bottom, and correspondingly the cross section of the tail flue is gradually narrowed from top to bottom; three sections of convection tube bundles are arranged in the tail flue from top to bottom with consistent interval to form a three-level heating surface; and the width of each section of the convection tube bundle is gradually narrowed from top to bottom and is matched with the width of the tail flue at the corresponding position. The corner tube boiler can furthest exert the heat transfer effect on the convection tube bundle under the premise of controlling the abrasion.

Owner:SHANGHAI INDAL BOILER RES INST

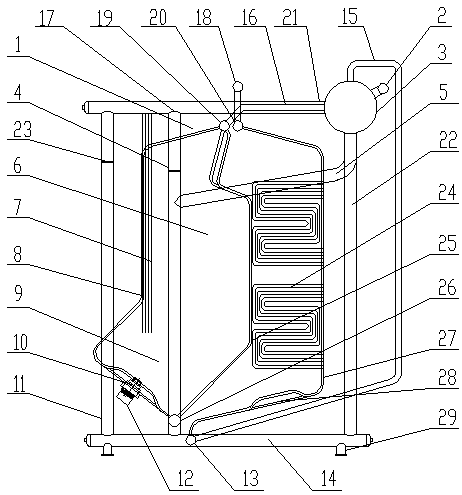

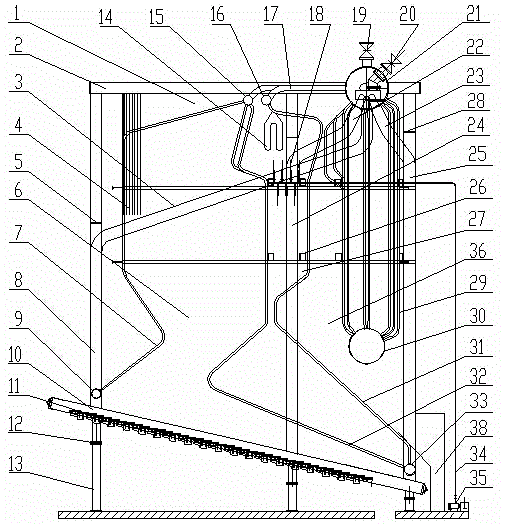

Vertical coal powder corner tube boiler

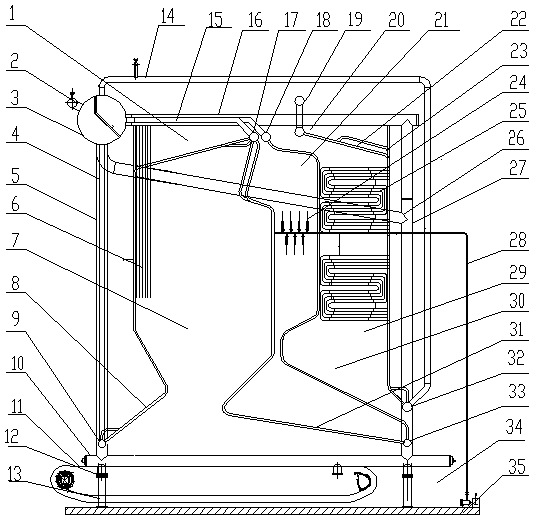

The invention discloses a vertical coal powder corner tube boiler which comprises combustors, a boiler hearth, a high-temperature air pre-heater, an economizer, a low-temperature air pre-heater convection bank, an upper header, a top header, a boiler barrel and a lower header, wherein the lower header is arranged on the bottom of a boiler body, the upper header and the top header are arranged on the top of the boiler body and are communicated through a steam communicating pipe. The vertical coal powder corner tube boiler is characterized in that the combustors are arranged in a V shape, the boiler body is of a vertical corner type membrane type water-cooling wall structure, four descending pipes are arranged in four corners, the descending pipes and two ends of the membrane type water-cooling wall are respectively communicated with the upper header and the lower heater, the convection bank is arranged on the outer side of the membrane type water cooling wall, the top of the convection bank is communicated with a hearth smoke outlet, and the bottom of the convection bank is communicated with the high-temperature air pre-heater. The vertical coal powder corner tube boiler has the advantages of compact integrated structure, simple appearance arrangement, small occupation area, low steel consumption, large water circulation pressure difference, safety and reliability in water circulation, and the like.

Owner:HANGZHOU JUNENG BOILER

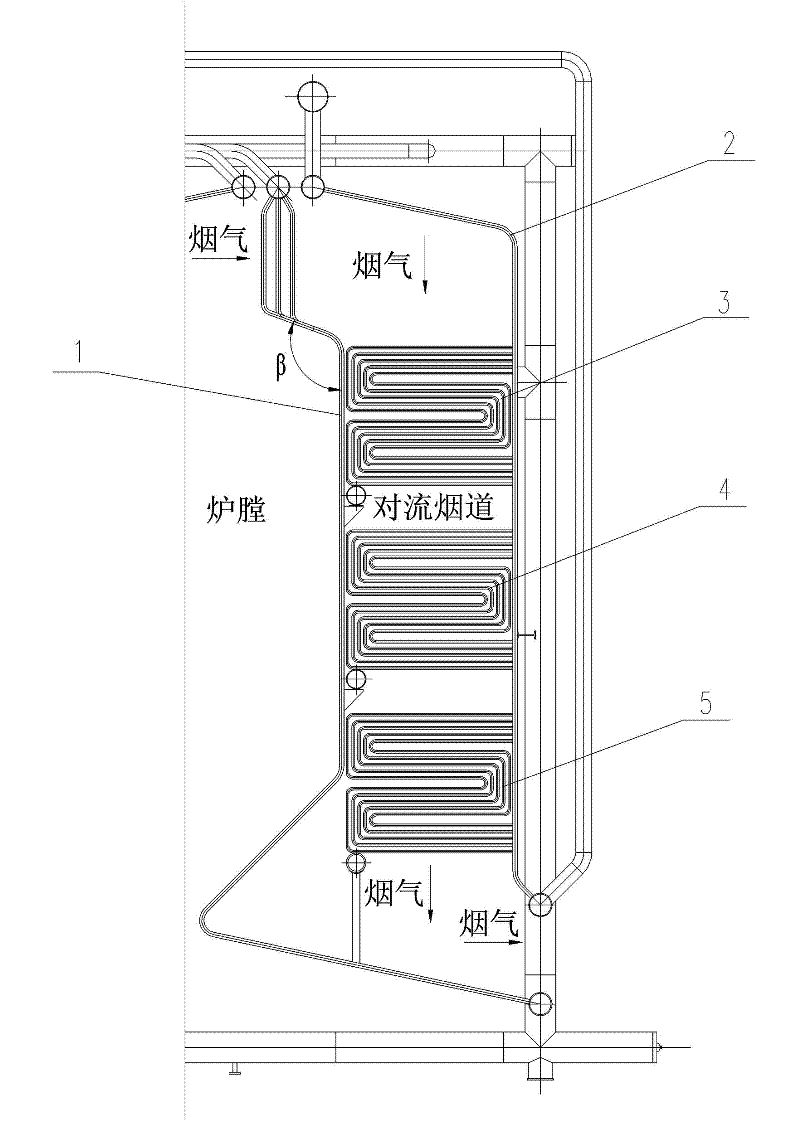

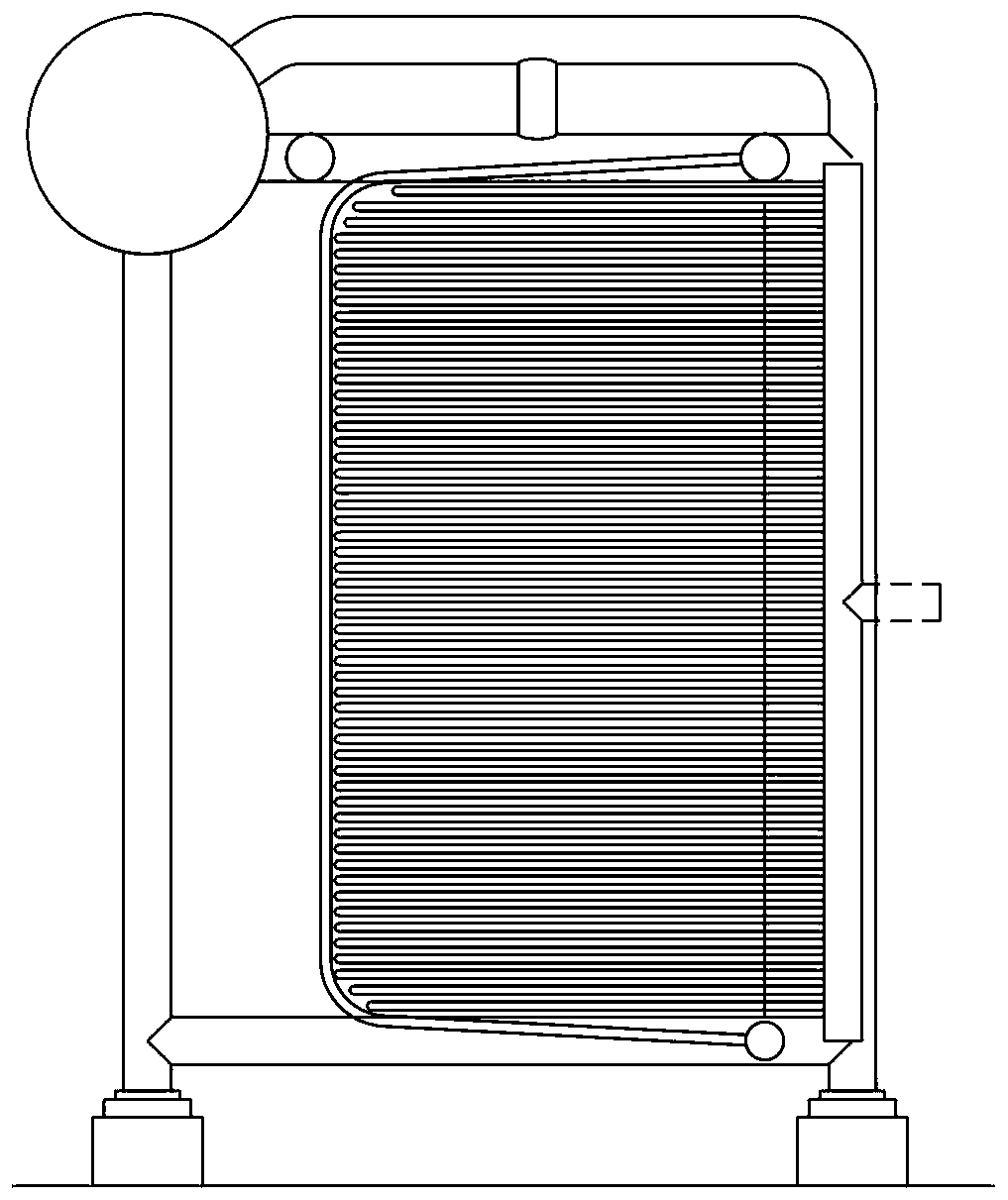

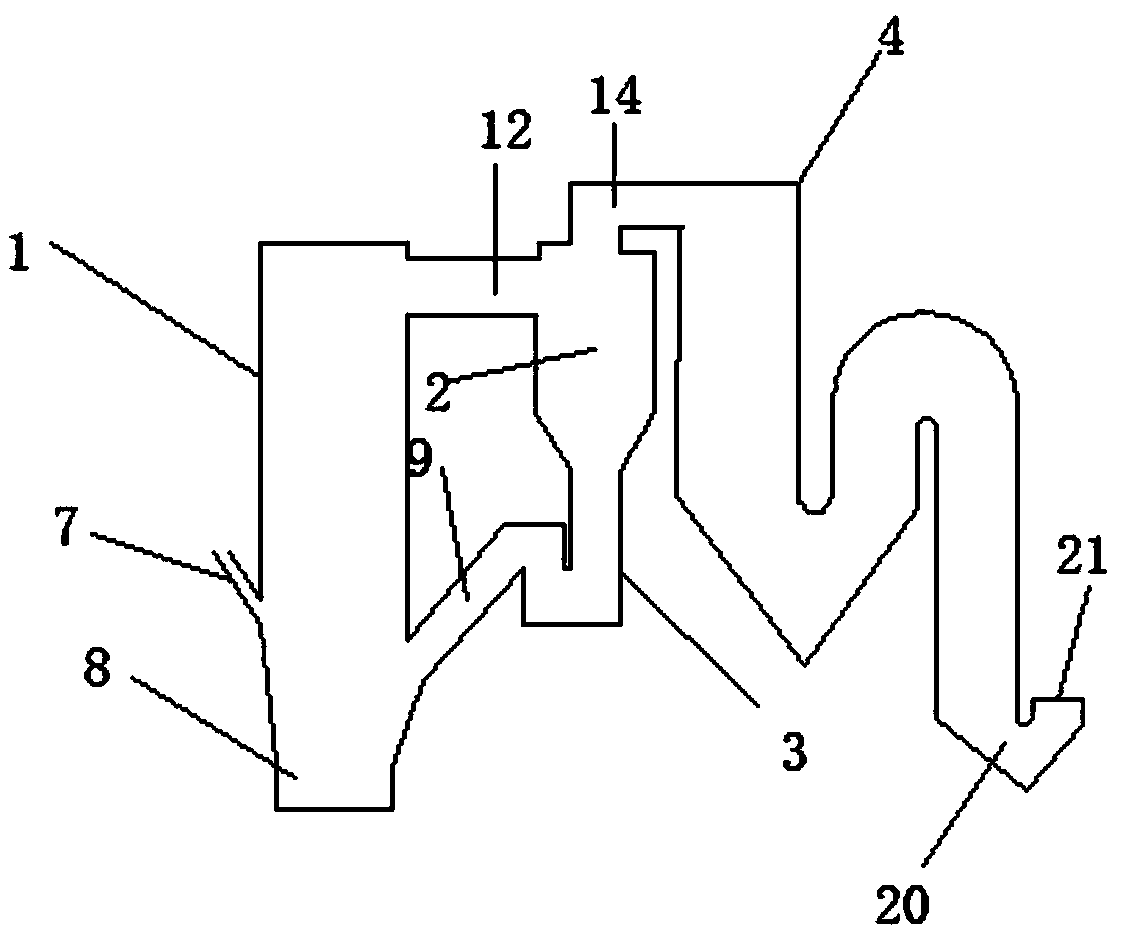

Novel structure of convection heating surface of corner tube hot-water boiler

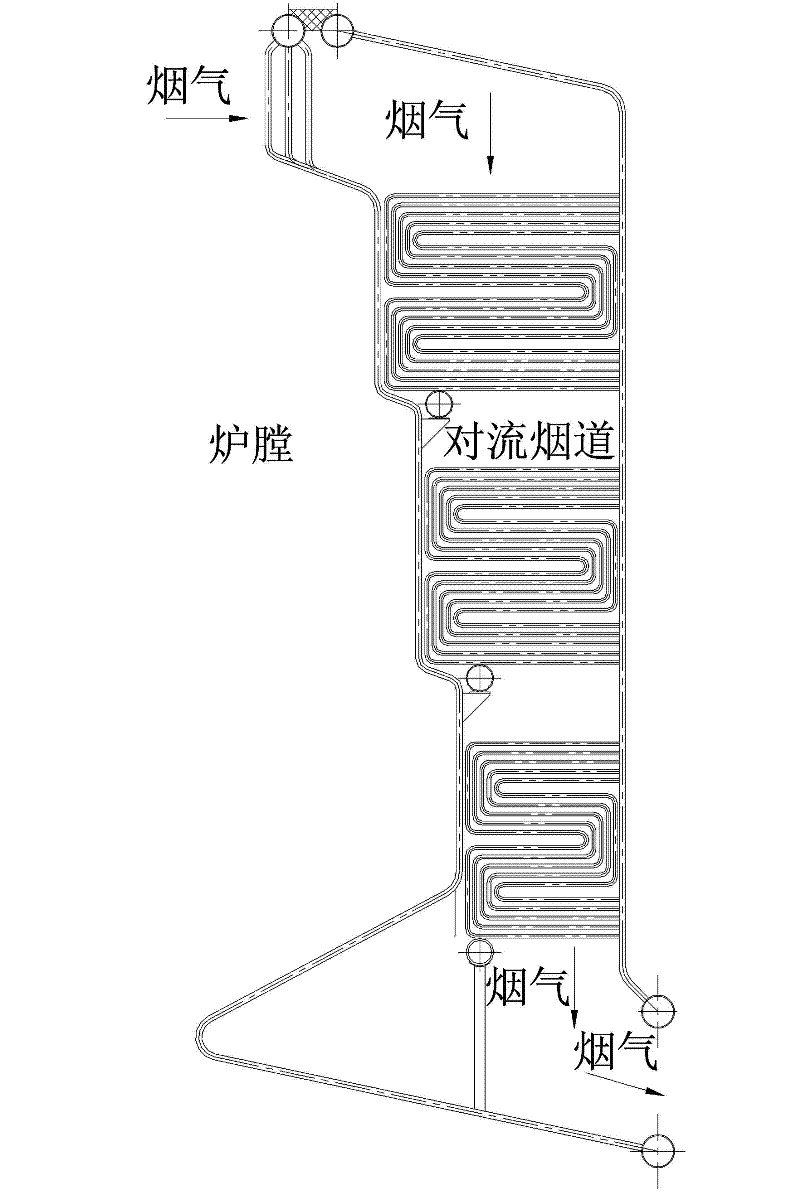

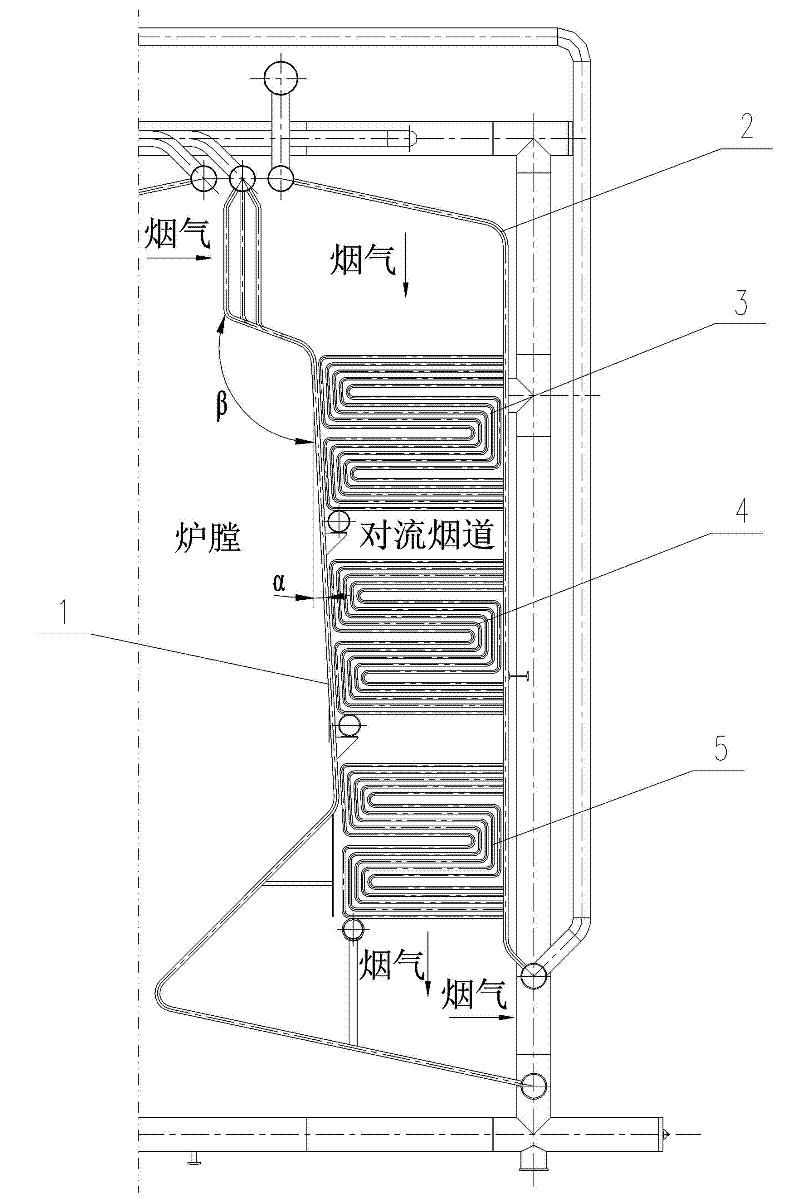

InactiveCN102338470AAvoid section mutationsIncrease flow rateFluid heatersEngineeringCorner tube boiler

