Low discharging and high-energy effect novel industrial boiler

An industrial boiler, high energy efficiency technology, applied in water-tube steam boilers, steam boilers, fluid heaters, etc., can solve problems such as fault points prone to water cycle accidents, high initial emission concentration of smoke and dust, complicated pipe bending process, etc. Long-term stability and reliability, safe, stable and reliable operation, enhanced convective heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

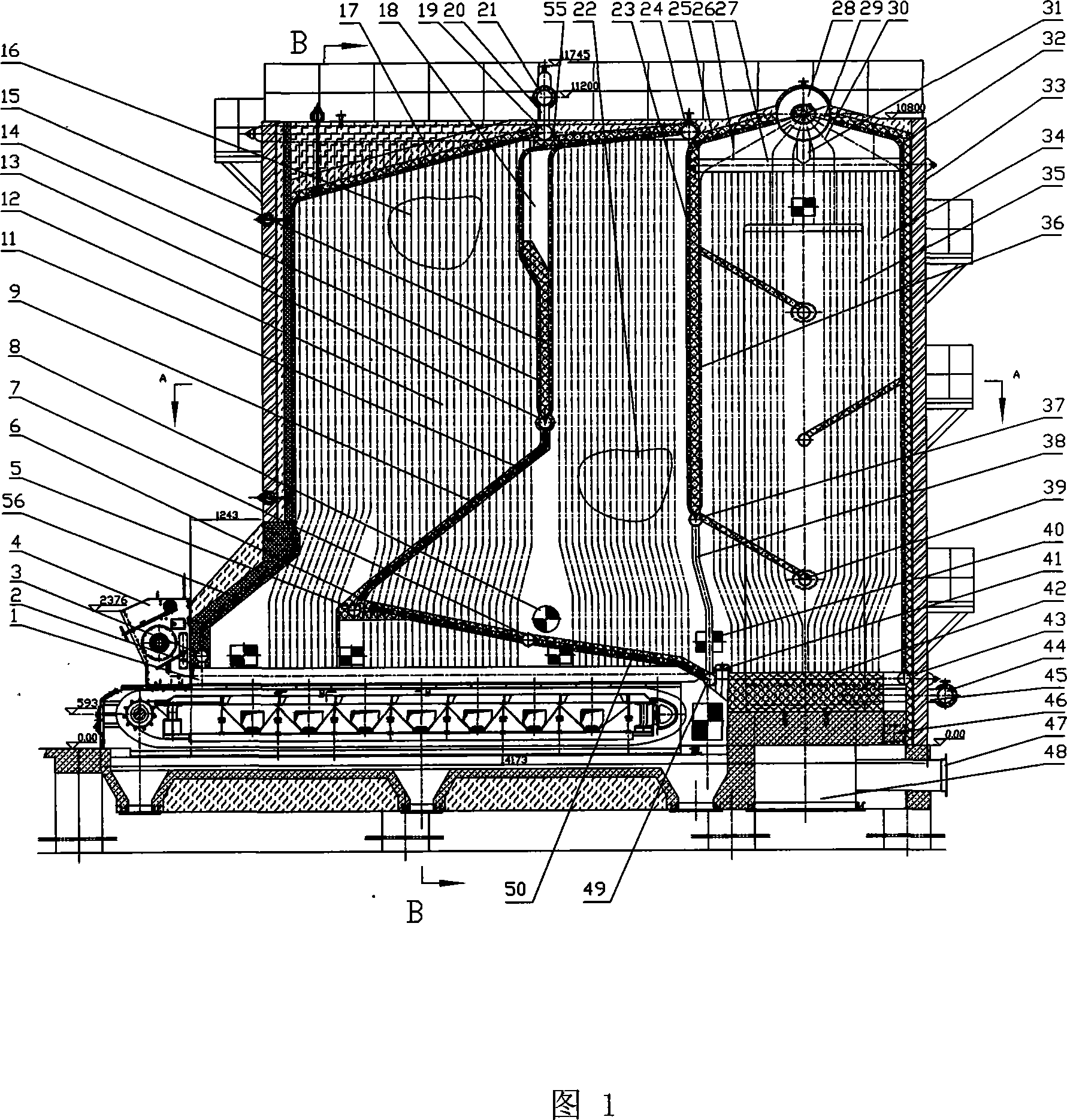