The invention discloses a novel structure of a convection heating surface of a corner tube hot-water boiler, which aims to solve the problem that the flow speed at the position of the convection heating surface of a traditional corner tube boiler is uneven. The novel structure of the convection heating surface of the corner tube hot-water boiler comprises a hearth rear wall, a channel rear wall, a first-stage flag type heating surface, a second-stage flag type heating surface and a third-stage flag type heating surface, and is mainly and technically characterized in that the hearth rear wall is purely inclined by an angle alpha, so that the smoke circulating sectional areas of all stages of convection heating surfaces in a convection flue are stably reduced so as to enable the smoke speeds of all the stages of flag type heating surfaces in the convection flue to tend to be consistent. The novel structure of the convection heating surface is mainly used for corner tube hot-water boiler systems.

Owner:SHANGHAI XINYE BOILER HIGH TECH

Low discharging and high-energy effect novel industrial boiler

InactiveCN101457981ARaise the outlet temperatureReduce carbon contentWater-tube boilersWater heatersHigh energyCogeneration

The invention discloses a novel industrial boiler with low emission and high energy efficiency, and relates to the series of twenty boilers which are different in fuels and mediums, namely large-scale grate firing: scattered coal, moulded coal and biomass and chamber firing: fuel gas, oil-fired hot water, steam, phase-conversion heat exchange and distributed heat and power cogeneration boilers. The novel industrial boiler comprises a transverse boiler, a transversal and longitudinal container, a water wall tube, a vertical boiler shell, a thread smoke tube, and the like. The invention integrates the advantages of a water-tube boiler, a water-fire tube boiler and a corner-tube boiler, more particularly solves the different defects of three types of boilers; namely, the water-tube boiler has the defects of complicated technology as well as large volume and steel consumption; the water-fire tube boiler has the defects of tube plate crackle, tube explosion, smoke tube abrasion, and the like; the corner-tube boiler has the defects that the technology is complicated technology and the dust deposition at the tail part is difficult to be eliminated; and the invention also greatly improves the difficult problems of the three types of boilers that the initial emission concentration of smoke and dust is higher generally. The invention has the advantages of advanced installation technology and extremely obvious energy conservation and emission reduction.

Owner:王森

Vertical type modular coal water slurry corner tube boiler

InactiveCN103134036ACompact structureOptimize layoutIndirect carbon-dioxide mitigationSteam boilersAir preheaterCoal water

The invention discloses a vertical type modular coal water slurry corner tube boiler. The vertical type modular coal water slurry corner tube boiler comprises a boiler body, a hearth, a combustor, a combustion stabilizing chamber, a dry bottom hopper, an air preheater, a coal economizer, a convection tube beam, an upper collecting tank, a top collecting tank, a boiler barrel and a lower collecting tank. The boiler body comprises 4 down pipes arranged at four corners and a membrane water wall. Two ends of each down pipe and two ends of the membrane water wall are respectively communicated with the upper collecting tank and the lower collecting tank. The convection tube beam is arranged on outer side of the membrane water wall, the top is communicated with a smoke outlet of the hearth, and the bottom is communicated with the bottom of the air preheater. The dry bottom hopper is arranged at the bottom of the boiler body. The boiler body is divided into the boiler barrel, the dry bottom hopper, the convection tube beam and the membrane water wall to be manufactured and installed. The vertical type modular coal water slurry corner tube boiler has the advantages of being compact in integral structure, simple in appearance arrangement, small in occupied area, low in steel consumption, large in boiler water circulating differential pressure, safe and reliable in water circulation, quick and simple in manufacture and installation, reliable in boiler operation, simple and convenient to maintain and the like.

Owner:HANGZHOU JUNENG BOILER

Corner tube boiler capable of being used for SCR denitration

PendingCN109340737AMeet environmental emission requirementsEmission preventionSolid fuel combustionAir preheaterFlue gas

The invention discloses a corner tube boiler capable of being used for SCR denitration, and relates to the technical field of boilers. The corner tube boiler capable of being used for the SCR denitration aims to solve the problems that the actual load of an existing corner tube boiler is low, the smoke temperature of a denitration window cannot meet the minimum requirement of a denitration temperature, and a final emission index of the boiler is affected. The corner tube boiler capable of being used for the SCR denitration comprises a boiler proper and a smoke exhaust mechanism. The smoke exhaust mechanism comprises a connecting flue, a high-temperature bypass flue, an SCR denitration reactor, a coal economizer and an air preheater; the inlet end of the connecting flue is connected with alow-temperature flue gas exhaust outlet of the boiler proper, and the low-temperature flue gas exhaust outlet is formed in the rear end of a flag type convection screen in the boiler proper; the SCR denitration reactor, the coal economizer and the air preheater are sequentially arranged at the other end of the connecting flue from inside to outside; and the inlet end of the high-temperature bypassflue is connected with a high-temperature flue gas exhaust outlet of the boiler proper, the high-temperature flue gas exhaust outlet is formed in the front end of the flag type convection screen in the boiler proper, and the outlet end of the high-temperature bypass flue is connected with the connecting flue. The corner tube boiler capable of being used for the SCR denitration is used for environment-friendly boilers.

Owner:哈尔滨红光锅炉总厂有限责任公司

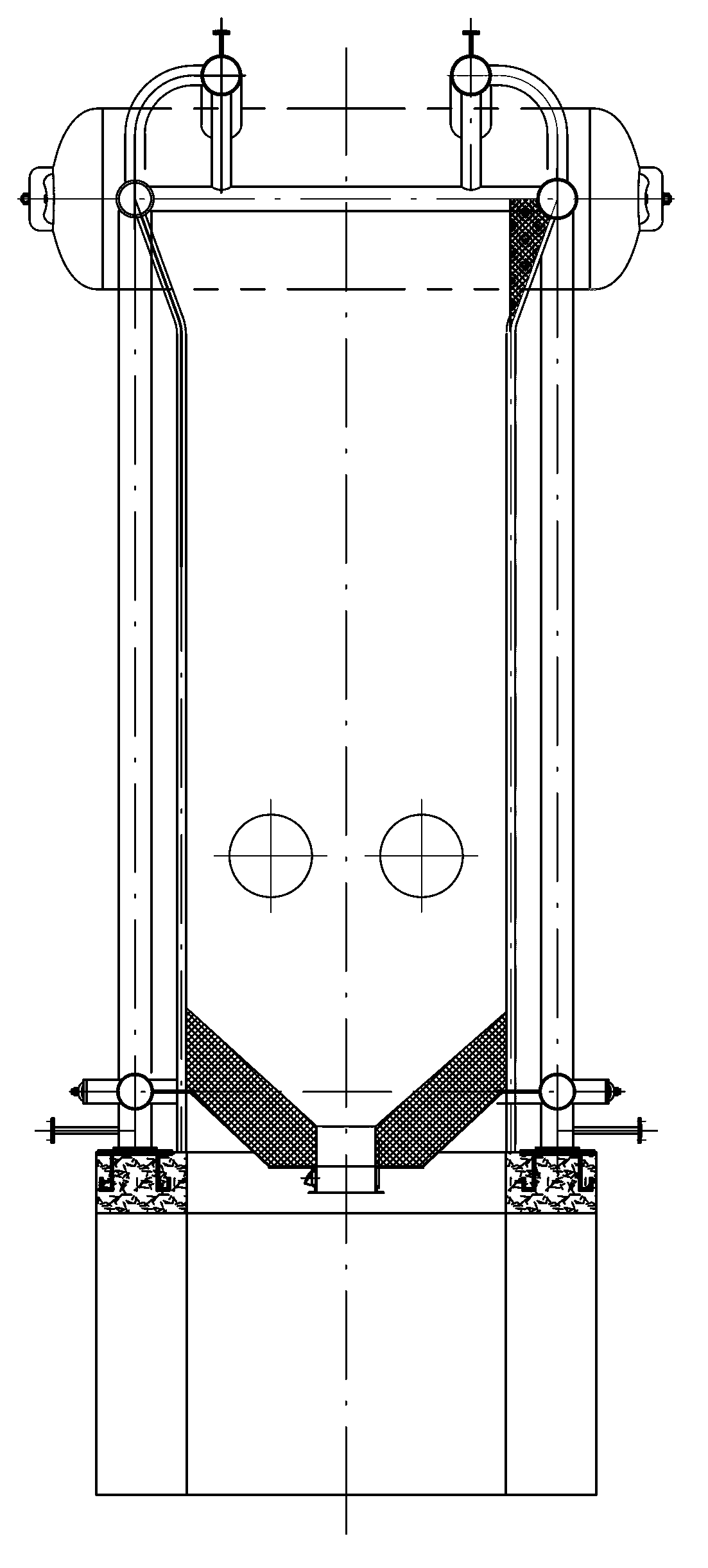

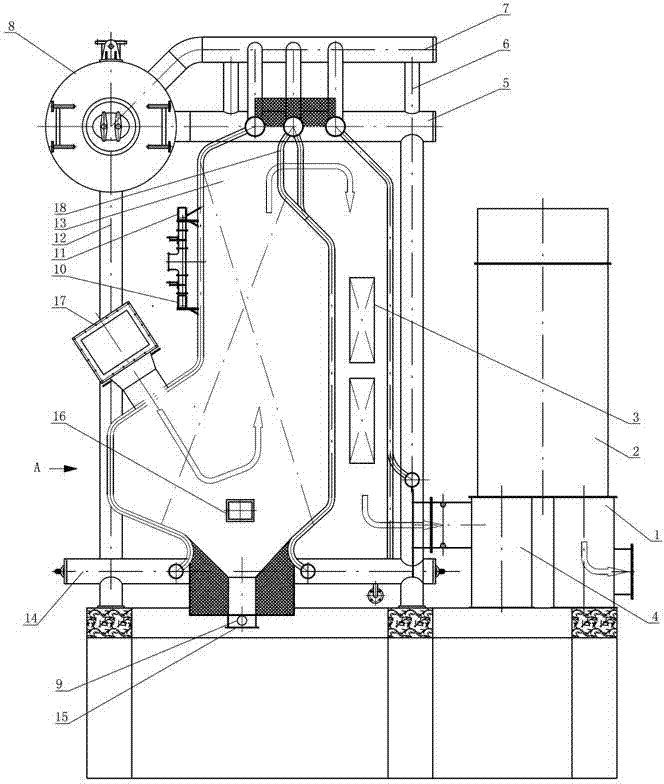

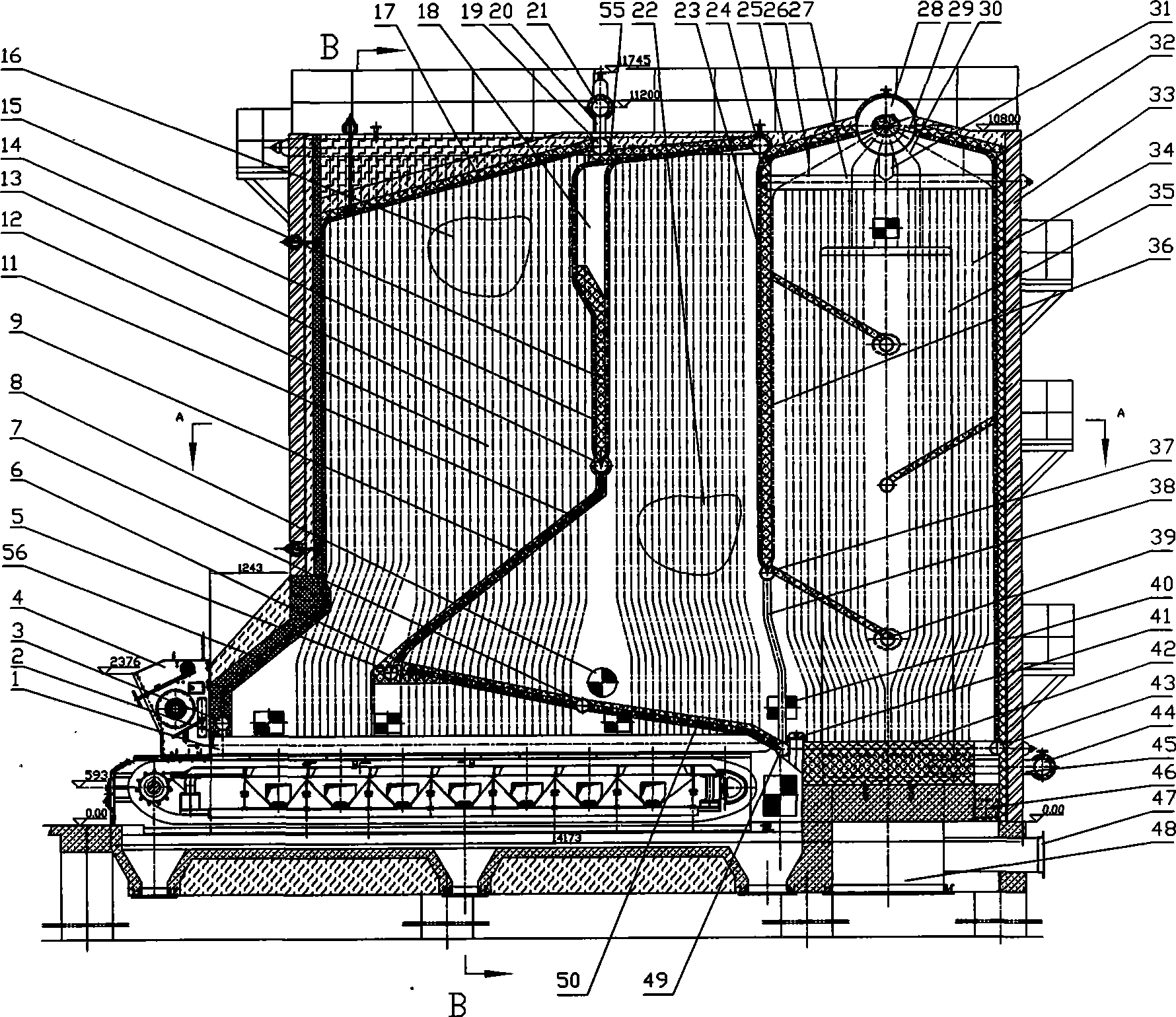

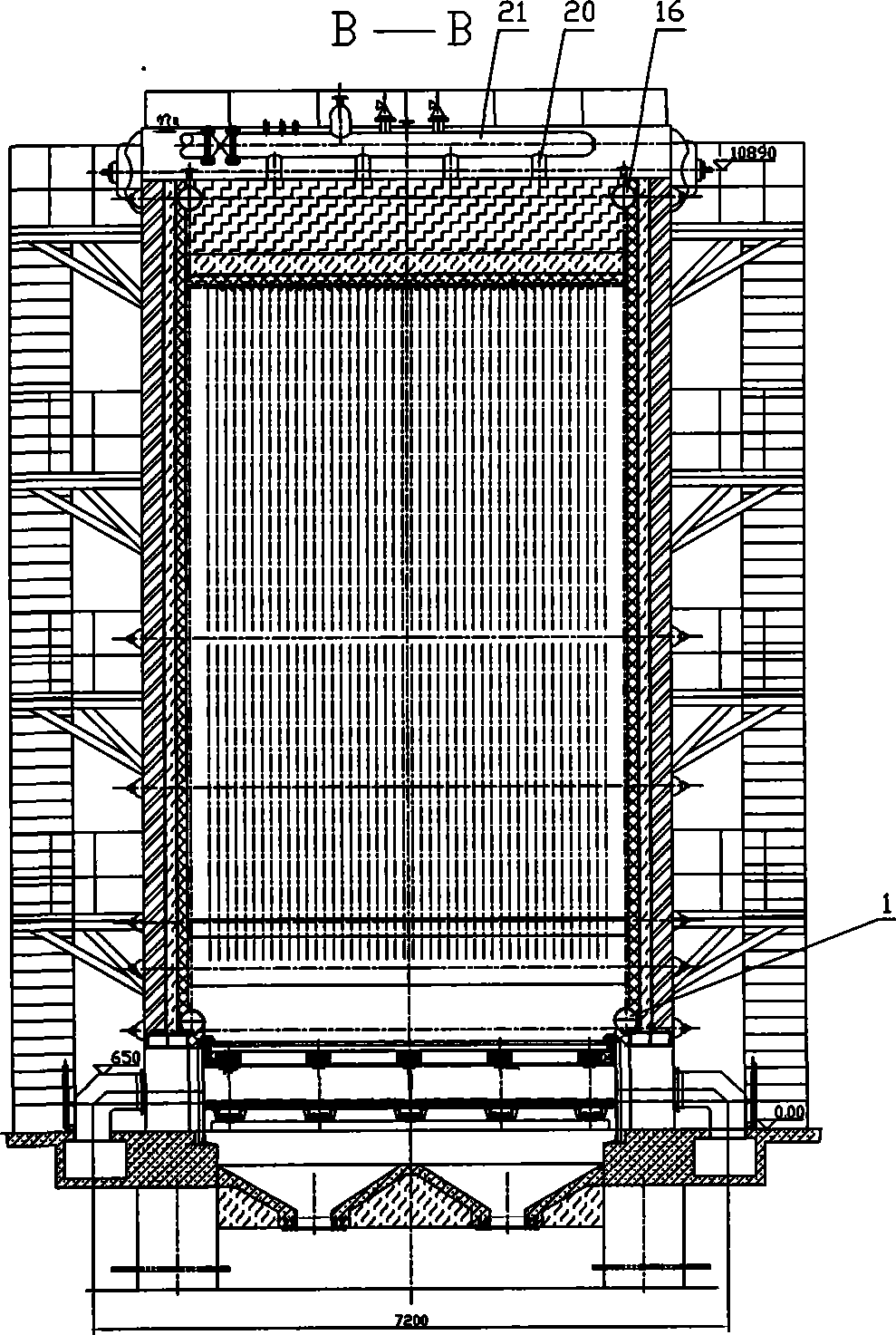

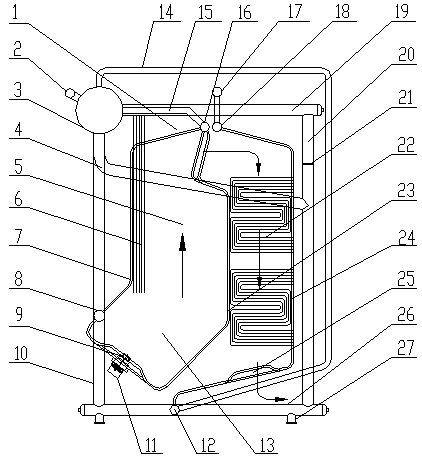

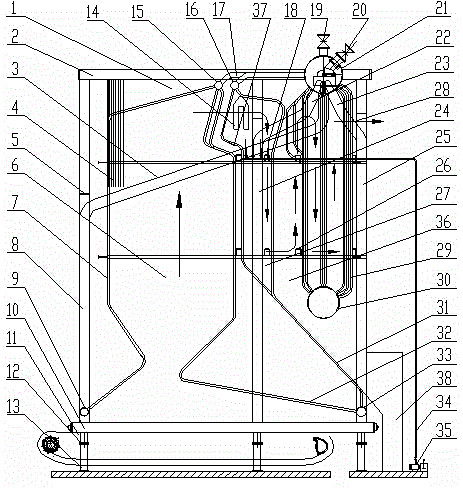

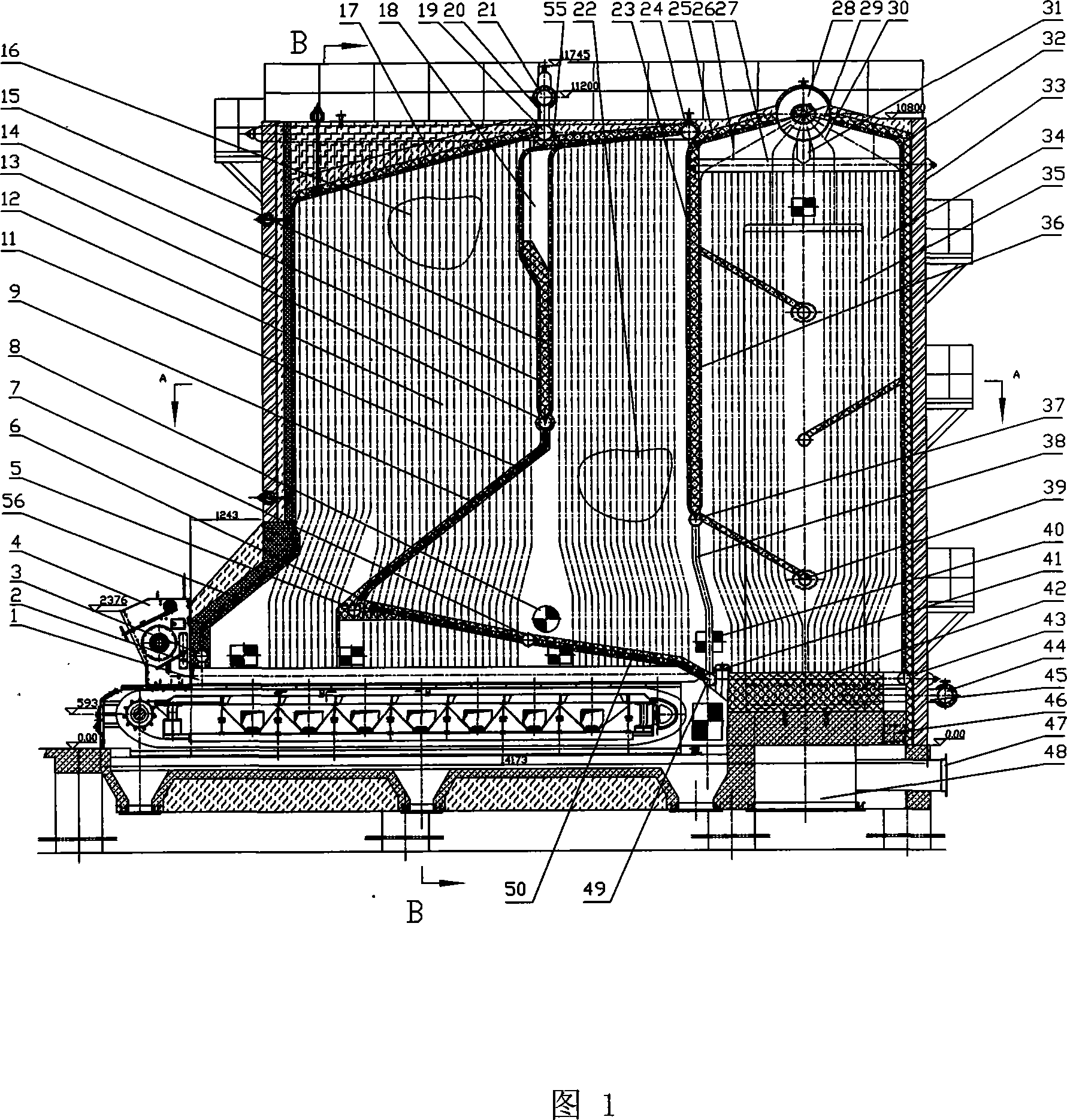

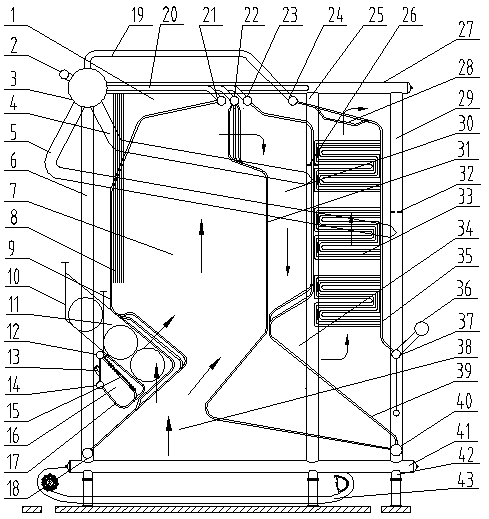

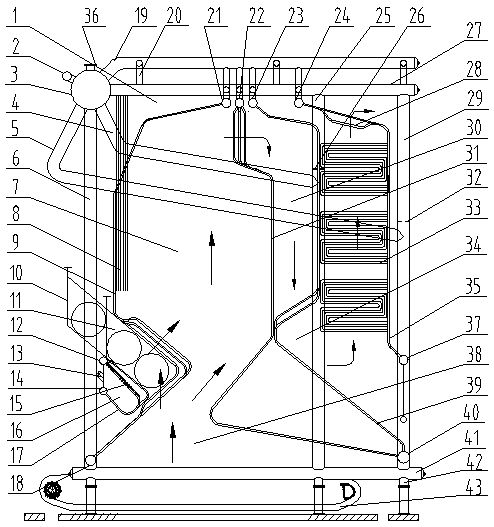

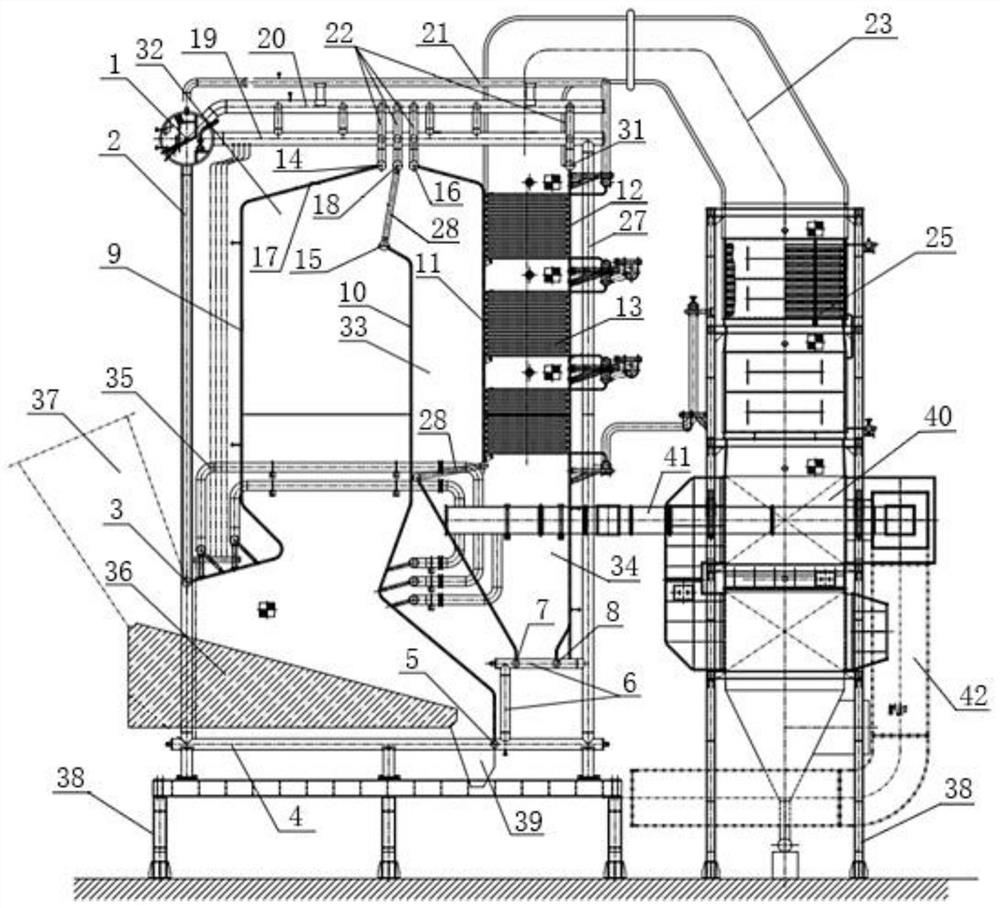

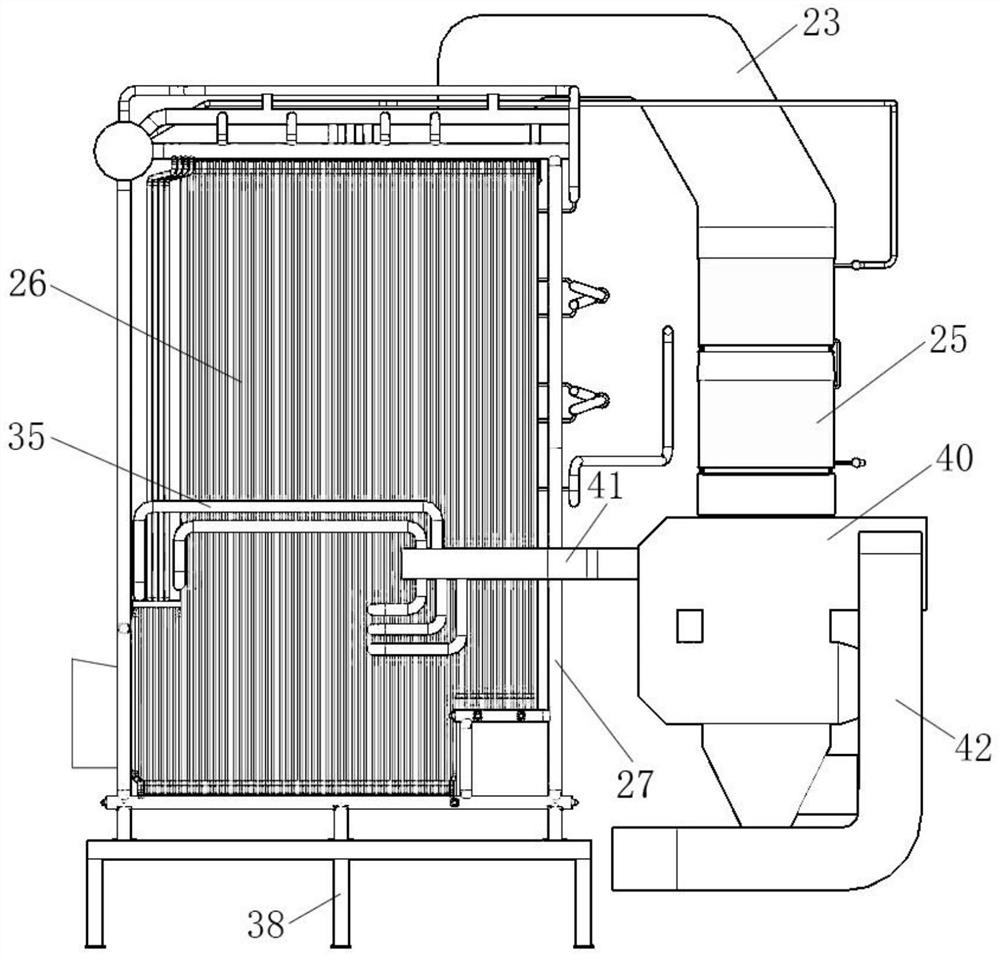

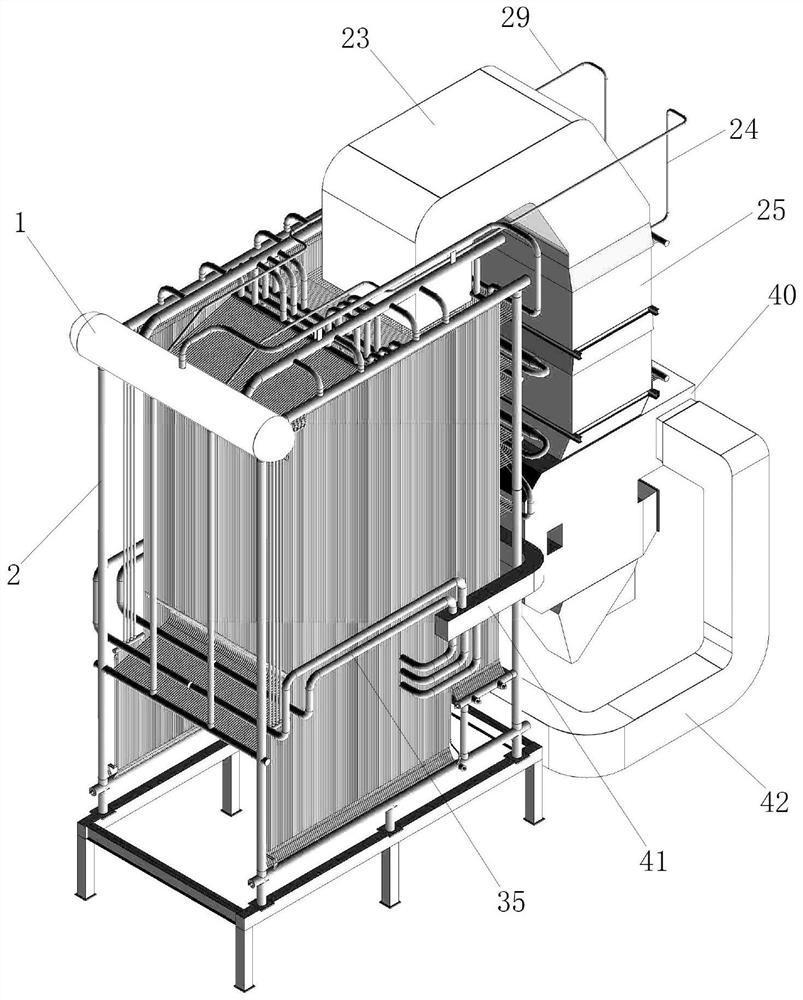

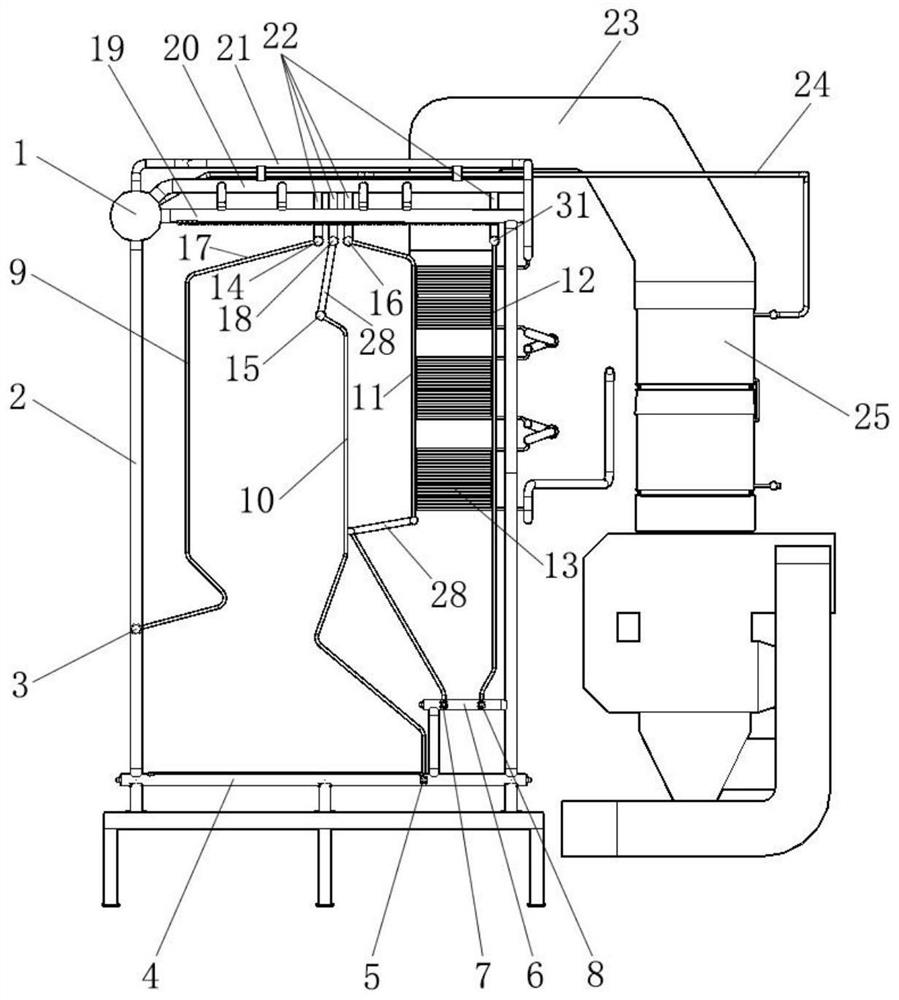

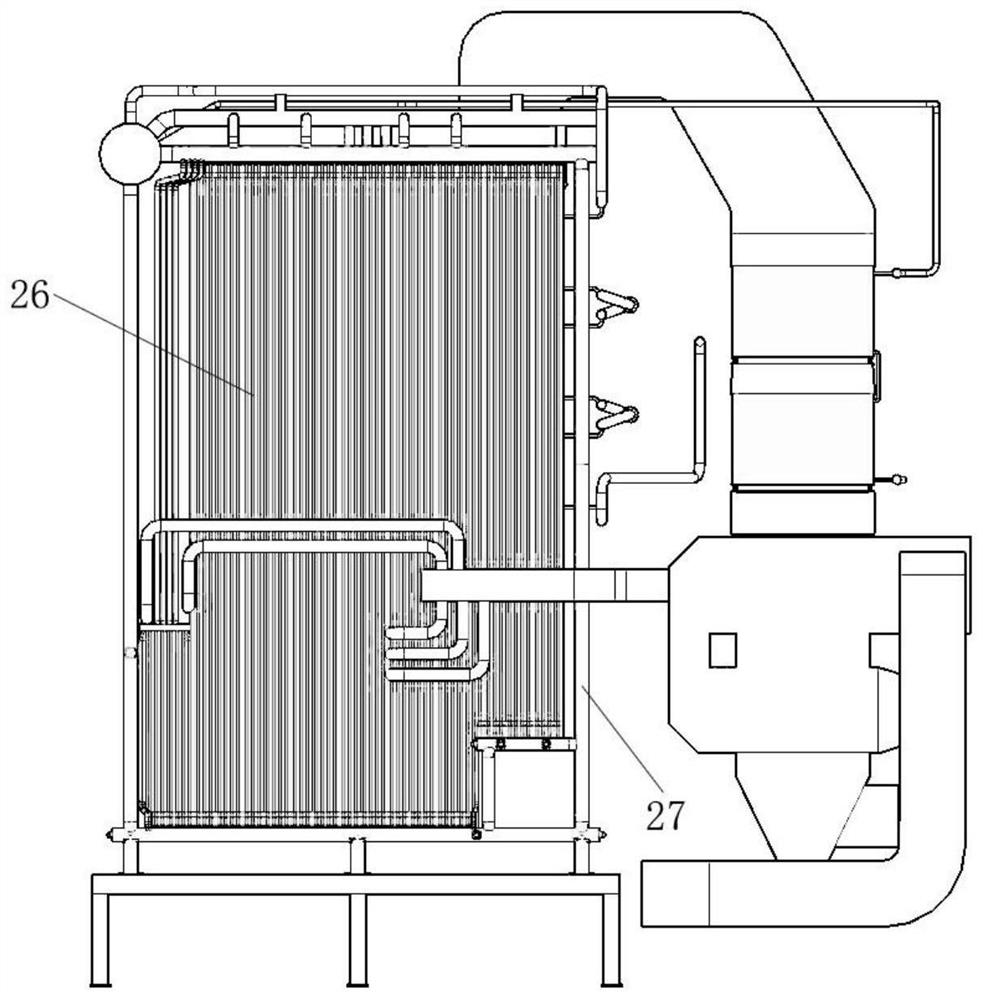

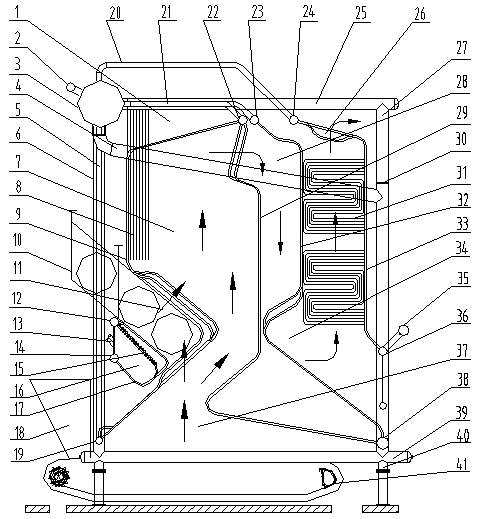

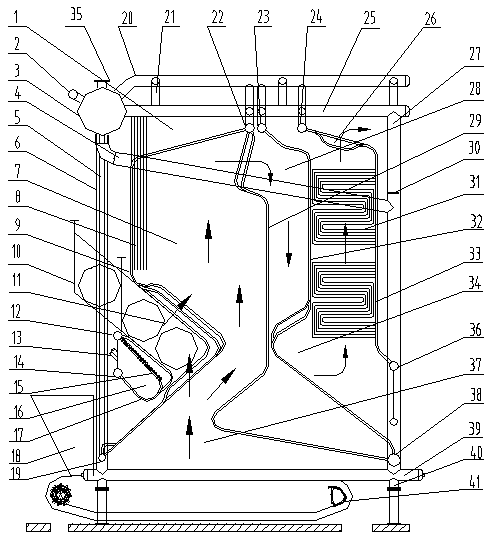

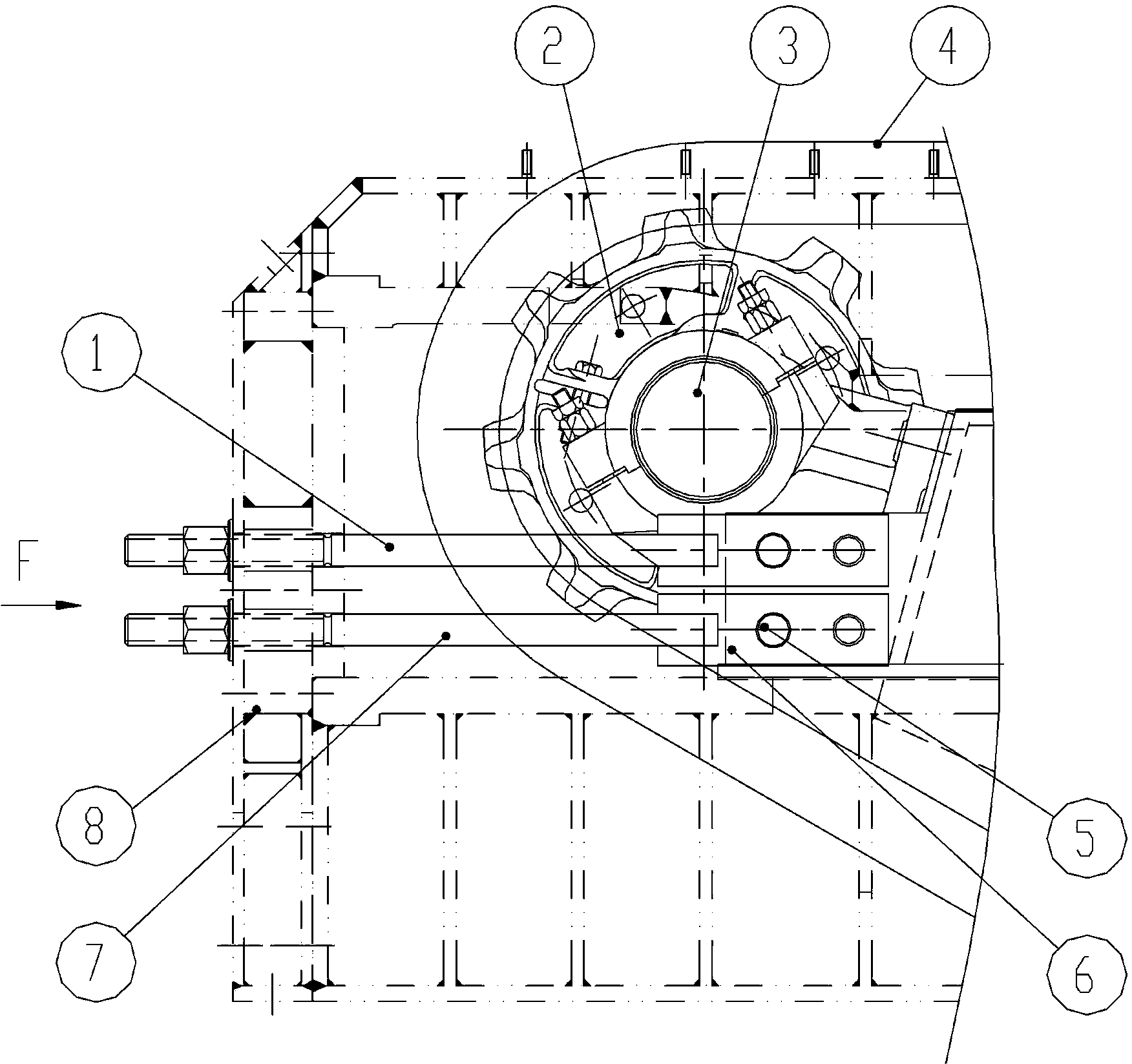

A single drum horizontal chain grate spray denitrification corner tube boiler

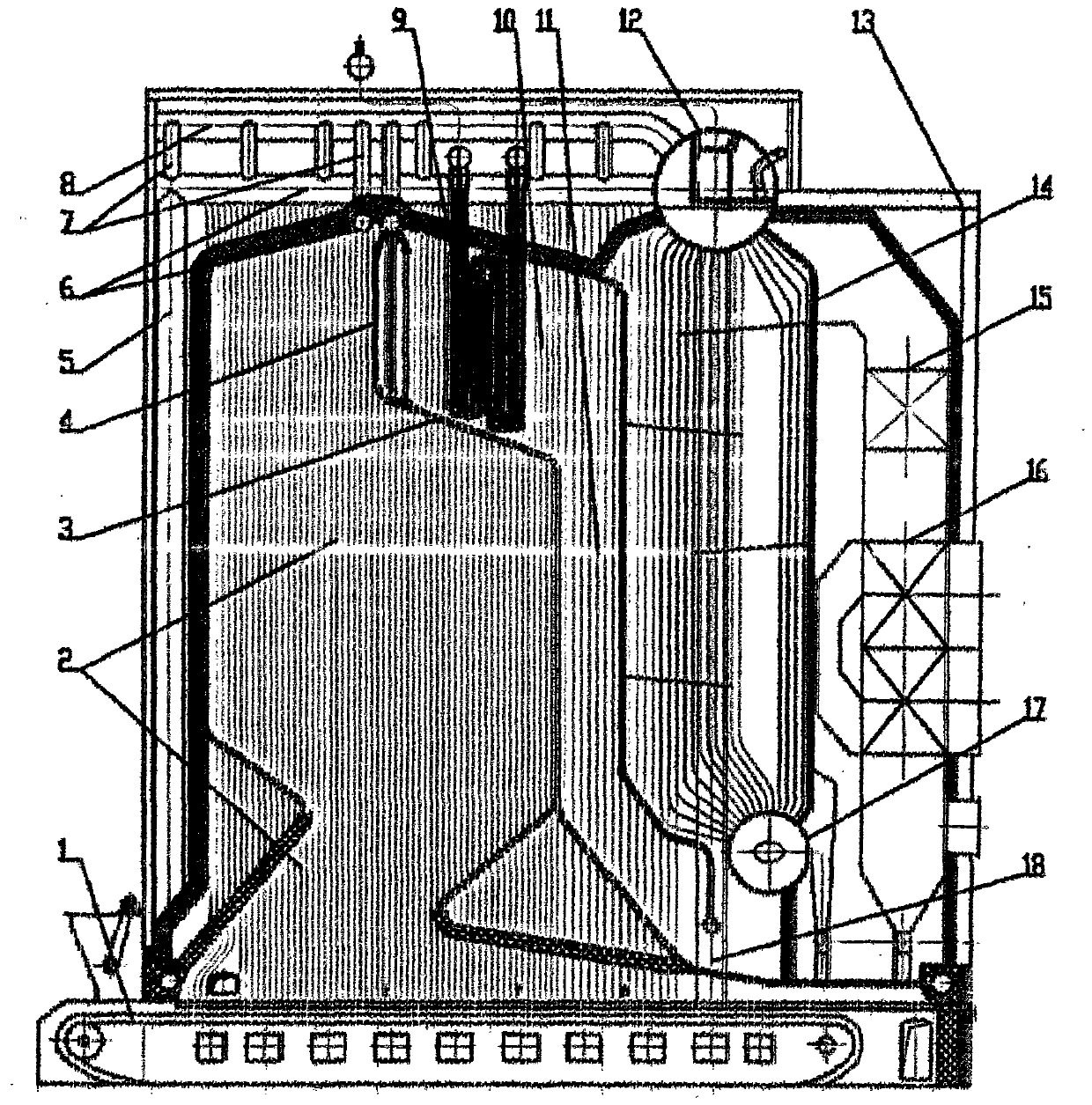

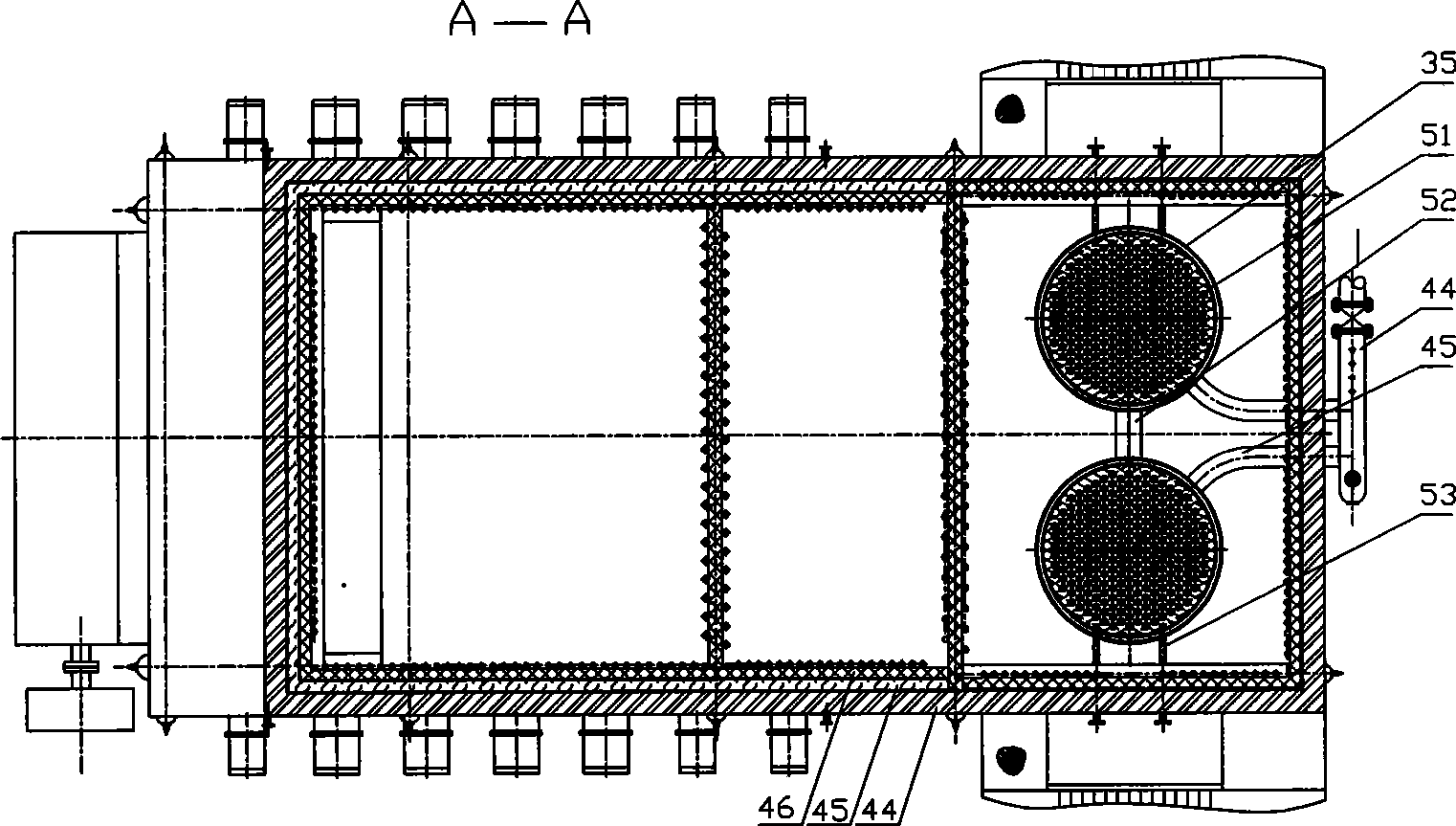

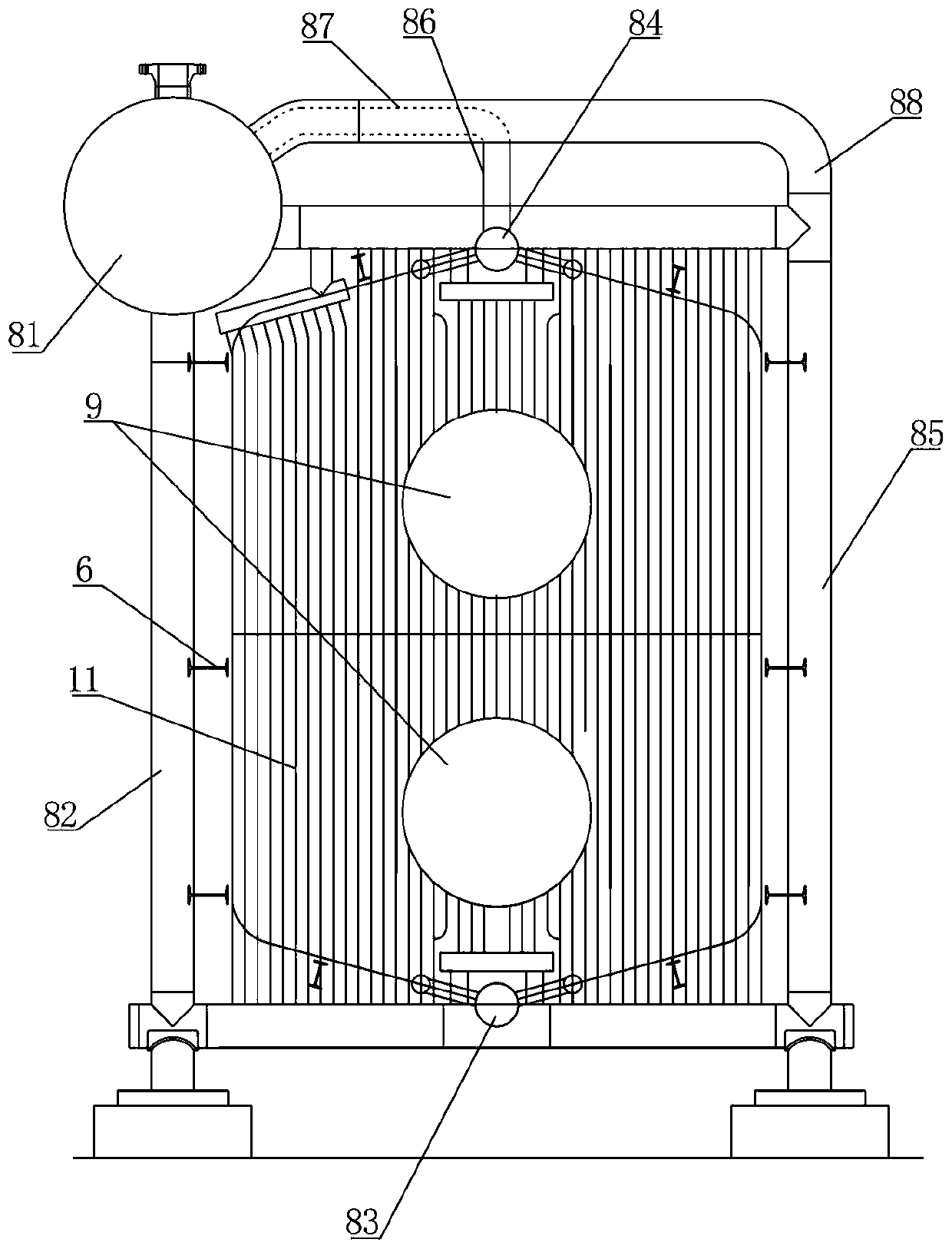

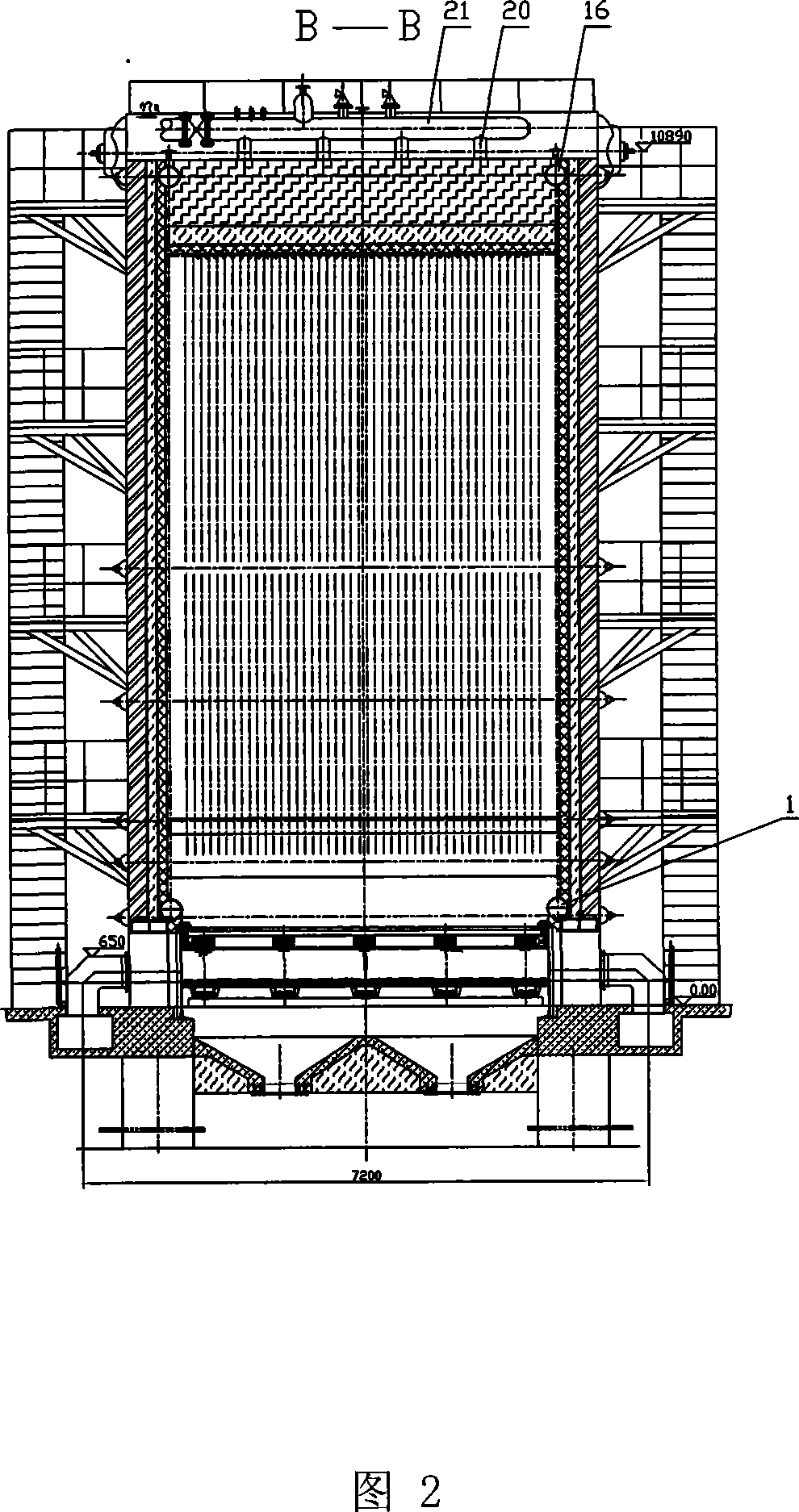

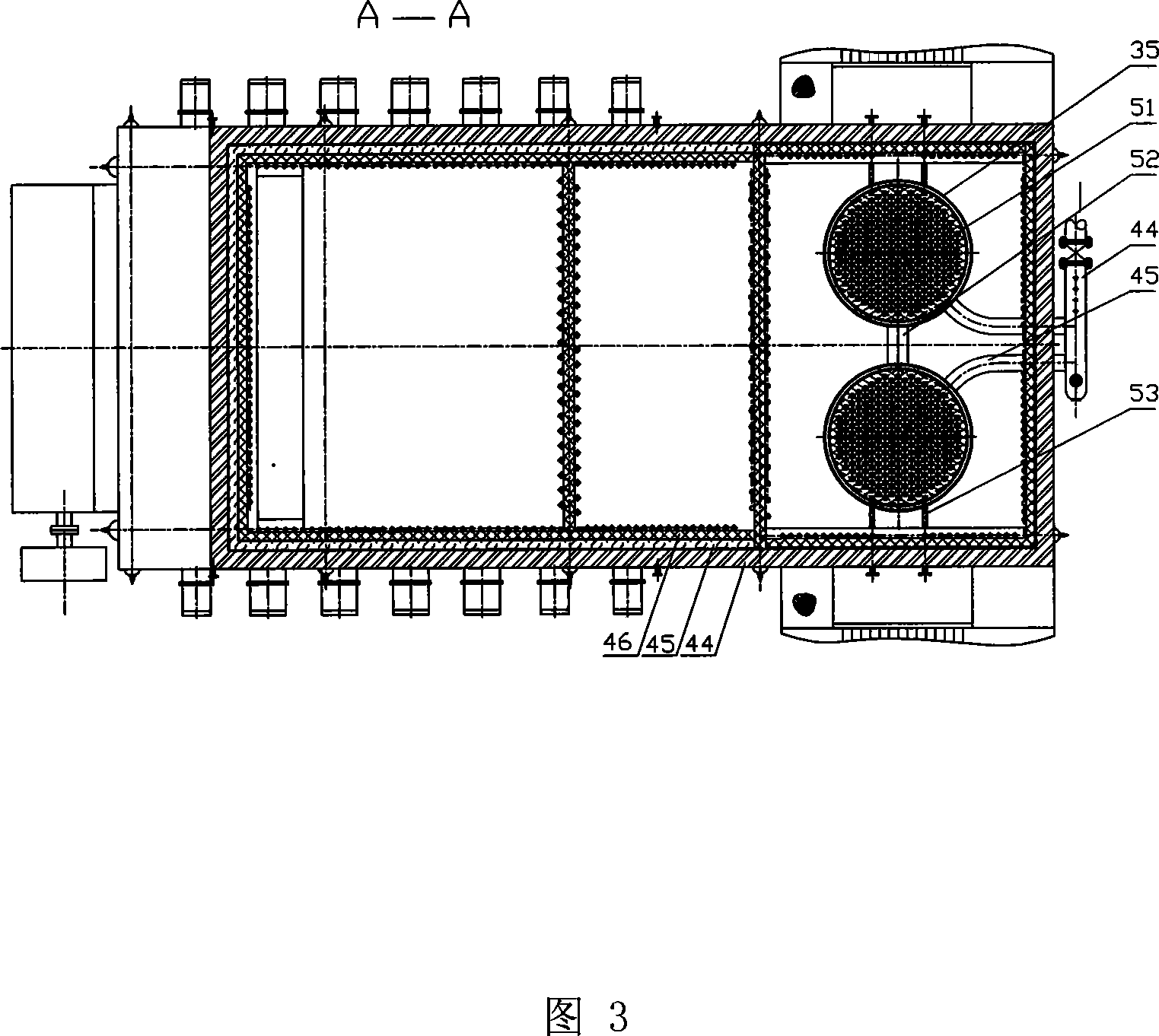

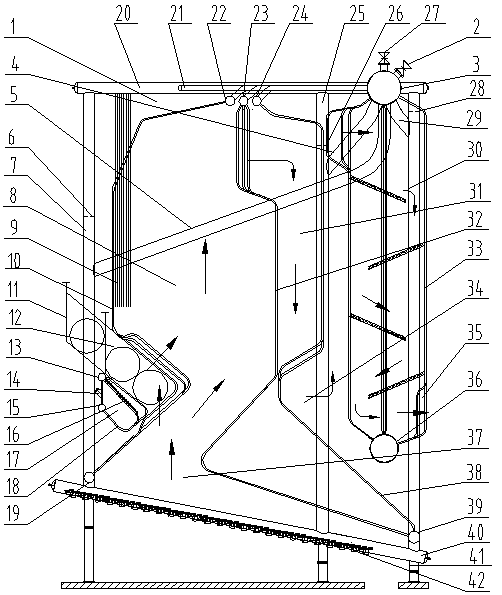

ActiveCN105318535BExtended service lifeHigh thermal efficiencyBoiler water tubesWater-tube boilersCycloneCyclonic separation

The invention relates to a single-drum horizontal-mounted chain grate spray denitrification corner tube boiler, which includes a boiler body and a chain grate part, wherein the chain grate part is arranged at the bottom of the boiler body part, and is characterized in that: Boiler body (1) is equipped with a boiler water circulation mechanism, which is composed of channel rear wall water wall (30) and settling chamber upper header (18) and lower header (33). Spray denitrification cyclone is set on boiler body 1 Separation and settling