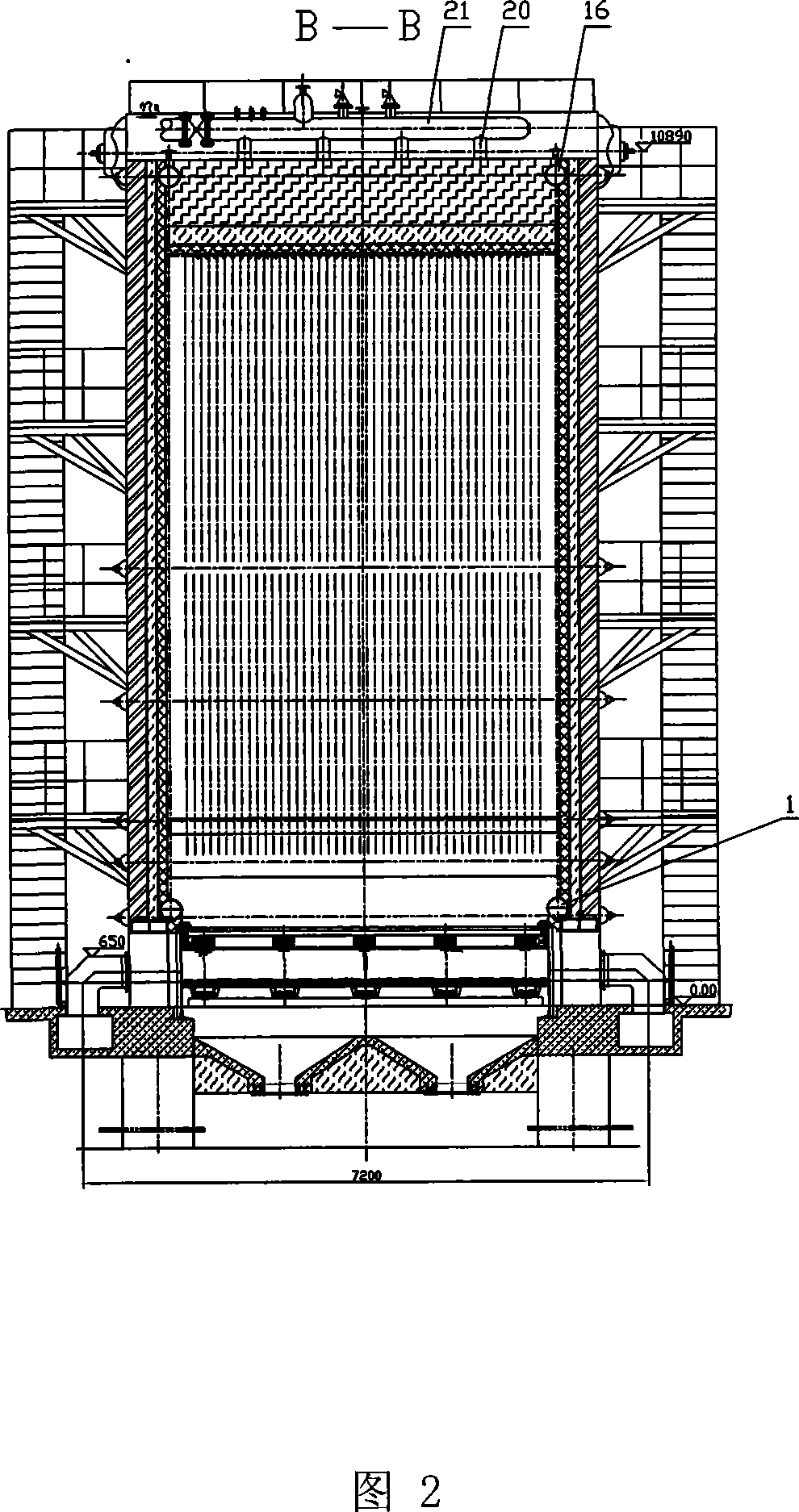

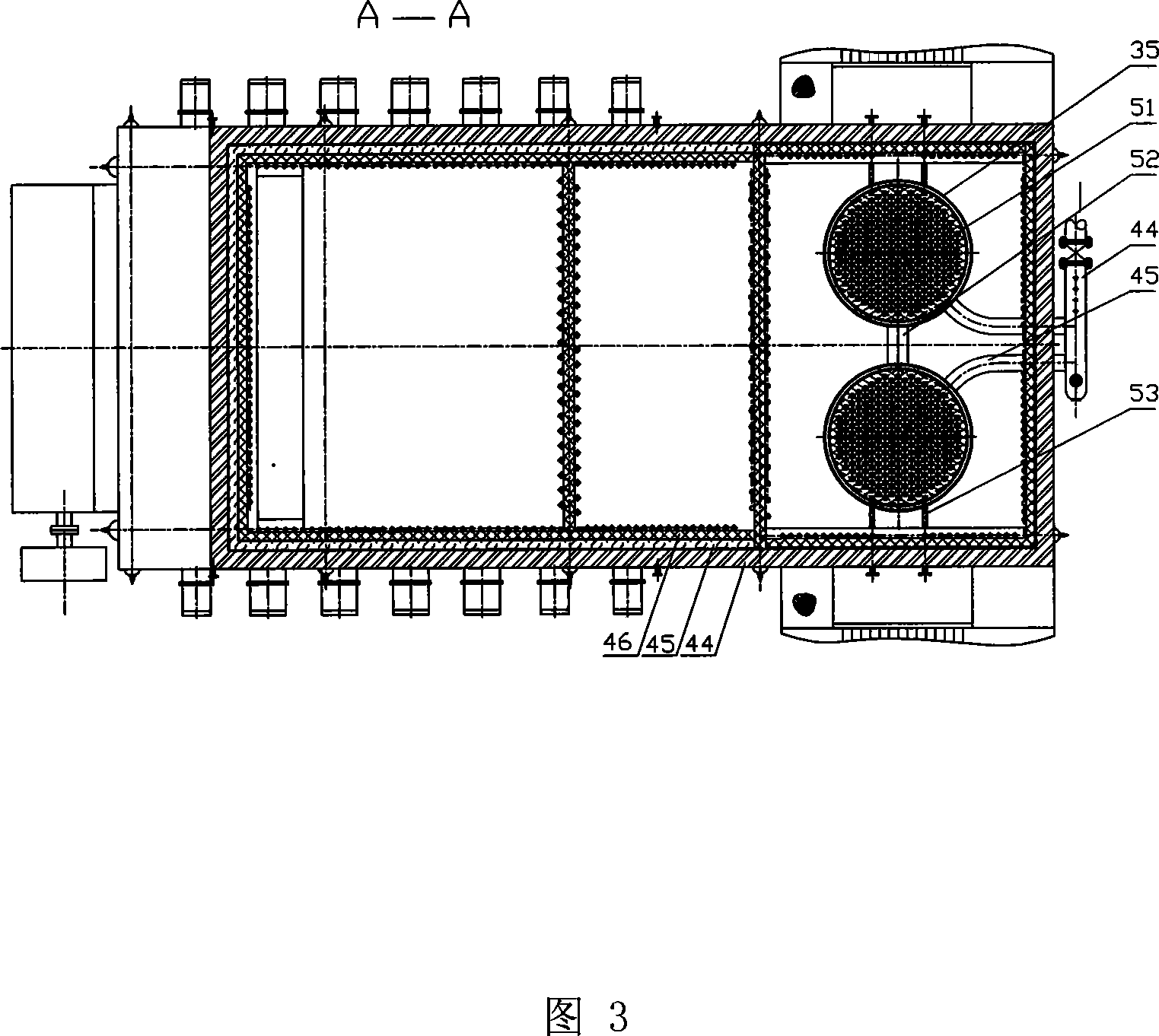

[0017] The present invention will be described in detail below in conjunction with accompanying drawing, a kind of low-emission high-energy-efficiency new-type industrial boiler, comprises: Horizontal drum (28), pot shell (35), vertical header (1) (16) horizontal header (3) )(5)(7)(12)(19)(24)(49), water wall pipes (11)(17), convection pipes (31)(34), etc., it is characterized in that the upper end of the riser pipe 30 It communicates with the lower part of the horizontal drum (28), its lower end communicates with the upper end of the pot shell (35), the upper end of the convection pipe (34) communicates with the lower part of the small longitudinal header (27), and its lower end communicates with the small longitudinal header (42) The upper part is connected, the upper front end of the convection pipe (31) is connected with the horizontal center of the horizontal drum (28), and its lower end is connected with the upper part of the horizontal header (43), and the upper rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com