device, which is composed of denitrification spray pipe (28), denitrification nozzle (24), denitrification agent supplier (35), upper sedimentation separation chamber (21), lower sedimentation separation chamber (29), has the ability to solve the problem of small heating area , The flue gas at the furnace outlet does not directly flush the serpentine tube of the flag-type heating surface, which reduces wear and tear, prolongs the service life of the boiler, reduces the number of maintenance and reduces the emission of nitrogen oxides, reduces air pollution, improves thermal efficiency, energy saving, environmental protection and safety.

Owner:HARBIN SIFANG BOILER

Horizontal gas corner tube boiler

InactiveCN110822402AUniform temperatureLittle fluctuation of steam temperatureBoiler drums/headersSteam superheatersCombustorSuperheater

The invention provides a horizontal gas corner tube boiler, and relates to the technical field of boiler equipment. The horizontal gas corner tube boiler comprises a hearth, a superheater, an evaporator, a denitration box and an economizer which are horizontally connected in sequence, wherein the hearth, the superheater and the evaporator are all wrapped in a membrane type water cooling wall whichis formed by splicing flat steel and a light tube in a sealing mode; the membrane type water cooling wall is connected with the denitration box and the economizer through a boiler flue; the membranetype water cooling wall is connected to a water circulation pipe cage; and the superheater is arranged on the outer side of a rear wall of the hearth, and a combustor is mounted on a front wall of thehearth. According to the horizontal gas corner tube boiler, the problem that the heat of a corner tube boiler in the prior art cannot be fully and efficiently utilized is solved.

Owner:SICHUAN CHUANGUO BOILER

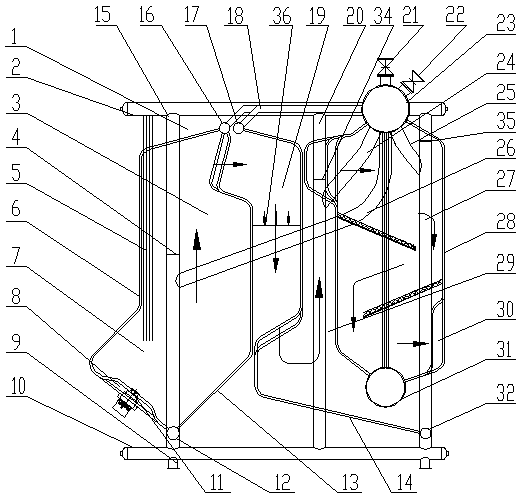

Single drum transverse type fuel gas and fuel oil corner tube boiler capable of achieving intake from below

PendingCN109114537AHigh thermal efficiencyExtended stayBoiler water tubesWater heatersCombustion systemEngineering

The invention provides a single drum transverse type fuel gas and fuel oil corner tube boiler capable of achieving intake from below. The boiler comprises a boiler body part and a combustion system part. A supporting structure is arranged in a boiler body and comprises a front descending pipe and a rear descending pipe which are arranged vertically. The two ends of the front descending pipe and the two ends of the rear descending pipe are connected with a side wall upper header and a side wall lower header which are arranged horizontally. A drum is arranged above one side of the boiler body. Awater inlet pipe is connected to the drum. The bottom of the drum is connected with a descending pipe communicating with the rear descending pipe. The bottom of the front descending pipe is connectedwith a front-and-back arch lower header. A front-and-back arch upper header communicating with the front-and-back arch lower header is arranged on the upper portion in the boiler body. The front-and-back arch upper header communicates with the drum through an upper water return pipe. According to the single drum transverse type fuel gas and fuel oil corner tube boiler capable of achieving intakefrom below, the fuel dwell time is long, flames can freely stretch, fuel can be fully combusted, the supporting structure is stable, and water circulation is safe.

Owner:HARBIN SIFANG BOILER

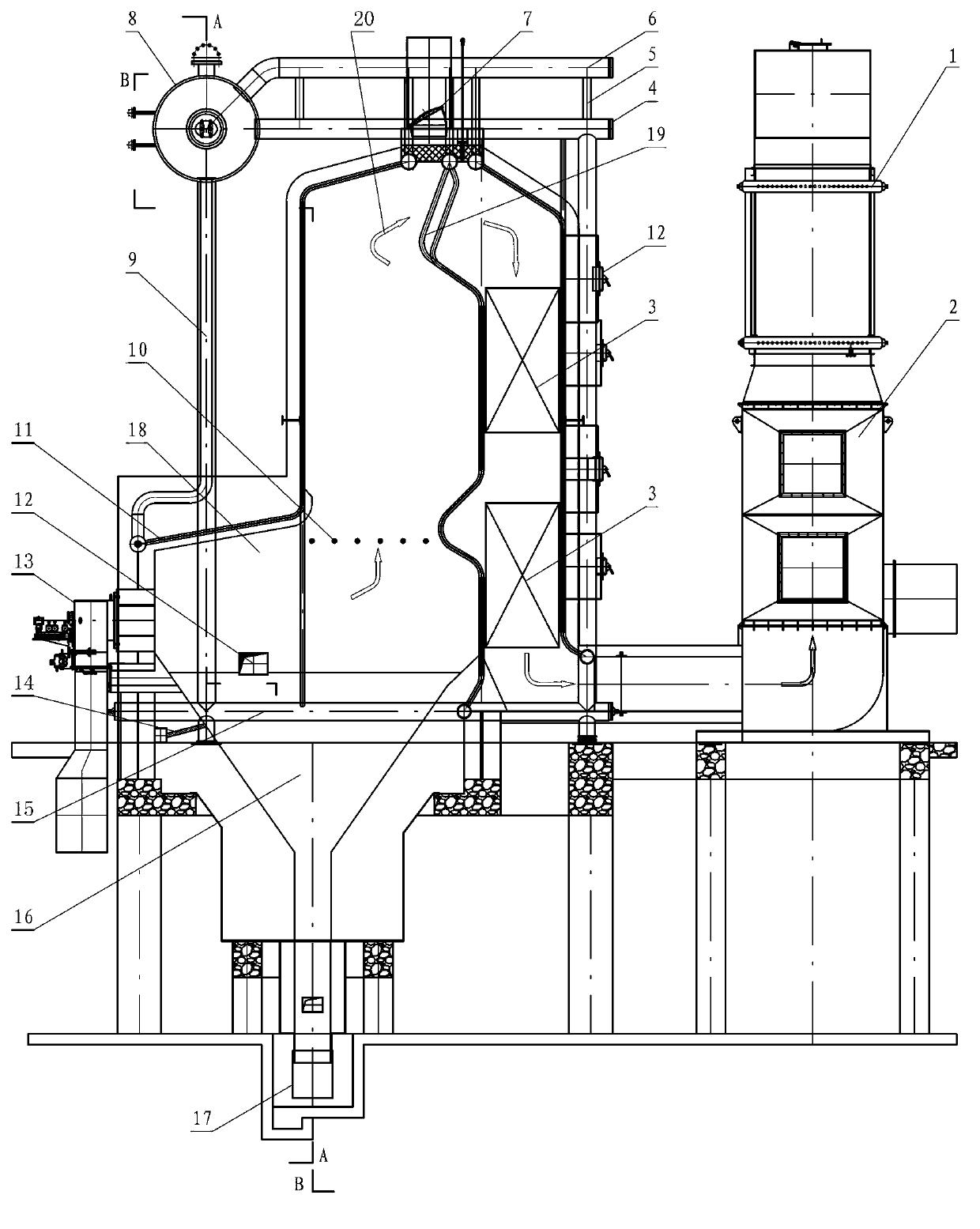

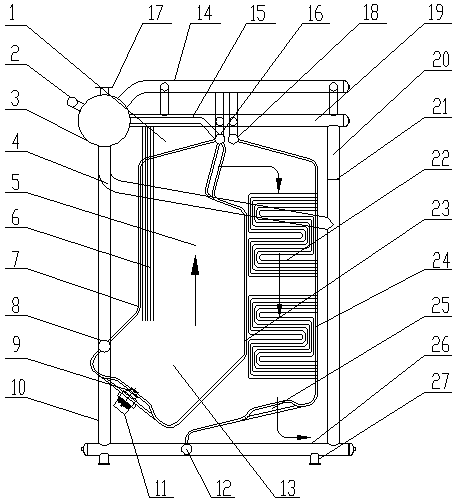

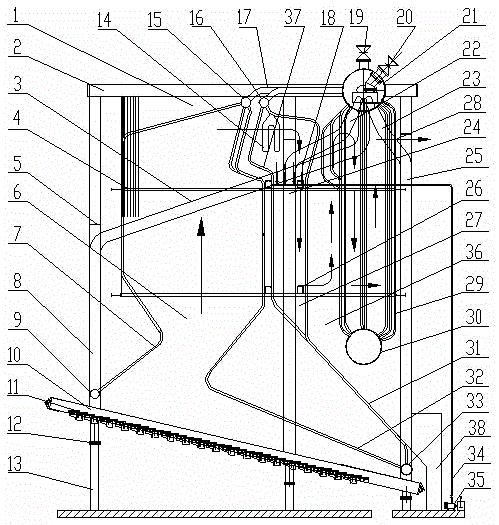

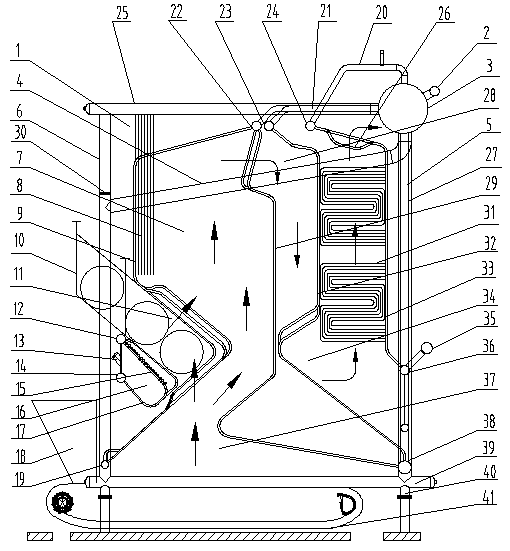

Two-drum spraying denitration settling separation corner-tube boiler

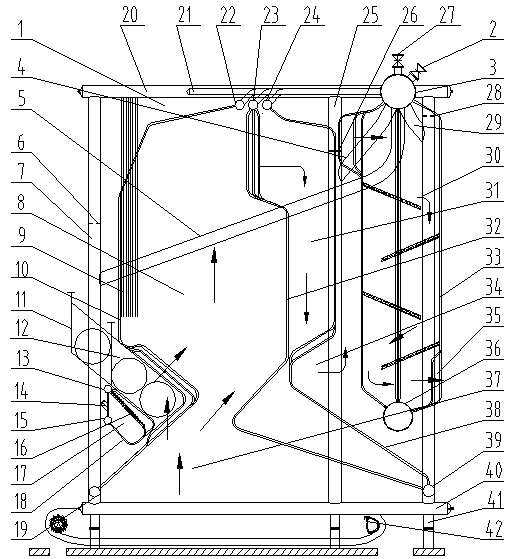

ActiveCN105318309AHigh thermal efficiencyEmission reductionDispersed particle separationSolid fuel combustionCyclonic separationEngineering

The invention relates to a two-drum spraying denitration settling separation corner-tube boiler, comprising a boiler body part and a fire grate part, wherein the fire grate part is arranged at the bottom of the boiler body part; the boiler is characterized in that a boiler body 1 is provided with a boil supporting mechanism, a boiler water circulation mechanism and a spraying denitration cyclone separation settling device, the boil supporting mechanism is formed by two vertically arranged side cooling wall supporting downcomers 24, a side wall water supply downcomer 22 communicated with the side cooling wall supporting downcomers 24, and supporting stiffening beams 26 arranged vertically and horizontally, the boiler water circulation mechanism is formed by a channel rear wall water cooling wall 31, a second channel rear wall water cooling wall 37, and an upper header 16 and a lower header 33 of a settling box, and the spraying denitration cyclone separation settling device is formed by denitration spraying pipes 34, denitration nozzles 18, a denitration agent supplier 35, an upper settling separation chamber 27 and a lower settling separation chamber 28. The two-drum spraying denitration settling separation corner-tube boiler has the characteristics of being high in supporting strength, stable in structure, capable of reducing nitric oxide emission, reducing air pollution and improving thermal efficiency, energy-saving, environment-friendly, safe and the like.

Owner:孙宇健

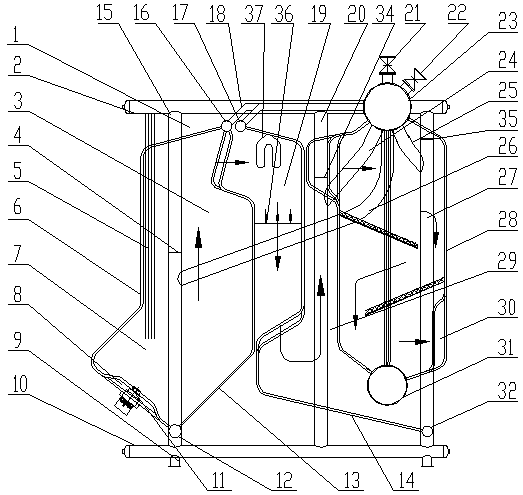

Single-drum oblique-injection down-intake gas-and-oil-fired corner tube boiler

PendingCN109140412AHigh thermal efficiencyExtended stayBoiler water tubesWater heatersCombustion systemRetention time

The invention discloses a single-drum oblique-injection down-intake gas-and-oil-fired corner tube boiler which comprises a boiler body provided with a combustion system; a support structure is arranged in the boiler body, and the support structure comprises a front side down pipe, a middle down pipe, and a rear side down and exhaust pipe; and the two ends of each of the front side down pipe, the middle down pipe and the rear side down and exhaust pipe are correspondingly connected with a side wall upper header and a side wall lower header which are horizontally arranged, a boiler drum is arranged above one side of the boiler body, a water inlet pipe is connected to the boiler drum, a down pipe connected with the middle down pipe is connected to the bottom of the boiler drum, a front and rear arch lower header is connected to the bottom of the middle down pipe, the upper part of the interior of the boiler body is provided with a front and rear arch upper header communicating with the front and rear arch lower header, and the front and rear arch upper header communicates with the boiler drum through an upper water return pipe. The single-drum oblique-injection down-intake gas-and-oil-fired corner tube boiler is long in fuel retention time, free in flame extension, full in combustion of fuel, stable in support structure and safe in water circulation.

Owner:HARBIN SIFANG BOILER

Low discharging and high-energy effect novel industrial boiler

InactiveCN101457981BStable, safe and reliable operationLong-term stable and reliable operationWater-tube boilersWater heatersHigh energyCogeneration

The invention discloses a novel industrial boiler with low emission and high energy efficiency, and relates to the series of twenty boilers which are different in fuels and mediums, namely large-scale grate firing: scattered coal, moulded coal and biomass and chamber firing: fuel gas, oil-fired hot water, steam, phase-conversion heat exchange and distributed heat and power cogeneration boilers. The novel industrial boiler comprises a transverse boiler, a transversal and longitudinal container, a water wall tube, a vertical boiler shell, a thread smoke tube, and the like. The invention integrates the advantages of a water-tube boiler, a water-fire tube boiler and a corner-tube boiler, more particularly solves the different defects of three types of boilers; namely, the water-tube boiler has the defects of complicated technology as well as large volume and steel consumption; the water-fire tube boiler has the defects of tube plate crackle, tube explosion, smoke tube abrasion, and the like; the corner-tube boiler has the defects that the technology is complicated technology and the dust deposition at the tail part is difficult to be eliminated; and the invention also greatly improvesthe difficult problems of the three types of boilers that the initial emission concentration of smoke and dust is higher generally. The invention has the advantages of advanced installation technology and extremely obvious energy conservation and emission reduction.

Owner:王森

Double-drum double-furnace composite-combustion settling chamber corner tube boiler

PendingCN109737598AEmission reductionHigh thermal efficiencyWater heatersCasings/liningsCombustion systemNitrogen oxides

The invention discloses a double-drum double-furnace composite-combustion settling chamber corner tube boiler. The boiler comprises a boiler furnace body part and a combustion system part; a supporting structure and a double-furnace structure are arranged in a boiler body; the supporting structure comprises a front side support downcomer, a middle support downcomer and a rear side support downcomer which are vertically arranged, the two ends of each of the front side support downcomer, the middle support downcomer and the rear side support downcomer are connected with a side water cooling wallupper header and a side water cooling wall lower header respectively, wherein the side water cooling wall upper header and the side water cooling wall lower header are horizontally arranged; one sideof the boiler body is provided with an upper drum and a lower drum which are connected through a convection tube bank, the upper end of the upper drum is connected with a water inlet pipe, and the bottom of the upper drum is connected with a downcomer I, a downcomer II and a downcomer II which communicate with the front side support downcomer, the middle support downcomer and the rear side support downcomer respectively; and the double-furnace structure is composed of a furnace I and a furnace II. The boiler has the characteristics that the supporting strength is high, the structure is stable, biomass fuel can be dried in the furnaces, the fuel can be directly bundled and fully combusted, emission of nitrogen oxides is reduced, the energy is saved and the environment is protected.

Owner:HARBIN SIFANG BOILER

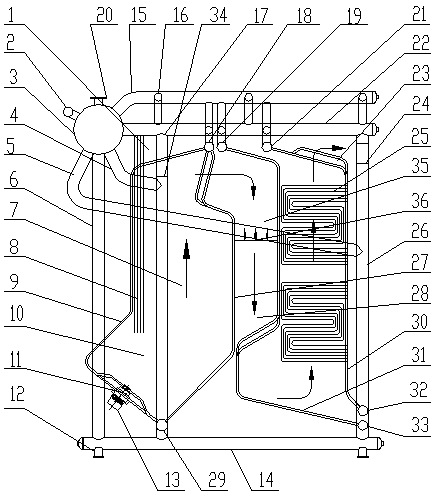

Two-drum settling chamber spraying denitration corner-tube boiler

ActiveCN105318306AHigh thermal efficiencyEmission reductionWater-tube boilersCyclonic separationEngineering

The invention relates to a two-drum settling chamber spraying denitration corner-tube boiler, comprising a boiler body part and a fire grate part, wherein the fire grate part is arranged at the bottom of the boiler body part; the boiler is characterized in that a boiler body 1 is provided with a boil supporting mechanism and a boiler water circulation mechanism, the boil supporting mechanism is formed by two vertically arranged side cooling wall supporting downcomers 24 and a side wall water supply downcomer 22 communicated with the side cooling wall supporting downcomers 24, the boiler water circulation mechanism is formed by a channel rear wall water cooling wall 31, and an upper header 16 and a lower header 33 of a settling box, and a spraying denitration cyclone separation settling device on the boiler body 1 is formed by denitration spraying pipes 34, denitration nozzles 18, a denitration agent supplier 35, an upper settling separation chamber 27 and a lower settling separation chamber 36. The two-drum settling chamber spraying denitration corner-tube boiler has the characteristics of being high in supporting strength, stable in structure, capable of reducing nitric oxide emission, reducing air pollution and improving thermal efficiency, energy-saving, environment-friendly, safe and the like.

Owner:HARBIN SIFANG BOILER

Single-drum double-furnace composite combustion settling chamber angle tube boiler

PendingCN109737373AEmission reductionHigh thermal efficiencyWater heatersCasings/liningsCombustion systemCombustion

The invention discloses a single-drum double-furnace composite combustion settling chamber angle tube boiler. The single-drum double-furnace composite combustion settling chamber angle tube boiler comprises a boiler body part and a combustion system part, wherein the boiler body is internally provided with a support structure and a double-furnace structure; the support structure comprises a vertically arranged front side support downtake pipe, an intermediate support downtake pipe, and a rear side support downtake pipe; the upper end of the front side support downtake pipe is connected with adrum, and the lower end of the front side support downtake pipe is connected to side water wall lower receiving boxes; two ends of the intermediate support downtake pipe and the rear side support downtake pipe are respectively connected with side water wall upper receiving boxes and the side water wall lower receiving boxes; the drum is arranged on the upper portion of one side of the boiler body;the drum is connected to a water inlet pipe; the bottom of the drum is connected to a first downtake pipe and a second downtake pipe communicating with the intermediate support downtake pipe and therear side support downtake pipe; and the double-furnace structure is composed of a first furnace and a second furnace. The single-drum double-furnace composite combustion settling chamber angle tube boiler has the advantages that the support strength is high, and the structure is stable, so that the biomass fuel is dried in the furnace, the fuel is directly bundled and fully burned, the nitrogen oxide emissions are reduced, the energy is saved and the environment friendliness is achieved.

Owner:HARBIN SIFANG BOILER

Double-drum settling denitration chamber jet lower gas inlet fuel gas and fuel oil corner tube boiler

PendingCN110953568AExtended stayEmission reductionBoiler water tubesEmission preventionCombustion systemBoiler furnace

The invention discloses a double-drum settling denitration chamber jet lower gas inlet fuel gas and fuel oil corner tube boiler. The corner tube boiler comprises a boiler body part and a combustion system part. A supporting structure is arranged in the boiler body and comprises a front side supporting downcomer, a middle supporting downcomer and a rear side supporting downcomer which are vertically arranged. A drum is arranged above one side of the boiler body; the drum is connected with a water inlet pipe; the bottom of the drum is connected with a downcomer communicated with the front side supporting downcomer, the middle supporting downcomer and the rear side supporting downcomer; the bottom of the front side supporting downcomer is connected with a front-back arch lower header; a front-back arch upper header communicated with the front-back arch lower header is arranged on the upper portion in the boiler body; and the front-back arch upper header is communicated with the drum through an upper water return pipe. Fuel stays for a long time, flames can freely extend, the fuel is fully combusted, the supporting structure and water circulation are safe, nitrogen oxide emission is reduced, boiler heat efficiency is improved, and the structure is simple.

Owner:HARBIN SIFANG BOILER

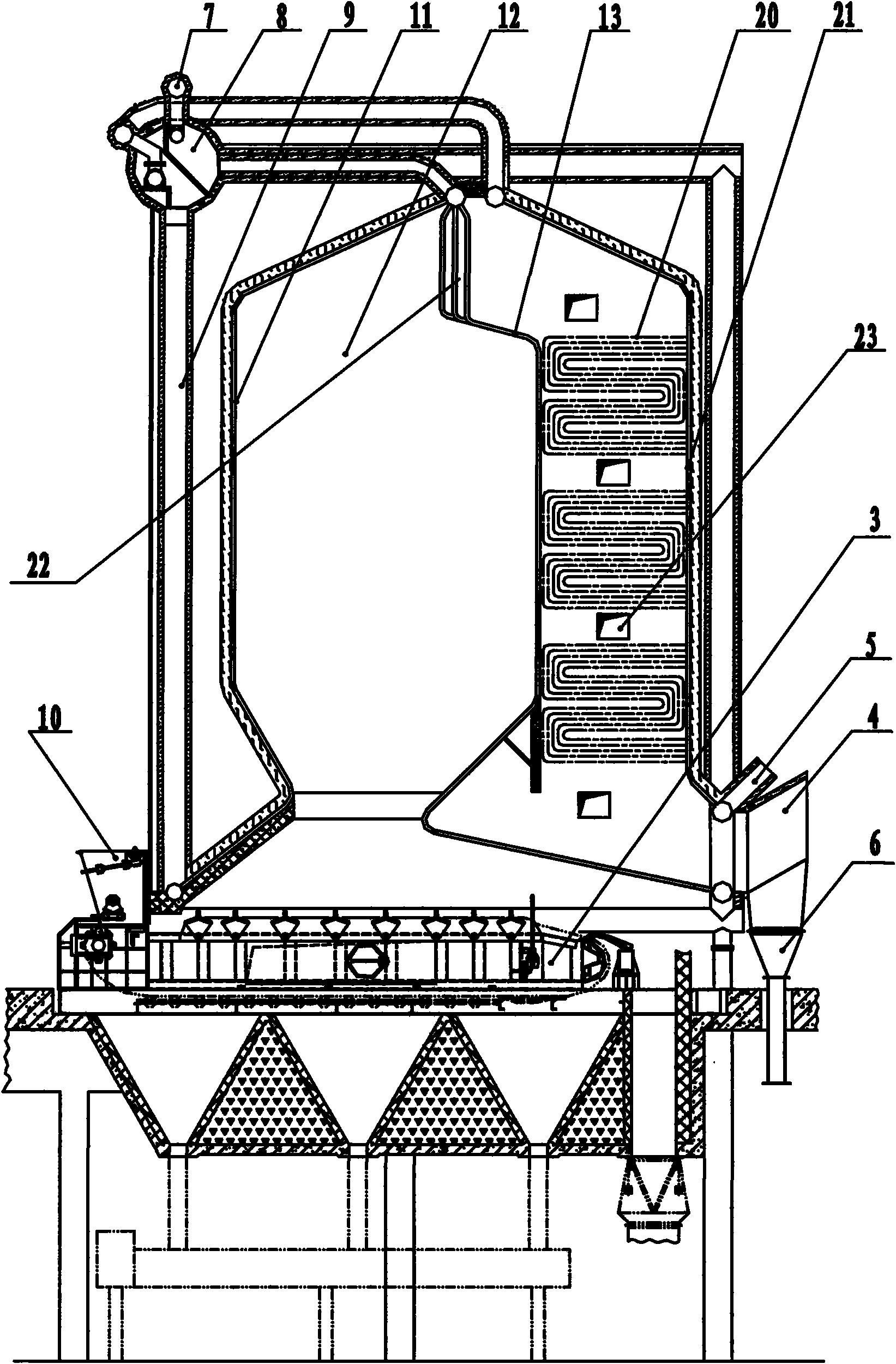

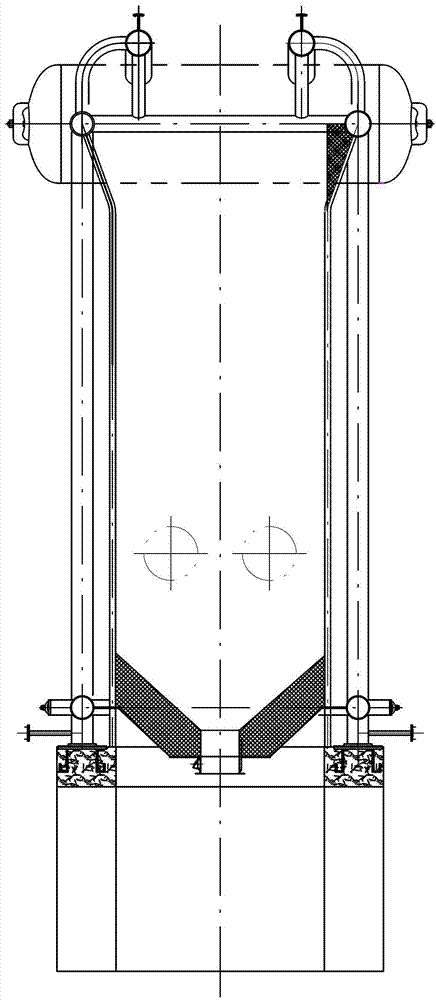

Single-boiler-barrel four-return-stroke biomass burning corner tube boiler

PendingCN114576617AImprove support strengthStable structureSolid fuel combustionIndirect carbon-dioxide mitigationThermodynamicsNitrogen oxides

The invention discloses a single-boiler-barrel four-return-stroke biomass burning corner tube boiler which is characterized in that two ends of a water circulation mechanism are connected to an inlet and an outlet of a boiler barrel, and the water circulation mechanism and a tail flue are fixedly arranged on a supporting frame body; the hearth is communicated with the upper end of the membrane type wall cavity, the membrane type wall cavity is communicated with the lower end of the flag type heating surface cavity, and the flag type heating surface cavity is communicated with the upper end of the tail flue; the side walls of the hearth, the membrane type wall cavity and the flag type heating surface cavity are all membrane type walls, the upper ends and the lower ends of the side walls of the hearth, the membrane type wall cavity and the flag type heating surface cavity are all communicated with the water circulation mechanism, a fire grate is arranged below the hearth, and the outer end of the fire grate is connected with a primary air supply outlet. The boiler is high in supporting strength, stable in structure, sufficient in fuel combustion, not prone to coking and corrosion on a heating surface and low in nitrogen oxide emission.

Owner:SHANGHAI INDAL BOILER RES INST

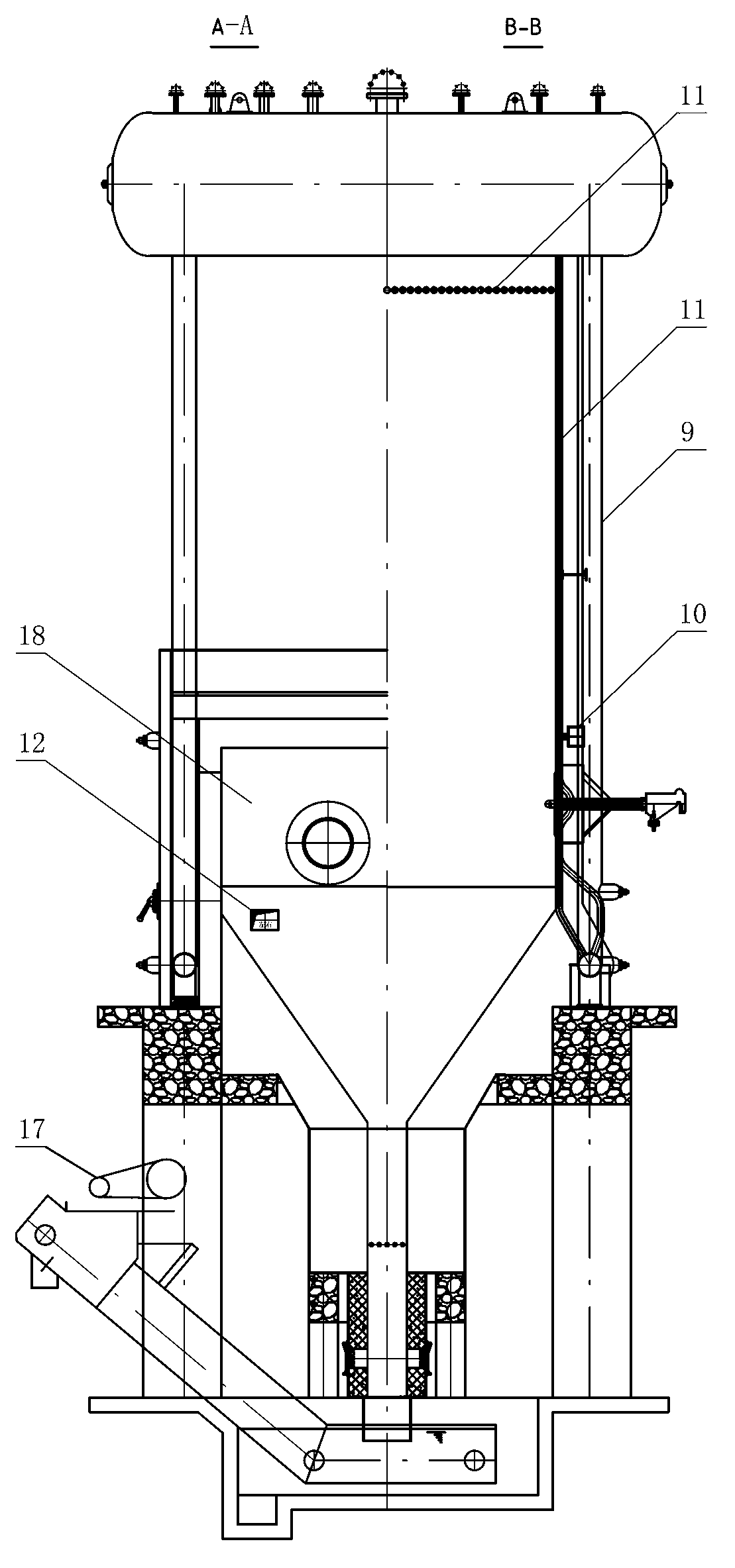

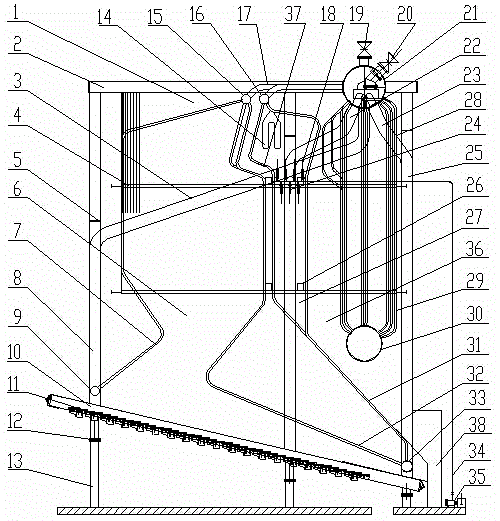

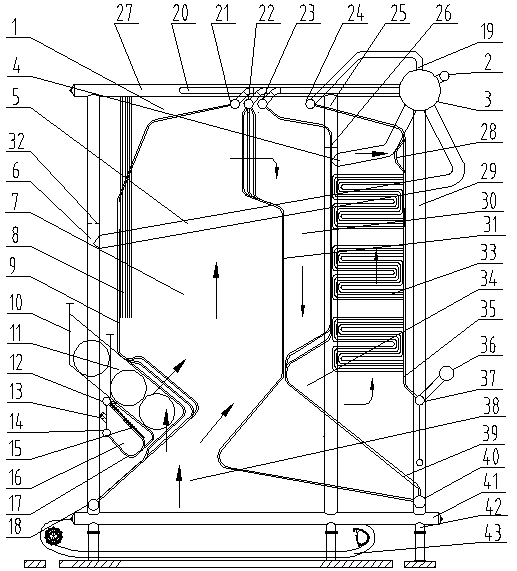

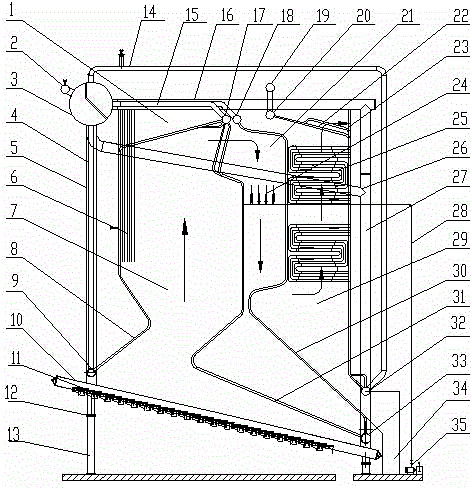

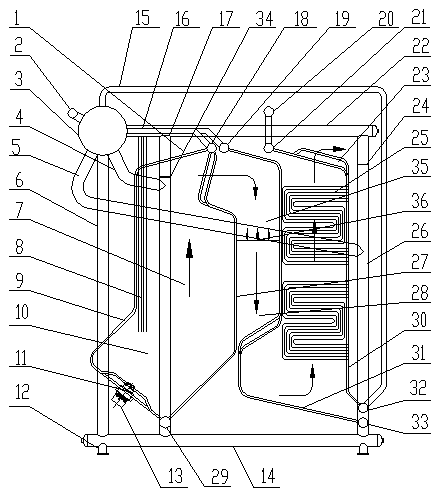

Single-boiler-barrel transversely-arranging type reciprocating grate spraying and denitration corner-tube boiler

ActiveCN105318536AHigh thermal efficiencyEmission reductionBoiler water tubesWater-tube boilersCyclonic separationPhysics

The invention relates to a single-boiler-barrel transversely-arranging type reciprocating grate spraying and denitration corner-tube boiler. The single-boiler-barrel transversely-arranging type reciprocating grate spraying and denitration corner-tube boiler comprises a boiler body and a reciprocating grate part, wherein the reciprocating grate part is arranged at the bottom of the boiler body; the single-boiler-barrel transversely-arranging type reciprocating grate spraying and denitration corner-tube boiler is characterized in that the boiler body 1 is provided with a broiler water circulating mechanism and is composed of a channel rear-wall water cooling wall 30, and an upper collection box 18 and a lower collection box 33 of a deposition chamber; the boiler body 1 is provided with a spraying and denitration cyclone separation sedimentation device which is composed of a denitration and spraying pipe 28, a denitration nozzle 24, a denitration agent supplying device 35, an upper sedimentation separation chamber 21 and a lower sedimentation separation chamber 29. The single-boiler-barrel transversely-arranging type reciprocating grate spraying and denitration corner-tube boiler has the characteristics that the emission of nitric oxide is reduced, the air pollution is reduced, the heat efficiency is improved, the energy is saved and the boiler is environmentally friendly and safe and the like.

Owner:HARBIN SIFANG BOILER

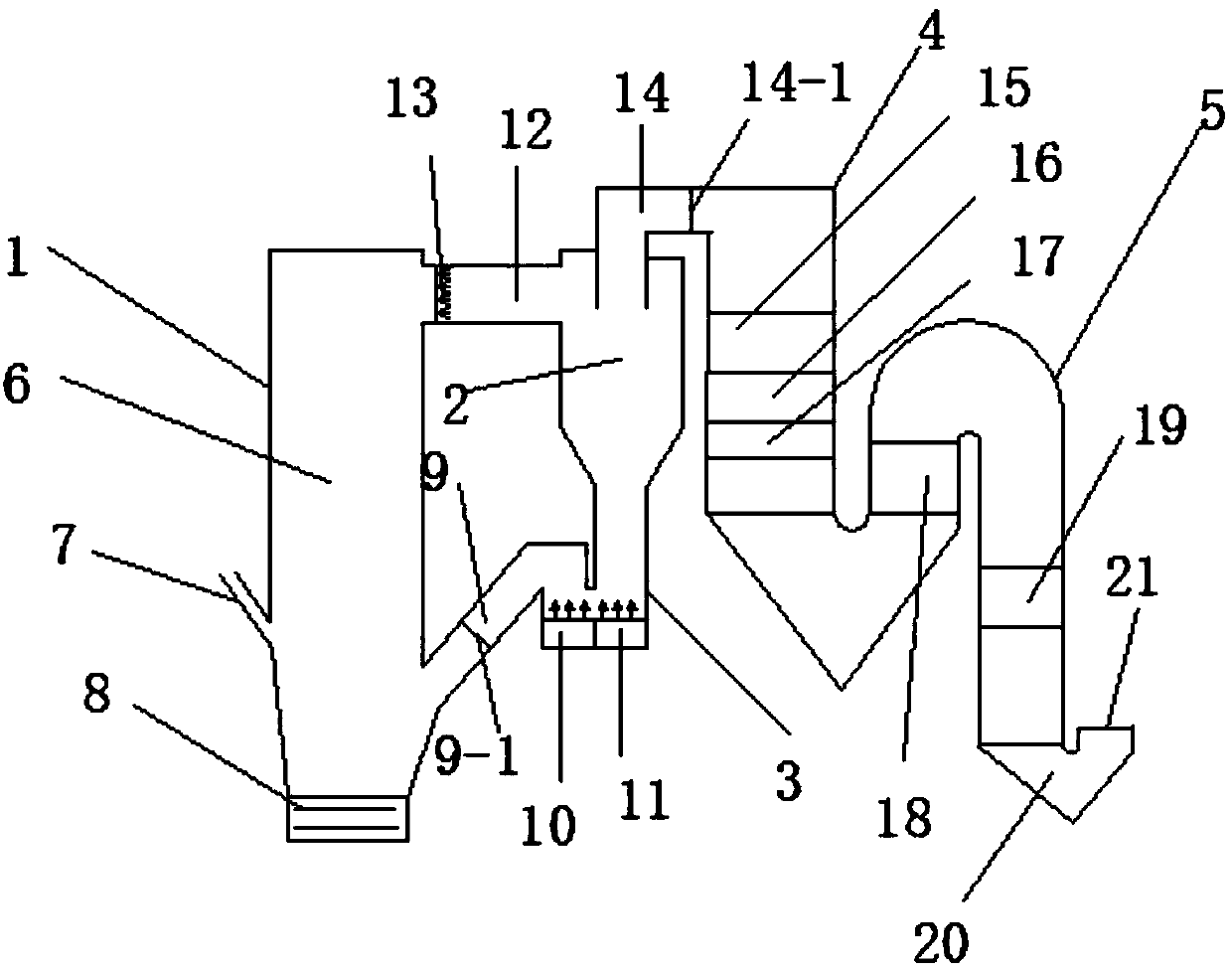

Chain-grate spraying and denitrifying corner tube boiler with horizontal single boiler barrel

InactiveCN109931588AFull reaction timePrevent coking accidentsSolid fuel combustionSolid removalEngineeringHearth

The invention discloses a chain-grate spraying and denitrifying corner tube boiler with a horizontal single boiler barrel. The chain-grate spraying and denitrifying corner tube boiler with the horizontal single boiler barrel structurally comprises a boiler body, a cyclone separator, a U-shaped return feeder, a treatment area and an exhaust pipe, wherein the boiler body is connected with the cyclone separator through a convection pass; the U-shaped return feeder is connected with the boiler body through a return flue; the treatment area is connected with the cyclone separator through a discharge flue; the cyclone separator comprises the convection pass, a denitrifying agent nozzle and the discharge flue; the convection pass is connected with a hearth; the denitrifying agent nozzle and the convection pass are connected through a bolt; the discharge flue is connected with the cyclone separator; the U-shaped return feeder comprises the return flue, a return fan and a loosening fan; and thetreatment area comprises an overheater, an economizer and a soot blower. A reducing agent and a flue gas are reacted for the sufficient reaction time, so that the accidents of return termination andboiler coking are avoided, and the chain-grate spraying and denitrifying corner tube boiler with the horizontal single boiler barrel is high in efficiency and saves energy.

Owner:赵珠峰

Single boiler drum horizontally-placing type chain grate spraying denitration corner tube boiler

InactiveCN109833744AFull reaction timePrevent coking accidentsDispersed particle separationFlue gasSpray nozzle

The invention discloses a single boiler drum horizontally-placing type chain grate spraying denitration corner tube boiler. The structure of the single boiler drum horizontally-placing type chain grate spraying denitration corner tube boiler comprises a boiler, a cyclone separator, a U-shaped material return device, a treatment zone and a gas discharge pipe, wherein the boiler and the cyclone separator are connected by a convection flue channel, the U-shaped material return device and the boiler are connected through a flue return channel, the treatment zone is connected to the cyclone separator through a flue outlet channel, the cyclone separator comprises the convection flue channel, a denitration agent spraying nozzle and the flue outlet channel, the convection flue channel is connectedto a furnace hearth, the denitration agent spraying nozzle is connected to the convection flue channel by a bolt, the flue outlet channel is connected to the cyclone separator, the U-shaped materialreturn device comprises the flue return channel, a material return fan and a loose fan, and the treatment zone comprises a superheater, an economizer and a soot blower. According to the present invention, with the single boiler drum horizontally-placing type chain grate spraying denitration corner tube boiler, the reducing agent and the flue gas have the sufficient reaction time, such that the accidents of material returning stopping and boiler coking can be avoided, and the advantages of high efficiency and energy saving can be achieved.

Owner:赵亮

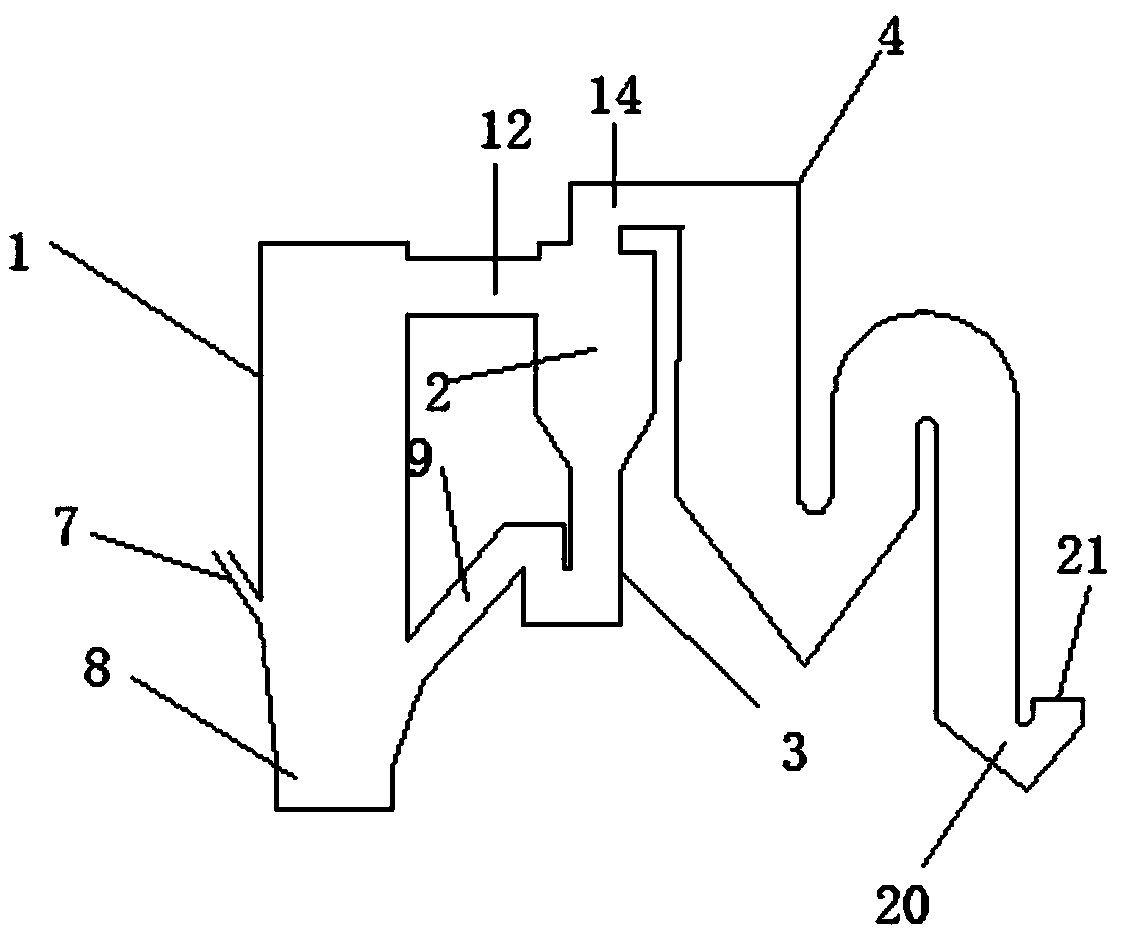

Water circulation system of single-drum four-return-stroke biomass burning corner tube boiler

The invention discloses a water circulation system of a single-drum four-return-stroke biomass burning corner tube boiler. The water circulation system comprises a drum, a boiler body and a water circulation mechanism, wherein the two ends of the water circulation mechanism are connected to an inlet and an outlet of the drum. The boiler body comprises a hearth, a membrane type wall cavity and a flag type heating surface cavity which are sequentially arranged from front to back, the hearth communicates with the upper end of the membrane type wall cavity, and the membrane type wall cavity communicates with the lower end of the flag type heating surface cavity; and the side walls of the hearth, the membrane type wall cavity and the flag type heating surface cavity are membrane type walls, andthe upper ends and the lower ends of the side walls of the hearth, the membrane type wall cavity and the flag type heating surface cavity communicate with the water circulation mechanism. According to the boiler water circulation system, the single drum is used for conducting water supply circulation on the four-return-stroke burning boiler, and a heat exchange environment is provided.

Owner:SHANGHAI INDAL BOILER RES INST

Single-drum transverse chain grate spraying denitration corner tube boiler

InactiveCN109915817AFull reaction timePrevent coking accidentsSolid fuel combustionSolid removalFlue gasSpray nozzle

The invention discloses a single-drum transverse chain grate spraying denitration corner tube boiler. The boiler structurally comprises a boiler body, a cyclone separator, a U-shaped return feeder, atreatment area and an exhaust pipe, wherein the boiler body is connected with the cyclone separator through a convection flue; the U-shaped return feeder is connected with the boiler body through a return flue; the treatment area is connected with the cyclone separator through an outlet flue; the cyclone separator comprises the convection flue, a denitration agent nozzle and the outlet flue; the convection flue is connected with a hearth, the denitration agent nozzle is connected with the convection flue through a bolt; the outlet flue is connected with the cyclone separator; the U-shaped return feeder comprises the return flue, a return fan and a loosening fan; and the treatment area comprises a superheater, a coal economizer and an ash blower. A reducing agent and flue gas have sufficient reaction time, the boiler coking accident caused by return stop is avoided, and high efficiency and energy conservation are achieved.

Owner:胡海涛

Double-furnace combined combustion settling chamber corner-tube boiler

PendingCN109737371AEmission reductionHigh thermal efficiencyWater heatersCasings/liningsCombustion systemNitrogen oxides

The invention discloses a double-furnace combined combustion settling chamber corner-tube boiler. The double-furnace combined combustion settling chamber corner-tube boiler comprises a boiler body portion and a combustion system portion, wherein a supporting structure and a double-furnace structure are arranged in the boiler body portion; the supporting structure comprises a front side supportingdowncomer and a rear side supporting downcomer which are vertically arranged; the upper end of the front side supporting downcomer is connected with a boiler barrel and the lower end of the front sidesupporting downcomer is connected with a side water wall lower container; each end of the rear side supporting downcomer is connected with a horizontal side water wall upper container and the horizontal side water wall lower container; the boiler barrel is arranged at the upper portion of the one side of a boiler body; a water inlet pipe is connected to the boiler barrel; the bottom of the boilerbarrel is connected with a first downcommer communicating to the rear side supporting downcomer and a second downcomer connecting with a front arch lower container; and the double-furnace structure is composed of a first furnace and a second furnace. The double-furnace combined combustion settling chamber corner-tube boiler has the characteristics that the support strength is high, the structureis stable, the biomass fuel is dried in the furnace, direct bundle and fully combustion of the fuel are achieved, the emission of nitrogen oxide is reduced, energy is saved and environmental friendliness is achieved.

Owner:HARBIN SIFANG BOILER

Single-drum settling denitration chamber jet lower gas inlet fuel oil corner tube boiler

PendingCN110953569AHigh thermal efficiencyExtended stayBoiler water tubesEmission preventionCombustion systemBoiler furnace

The invention discloses a single-drum settling denitration chamber jet lower gas inlet fuel oil corner tube boiler, which comprises a boiler body part and a combustion system part. A supporting structure is arranged in the boiler body and comprises a front side downcomer, a middle downcomer and a rear side downcomer which are vertically arranged. The two ends of the front side downcomer, the two ends of the middle downcomer and the two ends of the rear side downcomer are connected with a horizontally-arranged side water wall upper header and a horizontally-arranged side water wall lower headercorrespondingly. The bottom of the drum is connected with a downcomer communicated with the middle downcomer and the rear side downcomer, the bottom of the middle downcomer is connected with a frontand rear arch lower header, a front and rear arch upper header communicated with the front and rear arch lower header is arranged on the upper portion in the boiler body, and the front and rear arch upper header is communicated with the drum through an upper water return pipe. The single-drum settling denitration chamber jet lower gas inlet fuel oil corner tube boiler has the advantages of long fuel retention time, free extension of flame, sufficient combustion of fuel, stable support structure and safe water circulation.

Owner:HARBIN SIFANG BOILER

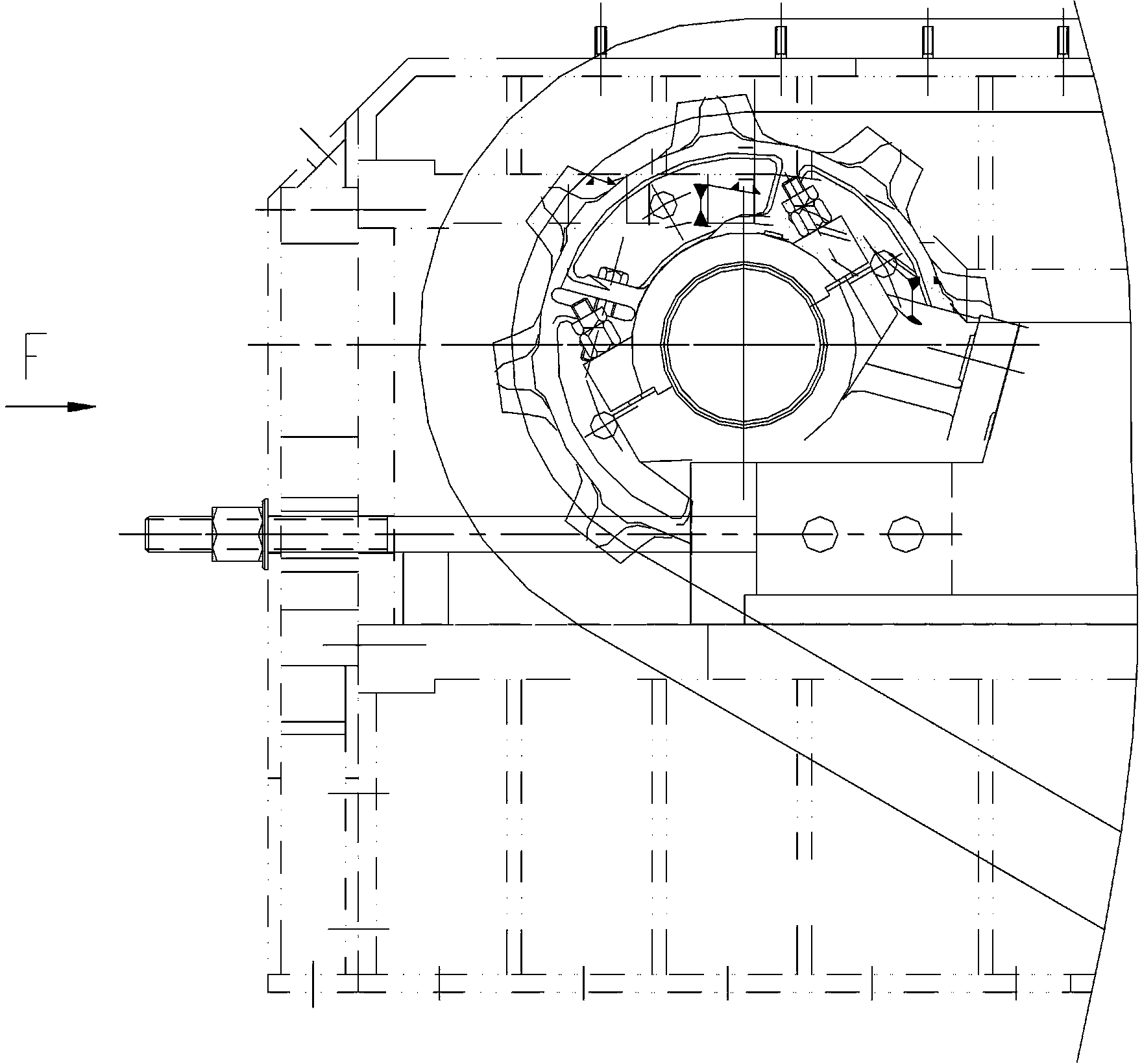

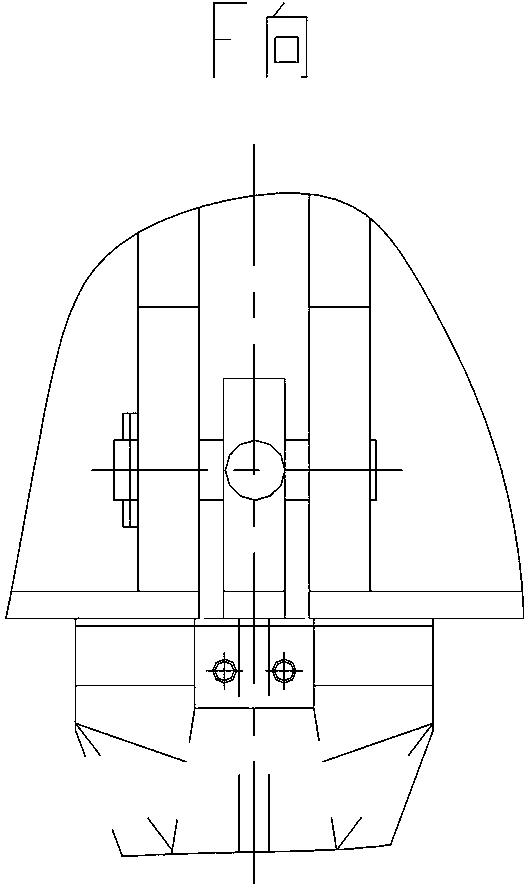

Double-grate spindle respective adjusting device on large-capacity corner tube boiler

The invention discloses a double-grate spindle respective adjusting device on a large-capacity corner tube boiler, which aims at solving the problems of grate bulging and chain tightness adjusting and comprises a left end adjusting bolt assembly, a chain wheel assembly, a spindle assembly, scale-type grate bars, a right end adjusting bolt assembly, a right side grate spindle assembly and a left side grate spindle assembly, wherein the chain wheel assembly is arranged on the spindle assembly, the scale-type grate bars are arranged on the chain wheel assembly, the left end adjusting bolt assembly is arranged on the left side grate spindle assembly, and the right end adjusting bolt assembly is arranged on the right side grate spindle assembly. The double-grate spindle respective adjusting device on the large-capacity corner tube boiler has the advantages that adjusting bolts are vertically arranged and respectively independently control a left side grate and a right side grate, so that the left side grate and the right side grate are not affected with each other during adjusting, labor intensity of operators is reduced, and the double-grate spindle respective adjusting device is convenient to operate and can be widely applied to the large-capacity corner tube boiler to serve as a spindle adjusting device.

Owner:SHANGHAI XINYE BOILER HIGH TECH

Corner tube boiler adopting uniform scouring convection tube bundle

The invention discloses a corner tube boiler adopting a uniform scouring convection tube bundle. The whole of the corner tube boiler has an n-shaped structure, wherein, the left side is a hearth, the right side is a tail flue, and the hearth back wall positioned in the middle is used as an interface of the hearth and the tail flue; the hearth front wall, the side wall and the hearth back wall form the hearth; the hearth back wall, the side wall and the flue back wall form the tail flue; the hearth front wall of the hearth is arranged vertically to the ground of the flue back wall; the hearth back wall is obliquely arranged towards the right from top to bottom so that the cross section of the hearth is gradually widened from top to bottom, and correspondingly the cross section of the tail flue is gradually narrowed from top to bottom; three sections of convection tube bundles are arranged in the tail flue from top to bottom with consistent interval to form a three-level heating surface; and the width of each section of the convection tube bundle is gradually narrowed from top to bottom and is matched with the width of the tail flue at the corresponding position. The corner tube boiler can furthest exert the heat transfer effect on the convection tube bundle under the premise of controlling the abrasion.

Owner:SHANGHAI INDAL BOILER RES INST

Flue gas emission system of single-drum four-return-stroke biomass burning corner tube boiler

PendingCN112377892AReduces the chance of coking corrosionEmission reductionSolid fuel combustionIndirect carbon-dioxide mitigationThermodynamicsNitrogen oxides

The invention discloses a flue gas emission system of a single-drum four-return-stroke biomass burning corner tube boiler. The flue gas emission system comprises a first return stroke, a second returnstroke, a third return stroke and a fourth return stroke which are sequentially arranged in the horizontal direction. The lower end of the first return stroke is open, the upper end of the first return stroke communicates with the upper end of the second return stroke, the lower end of the second return stroke communicates with the lower end of the third return stroke, and the upper end of the third return stroke communicates with the upper end of the fourth return stroke. The first return stroke is a hearth, the second return stroke is a membrane type wall cavity, the third return stroke isa flag type heating surface cavity, and the fourth return stroke is a tail flue. According to the flue gas emission system, four-return-stroke arrangement is adopted, the probability of coking corrosion of the heating surface is reduced, emission of nitric oxides is reduced, and fuel can be burnt more sufficiently.

Owner:SHANGHAI INDAL BOILER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com